Abstract

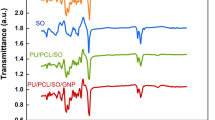

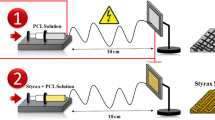

Protein-modified scaffolds have ability to provide biological functionality due to the similarity in structure of natural extracellular matrix (NECM) in tissues. In this paper, soy protein was selected to modify bacterial cellulose (BC) electrospun nanofiber scaffold prepared by fabricating BC nanofiber via electrospinning followed by ultrasound-induced self-assembly method. The modified nanofiber scaffold has multi-size distribution composed of BC electrospun nanofiber with diameter ranged from 80 to 360 nm and soy protein nanoparticles layer on the surface, which mimics the structure of NECM. The surface morphology and specific surface areas of soy protein modified BC electrospun nanofiber scaffold were investigated by scanning electronic microscopy and Brunauer–Emmett–Teller test. The structure, crystallinity, thermal stability, mechanical properties and hydrophilicity were characterized by Fourier transform infrared spectroscopy, energy dispersive X-ray spectroscopy, X-ray diffraction, thermogravimetric analysis, dynamic mechanical analysis, tensile test and water contact angle measurement. Soy protein surface modification does not obviously affect the crystalline structure of BC electrospun nanofiber. However, an increase in thermal stability and toughness can be observed. After soy protein surface modification, the nanofiber scaffold became more stretchable with the elongation at break greatly increased about 110% from 6.55 ± 0.71 to 13.81 ± 1.12%. The biodegradability and cytocompatibility of soy protein modified BC electrospun nanofiber scaffold were preliminarily evaluated by in vitro tests. Soy protein modified BC electrospun nanofiber scaffold exhibited higher biodegradation rate in enzyme solution and better biocompatibility. The as-prepared soy protein modified BC electrospun nanofiber scaffold is more bioactive and promising as bone tissue engineering scaffold.

Graphical abstract

Similar content being viewed by others

References

Ahn S, Chantre CO, Gannon AR, Lind JU, Campbell PH, Grevess T, O’Connor BB, Parker KK (2018) Soy protein/cellulose nanofiber scaffolds mimicking skin extracellular matrix for enhanced wound healing. Adv Healthc Mater 7(9):1701175

Arboleda JC, Hughes M, Lucia LA, Laine J, Ekman K, Rojas OJ (2013) Soy protein-nanocellulose composite aerogels. Cellulose 20(5):2417–2426

Azarniya A, Eslahi N, Mahmoudi N, Simchi A (2016) Effect of graphene oxide nanosheets on the physico-mechanical properties of chitosan/bacterial cellulose nanofibrous composites. Compos Part A Appl Sci 85:113–122

Babaee M, Jonoobi M, Hamzeh Y, Ashori A (2015) Biodegradability and mechanical properties of reinforced starch nanocomposites using cellulose nanofibers. Carbohydr Polym 132:1–8

Bhowmick S, Rother S, Zimmermann H, Lee PS, Moeller S, Schnabelrauch M, Koul V, Jordan R, Hintze V, Scharnweber D (2017) Biomimetic electrospun scaffolds from main extracellular matrix components for skin tissue engineering application—the role of chondroitin sulfate and sulfated hyaluronan. Mater Sci Eng, C 79:15–22

Burton TP, Corcoran A, Callanan A (2017) The effect of electrospun polycaprolactone scaffold morphology on human kidney epithelial cells. Biomed Mater 13(1):015006

Cai Z, Kim J (2010) Bacterial cellulose/poly(ethylene glycol) composite: characterization and first evaluation of biocompatibility. Cellulose 17(1):83–91

Cai Z, Xiong P, Zhu C, Zhai T, Guo J, Zhao K (2018) Preparation and characterization of a bi-layered nano-filtration membrane from a chitosan hydrogel and bacterial cellulose nanofiber for dye removal. Cellulose 25(9):5123–5137

