Abstract

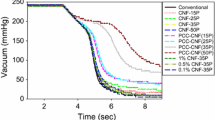

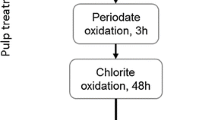

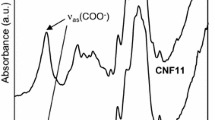

The use of micro and nanofibrillated celluloses (MFC, NFC or collectively MNFC) as a reinforcement fibre in composite papers and films has been an area of intensive research recently. The large relative surface area of MNFC makes it a promising material to improve strength and other properties of paper and board products. However, the high swelling of MNFC can lead to challenges in web dewatering. In this work, we have studied the dewatering and paper properties of a composite consisting of 70 % precipitated calcium carbonate (PCC), 20 % MNFC and 10 % kraft pulp fibers. The water uptake of the MNFC was controlled by changing the number of passes of the pulp feed stock through a microfluidizer. Additionally, the water binding was changed by precipitating PCC onto the MNFC surface, thus changing the surface conditions. Swelling, gravimetric, and press dewatering of the material were measured from composite handsheets. The results show that while increasing MNFC fibrillation decreases dewatering performance, this effect can be overcome by the in situ precipitation of PCC without decreasing important sheet properties. It was also evident that the in situ precipitation method can be used to fine tune the dewatering and material properties of the composite paper to achieve desired combination of process/material performance. The results show that the optimum combination of strength and dewatering is obtained by one pass through a microfluidizer. Further passes decrease dewatering and do not improve strength.

Similar content being viewed by others

References

Busker LH (1985) Effects of wet pressing on paper quality. In: Engineering conference, Proceedings of the technical association of the pulp and paper industry, pp 117–129

Carrillo CA, Laine J, Rojas OJ (2014) Microemulsion systems for fiber deconstruction into cellulose nanofibrils. ACS Appl Mater Interf 6:22622–22627

Ciobanu M, Bobu E, Ciolacu F (2010) In-situ cellulose fibres loading with calcium carbonate precipitated by different methods. Cellul Chem Technol 44:379–387

Dimic-Misic K, Gane PAC, Paltakari J (2013a) Micro and nanofibrillated cellulose as a rheology modifier additive in CMC-containing pigment-coating formulations. Ind Eng Chem Res 52:16066–16083

Dimic-Misic K, Puisto A, Gane P, Nieminen K, Alava M, Paltakari J, Maloney T (2013b) The role of MFC/NFC swelling in the rheological behavior and dewatering of high consistency furnishes. Cellulose 20:2847–2861

Dimic-Misic K, Puisto A, Paltakari J, Alava M, Maloney T (2013c) The influence of shear on the dewatering of high consistency nanofibrillated cellulose furnishes. Cellulose 20:1853–1864

Djafari Petroudy SR, Syverud K, Chinga-Carrasco G, Ghasemain A, Resalati H (2014) Effects of bagasse microfibrillated cellulose and cationic polyacrylamide on key properties of bagasse paper. Carbohydr Polym 99:311–318

Dufresne A, Dupeyre D, Vignon MR (2000) Cellulose microfibrils from potato tuber cells: processing and characterization of starch-cellulose microfibril composites. J Appl Polym Sci 76:2080–2092

Herrick FW, Casebier RL, Hamilton JK, Sandberg KR (1983) Microfibrillated cellulose: morphology and accessibility 37:797–813. doi:10.1007/s10570-011-9634-8

Hii C, Gregersen ØW, Chinga-Carrasco G, Eriksen Ø (2012) The effect of MFC on the pressability and paper properties of TMP and GCC based sheets. Nord Pulp Pap Res J 27:388–396. doi:10.3183/NPPRJ-2012-27-02-p388-396

Hoeger IC, Nair SS, Ragauskas AJ, Deng Y, Rojas OJ, Zhu JY (2013) Mechanical deconstruction of lignocellulose cell walls and their enzymatic saccharification. Cellulose 20:807–818

