Abstract

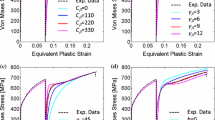

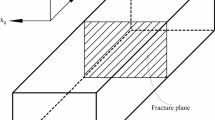

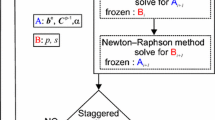

A continuum model of ductile fracture initiation is presented which is based on consideration of the work done on the system sufficient to cause release of the binding energy necessary for crack formation. The fracture criterion is posed for plastic materials with no pre-existing crack as a critical state reached when the energy release rate of the bulk system is balanced by the energy release rate associated with the fractured medium. Two fracture modes are considered which are commonly addressed in fracture mechanics: mode I crack opening perpendicular to the fracture plane and mode II shear rupture tangential to the fracture plane. A study of the use of the criterion for a plastic material with power law hardening is examined and compared with published experimental data and empirical criteria.

Similar content being viewed by others

References

Bai Y, Wierzbicki T (2010) Application extended Mohr–Coulomb criterion to ductile fracture. Int J Fract 161(1):1–20

Bao Y (2003) Prediction of ductile track formation in uncracked bodies. Doctoral dissertation, Massachusetts Institute of Technology

Bao Y, Wierzbicki T (2004) On fracture locus in the equivalent strain and stress triaxiality space. Int J Mech Sci 46(1):81–98

Bao Y, Wierzbicki T (2005) On the cut-off value negative triaxiality for fracture. Eng Fract Mech 72(7):1049–1069

Benzerga A, Leblond JB (2010) Ductile fracture by void growth to coalescence. Adv Appl Mech 44:169–305

Besson J (2009) Continuum models ductile fracture: a review. Int J Damage Mech 19(1):3–52

Boyce BL, Kramer SLB, Fang HE, Cordova TE, Neilsen MK, Dion K, Kaczmarowski AK, Karasz E, Xue L, Gross AJ, Ghahremaninezhad A, Ravi-Chandar K, Lin S-P, Chi S-W, Chen JS, Yreux E, Rüter M, Qian D, Zhou Z, Bhamare S, O’Connor DT, Tang S, Elkhodary KI, Zhao J, Hochhalter JD, Cerrone AR, Ingraffea AR, Wawrzynek PA, Carter BJ, Emery JM, Veilleux MG, Yang P, Gan Y, Zhang X, Chen Z, Madenci E, Kilic B, Zhang T, Fang E, Liu P, Lua J, Nahshon K, Miraglia M, Cruce J, DeFrese R, Moyer ET, Brinckmann S, Quinkert L, Pack K, Luo M, Wierzbicki T (2014) The Sandia fracture challenge: blind round robin predictions ductile tearing. Int J Fract 186(1–2):5–68

Bridgman PW (1952) Studies in large plastic flow and fracture with special emphasis on the effects hydrostatic pressure. McGraw-Hill, New York

Desai CS, Siriwardane HJ (1984) Constitutive laws for engineering materials with emphasis on geologic materials. Prentice-Hall, Englewood Cliffs

Dunand M, Mohr D (2010) Hybrid experimental-numerical analysis basic ductile fracture experiments for sheet metals. Int J Solids Struct 47(9):1130–1143

Ebnoether F, Mohr D (2013) Predicting ductile fracture of low carbon steel sheets: stress-based versus mixed stress/strain-based Mohr–Coulomb model. Int J Solids Struct 50(7):1055–1066

Fleck NA, Hutchinson JW, Tvergaard V (1989) Softening by void nucleation and growth in tension and shear. J Mech Phys Solids 37(4):515–540

Gao X, Faleskog J, Shih CF, Dodds RH (1998) Ductile tearing in part-through cracks: experiments and cell-model predictions. Eng Fract Mech 59(6):761–777

Gao X, Kim J (2006) Modeling ductile fracture: significance void coalescence. Int J Solids Struct 43(20):6277–6293

Garrison WM Jr, Moody NR (1987) Ductile fracture. J Phys Chem Solids 48(11):1035–1074

Griffith AA (1920) VI The Phenomena rupture and flow in solids. Philos Trans R Soc (London) A 221:163–198

Gross AJ, Ravi-Chandar K (2014) Prediction ductile failure using a local strain-to-failure criterion. Int J Fract 186(1–2):69–91

Gullerud AS, Gao X, Dodds RH, Haj-Ali R (2000) Simulation of ductile crack growth using computational cells: numerical aspects. Eng Fract Mech 66(1):65–92

Gurson AL (1977) Continuum theory ductile rupture by void nucleation and growth: part I-yield criteria and flow rules for porous ductile media. J Eng Mater Technol 99(1):2–15

Hahn GT, Kanninen MF, Rosenfield AR (1972) Fracture toughness of materials. Ann Rev Mater Sci 2(1):381–404

Hahn GT, Rosenfield AR (1975) Metallurgical factors affecting fracture toughness of aluminum alloys. Metall Trans A 6(4):653–668

Hallbäck N, Nilsson F (1994) Mixed-mode I/II fracture behaviour of an aluminium alloy. J Mech Phys Solids 42(9):1345–1374