Chang Y, Yan X, Wang Q, Ren L, Tong J, Zhou J (2017) High efficiency and low cost preparation of size controlled starch nanoparticles through ultrasonic treatment and precipitation. Food Chem 227:369–375

Chanphai P, Bekale L, Tajmir-Riahi HA (2015) Effect of hydrophobicity on protein–protein interactions. Eur Polym J 67:224–231

Chen P, Yun YS, Bak H, Cho SY, Jin HJ (2010) Multiwalled carbon nanotubes-embedded electrospun bacterial cellulose nanofibers. Mol Cryst Liq Cryst 519(1):169–178

Chen N, Lin L, Sun W, Zhao M (2014) Stable and ph-sensitive protein nanogels made by self-assembly of heat denatured soy protein. J Agric Food Chem 62(39):9553–9561

Chen W, Guo L, Masroujeh A, Augustine A, Cheng T, Chin T (2018) A single-step surface modification of electrospun silica nanofibers using a silica binding protein fused with an rgd motif for enhanced pc12 cell growth and differentiation. Materials 11(6):927–934

Chien KB, Makridakis E, Shah RN (2013a) Three-dimensional printing of soy protein scaffolds for tissue regeneration. Tissue Eng Part C Methods 19(6):417–426

Chien KB, Aguado BA, Bryce PJ, Shah RN (2013b) In vivo acute and humoral response to three-dimensional porous soy protein scaffolds. Acta Biomater 9(11):8983–8990

Cho D, Netravali AN, Joo YL (2012) Mechanical properties and biodegradability of electrospun soy protein isolate/pva hybrid nanofibers. Polym Degrad Stab 97(5):747–754

De AE, Pilolli R, Bavaro SL, Monaci L (2017) Insight into the gastro-duodenal digestion resistance of soybean proteins and potential implications for residual immunogenicity. Food Funct 8(4):1599–1610

Deng R, Chen Y, Chen P, Zhang L, Liao B (2006) Properties and biodegradability of water-resistant soy protein/poly(ε-caprolactone)/toluene-2,4-diisocyanate composites. Polym Degrad Stab 91(9):2189–2197

Dong F, Dong X, Zhou L, Xiao H, Ho PY, Wong MS, Wang Y (2016) Doxorubicin-loaded biodegradable self-assembly zein nanoparticle and its anti-cancer effect: preparation, in vitro evaluation, and cellular uptake. Colloids Surface B 140:324–331

Elayaraja S, Zagorsek K, Li F, Xiang J (2017) In situ synthesis of silver nanoparticles into tempo-mediated oxidized bacterial cellulose and their antivibriocidal activity against shrimp pathogens. Carbohydr Polym 166:329–337

Francesko A, González MD, Lozano GR, Tzanov T (2010) 12-Developments in the processing of chitin, chitosan and bacterial cellulose for textile and other applications. Adv Text Biotechnol 1:288–311

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896

Gan L, Zhao L, Zhao Y, Li K, Chen Y (2016) Cellulose/soy protein composite-based nerve guidance conduits with designed microstructure for peripheral nerve regeneration. J Neural Eng 13(5):056019

Gea S, Reynolds CT, Roohpur N, Soykeabkaew N, Wirjosentono B, Bilotti E, Peijs T (2010) Biodegradable composites based on poly(ε-caprolactone) and bacterial cellulose as a reinforcing agent. J Biobased Mater Bioenergy 4(4):384–390

Genovese MI, Barbosa ACL, Pinto MDS, Lajolo FM (2007) Soy protein ingredients as isoflavone sources for functional foods. Plant Food Hum Nutr 62(2):53–60

Gleadall A, Visscher D, Yang J, Thomas D, Segal J (2018) Review of additive manufactured tissue engineering scaffolds: relationship between geometry and performance. Burns Trauma 6(1):19–27

