Abstract

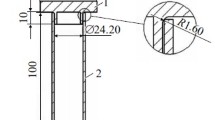

The present study aims to produce sandwich composites with curved surfaces with different surface geometries by adding rubber (EPDM) between glass fiber woven fabrics and to examine their behavior under the influence of low-velocity impact numerically and experimentally. For this purpose, glass fiber and rubber layers were added to steel molds manufactured in curved forms and sandwich plates were produced through the vacuum infusion method. Low-velocity impact tests were performed by lowering strikers with a hemispherical tip on the produced curved-surface plates, and the effect of the surface geometry on the impact energy absorption was determined. By using rubber intermediate layers, the energy absorption ability can be increased by a maximum of 21%. The curved surface geometry affects the absorbed energy. If the height of the curved surface composites is kept constant and the width is increased to 1.5 times, the impact energy absorption increases by 16 percent. If the width is kept constant and the height is increased to 2.3 times, the impact energy absorption has decreased by 13 percent. When the impact resistance of composites with triangular rectangular, R125 circular arc and flat geometries with the same height and width are compared, it is observed that the lowest impact absorption ability occurs in the plates with triangular geometry, while the impact damping feature increases as the surface geometry becomes flatter and accordingly the contact surface increases. The impact absorption energies of the specimens were determined to be 82% compared to the flat plates. When the impact absorption energies of the upper side lengths of the outer tangent quadrilaterals to the R125 circle arc are compared, a significant increase in the impact absorption capabilities was observed as the side lengths increased. In the numerical part, the tests performed were modeled using the LS-DYNA finite element package program and the Hashin damage criterion-based MAT162 material model was used in order to see the damage caused to the composite structure in three dimensions after the tests. The numerical results obtained were a minimum of 84% compatible to the experimental results.

Similar content being viewed by others

Availability of Data and Material

The datasets generated during the current study are available from the corresponding author on reasonable request.

References

Valenҫa, S.L., Griza, S., De Oliveira, V.G., Sussuchi, E.M., De Cunha, F.G.C.: Evaluation of the mechanical behavior of epoxy composite reinforced with Kevlar plain fabric and glass/Kevlar hybrid fabric. Compos. Part B Eng. 70, 1–8 (2015). https://doi.org/10.1016/j.compositesb.2014.09.040

Düring, D., Weiß, L., Stefaniak, D., Jordan, N., Hühne, C.: Low-velocity impact response of composite laminates with steel and elastomer protective layer. Compos. Struct. 134, 18–26 (2015). https://doi.org/10.1016/j.compstruct.2015.08.001

Sangamesh Ravishankar, K.S., Kulkarni, S.M.: Ballistic impact study on jute-epoxy and natural rubber sandwich composites. Mater. Today Proc. 5, 6916–23 (2018). https://doi.org/10.1016/j.matpr.2017.11.353

Vishwas, M., Joladarashi, S., Kulkarni, S.M.: Behaviour of natural rubber in comparison with structural steel, aluminium and glass epoxy composite under low velocity impact loading. Mater Today Proc 4, 10721–10728 (2017). https://doi.org/10.1016/j.matpr.2017.08.019

Adachı, T., Ozawa, T., Wıtono, H., Onıshı, S., Ishıı, Y.: Energy absorption of thin-walled cylinders filled with silicone rubber subjected to low-velocity impact. Mech. Eng. J 4, 17–00052–17–00052 (2017). https://doi.org/10.1299/mej.17-00052

Abo Sabah, S.H., Kueh, A.B.H., Al-Fasih, M.Y.: Bio-inspired vs. conventional sandwich beams: A low-velocity repeated impact behavior exploration. Constr. Build. Mater. 169, 193–204 (2018). https://doi.org/10.1016/j.conbuildmat.2018.02.201

Khodadadi, A., Liaghat, G., Ahmadi, H., Bahramian, A.R., Anani, Y., Razmkhah, O., et al.: Numerical and experimental study of impact on hyperelastic rubber panels. Iran. Polym. J. (English Ed) 28, 113–22 (2019). https://doi.org/10.1007/s13726-018-0682-x

