Abstract

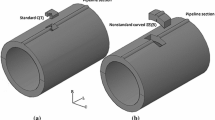

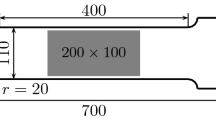

This paper investigates the ductile crack extension in the API 5L X65 pipeline steels in 3-D small-scale yielding (SSY) models using the Gurson-Tvergaard (GT) dilatational plasticity model implemented in the “computational cell” framework. The objective of the study targets at determining an out-of-plane length scale of the computational cell for 3-D crack extensions in fracture models with a through-thickness, straight crack front. The basic Gurson material parameters: the initial void volume fraction f 0 and the in-plane size of the computational cell D, calibrate from a set of notched tension specimens fabricated using API X65 steels. Cell extinctions based on a critical void volume fraction facilitates the process of the void growth and void coalescence which leads to the final failure of the “cell” and thus crack extensions. This study examines two types of 3-D SSY models: the side-grooved model and the plane-sided model. The element size in the thickness direction imposes significant effects on the computed fracture resistance and crack extension. Converged predictions of the J-Δa curve requires the out-of-plane length scale near the side groove equal to the in-plane length scale D. Plane-sided models converge faster than does the side-grooved model and requires the out-of-plane length scale to be 2D near the free surface. The required out-of-plane length scale does not indicate strong dependence on the material hardening exponent and the initial void volume fraction of the material.

Similar content being viewed by others

Abbreviations

- A :

-

Scaling coefficient for void nucleation

- B :

-

Thickness of the small-scale yielding Model

- B N :

-

Net thickness of the small-scale yielding model, excluding the side groove

- D :

-

In-plane length scale of the computational cell

- E :

-

Elastic modulus

- J :

-

Elastic-plastic energy release rate

- K I :

-

Mode I stress-intensity factor

- L :

-

Size of the element in the thickness Direction

- R :

-

Radius of the small-scale yielding model

- da :

-

Incremental crack extension

- d :

-

Height of the undeformed cell

- \({\overline{d}}\) :

-

Current height of the cell

- \({\overline{d}_0}\) :

-

Height of cell at f = f E

- f :

-

Void volume fraction

- f 0 :

-

Initial void volume fraction

- f E :

-

Void volume fraction at the element extinction

- f N :

-

Void volume fraction for the nucleating particles

- n :

-

Strain hardening exponent

- q i (i = 1, 2, 3):

-

Material parameters in the Gurson model introduction by Tvergaard

- r :

-

Radius of the notch in the tension specimens

- s ij :

-

Deviatoric stress tensor

- s N :

-

Standard deviation of the nucleation strain

- u :

-

Displacement in the x-direction

- v :

-

Displacement in the y-direction

- (x, y, z):

-

Cartesian coordinate system with the origin at the crack tip

- Φ:

-

Yield surface and flow potential

- α g :

-

Groove angle

- \({\varepsilon_{eq}^p}\) :

-

Equivalent plastic strain

- ε ij :

-

Strain tensor

- ε N :

-

Nucleating strain

- ε y :

-

Yield strain

- γ :

-

Remaining force factor in the killed cell

- λ:

-

Force release factor

- θ :

-

Counter-clockwise angle measured from the horizontal x-axis

- σ 0 :

-

Flow stress

- σ e :

-

Mises effective stress

- σ m :

-

Mean stress

- σ y :

-

Yield stress

- υ :

-

Poisson’s ratio

References

American Society of Testing and Materials (2008) ASTM E 1820-08: Standard test method for measurement of fracture toughness

British Standards Institution (2005) BS7910: Guide to methods for assessing the acceptability of flaws in metallic structures

Chapetti MD, Otegui JL, Motylicki J (2002) Fatigue assessment of an electrical resistance welded oil pipeline. Int J Fatigue 24: 21–28. doi:10.1016/S0142-1123(01)00111-6

Chen Y, Lambert S (2003) Analysis of ductile tearing of pipeline-steel in single edge notch tension specimens. Int J Fracture 124: 179–199

Chen Y, Lambert S (2005) Numerical modeling of ductile tearing for semi-elliptical surface cracks in wide plates. Int J Pres Ves Pip 82: 417–426. doi:10.1016/j.ijpvp.2004.09.008

Cravero S, Ruggieri C (2005) Correlation of fracture behavior in high pressure pipelines with axial flaws using constraint designed test specimens—part I: plane-strain analyses. Eng Fract Mech 72: 1344–1360. doi:10.1016/j.engfracmech.2004.10.010

Cravero S, Ruggieri C (2007) Estimation procedure of J-resistance curves for SE(T) fracture specimens using unloading compliance. Eng Fract Mech 74: 2735–2757. doi:10.1016/j.engfracmech.2007.01.012

Dotta F, Ruggieri C (2004) Structural integrity assessments of high pressure pipelines with axial flaws using a micromechanics model. Int J Pres Ves Pip 81: 761–770. doi:10.1016/j.ijpvp.2004.04.004