Grigoriev D, Miller R, Shchukin D, Möhwald H (2007) Interfacial assembly of partially hydrophobic silica nanoparticles induced by ultrasonic treatment. Small 3(4):665–671

Gromovykh TI, Sadykova VS, Lutcenko SV, Dmitrenok AS, Feldman NB, Danilchuk TN, Kashirin VV (2017) Bacterial cellulose synthesized by Gluconacetobacter hansenii, for medical applications. Appl Biochem Microbiol 53(1):60–67

Heidari-Keshel S, Ahmadian M, Biazar E, Gazmeh A, Rabiei M, Adibi M (2016) Surface modification of poly hydroxybutyrate (PHB) nanofibrous mat by collagen protein and its cellular study. Mater Proc Rep 31(13):799–805

Hettiarachchy NS (1998) Functional properties of soy proteins. Biochem J 708(2):80–95

Hosseini H, Kokabi M, Mousavi SM (2018) Dynamic mechanical properties of bacterial cellulose nanofibres. Iran Polym J 27:433–443

Hou Y, Wang X, Yang J, Zhu R, Zhang Z, Li Y (2018) Development and biocompatibility evaluation of biodegradable bacterial cellulose as a novel peripheral nerve scaffold. J Biomed Mater Res A 106(5):1288–1298

Hu Y, Catchmark JM (2010) Influence of 1-methylcyclopropene (1-mcp) on the production of bacterial cellulose biosynthesized by acetobacter xylinum under the agitated culture. Lett Appl Microbiol 51(1):109–113

Iguchi M, Yamankas S, Budhiono A (2000) Bacterial cellulose: a masterpiece of nature’s arts. J Mater Sci 35:261–270

Jasim A, Ullah MW, Shi Z, Xiao L, Yang G (2017) Fabrication of bacterial cellulose/polyaniline/single-walled carbon nanotubes membrane for potential application as biosensor. Carbohydr Polym 163:62–69

Jeon JH, Oh IK, Kee CD, Kim SJ (2010) Bacterial cellulose actuator with electrically driven bending deformation in hydrated condition. Sensor Actuat B Chem 146(1):307–313

Kim HJ, Jin JN, Kan E, Kim KJ, Sang HL (2017) Bacterial cellulose-chitosan composite hydrogel beads for enzyme immobilization. Biotechnol Bioprocess Eng 22(1):89–94

Kirdponpattara S, Phisalaphong M, Kongruang S (2017) Gelatin-bacterial cellulose composite sponges thermally cross-linked with glucose for tissue engineering applications. Carbohydr Polym 177:361–368

Klymov A, Song J, Cai X, Te RJ, Leeuwenburgh S, Jansen JA, Walboomers XF (2016) Increased acellular and cellular surface mineralization induced by nanogrooves in combination with a calcium-phosphate coating. Acta Biomater 31(1):368–377

Lee SE, Yong SP (2017) The role of bacterial cellulose in artificial blood vessels. Mol Cell Toxicol 13(3):257–261

Li HP, Ma BG, Zhou SM, Zhang LM, Yi JZ (2010) Thermally responsive graft copolymer of soy protein isolate and n-isopropylacrylamide: synthesis and self-assembly behavior in aqueous solution. Colloid Polym Sci 288(14–15):1419–1426

Li H, He X, Yang L, Hang Y, Kang Z, Lee ST (2011a) Synthesis of fluorescent carbon nanoparticles directly from active carbon via a one-step ultrasonic treatment. Mater Res Bull 46(1):147–151

Li WM, Liu DM, Chen SY (2011b) Amphiphilically-modified gelatin nanoparticles: self-assembly behavior, controlled biodegradability, and rapid cellular uptake for intracellular drug delivery. J Mater Chem 21(33):12381–12388

Li H, Lu X, Yang H, Hu J (2016a) Preparation and properties of polylactic acid/bacterial cellulose bio-composites with interpenetrating networks structure. Polym Mater Sci Eng 1:114–121