Hancock JW, Mackenzie AC (1976) On the mechanisms ductile failure in high-strength steels subjected to multi-axial stress-states. J Mech Phys Solids 24(2):147–160

Hopperstad OS, Børvik T, Langseth M, Labibes K, Albertini C (2003) On the influence stress triaxiality and strain rate on the behaviour a structural steel part I experiments. Eur J Mech-A/Solids 22(1):1–13

Hussain MA, Pu SL, Underwood J (1974) Strain energy release rate for a crack under combined mode I and mode II. Fract Anal ASTM STP 560(1):2–28

Irwin GR (1957) Analysis of stresses and strains near the end of cracking traversing a plate. J App Mech 24:361–364

Johnson GR, Cook WH (1985) Fracture characteristics three metals subjected to various strains strain rates temperatures and pressures. Eng Fract Mech 21(1):31–48

Kamat SV, Hirth JP (1996) Mixed mode I/II fracture toughness of 2034 aluminum alloys. Acta Mater 44(1):201–208

Key PL (1969) A relation between crack surface displacements and the strain energy release rate. Int J Fract Mech 5(4):287–296

Khan AS, Liu H (2012) A new approach for ductile fracture prediction on Al 2024-T351 alloy. Int J Plast 35:1–12

Li H, Fu MW, Lu J, Yang H (2011) Ductile fracture: experiments and computations. Int J Plast 27(2):147–180

Li Y, Karr DG (2009) Prediction of ductile fracture in tension by bifurcation, localization, and imperfection analyses. Int J Plast 25(6):1128–1153

Lubliner J (2008) Plasticity theory. Courier Dover Publications, New York

McClintock FA (1968) A criterion for ductile fracture by the growth holes. J Appl Mech 35(2):363–371

Mirone G, Corallo D (2010) A local viewpoint for evaluating the influence stress triaxiality and Lode angle on ductile failure and hardening. Int J Plast 26(3):348–371

Nahshon K, Hutchinson JW (2008) Modification the Gurson model for shear failure. Eur J Mech-A/Solids 27(1):1–17

Needleman A (1972) Void growth in an elastic-plastic medium. J Appl Mech 39(4):964–970

Needleman A (2000) Computational mechanics at the mesoscale. Acta Mater 48(1):105–124

Needleman A, Tvergaard V (1984) An analysis ductile rupture in notched bars. J Mech Phys Solids 32(6):461–490

Neilsen MK, Schreyer HL (1993) Bifurcations in elastic-plastic materials. Int J Solids Struct 30(4):521–544

Orowan E (1954) Energy criteria of fracture. Massachusetts Institute of Technology, Dept of Mechanical Engineering, Technical Report No 3

Pandolfi A, Li B, Ortiz M (2013) Modeling fracture by material-point erosion. Int J Fract 184(1):3–16

Rice JR (1968a) A path independent integral and the approximate analysis strain concentration by notches and cracks. J Appl Mech 35(2):379–386

Rice JR (1968b) Mathematical analysis in the mechanics fracture. Fract: Adv Treatise 2:191–311

Rice JR, Tracey DM (1969) On the ductile enlargement voids in triaxial stress fields. J Mech Phys Solids 17(3):201–217

Seaman L, Curran DR, Shockey DA (2008) Computational models for ductile and brittle fracture. J Appl Phys 47(11):4814–4826

Steglich D, Brocks W, Heerens J, Pardoen T (2008) Anisotropic ductile fracture of Al 2024 alloys. Eng Fract Mech 75(12):3692–3706

Stoughton TB, Yoon JW (2011) A new approach for failure criterion for sheet metals. Int J Plast 27(3):440–459

Stüwe HP (1980) The work necessary to form a ductile fracture surface. Eng Fract Mech 13(2):231–236

Tvergaard V (1982) Ductile fracture by cavity nucleation between larger voids. J Mech Phys Solids 30(4):265–286

Weertman J (1978) Fracture mechanics: a unified view for Griffith–Irwin–Orowan cracks. Acta Metall 26(11):1731–1738

Wierzbicki T, Bao Y, Lee YW, Bai Y (2005) Calibration and evaluation seven fracture models. Int J Mech Sci 47(4):719–743

Xia L, Shih CF (1995) Ductile crack growth-I A numerical study using computational cells with microstructurally-based length scales. J Mech Phys Solids 43(2):233–259

Xue L (2008) Constitutive modeling void shearing effect in ductile fracture porous materials. Eng Fract Mech 75(11):3343–3366

Xue L, Wierzbicki T (2008) Ductile fracture initiation and propagation modeling using damage plasticity theory. Eng Fract Mech 75(11):3276–3293

Acknowledgments

The authors wish to express their gratitude to the American Bureau of Shipping for support of this research and to the Turkish National Education Ministry for financial assistance provided to the second author.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Karr, D.G., Akçay, F.A. A criterion for ductile fracture based on continuum modeling of energy release rates. Int J Fract 197, 201–212 (2016). https://doi.org/10.1007/s10704-016-0079-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-016-0079-9