Klungness JH, Sykes MS, Tan F, Abubakr S, Eisenwasser JD (1996) Effect of fiber loading on paper properties. Tappi J 79:297–301

Li J, Wang Y, Wei X, Wang F, Han D, Wang Q, Kong L (2014) Homogeneous isolation of nanocelluloses by controlling the shearing force and pressure in microenvironment. Carbohydr Polym 113:388–393

Liimatainen H, Visanko M, Sirviö J, Hormi O, Niinimäki J (2013) Sulfonated cellulose nanofibrils obtained from wood pulp through regioselective oxidative bisulfite pre-treatment. Cellulose 20:741–749

MacGregor MA (1983) Description of sheet stratification caused by wet pressing. Tappi J 66:54–57

MacGregor MA (1986) Paper defects caused by fluid shear force during pressing. TAPPI Notes, pp 75–92

Maloney TC (2015) Network swelling of TEMPO-oxidized nanocellulose. Holzforschung 69:207–213

Mautner A, Lee K-, Lahtinen P, Hakalahti M, Tammelin T, Li K, Bismarck A (2014) Nanopapers for organic solvent nanofiltration. Chem Commun 50:5778–5781

Mautner A, Lee K-, Tammelin T, Mathew AP, Nedoma AJ, Li K, Bismarck A (2015) Cellulose nanopapers as tight aqueous ultra-filtration membranes. React Funct Polym 86:209–214

McDonald JD, Kerekes RJ (1995) A decreasing-permeability model of wet pressing with rewetting. Tappi J 78:107–111

Nakagaito AN, Yano H (2004) The effect of morphological changes from pulp fiber towards nano-scale fibrillated cellulose on the mechanical properties of high-strength plant fiber based composites. Appl Phys A Mater Sci Process 78:547–552

Olsson RT, Azizi Samir MAS, Salazar-Alvarez G, Belova L, Ström V, Berglund LA, Ikkala O, Nogués J, Gedde UW (2010) Making flexible magnetic aerogels and stiff magnetic nanopaper using cellulose nanofibrils as templates. Nat Nanotechnol 5:584–588

Paulapuro H (2008) Papermaking science and technology. Part 1: stock preparation and wet end/Book 8, Papermaking. Finnish Paper Engineers’ Association, Helsinki

Pelton R (2009) Bioactive paper provides a low-cost platform for diagnostics. TrAC Trends Anal Chem 28:925–942

Penttilä A, Sievänen J, Torvinen K, Ojanperä K, Ketoja JA (2013) Filler-nanocellulose substrate for printed electronics: experiments and model approach to structure and conductivity. Cellulose. doi:10.1007/s10570-013-9883-9

Qua EH, Hornsby PR, Sharma HSS, Lyons G (2011) Preparation and characterisation of cellulose nanofibres. J Mater Sci 46:6029–6045

Rantanen J, Maloney T (2013) Press dewatering and nip rewetting of paper containing nano- and microfibril cellulose. Nord Pulp Pap Res J 28:582–587

Rantanen J, Maloney TC (2015) Consolidation and dewatering of a microfibrillated cellulose fiber composite paper in wet pressing. Eur Polymer J. doi:10.1016/j.eurpolymj.2015.03.045

Rantanen J, Lahtinen P, Maloney T (2013) Property space for fibre, microfibrillar cellulose and precipitated CaCO3 composite sheets. Int Paperworld IPW 5:46–51

Rantanen J, Paulig T, Laiti E, Maloney T (2014) Microfibrillated cellulose as a component in novel nonwoven composite structures. Innovative nonwovens conference, Nashville, TN

Rantanen J, Dimic-Misic K, Pirttiniemi J, Kuosmanen P, Maloney TC (2015) Forming and dewatering of a microfibrillated cellulose composite paper. BioResources 10:3492–3506