Li N, Xiao J, Hai X, Wang K, Dang F (2016b) Key role of ionic hydrogen bonding in nonspecific protein adsorption on a hydrophobic surface. J Phys Chem C 120(34):19135–19141

Liu X, Souzandeh H, Zheng Y, Xie Y, Zhong WH, Cai W (2017) Soy protein isolate/bacterial cellulose composite membranes for high efficiency particulate air filtration. Compos Sci Technol 138:124–133

Luo LH, Zhang YF, Wang XM, Wan Y, Chang PR, Anderson DP (2010) Preparation, characterization, and in vitro and in vivo evaluation of cellulose/soy protein isolate composite sponges. J Biomater Appl 24(6):503–526

Luo L, Gong W, Zhou Y, Yang L, Li D, Huselstein C (2015) Cellulose/soy protein isolate composite membranes: evaluations of in vitro cytocompatibility with schwann cells and in vivo toxicity to animals. Biomed Mater Eng 25:57–64

Luz EPCG, Borges MDF, Andrade FK, Rosa MDF, Infantes-Molina A, Rodríguez-Castellón E et al (2018) Strontium delivery systems based on bacterial cellulose and hydroxyapatite for guided bone regeneration. Cellulose 1:1. https://doi.org/10.1007/s10570-018-2008-8

Mei-Chun L, Qinglin W, Kunlin S, Sunyoung L, Chunde J, Suxia R, Tingzhou L (2015) Soy protein isolate as fluid loss additive in bentonite-water-based drilling fluids. ACS Appl Mater Interfaces 7(44):24799–24809

Merolli A, Nicolais L, Ambrosio L, Santin M (2010) A degradable soybean-based biomaterial used effectively as a bone filler in vivo in a rabbit. Biomed Mater 5(1):15008

Millon LE, Guhados G, Wan W (2008) Anisotropic polyvinyl alcohol-bacterial cellulose nanocomposite for biomedical applications. J Biomed Mater Res B 86(2):444–452

Ozeki N, Hase N, Higuchi N, Hiyama T, Yamaguchi H, Kawai R (2017) Gelatin scaffold combined with bone morphogenetic protein-4 induces odontoblast-like cell differentiation involving integrin profile changes, autophagy-related gene 10, and wnt5 sequentially in human induced pluripotent stem cells. Differentiation 93:1–14

Palaninathan V, Raveendran S, Rochani AK, Chauhan N, Kumar DS (2018) Bioactive bacterial cellulose sulfate electrospun nanofibers for tissue engineering applications. J Tissue Eng Regen Med 12(7):1634–1645

Panaitescu DM, Frone AN, Chiulan I, Casarica A, Nicolae CA, Ghiurea M, Trusca R, Damian CM (2016) Structural and morphological characterization of bacterial cellulose nano-reinforcements prepared by mechanical route. Mater Des 110:790–801

Paramadini AW, Widiyanti P, Rudyardjo DI (2017) Effects of collagen concentration variation toward characteristics of bacterial cellulose-collagen biocomposites as candidate of artificial dura mater. J Biomim Biomater Biomed Eng 33:80–87

Peles Z, Zilberman M (2012) Novel soy protein wound dressings with controlled antibiotic release: mechanical and physical properties. Acta Biomater 8(1):209–217

Prodanov L, Te RJ, Lamers E, Domanski M, Luttge R, van Loon JJ, Jansen JA, Walboomers F (2010) The interaction between nanoscale surface features and mechanical loading and its effect on osteoblast-like cells behavior. Biomaterials 31(30):7758–7765

Qu P, Huang H, Wu G, Sun E, Chang Z (2015) Hydrolyzed soy protein isolates modified urea-formaldehyde resins as adhesives and its biodegradability. J Adhes Sci Technol 29:2381–2398

