Abstract

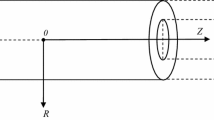

A finite strain fibre-reinforced viscoelasto-viscoplastic model implemented in a finite element (FE) analysis is presented to study the expansive growth of plant cell walls. Three components of the deformation of growing cell wall, i.e. elasticity, viscoelasticity and viscoplasticity-like growth, are modelled within a consistent framework aiming to present an integrative growth model. The two aspects of growth—turgor-driven creep and new material deposition—and the interplay between them are considered by presenting a yield function, flow rule and hardening law. A fibre-reinforcement formulation is used to account for the role of cellulose microfibrils in the anisotropic growth. Mechanisms in in vivo growth are taken into account to represent the corresponding biology-controlled behaviour of a cell wall. A viscoelastic formulation is proposed to capture the viscoelastic response in the cell wall. The proposed constitutive model provides a unique framework for modelling both the in vivo growth of cell wall dominated by viscoplasticity-like behaviour and in vitro deformation dominated by elastic or viscoelastic responses. A numerical scheme is devised, and FE case studies are reported and compared with experimental data.

Similar content being viewed by others

References

Refregier G, Pelletier S, Jaillard D, Hofte H (2004) Interaction between wall deposition and cell elongation in dark-grown hypocotyl cells in Arabidopsis. Plant Physiol 135:959–968

Cosgrove DJ (2001) Wall structure and wall loosening. A look backwards and forwards. Plant Physiol 125:131–134

McCann MC, Wells B, Roberts K (1990) Direct visualization of cross-links in the primary plant cell wall. J Cell Sci 96:323–334

Iwamoto S, Kai W, Isogai A, Iwata T (2009) Elastic modulus of single cellulose microfibrils from tunicate measured by atomic force microscopy. Biomacromolecules 10:2571–2576

Marga F, Grandbois M, Cosgrove DJ, Baskin TI (2005) Cell wall extension results in the coordinate separation of parallel microfibrils: evidence from scanning electron microscopy and atomic force microscopy. Plant J 43:181–190

Suslov D, Verbelen J-P (2006) Cellulose orientation determines mechanical anisotropy in onion epidermis cell walls. J Exp Bot 57:2183–2192

Dumais J, Shaw SL, Steele CR, Long SR, Ray PM (2006) An anisotropic-viscoplastic model of plant cell morphogenesis by tip growth. Int J Dev Biol 50:209–222

Cosgrove DJ (1993) Wall extensibility: its nature, measurement and relationship to plant cell growth. New Phytol 124:1–23

Schopfer P (2006) Biomechanics of plant growth. Am J Bot 93:1415–1425

Cosgrove DJ (1998) Cell wall loosening by expansins. Plant Physiol 118:333–339

Cosgrove DJ (2000) Loosening of plant cell walls by expansins. Nature 407:321–326

Cosgrove DJ (2005) Growth of the plant cell wall. Nat Rev Mol Cell Biol 6(11):850–861

Choi D, Cho H, Lee Y (2006) Expansins: expanding importance in plant growth and development. Physiol Plant 126:511–518

Taiz L (1984) Plant cell expansion: regulation of cell wall mechanical properties. Annu Rev Plant Physiol 35:585–657

Kutschera U (1990) Cell-wall synthesis and elongation growth in hypocotyls of Helianthus annuus. Planta 181:316–323

Proseus TE, Boyer JS (2006) Identifying cytoplasmic input to the cell wall of growing Chara corallina. J Exp Bot 57:3231–3242

Rojas ER, Hotton S, Dumais J (2011) Chemically mediated mechanical expansion of the pollen tube cell wall. Biophys J 101:1844–1853

Fung YC (1993) Biomechanics: mechanical properties of living tissues. Springer, New York

Hohl M, Schopfer P (1992) Physical extensibility of maize coleoptile cell walls: apparent plastic extensibility is due to elastic hysteresis. Planta 187:498–504

