Abstract

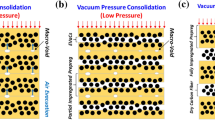

The non-autoclave curing technique with vacuum bag only (VBO) prepreg has been conceived as a cost-effective manufacturing method for producing high-quality composite part. This study demonstrated the feasibility of improving composite part’s performances and established the effective mitigation strategies for manufacturing induced defects, such as internal voids and surface porosity. The experimental results highlighted the fact that voids and surface porosity were clearly dependent on the resin viscosity state at an intermediate dwell stage of the curing process. Thereafter, the enhancement of resin flow could lead to achieving high quality parts with minimal void content (1.3%) and high fiber fraction (53 vol.%). The mechanical testing showed comparable in-plane shear and compressive strength to conventional autoclave. The microscopic observations also supported the evidence of improved interfacial bonding in terms of excellent fiber wet-out and minimal void content for the optimized cure cycle condition.

Similar content being viewed by others

References

Varvani-Farahani, A.: Composite materials: characterization, fabrication and application-research challenges and directions. Appl. Compos. Mater. 17(2), 63–67 (2010)

Lachaud, F., Espinosa, C., Michel, L., Rahme, P., Piquet, R.: Modelling strategies for predicting the residual strength of impacted composite aircraft fuselages. Appl. Compos. Mater. 22(6), 599–621 (2015)

Alderliesten, R.C.: Critical review on the assessment of fatigue and fracture in composite materials and structures. Eng. Fail. Anal. 35(15), 370–379 (2013)

Grunenfelder, L.K., Dills, A., Centea, T., Nutt, S.R.: Effect of prepreg format on defect control in out-of-autoclave processing. Compos. A: Appl. Sci. Manuf. 93, 88–99 (2017)

Aleksendrić, D., Carlone, P., Ćirović, V.: Optimization of the temperature-time curve for the curing process of thermoset matrix composites. Appl. Compos. Mater. 23(5), 1047–1063 (2016)

Bodaghi, M., Cristóvão, C., Gomes, R., Correia, N.C.: Experimental characterization of voids in high fibre volume fraction composites processed by high injection pressure RTM. Compos Part A. Appl. Sci. Manuf. 82, 88–99 (2016)

Marsh, G.: De-autoclaving’ prepreg processing. Reinf. Plast. 56(5), 20–25 (2012)

Xu, X., Wang, X., Liu, W., Zhang, X., Li, Z., Du, S.: Microwave curing of carbon fiber/bismaleimide composite laminates: material characterization and hot pressing pretreatment. Mater. Des. 97(5), 316–323 (2016)

Grunenfelder, L.K., Nutt, S.R.: Void formation in composite prepregs – effect of dissolved moisture. Compos. Sci. Technol. 70(16), 2304–2309 (2010)

Helmus, R., Centea, T., Hubert, P., Hinterhölzl, R.: Out-of-autoclave prepreg consolidation: coupled air evacuation and prepreg impregnation modeling. J. Compos. Mater. 50(10), 1403–1413 (2015)

Garschke, C., Weimer, C., Parlevliet, P.P., Fox, B.L.: Out-of-autoclave cure cycle study of a resin film infusion process using in situ process monitoring. Compos Part A. Appl. Sci. Manuf. 43(6), 935–944 (2012)

Han, K., Jiang, S., Zhang, C., Wang, B.: Flow modeling and simulation of SCRIMP for composites manufacturing. Compos Part A. Appl. Sci. Manuf. 31(1), 79–86 (2000)

Li, W., Krehl, J., Gillespie, J.W., Heider, D., Endrulat, M., Hochrein, K., Dunham, M.G., Dubois, C.J.: Process and performance evaluation of the vacuum-assisted process. J. Compos. Mater. 38(20), 1803–1814 (2004)

Centea, T., Nutt, S.R.: Manufacturing cost relationships for vacuum bag-only prepreg processing. J. Compos. Mater. 50(17), 2305–2321 (2015)

Thomas, S., Nutt, S.R.: Temperature dependence of resin flow in a resin film infusion (RFI) process by ultrasound imaging. Appl. Compos. Mater. 16(3), 183–196 (2009)

Ridgard, C.: Out of autoclave composite technology for aerospace, defense and space structures. In: Proceeding of SAMPE Conference, Baltimore, MD (2009)

Ridgard, C.: Next generation out of autoclave systems. In: Proceeding of SAMPE Conference, Seattle, WA (2010)

Kratz, J., Hsiao, K., Fernlund, G., Hubert, P.: Thermal models for MTM45-1 and Cycom 5320 out-of-autoclave prepreg resins. J. Compos. Mater. 47, 341–352 (2012)

Agius, S.L., Magniez, K.J.C., Fox, B.L.: Cure behaviour and void development within rapidly cured out-of-autoclave composites. Compos. Part B. 47, 230–237 (2013)

Cong, J., Zhang, B.: Methodology for evaluating manufacturability of composite materials. Appl. Compos. Mater. 19(3–4), 189–201 (2012)

Guo, Z.S., Liu, L., Zhang, B.M., Du, S.: Critical void content for thermoset composite laminates. J. Compos. Mater. 43(17), 1775–1790 (2006)

Hernández, S., Sket, F., González, C., Llorca, J.: Optimization of curing cycle in carbon fiber-reinforced laminates: void distribution and mechanical properties. Compos. Sci. Technol. 85(21), 73–82 (2013)