Rahman MM, Netravali AN (2016) Oriented bacterial cellulose-soy protein based fully ‘green’ nanocomposites. Compos Sci Technol 136:85–93

Rahman MM, Netravali AN (2017) High-performance green nanocomposites using aligned bacterial cellulose and soy protein. Compos Sci Technol 146:183–190

Rampichová ME, Kuželová KE, Filová J, Chvojka JŠ, Pelcl M, Daňková J, Prosecká E, Buzgo M, Plencner M, Lukáš D, Amler E (2017) Composite 3D printed scaffold with structured electrospun nanofibers promotes chondrocyte adhesion and infiltration. Cell Adhaes Migr 12(10):1–15

Schoen B, Avrahami R, Baruch L, Efraim Y, Goldfracht I, Elul O, Davidov T, Gepstein L, Zussman E, Machluf M (2017) Electrospun extracellular matrix: paving the way to tailor-made natural scaffolds for cardiac tissue regeneration. Adv Funct Mater 27(34):1700427

Shi Z, Zhang Y, Phillips GO, Yang G (2014) Utilization of bacterial cellulose in food. Food Hydrocolloids 35(1):539–545

Silva GA, Vaz CM, Coutinho OP, Cunha AM, Reis RL (2003) In vitro degradation and cytocompatibility evaluation of novel soy and sodium caseinate-based membrane biomaterials. J Mater Sci Med 14(12):1055–1066

Sobral JM, Caridade SG, Sousa RA, Mano JF, Reis RL (2011) Three-dimensional plotted scaffolds with controlled pore size gradients: effect of scaffold geometry on mechanical performance and cell seeding efficiency. Acta Biomater 7(3):1009–1018

Stocco E, Barbon S, Grandi F, Gamba PG, Borgio L, Gaudio CD (2017) Partially oxidized polyvinyl alcohol as a promising material for tissue engineering. J Tissue Eng Regen Med 11:2060–2070

Su JF, Yuan XY, Huang Z, Xia WL (2010) Properties stability and biodegradation behaviors of soy protein isolate/poly (vinyl alcohol) blend films. Polym Degrad Stab 95(7):1226–1237

Subramanian A, Lin HY (2010) Crosslinked chitosan: its physical properties and the effects of matrix stiffness on chondrocyte cell morphology and proliferation. J Biomed Mater Res A 75A(3):742–753

Sun D, Yang J, Li J, Zhou L, Yu J (2009) Preparation and antibacterial capacity of artificial skin loaded with nanoparticles silver using bacterial cellulose. J Biomed Eng 26(5):1034–1038

Tansaz S, Boccaccini AR (2016) Biomedical applications of soy protein: a brief overview. J Biomed Mater Res, Part A 104(2):553–569

Thomas S (2008) A review of the physical, biological and clinical properties of a bacterial cellulose wound dressing. J Wound Care 17(8):349–352

Treesuppharat W, Rojanapanthu P, Siangsanoh C, Manuspiya H, Ummartyotin S (2017) Synthesis and characterization of bacterial cellulose and gelatin-based hydrogel composites for drug-delivery systems. Biotechnol Rep 15:84–91

Ullah H, Badshah M, Mäkilä E, Salonen J, Shahbazi MA, Santos HA, Khan T (2017) Fabrication, characterization and evaluation of bacterial cellulose-based capsule shells for oral drug delivery. Cellulose 24(3):1445–1454

Vasconcelos NF, Feitosa JPA, de Gama FMPD, Morais JPS, Andrade FK, de Souza MDSM, de Freitas Rosa M (2017) Bacterial cellulose nanocrystals produced under different hydrolysis conditions: properties and morphological features. Carbohydr Polym 155:425–431

Wang X, Mao J, Chen Y, Song D, Gao Z, Zhang X (2016) Design of antibacterial biointerfaces by surface modification of poly (ε-caprolactone) with fusion protein containing hydrophobin and pa-1. Colloids Surf B Biointerfaces 151:255–263

