Abstract

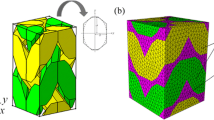

This paper presents a modified finite element model (FEM) to investigate the thermo-mechanical properties of three-dimensional (3D) braided composite. The effective coefficients of thermal expansion (CTE) and the meso-scale mechanical response of 3D braided composites are predicted. The effects of the braiding angle and fiber volume fraction on the effective CTE are evaluated. The results are compared to the experimental data available in the literature to demonstrate the accuracy and reliability of the present method. The tensile stress distributions of the representative volume element (RVE) are also outlined. It is found that the stress of the braiding yarn has a significant increase with temperature rise; on the other hand, the temperature change has an insignificant effect on the stress of the matrix. In addition, a rapid decrease in the tensile strength of 3D braided composites is observed with the increase in temperature. It is revealed that the thermal conditions have a significant effect on the strength of 3D braided composites. The present method provides an effective tool to predict the stresses of 3D braided composites under thermo-mechanical loading.

Similar content being viewed by others

References

Chou, T.W., Ko, F.K.: Textile structural composites. Elsevier Science Publishers, Amsterdam (1989)

Whyte DW: Ph.D. thesis, Drexel University, Philadelphia, PA (1986)

Ma, C.L., Yang, J.M., Chou, T.W.: Elastic stiffness of three-dimensional braided textile structural composites. In: Whitney, J.M. (ed.) Composite materials: testing and design (seventh conference), ASTM STP 893, pp. 404–421. American Society for Testing and Materials, Philadelphia (1986)

Yang, J.M., Ma, C.L., Chou, T.W.: Fiber inclination model of three-dimensional textile structural composites. J. Compos. Mater. 20(5), 472–483 (1986)

Byun JH, Du GW, Chou TW: Analysis and modeling of three dimensional textile structural composites. High-Tech Fibrous Materials, pp. 22–33 (1991)

Wu, D.L.: Three-cell model and 5D braided structural composites. Compos. Sci. Technol. 56(3), 225–233 (1996)

Chen, L., Tao, X.M., Choy, C.L.: On the microstructure of three-dimensional braided preforms. Compos. Sci. Technol. 59(3), 2383–2391 (1999)

Sun, H.Y., Qiao, X.: Prediction of the mechanical properties of three-dimensionally braided composites. Compos. Sci. Technol. 57(6), 623–629 (1997)

Yu, X.G., Cui, J.Z.: The prediction on mechanical properties of 4-step braided composites via two-scale method. Compos. Sci. Technol. 67(3–4), 471–480 (2007)

Tang, Z.X., Postle, R.: Mechanics of three-dimensional braided structures for composite materials-part II: prediction of the elastic moduli. Compos. Struct. 51(4), 451–457 (2001)

Dong, J.W., Feng, M.L.: Asymptotic expansion homogenization for simulating progressive damage of 3D braided composites. Compos. Struct. 92(4), 873–882 (2010)

Mohajerjasbi, S.: Predictions for coefficients of thermal expansion of three-dimensional braided composites. AIAA J. 35(1), 141–144 (1997)

Yao, X.F., Yang, G., Yao, Z.H., Dai, F.L.: Experimental study of thermal expansion behavior on braided structure composite. Acta Mater Compos Sin. 17(4), 20–25 (2000)

Wang, A.S.D., Mohajerjasbi, S.: Thermoelastic properties of 3-D braided composites: experiment and predictions. Am. Soc. Mech. Eng., Noise Control Acoust. Div. NCA 20, 275–293 (1995)

Cheng, L.: Thermal expansion coefficients of carbon/epoxy braided composites. J. Solid Rocket Technol. 33(1), 108–111 (2010)

Li, D.S., Lu, Z.X., Liu, Z.G., Li, Z.P.: Finite element analysis of thermal conductivity of three dimensional and five directional braided composites. J. Aerosp Power. 23(8), 1455–1460 (2008)

Liang, J., Du, S.Y., Chen, X.F.: Thermal expansion coefficients of 3-D braided composites with penny-shaped microcracks. Acta Mater Compos Sin. 15(3), 103–107 (1998)