Haworth, B., Chadwick, D., Chen, L., Ang, Y.J.: Thermoplastic composite beam structures from mixtures of recycled HDPE and rubber crumb for acoustic energy absorption. J. Thermoplast. Compos. Mater. 31, 119–142 (2018). https://doi.org/10.1177/0892705716681836

Liu, J., He, W., Xie, D., Tao, B.: The effect of impactor shape on the low-velocity impact behavior of hybrid corrugated core sandwich structures. Compos. Part B Eng. 111, 315–331 (2017). https://doi.org/10.1016/j.compositesb.2016.11.060

Stelldinger, E., Kühhorn, A., Kober, M.: Experimental evaluation of the low-velocity impact damage resistance of CFRP tubes with integrated rubber layer. Compos. Struct. 139, 30–35 (2016). https://doi.org/10.1016/j.compstruct.2015.11.069

Baba, B.O.: Curved sandwich composites with layer-wise graded cores under impact loads. Compos. Struct. 159, 1–11 (2017). https://doi.org/10.1016/j.compstruct.2016.09.054

Bidi, A., Liaghat, G., Rahimi, G.: Low-velocity impact on cylindrically curved bilayers. Proc. Inst. Mech. Eng. Part K. J. Multi-Body Dyn. 232, 568–576 (2018). https://doi.org/10.1177/1464419318756661

Arachchige, B., Ghasemnejad, H.: Post impact analysis of damaged variable-stiffness curved composite plates. Compos. Struct. 166, 12–21 (2017). https://doi.org/10.1016/j.compstruct.2017.01.018

Choi, I.H.: Finite element analysis of low-velocity impact response of convex and concave composite laminated shells. Compos. Struct. 186, 210–220 (2018). https://doi.org/10.1016/j.compstruct.2017.11.090

Tan, P.: Ballistic protection performance of curved armor systems with or without debondings/delaminations. Mater. Des. 64, 25–34 (2014). https://doi.org/10.1016/j.matdes.2014.07.028

Saghafi, H., Brugo, T., Minak, G., Zucchelli, A.: The effect of pre-stress on impact response of concave and convex composite laminates. Procedia. Eng. 88, 109–116 (2014). https://doi.org/10.1016/j.proeng.2014.11.133

Hao, W., Yuan, Y., Zhu, J., Chen, L.: Effect of impact damage on the curved beam interlaminar strength of carbon/epoxy laminates. J. Adhes. Sci. Technol. 30, 1189–1200 (2016). https://doi.org/10.1080/01694243.2016.1144261

Martins, R.D., Donadon, M.V., De Almeida, S.F.M.: The effects of curvature and internal pressure on the compression-after-impact strength of composite laminates. J. Compos. Mater. 50, 825–848 (2016). https://doi.org/10.1177/0021998315582079

Choi, I.H.: Geometrically nonlinear transient analysis of composite laminated plate and shells subjected to low-velocity impact. Compos. Struct. 142, 7–14 (2016). https://doi.org/10.1016/j.compstruct.2016.01.070

Hu, Y., Liu, W., Shi, Y.: Low-velocity impact damage research on CFRPs with Kevlar-fiber toughening. Compos. Struct. 216, 127–141 (2019). https://doi.org/10.1016/j.compstruct.2019.02.051

Liu, P.F., Liao, B.B., Jia, L.Y., Peng, X.Q.: Finite element analysis of dynamic progressive failure of carbon fiber composite laminates under low velocity impact. Compos. Struct. 149, 408–422 (2016). https://doi.org/10.1016/j.compstruct.2016.04.012

Zhang, C., Duodu, E.A., Gu, J.: Finite element modeling of damage development in cross-ply composite laminates subjected to low velocity impact. Compos. Struct. 173, 219–227 (2017). https://doi.org/10.1016/j.compstruct.2017.04.017

Bunea, M., Cîrciumaru, A., Buciumeanu, M., Bîrsan, I.G., Silva, F.S.: Low velocity impact response of fabric reinforced hybrid composites with stratified filled epoxy matrix. Compos. Sci. Technol. 169, 242–248 (2019). https://doi.org/10.1016/j.compscitech.2018.11.024