Watanabe K, Tabuchi M, Morinaga Y, Yoshinaga F (1998) Structural features and properties of bacterial cellulose produced in agitated culture. Cellulose 5(3):187–200

Wei G, Guo C, Sun L, Sun Y, Song Y (2008) Photochemical synthesis and self-assembly of gold nanoparticles. Colloid Surface A 312(2):148–153

Woehl MA, Canestraro CD, Mikowski A, Sierakowski MR, Ramos LP, Wypych F (2010) Bionanocomposites of thermoplastic starch reinforced with bacterial cellulose nanofibres: effect of enzymatic treatment on mechanical properties. Carbohydr Polym 80(3):866–873

Xiang Z, Jin X, Liu Q, Chen Y, Li J, Lu F (2017) The reinforcement mechanism of bacterial cellulose on paper made from woody and non-woody fiber sources. Cellulose 24:5147–5156

Yan H, Chen X, Feng M, Shi Z, Zhang D, Lin Q (2017) Layer-by-layer assembly of 3D alginate-chitosan-gelatin composite scaffold incorporating bacterial cellulose nanocrystals for bone tissue engineering. Mater Lett 209:492–496

Zhang Y, Zhou F, Zhao M, Lin L, Ning Z, Sun B (2017) Soy peptide nanoparticles by ultrasound-induced self-assembly of large peptide aggregates and their role on emulsion stability. Food Hydrocolloid 74:62–71

Zhao Y, He M, Zhao L, Wang S, Li Y, Gan L, Li M, Xu L, Chang PR, Anderson DP, Chen Y (2016) Epichlorohydrin-cross-linked hydroxyethyl cellulose/soy protein isolate composite films as biocompatible and biodegradable implants for tissue engineering. Appl Mater Interfaces 8(4):2781–2795

Zhao Y, Meng H, Jin H, Lei Z, Du Q, Deng H, Tian W, Li Y, Lv X, Chen Y (2018) Construction of highly biocompatible hydroxyethyl cellulose/soy protein isolate composite sponges for tissue engineering. Chem Eng J 341(1):402–413

Zheng C, Yang R, Xu L, Xiao L, Hua C (2017) Green synthesis of bacterial cellulose via acetic acid pre-hydrolysis liquor of agricultural corn stalk used as carbon source. Bioresour Technol 234:8–14

Zhijiang C, Cong Z, Jie G, Qing Z, Kongyin Z (2018a) Electrospun carboxyl multi-walled carbon nanotubes grafted polyhydroxybutyrate composite nanofibers membrane scaffolds: preparation, characterization and cytocompatibility. Mater Sci Eng, C 82:29–40

Zhijiang C, Cong Z, Ping X, Yunming Q (2018b) Preparation, characterization and antibacterial activity of biodegradable polyindole/bacterial cellulose conductive nanocomposite fiber membrane. Mater Lett 222:146–149

Zhu Y, Yang Q, Yang M, Zhan X, Lan F, He J (2017) Protein corona of magnetic hydroxyapatite scaffold improves cell proliferation via activation of mitogen-activated protein kinase signaling pathway. ACS Nano 11(4):3690–3704

Zhu S, Yuan Q, Yin T, You J, Gu Z, Xiong S, Hu Y (2018) Self-assembly of collagen-based biomaterials: preparation, characterizations and biomedical applications. J Mater Chem B 6:2650–2676

Acknowledgments

This work was supported by Tianjin Science Technology Research Funds of China (16JCZDJC37500) and The project of Tianjin science and technology correspondent (16JCTPJC44800).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhijiang, C., Ping, X., Shiqi, H. et al. Soy protein nanoparticles modified bacterial cellulose electrospun nanofiber membrane scaffold by ultrasound-induced self-assembly technique: characterization and cytocompatibility. Cellulose 26, 6133–6150 (2019). https://doi.org/10.1007/s10570-019-02513-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-019-02513-x