Xia, B., Lu, Z.X.: Finite element analysis on thermo-physical properties of 3D braided composites. Acta Aeronaut Astronaut Sin. 32(6), 1040–1049 (2011)

Li, Z.M., Shen, H.S.: Postbuckling analysis of three-dimensional textile composite cylindrical shells under axial compression in thermal environments. Compos. Sci. Technol. 68(3–4), 872–879 (2008)

Li, K.Z., Li, H.J.: Thermal expansion property of carbon/carbon composite. Trans. Mater. Heat Treat. 27(6), 1–4 (2006)

Liao, X.L., Li, H.J., Xu, W.F.: Study on the thermal expansion properties of C/C composites. J. Mater. Sci. 42(10), 3435–3439 (2007)

Zeng, T., Wu, L.Z., Guo, L.C.: Mechanical analysis of 3D braided composites: a finite element model. Compos. Struct. 64(3–4), 399–404 (2004)

Zeng, T., Wu, L.Z., Guo, L.C.: A finite element model for failure analysis of 3D braided composites. Mater. Sci. Eng., A 366(1), 144–151 (2004)

Zeng, T., Fang, D.N., Ma, L., Guo, L.C.: Predicting the nonlinear response and failure of 3D braided composites. Mater. Lett. 58(26), 3237–3241 (2004)

Li, W., Hammad, M., El-Shiekh, A.: Structural analysis of 3-D braided preforms for composites part II: the two-step preforms. J. Text. Inst. 81(4), 491–514 (1990)

Wang, Y.Q., Wang, A.S.D.: On the topological yarn structure of 3-D rectangular and tubular braided preforms. Compos. Sci. Technol. 51(4), 575–586 (1994)

Kalidindi, S.R., Franco, E.: Numerical evaluation of isostrain and weighted-average models for elastic moduli of three-dimensional composites. Compos. Sci. Technol. 57(3), 293–305 (1997)

Sun, B.Z., Liu, R.Q., Gu, B.H.: Numerical simulation of three-point bending fatigue of four-step 3-D braided rectangular composite under different stress levels from unit-cell approach. Comput. Mater. Sci. 65, 836–841 (2012)

Jiang, L.L., Zeng, T., Yan, S., Fang, D.N., Guo, Y.: Predicting mechanical properties of 3D braided composites using a helix geometry model. Polym. Polym. Compos. 19(4–5), 397–400 (2011)

Xu, K., Xu, X.W.: Finite element analysis of mechanical properties of 3D five-directional braided composites. Mater. Sci. Eng., A 487(1–2), 499–509 (2008)

Chamis, C.C.: Simplified composite equations for strength, fracture toughness and environmental. SAMPE J. 15(4), 41–55 (1984)

Li, Z.M.: Thermal postbuckling behavior of 3D braided rectangular plates. J. Therm Stresses. 34(7), 626–649 (2011)

Zhao, S.G., Liu, Z.G., Feng, Z.H., Yao, C.Z., Yu, R.L.: Thermal property of 3-D braided fiber composites: experimental and numerical results. Acta Aeronaut Astronaut Sin. 23(2), 102–105 (2002). Cheng W../../Program Files/Youdao/Dict/resultui/queryresult.html

Acknowledgments

The authors would like to thank the Foundation of Heilongjiang Department of Education (12521102), the National Natural Science Foundation of China (11272110, 9101602, 10972070) and the Science and Technology Innovation Team in University of Heilongjiang Province.

Author information

Authors and Affiliations

Corresponding author

Appendix A

Appendix A

The stiffness matrix of the braiding yarns is

where [D ′ Y ] is the stiffness matrix referred to the material coordinate system

[T] is the transformation matrix

where (l i , m i , n i ) (i = 1, 2, 3) are the direction cosines between the axial direction of the braiding yarns and axis of the global coordinate system (X-Y-Z).

The stiffness matrix of the resin is

Rights and permissions

About this article

Cite this article

Jiang, Ll., Xu, Gd., Cheng, S. et al. Finite Element Analysis of Thermo-Mechanical Properties of 3D Braided Composites. Appl Compos Mater 21, 325–340 (2014). https://doi.org/10.1007/s10443-013-9339-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-013-9339-2