Ismail, K.I., Sultan, M.T.H., Shah, A.U.M., Jawaid, M., Safri, S.N.A.: Low velocity impact and compression after impact properties of hybrid bio-composites modified with multi-walled carbon nanotubes. Compos. Part B Eng. 163, 455–463 (2019). https://doi.org/10.1016/j.compositesb.2019.01.026

Albayrak, M., Kaman, M.O.: Production of curved surface composites reinforced with rubber layer. Eur. J. Tech. 11, 19–22 (2021). https://doi.org/10.36222/ejt.824761

Gama, B.A., Bogetti, T.A., Gillespie, Jr, J.W.: Progressive damage modeling of plain-weave composites using LS-Dyna Composite Damage Model MAT162. 7th Eur. LS-DYNA Conf. (2009)

Albayrak, M., Kaman, M.O., Bozkurt, I.: Determination of LS-DYNA MAT162 Material input Parameters for Low Velocity Impact Analysis of Layered Composites. IRC 16 (2022). International Research Conference, Paris, 17–18 February

Mat_161.: A progressıve composıte damage model for unıdırectıonal and woven fabrıc composıtes Ud-Ccm updates on MAT162 User Manual. (2017)

Thumann, P., Swidergal, K., Wagner, M.: Calculation and validation of material tests with specimens made out of filled elastomers. (2015)

Hashin, Z.: Failure criteria for unidirectional Mr ! J. Appl. Mech. 47, 329–334 (1980)

Matzenmiller, A., Lubliner, J., Taylor, R.L.: A constitutive model for anisotropic damage in fiber-composites. Mech. Mater. 20, 125–152 (1995). https://doi.org/10.1016/0167-6636(94)00053-0

Xiao, J.R., Gama, B.A., Gillespie, J.W.: Progressive damage and delamination in plain weave S-2 glass/SC-15 composites under quasi-static punch-shear loading. Compos. Struct. 78, 182–196 (2007). https://doi.org/10.1016/j.compstruct.2005.09.001

Vescovini, A., Balen, L., Scazzosi, R., da Silva, A.A.X., Amico, S.C., Giglio, M., et al.: Numerical investigation on the hybridization effect in inter-ply S2-glass and aramid woven composites subjected to ballistic impacts. Compos. Struct. 276, 114506 (2021). https://doi.org/10.1016/j.compstruct.2021.114506

Chen, Y., Fu, K., Hou, S., Han, X., Ye, L.: Multi-objective optimization for designing a composite sandwich structure under normal and 45° impact loadings. Compos. Part B Eng. 142, 159–170 (2018). https://doi.org/10.1016/j.compositesb.2018.01.020

García-Moreno, I., Caminero, M.Á., Rodríguez, G.P., López-Cela, J.J.: Effect of thermal ageing on the impact damage resistance and tolerance of carbon-fibre-reinforced epoxy laminates. Polymers (Basel) 11, 10–12 (2019). https://doi.org/10.3390/polym11010160

Ginzburg, D., Pinto, F., Iervolino, O., Meo, M.: Damage tolerance of bio-inspired helicoidal composites under low velocity impact. Compos. Struct. 161, 187–203 (2017). https://doi.org/10.1016/j.compstruct.2016.10.097

Heimbs, S., Heller, S., Middendorf, P., Hähnel, F., Weiße, J.: Low velocity impact on CFRP plates with compressive preload: Test and modelling. Int. J. Impact. Eng. 36, 1182–1193 (2009). https://doi.org/10.1016/j.ijimpeng.2009.04.006

Cheng, L., Thomas, A., Glancey, J.L., Karlsson, A.M.: Mechanical behavior of bio-inspired laminated composites. Compos. Part A Appl. Sci. Manuf. 42, 211–220 (2011). https://doi.org/10.1016/j.compositesa.2010.11.009

Seifoori, S., Mahdian Parrany, A., Mirzarahmani, S.: Impact damage detection in CFRP and GFRP curved composite laminates subjected to low-velocity impacts. Compos. Struct. 261, 113278 (2021). https://doi.org/10.1016/j.compstruct.2020.113278

Islam, F., Caldwell, R., Phillips, A.W., John, N.A.S., Prusty, B.G.: A review of relevant impact behaviour for improved durability of marine composite propellers. Compos. Part C Open Access p. 100251 (2022). https://doi.org/10.1016/j.jcomc.2022.100251