Keckes J, Burgert I, Frühmann K, Müller M, Kölln K, Hamilton M, Burghammer M, Roth SV, Stanzl-Tschegg SE, Fratzl P (2003) Cell-wall recovery after irreversible deformation of wood. Nat Mater 2:810–814

Lockhart JA (1965) An analysis of irreversible plant cell elongation. J Theor Biol 8:264–275

Lockhart JA (1965) Cell extension. In: Bonner J, Varner JE (eds) Plant biochemistry. Academic Press, New York, pp 827–849

Verbelen J-P, Vissenberg K (2007) Cell expansion: past, present and perspectives. In: Verbelen J-P, Vissenberg K (eds) The expanding cell. Springer, Berlin, pp 1–6

Green PB, Erickson RO, Buggy J (1971) Metabolic and physical control of cell elongation rate. In vivo studies in Nitella. Plant Physiol 47:423–430

Ray PM, Green PB, Cleland R (1972) Role of turgor in plant cell growth. Nature 239:163–164

Ortega JKE (1990) Governing equations for plant cell growth. Physiol Plant 79:116–121

Cosgrove DJ (1986) Biophysical control of plant cell growth. Annu Rev Plant Physiol 37:377–405

Geitmann A, Ortega JKE (2009) Mechanics and modelling of plant cell growth. Trends Plant Sci 14:467–478

Pietruszka M (2009) General proof of the validity of a new tensor equation of plant growth. J Theor Biol 256:584–585

Veytsman BA, Cosgrove DJ (1998) A model of cell wall expansion based on thermodynamics of polymer networks. Biophys J 75:2240–2250

Boudaoud A (2003) Growth of walled cells: from shells to vesicles. Phys Rev Lett 91:018104

Bruce DM (2003) Mathematical modelling of the cellular mechanics of plants. Philos Trans R Soc Lond B 358:1437–1444

Kerstens S, Decraemer WF, Verbelen J-P (2001) Cell walls at the plant surface behave mechanically like fiber-reinforced composite materials. Plant Physiol 127:381–385

Hettiaratchi DRP, O’Callaghan JR (1978) Structural mechanics of plant cells. J Theor Biol 74:235–257

Chaplain MAJ (1993) The strain energy function of an ideal plant cell wall. J Theor Biol 163:77–97

Dyson RJ, Jensen OE (2010) A fibre-reinforced fluid model of anisotropic plant cell growth. J Fluid Mech 655:472–503

Dyson RJ, Band LR, Jensen OE (2012) A model of crosslink kinetics in the expanding plant cell wall: yield stress and enzyme action. J Theor Biol 307:125–136

Geitmann A (2010) Mechanical modeling and structural analysis of the primary plant cell wall. Curr Opin Plant Biol 13:693–699

Geitmann A (2011) Generating a cellular protuberance: mechanics of tip growth. In: Wojtaszek P (ed) Mechanical integration of plant cells and plants. Springer, Berlin, pp 117–132

Kha H, Tuble SC, Kalyanasundaram S, Williamson RE (2010) WallGen, software to construct layered cellulose-hemicellulose networks and predict their small deformation mechanics. Plant Physiol 152:774–786

Goriely A, Tabor M (2003) Biomechanical models of hyphal growth in actinomycetes. J Theor Biol 222:211–218

Bernal R, Rojas ER, Dumais J (2007) The mechanics of tip growth morphogenesis: what we have learned from rubber balloons. J Mech Mater Struct 2:1157–1168

Hamant O, Heisler MG, Jönsson H, Krupinski P, Uyttewaal M, Bokov P, Corson F, Sahlin P, Boudaoud A, Meyerowitz EM, Couder Y, Traas J (2008) Developmental patterning by mechanical signals in Arabidopsis. Science 322:1650–1655

Kierzkowski D, Nakayama N, Routier-Kierzkowska A-L, Weber A, Bayer E, Schorderet M, Reinhardt D, Kuhlemeier C, Smith RS (2012) Elastic domains regulate growth and organogenesis in the plant shoot apical meristem. Science 335:1096–1099