Jeong, H.: Effects of voids on the mechanical strength and ultrasonic attenuation of laminated composites. J. Compos. Mater. 31(3), 276–292 (1997)

Park, S.Y., Choi, W.J., Choi, H.S.: The effects of void contents on the long-term hygrothermal behaviors of glass/epoxy and GLARE laminates. Compos. Struct. 92(1), 18–24 (2010)

Costa, M.L., Rezende, M.C., De Almeida, S.F.M.: Strength of hygrothermally conditioned polymer composites with voids. J. Compos. Mater. 39(21), 1943–1961 (2005)

Pang, K.P., Gillham, J.K.: Competition between cure and thermal degradation in a high Tg epoxy system: effect of time and temperature of isothermal cure on the glass transition temperature. J. Appl. Polym. Sci. 39(4), 909–933 (1990)

Yenilmez, B., Senan, M., Sozer, E.M.: Variation of part thickness and compaction pressure in vacuum infusion process. Compos. Sci. Technol. 69(11–12), 1710–1719 (2009)

Kim, D., Centea, T., Nutt, S.R.: Out-time effects on cure kinetics and viscosity for an out-of-autoclave (OOA) prepreg: modelling and monitoring. Compos. Sci. Technol. 100(21), 63–69 (2014)

Kim, D., Centea, T., Nutt, S.R.: Effects of out-time on viscosity, gelation and vitrification. Compos. Sci. Technol. 102(6), 132–138 (2014)

Garschke, C., Parlevliet, P.P., Weimer, C., Fox, B.L.: Cure kinetics and viscosity modelling of a high-performance epoxy resin film. Polym. Test. 32(1), 150–157 (2013)

AITM 3-0002. Analysis of non metallic materials (uncured) by differential scanning calorimetry. Airbus Industry, France (1997)

Abouhamzeh, M., Sinke, J., Jansen, K.M.B., Benedictus, R.: Kinetic and thermo-viscoelastic characterisation of the epoxy adhesive in GLARE. Compos. Struct. 124, 19–28 (2015)

Xie, M., Zhang, Z., Gu, Y., Li, M., Su, Y.: A new method to characterize the cure state of epoxy prepreg by dynamic mechanical analysis. Thermochim. Acta. 487(1–2), 8–17 (2009)

Boey, F.Y.C., Qiang, W.: Experimental modeling of the cure kinetics of an epoxy-hexaanhydro-4-methylphthalicanhydride (MHHPA) system. Polymer. 41, 2081–2094 (2000)

Alavi-Soltani, S., Sabzevari, S., Koushyar, H., Minaie, B.: Thermal, rheological, and mechanical properties of a polymer composite cured at different isothermal cure temperatures. J. Compos. Mater. 46(5), 575–587 (2011)

ASTM D3529/D3529M-97: Standard test method for matrix solids content and matrix content of composite prepreg. ASTM International, West Conshohocken (1997)

ASTM D3530-97: Standard test method for volatiles content of composite material prepreg. ASTM International, West Conshohocken (2015)

Hamill, L., Centea, T., Nutt, S.R.: Surface porosity during vacuum bag-only prepreg processing: Causes and mitigation strategies. Compos Part A. Appl. Sci. Manuf. 7, 1–10 (2015)

Tomblin, J.S., Ng, Y.C., Raju, K.S.: Material qualification and equivalency for polymer matrix composite material systems: updated procedure (report no.: DOT/FAA/AR-03/19). U.S. Department of Transportation, Washington, D.C (2003)

ASTM D792-13: Standard test methods for density and specific gravity (relative density) of plastics by displacement. ASTM International, West Conshohocken (2013)

ASTM D3171-15: Standard test methods for constituent content of composite materials. ASTM International, West Conshohocken (2015)

ASTM D2734-16: Standard test methods for void content of reinforced plastics. ASTM International, West Conshohocken (2016)

AITM1-0003. Determination of the glass transition temperatures (DMA). Airbus Industry, France (1997)

ASTM D3518-13: Standard test methods for in-plane shear response of polymer matrix composite materials by tensile test of a ±45° laminate. ASTM International, West Conshohocken (2013)

ASTM D6641-16: Standard test methods for compressive properties of polymer matrix composite materials using a combined loading compression (CLC) test fixture. ASTM International, West Conshohocken (2016)

MIL-HDBK-17-1F. Composite materials handbook, Volume 1, polymer matrix composites guidelines for characterization of structural materials. U.S. Department of Defense, Washington, D.C (2002)

Costa, M.L., Rezende, M.C., Almeida, S.F.M.: Effect of void content on the moisture absorption in polymeric composites. Polym. Plast. Technol. Eng. 45(6), 691–698 (2006)

Liu, L., Zhang, B.M., Wang, D.F., Wu, Z.J.: Effects of cure cycles on void content and mechanical properties of composite laminates. Compos. Struct. 73(3), 303–309 (2006)

Choi, H.S., Ahn, K.J., Nam, J.D., Chun, H.J.: Hygroscopic aspects of epoxy/carbon fiber composite laminates in aircraft environments. Compos Part A. Appl. Sci. Manuf. 32(5), 709–720 (2001)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, S.Y., Choi, C.H., Choi, W.J. et al. A Comparison of the Properties of Carbon Fiber Epoxy Composites Produced by Non-autoclave with Vacuum Bag Only Prepreg and Autoclave Process. Appl Compos Mater 26, 187–204 (2019). https://doi.org/10.1007/s10443-018-9688-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-018-9688-y