Faleskog J, Gao X, Shih CF (1998) Cell model for nonlinear fracture analysis—I. Micromechanics calibration. Int J Fracture 89: 355–373

Fazzini PG, Belmonte JC, Chapetti MD, Otegui JL (2007) Fatigue assessment of a double submerged arc welded gas pipeline. Int J Fatigue 29: 1115–1124. doi:10.1016/j.ijfatigue.2006.09.013

Gao X, Faleskog J, Shih CF (1998) Cell model for nonlinear fracture analysis—II. Fracture-process calibration and verification. Int J Fracture 89: 375–398

Gullerud AS, Gao X, Dodds RH Jr, Haj-Ali R (2000) Simulation of ductile crack growth using computational cells: numerical aspects. Eng Fract Mech 66: 65–92. doi:10.1016/S0013-7944(99)00147-2

Gullerud A, Koppenhoefer K, Roy A, RoyChowdhury S, Walters M, Bichon B, Cochran K, Carlyle A, Dodds RH Jr (2009) WARP3D: 3-D dynamic nonlinear fracture analysis of solids using parallel computers and workstations. Structural Research Series (SRS) 607, UILU-ENG-95-2012, University of Illinois at Urbana Champaign

Gurson AL (1977) Continuum theory of ductile rupture by void nucleation and growth: part I—yield criteria and flow rules for porous ductile media. J Eng Mater Technol 99: 2–15

Hippert E Jr, Dotta F, Ruggieri C (2002) Structural integrity assessments of pipelines using crack growth resistance curves. In: Proceedings of the 4th international pipeline conference, 29 Sep–3 Oct 2002, Calgary, Alberta, Canada, pp 1741–1749

MSC Software Corporation (2009) Patran User’s Manual, 2008 r2 edition

Nahshon K, Hutchinson JW (2008) Modification of the Gurson model for shear failure. Eur J Mech A Solids 27: 1–17. doi:10.1016/j.euromechsol.2007.08.002

Oh C-K, Kim Y-J, Baek J-H, Kim W-S (2007a) Development of stress-modified fracture strain for ductile failure of API X65 steel. Int J Fracture 143: 119–133

Oh C-K, Kim Y-J, Baek J-H, Kim Y-P, Kim W-S (2007b) A phenomenological model of ductile fracture for API X65 steel. Int J Mech Sci 49: 1399–1412. doi:10.1016/j.ijmecsci.2007.03.008

Oh C-K, Kim Y-J, Baek J-H, Kim Y-P, Kim W-S (2007c) Ductile failure analysis of API X65 pipes with notch-type defects using a local fracture criterion. Int J Pres Ves Pip 84: 512–525. doi:10.1016/j.ijpvp.2007.03.002

Rivalin F, Pineau A, Fant MD, Besson J (2001a) Ductile tearing of pipeline-steel wide plates I. Dynamic and quasi-static experiments. Eng Fract Mech 68: 329–345. doi:10.1016/S0013-7944(00)00107-7

Rivalin F, Besson J, Pineau A, Fant MD (2001b) Ductile tearing of pipeline-steel wide plates II. Modeling of in-plane crack extension. Eng Fract Mech 68: 347–364. doi:10.1016/S0013-7944(00)00108-9

Ruggieri C, Hippert E (2003) Cell model predictions of ductile fracture in damaged pipelines. Fatigue fracture mechanics vol 33. American Society for Testing and Materials Special Technical Publication 1417:176–191

Ruggieri C, Panontin TL, Dodds RH Jr (1996) Numerical modeling of ductile crack growth in 3-D using computational cell elements. Int J Fracture 82: 67–95

Tvergaard V (1981) Influence of voids on shear band instabilities under plane strain conditions. Int J Fracture 17: 389–407

Wang X, Roy G, Xu S, Tyson WR (2008) Numerical simulation of ductile crack growth in pipeline steels. In: Proceedings of ASME press ves piping conference 2007, vol 2. Computer applications/technology and bolted joints. Pressure Vessel and Piping Division of the American Society of Mechanical Engineers, pp 105–111

Xia L, Shih CF (1995) Ductile crack growth. Part I: a numerical study using computational cells with microstructurally-based length scales. J Mech Phys Solids 43: 233–259. doi:10.1016/0022-5096(94)00064-C

Xia L, Shih CF (1995) Ductile crack growth. Part II: void nucleation and geometry effects on macroscopic fracture behavior. J Mech Phys Solids 43: 1953–1981. doi:10.1016/0022-5096(95)00063-O

Zhang ZL, Thaulow C, Ødegard J (2000) A complete Gurson model approach for ductile fracture. Eng Fract Mech 67: 155–168. doi:10.1016/S0013-7944(00)00055-2

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qian, X. An out-of-plane length scale for ductile crack extensions in 3-D SSY models for X65 pipeline materials. Int J Fract 167, 249–265 (2011). https://doi.org/10.1007/s10704-010-9550-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-010-9550-1