Abstract

Objective

To explore the glycerol utilization pathway in Corynebacterium glutamicum for succinate production under O2 deprivation.

Result

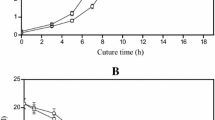

Overexpression of a glycerol facilitator, glycerol dehydrogenase and dihydroxyacetone kinase from Escherichia coli K-12 in C. glutamicum led to recombinant strains NC-3G diverting glycerol utilization towards succinate production under O2 deprivation. Under these conditions, strain NC-3G efficiently consumed glycerol and produced succinate without growth. The recombinant C. glutamicum utilizing glycerol as the sole carbon source showed higher intracellular NADH/NAD+ ratio compare with utilizing glucose. The mass conversion of succinate increased from 0.64 to 0.95. Using an anaerobic fed-batch fermentation process, the final strain produced 38.4 g succinate/l with an average yield of 1.02 g/g.

Conclusions

The metabolically-engineered strains showed an efficient succinate production using glycerol as sole carbon source under O2 deprivation.

Similar content being viewed by others

References

Blankschien MD, Clomburg JM, Gonzalez R (2010) Metabolic engineering of Escherichia coli for the production of succinate from glycerol. Metab Eng 12:409–419

Glassner DA, Datta R (1992) Process for the production and purification of succinic acid. US Patent 5,143–834

Guettler MV, Jain MK, Rumler D (1996) Method for making succinic acid, bacterial variants for use in the process, and methods for obtaining variants. US Patent 5,573–931

Ikeda M, Nakagawa S (2003) The Corynebacterium glutamicum genome: features and impacts on biotechnological processes. Appl Microbiol Biotechnol 62:99–109

Inui M, Murakami S, Okino S, Kawaguchi H, Vertès AA, Yukawa H (2004) Metabolic analysis of Corynebacterium glutamicum during lactate and succinate productions under O2 deprivation conditions. J Mol Microbiol Biotechnol 7:182–196

Jakoby M, Ngouoto-Nkili CE, Burkovski A (1999) Construction and application of new Corynebacterium glutamicum vectors. Biotechnol Technol 13:437–441

Kalinowski J, Bathe B, Bartels D, Bischoff N et al (2003) The complete Corynebacterium glutamicum ATCC 13032 genome sequence and its impact on the production of L-aspartate-derived amino acids and vitamins. J Biotechnol 104:5–25

Kirchner O, Tauch A (2003) Tools for genetic engineering in the amino acid-producing bacterium Corynebacterium glutamicum. J Biotechnol 104:287–299

Lee PC, Lee WG, Lee SY, Chang HN (2001) Succinic acid production with reduced by-product formation in the fermentation of Anaerobiospirillum succiniciproducens using glycerol as a carbon source. Biotechnol Bioeng 72:41–48

Lee PC, Lee SY, Hong SH, Chang HN (2002) Isolation and characterization of a new succinic acid-producing bacterium, Mannheimia succiniciproducens MBEL55E, from bovine rumen. Appl Microbiol Biotechnol 58:663–668

Litsanov B, Brocker M, Bott M (2012) Toward Homosuccinate Fermentation: metabolic engineering of Corynebacterium glutamicum for anaerobic production of succinate from glucose and formate. Appl Environ Microbiol 78:3325–3337

Litsanov B, Brocker M, Bott M (2013) Glycerol as a substrate for aerobic succinate production in minimal medium with Corynebacterium glutamicum. Microb Biotechnol 6:189–195

Molin M, Norbeck J, Blomberg A (2003) Dihydroxyacetone kinases in Saccharomyces cerevisiae are involved in detoxification of dihydroxyacetone. J Biol Chem 278(3):1415–1423

Okino S, Noburyu R, Suda M, Jojima T, Inui M, Yukawa H (2008) An efficient succinic acid production process in a metabolically engineered Corynebacterium glutamicum strain. Appl Microbiol Biotechnol 81:459–464

Schäfer A, Tauch A, Jäger W, Kalinowski J, Thierbach G, Pühler A (1994) Small mobilizable multi-purpose cloning vectors derived from the Escherichia coli plasmids pK18 and pK19: selection of defined deletions in the chromosome of Corynebacterium glutamicum. Gene 145:69–73

Scholten E, Dagele D (2008) Succinic acid production by a newly isolated bacterium. Biotechnol Lett 30:2143–2146

Shams YS, Gonzalez R (2008) Engineering Escherichia coli for the efficient conversion of glycerol to ethanol and coproducts. Metab Eng 10:340–351

Vertès AA, Inui M, Yukawa H (2005) Manipulating corynebacteria, from individual genes to chromosomes. Appl Environ Microbiol 71:7633–7642

Wang C, Zhang HL, Cai H, Zhou ZH, Chen YL, Chen YL, Ouyang PK (2014a) Succinic acid production from corn cob hydrolysates by genetically engineered Corynebacterium glutamicum. Appl Biochem Biotechnol 172:340–350

Wang C, Cai H, Zhou ZH, Zhang K, Chen ZJ, Chen YL, Wan HG, Ouyang PK (2014b) Investigation of ptsG gene in response to xylose utilization in Corynebacterium glutamicum. J Ind Microbiol Biotechnol 41:1249–1258

Yazdani SS, Gonzalez R (2007) Anaerobic fermentation of glycerol: a path to economic viability for the biofuels industry. Curr Opin Biotechnol 18:213–219

Yukawa H, Omumasaba CA, Nonaka H, Kos P, Okai N, Suzuki N, Suda N, Tsuge Y, Watanabe J, Ikeda Y, Vertès AA, Inui M (2007) Comparative analysis of the Corynebacterium glutamicum group and complete genome sequence of strain R. Microbiology 153:1042–1058

Zeikus JG, Jain MK, Elankovan P (1999) Biotechnology of succinic acid production and markets for derived industrial products. Appl Microbiol Biotechnol 51:545–552

Zhang X, Shanmuqam KT, Ingram LO (2010) Fermentation of glycerol to succinate by metabolically engineered strains of Escherichia coli. Appl Environ Microbiol 76:2397–2401

Acknowledgments

This work was supported by the 973 Program of China (Grant No. 2011CB707405).

Supporting information

Supplementary Table 1—Strains and plasmids used in this study.

Supplementary Table 2—Oligonucleotides used in this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wang, C., Cai, H., Chen, Z. et al. Engineering a glycerol utilization pathway in Corynebacterium glutamicum for succinate production under O2 deprivation. Biotechnol Lett 38, 1791–1797 (2016). https://doi.org/10.1007/s10529-016-2166-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-016-2166-4