Baskin TI (2005) Anisotropic expansion of the plant cell wall. Annu Rev Cell Dev Biol 21:203–222

Epstein M, Maugin GA (2000) Thermomechanics of volumetric growth in uniform bodies. Int J Plast 16:951–978

Kuhl E, Steinmann P (2003) Mass- and volume-specific views on thermodynamics for open systems. Proc R Soc Lond A 459:2547–2568

Guillou A, Ogden RW (2006) Growth in soft biological tissue and residual stress development. In: Holzapfel GA, Ogden RW (eds) Mechanics of biological tissue. Springer, Berlin, pp 47–62

Garikipati K, Arruda EM, Grosh K, Narayanan H, Calve S (2004) A continuum treatment of growth in biological tissue the coupling of mass transport and mechanics. J Mech Phys Solids 52:1595–1625

Humphrey JD, Rajagopal KR (2002) A constrained mixture model for growth and remodeling of soft tissues. Math Models Methods Appl Sci 12:407–430

Huang R, Becker AA, Jones IA (2012) Modelling cell wall growth using a fibre-reinforced hyperelastic–viscoplastic constitutive law. J Mech Phys Solids 60:750–783

Simo JC, Hughes TJR (1998) Computational inelasticity. Springer, New York

Moran B, Ortiz M, Shih CF (1990) Formulation of implicit finite element methods for multiplicative finite deformation plasticity. Int J Numer Methods Eng 29:483–514

Belytschko T, Liu WK, Moran B (2001) Nonlinear finite elements for continua and structures. Wiley, Chichester

Marsden JE, Hughes TJR (1994) Mathematical foundation of elasticity. Dover, NewYork

Gasser TC, Ogden RW, Holzapfel GA (2006) Hyperelastic modelling of arterial layers with distributed collagen fibre orientations. J R Soc Interface 3:15–35

Skalak R (1981) Growth as a finite displacement field. In: Carlson DE, Shield RT (eds) Proceedings off the IUTAM symposium on finite elasticity. Martinus Nijhoff Publishers, The Hague, pp 347–355

Chuong CJ, Fung YC (1986) Residual stress in arteries. In: Schmid-Schonbein GW, Woo SL-Y, Zweifach BW (eds) Frontiers in biomechanics. Springer, New York, pp 117–129

Chuong CJ, Fung YC (1986) On residual stresses in arteries. J Biomech Eng 108:189–192

Fung YC (1990) Biomechanics: motion, flow, stress, and growth. Springer, New York

Rodriguez EK, Hoger A, McCulloch A (1994) Stress-dependent finite growth in soft elastic tissue. J Biomech 27:455–467

Lee EH (1969) Elastic-plastic deformation at finite strain. J Appl Mech ASME 36:1–6

Gasser TC, Forsell C (2011) The numerical implementation of invariant-based viscoelastic formulations at finite strains. An anisotropic model for the passive myocardium. Comput Methods Appl Mech Eng 200:3637–3645

Humphrey JD, Rajagopal KR (2003) A constrained mixture model for arterial adaptations to a sustained step change in blood flow. Biomech Model Mechanobiol 2:109–126

Maugin GA (1999) The thermomechanics of nonlinear irreversible behaviours. World Scientific, Singapore

Proseus TE, Ortega JKE, Boyer JS (1999) Separating growth from elastic deformation during cell enlargement. Plant Physiol 119:775–784

Reese S, Govindjee S (1998) A theory of finite viscoelasticity and numerical aspects. Int J Solids Struct 35:3455–3482

Spencer AJM (2001) A theory of viscoplasticity for fabric-reinforced composites. J Mech Phys Solids 49:2667–2687

Proseus TE, Zhu G-L, Boyer JS (2000) Turgor, temperature and the growth of plant cells using Chara corallina as a model system. J Exp Bot 51:1481–1494