Krollmann, J., Schreyer, T., Veidt, M., Drechsler, K.: Impact and post-impact properties of hybrid-matrix laminates based on carbon fiber-reinforced epoxy and elastomer subjected to low-velocity impacts. Compos. Struct. 208, 535–545 (2019). https://doi.org/10.1016/j.compstruct.2018.09.087

Mahesh, V., Joladarashi, S., Kulkarni, S.M.: Comparative study on kevlar/carbon epoxy face sheets with rubber core sandwich composite for low velocity impact response: FE approach. Mater. Today Proc. 44, 1495–1499 (2021). https://doi.org/10.1016/j.matpr.2020.11.688

Lawrence Sy, B., Oguamanam, D., Bougherara, H.: Impact response of a new kevlar/flax/epoxy hybrid composite using infrared thermography and high-velocity imaging. Compos. Struct. 280, 114885 (2022). https://doi.org/10.1016/j.compstruct.2021.114885

Kawai, N., Zama, S., Takemoto, W., Moriguchi, K., Arai, K., Hasegawa, S., et al.: Stress wave and damage propagation in transparent materials subjected to hypervelocity impact. Proc. Eng. 103, 287–293 (2015). https://doi.org/10.1016/j.proeng.2015.04.049

Ahmed, A., Bingjie, Z., Hasan Ikbal, M., Qingtao, W., Obed, A., Wei, L.: Experimental study on the effects of stacking sequence on low velocity impact and quasi-static response of foam sandwich composite structures. Adv. Struct. Eng. 18, 1789–1805 (2015). https://doi.org/10.1260/1369-4332.18.11.1789

Kim, S.J., Goo, N.S., Kim, T.W.: The effect of curvature on the dynamic response and impact-induced damage in composite laminates. Compos. Sci. Technol. 57, 763–773 (1997). https://doi.org/10.1016/S0266-3538(97)80015-2

He, W., Lu, S., Yi, K., Wang, S., Sun, G., Hu, Z.: Residual flexural properties of CFRP sandwich structures with aluminum honeycomb cores after low-velocity impact. Int. J. Mech. Sci. pp. 161–162 (2019). https://doi.org/10.1016/j.ijmecsci.2019.105026

Odacı, İ.K.: (TEZ) Experimental and numerical evaluation of the blast-like loading of fiber reinforced polymer composites and aluminum corrugated core composite sandwiches through projectile impact testing using aluminum corrugated projectiles. 27, (2015)

Chow, Z.P., Ahmad, Z., Wong, K.J., Koloor, S.S.R., Petrů, M.: Thermal delamination modelling and evaluation of aluminium–glass fibre-reinforced polymer hybrid. Polymers (Basel) 13, 1–19 (2021). https://doi.org/10.3390/polym13040492

Rodriguez, G.: Finite element modeling of delamination damage in carbon by (2016)

Yen, C.F.: A ballistic material model for continuous-fiber reinforced composites. Int. J. Impact. Eng. 46, 11–22 (2012). https://doi.org/10.1016/j.ijimpeng.2011.12.007

Acknowledgements

The authors would like to thank Prof. Dr. Mustafa GUDEN and Prof. Dr. Alper TASDEMIRCI from "Izmir Institute of Technology", who achieved the Split Hopkinson Bar test to find the "Creates" parameters that use in the MAT-162 model. The authors would like to thank the Fırat University Scientific Research Coordination Unit, which supported this study with the project number MF20.10.

Funding

The research work was supported by the Research Project Unit of Firat University (MF.20.10 and MF.20.32).

Author information

Authors and Affiliations

Contributions

Mustafa Albayrak: Methodology, Software, Experiment, Validation, Manuscript Writing. Mete Onur Kaman: Conceptualization, Supervision, Writing Review. Ilyas Bozkurt: Manuscript writing, Software, Funding Acquisition.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Albayrak, M., Kaman, M.O. & Bozkurt, I. Experimental and Numerical Investigation of the Geometrical Effect on Low Velocity Impact Behavior for Curved Composites with a Rubber Interlayer. Appl Compos Mater 30, 507–538 (2023). https://doi.org/10.1007/s10443-022-10094-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-022-10094-5