Rezayati Charani P, Dehghani-Firouzabadi M, Afra E, Blademo Å, Naderi A, Lindström T (2013) Production of microfibrillated cellulose from unbleached kraft pulp of Kenaf and Scotch Pine and its effect on the properties of hardwood kraft: microfibrillated cellulose paper. Cellulose 20:2559–2567. doi:10.1007/s10570-013-9998-z

Ropp RC (2013) Encyclopedia of the alkaline earth compounds. Elsevier, Oxford

Sandås S, Salminen PJ, Eklund D (1989) Measuring the water retention of coating colors. TAPPI 72:207–210

Silenius P (2003) Improving the combinations of critical properties and process parameters of printing and writing papers and paperboards by new paper-filling methods. Doctoral Dissertation. Teknillinen korkeakoulu, Espoo

Solala I, Volperts A, Andersone A, Dizhbite T, Mironova-Ulmane N, Vehniäinen A, Pere J, Vuorinen T (2012) Mechanoradical formation and its effects on birch kraft pulp during the preparation of nanofibrillated cellulose with Masuko refining. Holzforschung 66:477–483

Spence KL, Venditti RA, Rojas OJ, Habibi Y, Pawlak JJ (2011) A comparative study of energy consumption and physical properties of microfibrillated cellulose produced by different processing methods. Cellulose 18:1097–1111

Subramanian R, Maloney T, Paulapuro H (2005) Calcium carbonate composite fillers. Tappi J 4:23–27

Subramanian R, Fordsmand H, Paltakari J, Paulapuro H (2008) A new composite fine paper with high filler loading and functional cellulosic microfines. J Pulp Pap Sci 34:146–152

Svending P (2014) Commercial Break-through in MFC Processing. 2014 TAPPI international conference on nanotechnology for renewable materials. Vancouver

Taipale T, Österberg M, Nykänen A, Ruokolainen J, Laine J (2010) Effect of microfibrillated cellulose and fines on the drainage of kraft pulp suspension and paper strength. Cellulose 17:1005–1020. doi:10.1007/s10570-010-9431-9

Taniguchi T, Okamura K (1998) New films produced from microfibrillated natural fibres. Polym Int 47:291–294. doi:10.1002/(SICI)1097-0126(199811)47:3<291:AID-PI11>3.0.CO;2-1

Torvinen K, Sievänen J, Hjelt T, Hellén E (2012) Smooth and flexible filler-nanocellulose composite structure for printed electronics applications. Cellulose 19:821–829. doi:10.1007/s10570-012-9677-5

Turbak AF, Snyder FW, Sandberg KR (1983) Microfibrillated cellulose, a new cellulose product: Properties, uses, and commercial potential. Proceedings of the ninth cellulose conference; held at Syracuse, New York, May 24–27, 1982:815–827

Varanasi S, Batchelor WJ (2013) Rapid preparation of cellulose nanofibre sheet. Cellulose 20:211–215. doi:10.1007/s10570-012-9794-1

Zhang J, Song H, Lin L, Zhuang J, Pang C, Liu S (2012) Microfibrillated cellulose from bamboo pulp and its properties. Biomass Bioenergy 39:78–83. doi:10.1016/j.biombioe.2010.06.013

Zolin L, Destro M, Chaussy D, Penazzi N, Gerbaldi C, Beneventi D (2015) Aqueous processing of paper separators by filtration dewatering: towards Li-ion paper batteries. J Mater Chem A 3:14894–14901

Acknowledgments

The authors would like to thank the technical staff of the Department of Forest Products Technology at Aalto University. The financial support from the International Doctoral Programme in Bioproducts Technology (PaPSaT) is also appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rantanen, J., Dimic-Misic, K., Kuusisto, J. et al. The effect of micro and nanofibrillated cellulose water uptake on high filler content composite paper properties and furnish dewatering. Cellulose 22, 4003–4015 (2015). https://doi.org/10.1007/s10570-015-0777-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0777-x