Thomas A, Tomos AD, Stoddart JL, Thomas H, Pollock CJ (1989) Cell expansion rate, temperature and turgor pressure in growing leaves of Lolium temulentum L. New Phytol 112:1–5

Mandel J (1971) Plasticité Classique et Viscoplasticité (CISM Lecture Notes, Udine, Italy). Springer, Vienna

Lubliner J (1990) Plasticity theory. Macmillan, New York

Maugin GA (2011) Configurational forces: thermo-mechanics, physics, mathematics and numerics. CRC Press, Boca Raton

Epstein M, Maugin GA (1996) On the geometrical structure of anelasticity. Acta Mech 115:119–131

Proseus TE, Boyer JS (2007) Tension required for pectate chemistry to control growth in Chara corallina. J Exp Bot 58:4283–4292

Niklas KJ (1992) Plant biomechanics: an engineering approach to plant form and function. University of Chicago Press, Chicago

Boyer JS (2009) Cell wall biosynthesis and the molecular mechanism of plant enlargement. Funct Plant Biol 36:383–394

Proseus TE, Boyer JS (2005) Turgor pressure moves polysaccharides into growing cell walls of Chara corallina. Ann Bot 95:967–979

Toole GA, Gunning PA, Parker ML, Smith AC, Waldron KW (2001) Fracture mechanics of the cell wall of Chara corallina. Planta 212:606–611

Milani P, Gholamirad M, Traas J, Arnéodo A, Boudaoud A, Argoul F, Hamant O (2011) In vivo analysis of local wall stiffness at the shoot apical meristem in Arabidopsis using atomic force microscopy. Plant J 67:1116–1123

Cousins WJ (1978) Young’s modulus of hemicelluloses as related to moisture content. Wood Sci Techol 12:161–167

Wang CX, Wang L, Thomas CR (2004) Modelling the mechanical properties of single suspension-cultured tomato cells. Ann Bot 93:443–453

Wei C, Lintilhac PM, Tanguay JJ (2001) An insight into cell elasticity and load-bearing ability: measurement and theory. Plant Physiol 126:1129–1138

Acknowledgments

This work was conducted in the Centre for Plant Integrative Biology, the University of Nottingham, U.K., which is jointly funded by the BBSRC/EPSRC (BB/D0196131/1) as part of their Systems Biology Initiative. The authors also gratefully acknowledge the valuable input of Prof. M. Bennett, Dr. L. Band and Dr. Zhefeng Lin to the literature survey.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1: The update algorithm of \({\overline{\varvec{S}}}\) and \(\overline{\mathbb {C}}^\mathrm{v}\)

The update criterion (11) for the configuration \(\tilde{{\mathcal {B}}}_t \) is implemented as follows:

where the increments \(\Delta {\tilde{\varvec{F}}}_n \) and  are defined as follows:

are defined as follows:

in which the velocity gradient \({\varvec{L}}_n^\mathrm{ve}\) is computed from \(\Delta {\varvec{F}}_n^\mathrm{ve}\) by using the relation

The update of the algorithmic internal variables \({\tilde{\varvec{H}}}_{n+1}\) and  is obtained by using the middle rule [52] as follows:

is obtained by using the middle rule [52] as follows:

where \({\tilde{\tilde{\varvec{H}}}}_n \) and  are defined as

are defined as

In order to obtain expressions of \({\overline{\varvec{S}}}\) and \(\overline{\mathbb {C}}^\mathrm{v}\), specified functions \(W^{\circ }\) and \(\tilde{W}^{\circ }\) in Eqs. (38) and (39) are set in the similar form as the deviatoric part of the free energy of wall matrix in Eq. (31) as follows:

Thus, the stress tensors \({\tilde{\varvec{S}}{}_{n+1}^\circ }\) and  in Eqs. (105) and (106) is obtained by using Eqs. (38) and (39) as

in Eqs. (105) and (106) is obtained by using Eqs. (38) and (39) as

where the deviatoric operators are defined as

Substituting Eqs. (105), (106), (111), (112) into Eq. (45) yields

where the two functions \(\tilde{g}{}_n^*\) and  are defined, respectively, as

are defined, respectively, as

By using Eqs. (115), (24) indicates that the viscoelastic components of tangent modulus is

where two operators, \(\widetilde{\hbox {DEV}}[ { \cdot } ]\) and \({\partial \{ {{\overline{J}{}^{-2/3}}\hbox {DEV}} \}}/{\partial {\overline{\varvec{C}}}}[ { \cdot }]\), are defined, respectively, as

The remaining work is to compute two tensors  and \({\partial {\tilde{\varvec{S}}{}_{n+1}^\circ } }/{\partial {\overline{\varvec{C}}}}\) in Eq. (117).

and \({\partial {\tilde{\varvec{S}}{}_{n+1}^\circ } }/{\partial {\overline{\varvec{C}}}}\) in Eq. (117).

By using Eqs. (112) and (119),  is obtained straightforward as

is obtained straightforward as

On the other hand, by using the criterion (103) (if \(\hbox {tr}\,{\varvec{L}}^\mathrm{ve}\ge 0), {\partial {\tilde{\varvec{S}}{}_{n+1}^\circ } }/{\partial {\overline{\varvec{C}}}}\) is computed by the chain rule as follows:

where tensor \({\partial {\tilde{\varvec{S}}{}_{n+1}^\circ } }/{\partial {\tilde{\varvec{C}}}}\) is expressed as

in which by using Eq. (111) we have

The other unknown tensor in Eq. (121), \({\partial {\tilde{\varvec{C}}}}/{\partial {\overline{\varvec{C}}}}\), is deduced as follows. It can be shown that (if \(\hbox {tr}\,({\varvec{L}}^\mathrm{ve})\ge 0)\)

By using Eq. (124), two one-parameter families of right Cauchy–Green tensors are constructed in the forms of

where \(\varepsilon \) is a scalar parameter, tensor \({\varvec{H}}_n \) is defined as

The derivative of \({\tilde{\varvec{C}}}_\varepsilon \) with respect to \(\varepsilon \) is computed from Eq. (126) as

The definitions (125) and (126) indicate that

Therefore, Eqs. (128) and (129) yield the expression of \({\partial {\tilde{\varvec{C}}}}/{\partial {\overline{\varvec{C}}}}\) as follows:

Once tensors \({\partial {\tilde{\varvec{S}}{}_{n+1}^\circ } }/{\partial {\tilde{\varvec{C}}}}\) and \({\partial {\tilde{\varvec{C}}}}/{\partial {\overline{\varvec{C}}}}\) are obtained by Eqs. (122) and (130), respectively, Eq. (121) yields the expression of \({\partial {\tilde{\varvec{S}}{}_{n+1}^\circ } }/{\partial {\overline{\varvec{C}}}}\). Then the expression of \(\overline{\mathbb {C}}^\mathrm{v}\) is obtained by substituting Eqs. (118–121) into Eq. (117).

Appendix 2: The derivative of function \(\phi \)

Let \(( \cdot )\) be an entity standing for tensor, vector or scalar. By taking the derivative of Eq. (67) with respect to \(( \cdot )\) we obtain

where

in which

Using the chain rule and substituting Eq. (131) into the derivative of the distance function \(\phi \) with respect to \(\left( \cdot \right) \) yields

in which

Rights and permissions

About this article

Cite this article

Huang, R., Becker, A.A. & Jones, I.A. A finite strain fibre-reinforced viscoelasto-viscoplastic model of plant cell wall growth. J Eng Math 95, 121–154 (2015). https://doi.org/10.1007/s10665-014-9761-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10665-014-9761-y

Keywords

- Biological material

- Cell wall growth

- Constitutive behaviour

- Fibre-reinforced composite material

- Finite strain

- Finite element analysis

- Viscoplastic material