Abstract

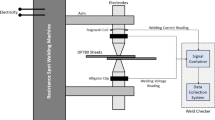

Resistance spot welding (RSW) is a highly used joining procedure in automotive industry. In RSW, after a number of welds the welding electrode starts to wear and its diameter changes. This causes the weld nugget diameter abnormal variations and consequently reduces the weld strength. Therefore the tip of the electrode should be dressed in RSW. Selecting the optimum time for the welding electrode tip dressing operations is very important. In this research three welding parameters including the welding time, the welding current, and the welding pressure were identified as the main effective parameters on the weld nugget dimensions including the weld nugget diameter and height using full factorial design of experiments. Then using hybrid combination of the artificial neural networks and multi-objective genetic algorithm, the optimized values of the aforementioned parameters were specified. Finally experiments were fulfilled to estimate the admissible number of the weld spots which should be done before the electrode tip dressing operation.

Similar content being viewed by others

Notes

KES C-G006 P.14 STANDARD.

References

Bishop, C. M. (1996). Neural network for pattern recognition. Oxford: Oxford University Press.

Canyurt, O. E. (2005). Estimation of welded joint strength using genetic algorithm approach. International Journal of Mechanical Sciences, 47, 1249–1261.

Darwish, S. M., & Al-Dekhial, S. D. (1999). Statistical models for spot welding of commercial aluminium sheets. International Journal of Machine Tools and Manufacture, 39, 1589–1610.

Deb, K., Agrawal, S., Pratap, A., & Meyarivan, T. (2000). A fast elitist non-dominated sorting genetic algorithm for multi objective optimization: NSGA-II. In M. Schoenauer, K. Deb, G. Rudolph, X. Yao, E. Lutton, J. J. Merelo, & H. P. Schwefel (Eds.), Parallel problem solving from nature (PPSN VI). Lecture notes in computer science (Vol. 1917). Berlin: Springer.

Eisazadeh, H., Hamedi, M., & Halvaee, A. (2010). New parametric study of nugget size in resistance spot welding process using finite element method. Materials and Design, 31, 149–157.

Ganjigatti, J. P., Pratihar, D. K., & RoyChoudhury, A. (2008). Modeling of the MIG welding process using statistical approaches. The International Journal of Advanced Manufacturing Technology, 35, 1166–1190.

Hamedi, M., Shariatpanahi, M., & Mansourzadeh, A. (2007). Optimizing spot welding parameters in a sheet metal assembly by neural networks and genetic algorithm. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 221, 1175–1184.

Hashemi, R., Pashazadeh, H., & Hamedi, M. (2012). An incrementally coupled thermo-electro-mechanical model for resistance spot welding. Materials and Manufacturing Processes, 27, 1442–1449.

Karimzadeh, F., Ebnonnasir, A., & Foroughi, A. (2006). Artificial neural network modeling for evaluating of epitaxial growth of Ti6Al4V weldment. Materials Science and Engineering A, 432, 184–190.

Li, W., Cheng, S., Hu, S. J., & Ni, J. (2000). On-line quality estimation in resistance spot welding. Journal of manufacturing Science and Engineering, 122, 511–512.

Li, W., Cheng, S., Hu, S. J., & Shriver, J. (2001). Statistical investigation on resistance spot welding quality using a two-state. Sliding-Level Experiment, Journal of Manufacturing Science and Engineering, 123, 513–520.

Meran, C. (2006). Prediction of the optimized welding parameters for the joined brass plates using genetic algorithm. Materials and Design, 27, 356–363.

Montgomery, D. C. (2000). Design and analysis of experiments (5th ed.). London: Wiley.

Podrzaj, P., Polajnar, I., Diaci, J., & Kariz, Z. (2004). Expulsion detection system for resistance spot welding based on a neural network. Measurement Science and Technology, 15, 592–598.

Rogers, R. D., & Vemuri, V. R. (1994). Artificial neural networks forecasting time series. Los Alamitos, CA: IEEE Computer Society Press.

Yildiz, A. R. (2008). Hybrid Taguchi–Harmony search algorithm for solving engineering optimization problems. International Journal of Industrial Engineering Theory, Applications and Practice, 15(3), 286–293.

Yildiz, A. R. (2009a). A new design optimization framework based on immune algorithm and Taguchi method. Computers in Industry, 60(8), 613–620.

Yildiz, A. R. (2009b). A novel hybrid immune algorithm for global optimization in design and manufacturing. Robotics and Computer-Integrated Manufacturing, 25(2), 261–270.

Yildiz, A. R. (2009c). Hybrid immune-simulated annealing algorithm for optimal design and manufacturing. International Journal of Materials and Product Technology, 34(3), 217–226.

Yildiz, A. R. (2009d). A novel particle swarm optimization approach for product design and manufacturing. International Journal of Advanced Manufacturing Technology, 40(5–6), 617–628.

Yildiz, A. R. (2009e). An effective hybrid immune-hill climbing optimization approach for solving design and manufacturing optimization problems in industry. Journal of Materials Processing Technology, 209(6), 2773–2780.

Yildiz, A. R. (2012a). A comparative study of population-based optimization algorithms for turning operations. Information Sciences, 210, 81–88.

Yildiz, A. R. (2012b). Structural design optimization of vehicle components using Cuckoo search algorithm. Materials Testing, 54(3), 185–188.

Yildiz, A. R. (2013a). Comparison of evolutionary-based optimization algorithms for structural design optimization. Engineering Applications of Artificial In telligence, 26(1), 327–333.

Yildiz, A. R. (2013b). A new hybrid bee colony optimization approach for robust optimal design and manufacturing. Applied Soft Computing, 13(5), 2906–2912.

Yildiz, A. R. (2013c). Hybrid Taguchi-differential evolution algorithm for optimization of multi-pass turning operations. Applied Soft Computing, 13(3), 1433–1439.

Yildiz, A. R. (2013d). Optimization of cutting parameters in multi-pass turning using artificial bee colony-based approach. Information Sciences, 220, 399–407.

Yildiz, A. R. (2013e). A new hybrid differential evolution algorithm for the selection of optimal machining parameters in milling operations. Applied Soft Computing, 13(3), 1561–1566.

Yildiz, A. R. (2013f). Cuckoo search algorithm for the selection of optimal machining parameters in milling operations. International Journal of Advanced Manufacturing Technology, 64(1–4), 55–61.

Zhang, H., Hu, S. J., Senkara, J., & Cheng, S. (2000). A statistical analysis of expulsion limits in resistance spot welding. Journal of Manufacturing Science and Engineering, 122, 510–510.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pashazadeh, H., Gheisari, Y. & Hamedi, M. Statistical modeling and optimization of resistance spot welding process parameters using neural networks and multi-objective genetic algorithm. J Intell Manuf 27, 549–559 (2016). https://doi.org/10.1007/s10845-014-0891-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-014-0891-x