Abstract

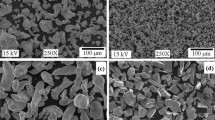

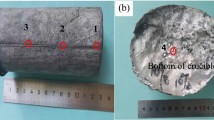

Si3N4/Al–Mg composites based on Al–Mg alloy reinforced by ceramic interpenetrating network structure were fabricated via pressureless infiltration technology. Infiltration temperature and infiltration time are the key parameters distinctly effecting on infiltration processes. Moreover, the increasing of Mg content (2–8 wt.%) resulted in an increased amount of infiltration. Microstructural characterization of the composites reveals a special topology of skeleton and good integrity of metal/ceramic interface. The presence of second reinforced phase results in a significant increase in 0.2% offset yield and ultimate tensile strength of composites materials. However, when the volume fraction of reinforcement is large than 6%, there are a distinctly reduction of strength. The presence of additional secondary brittle phase in matrix results in the reduction in ductility and increase in hardness of 3-DNRMMCs. The failure features as cracking and void in reinforcement, interface cracking and interface debonding as well as matrix damage result in the decreases of fracture toughness. With the increases of volume fraction of reinforcement, 3-DRMMC exhibits excellent wear-resistance property.

Similar content being viewed by others

References

Mohamed, N.S., Ganesan, N.: Comparison of beam and plate theories for free vibrations of metal matrix composite pre-twisted blades. J. Sound Vib. 189(2), 149–160 (1996)

Xu, Z.R., Chawla, K.K., Wolfenden, A., Neuman, A., Liggett, G.M., Chawla, N.: Stiffness loss and density decrease due to thermal cycling in an alumina fiber/magnesium alloy composites. Mater. Sci. Eng. A 203, 75–80 (1995)

Geng, L., Li, A.B., Meng, Q.Y.: Experimental and numerical studies of the effect of whisker misalignment on the hot compressive deformation behavior of the metal matrix composites. Mater. Sci. Eng. A 386(1–2), 212–221 (2004)

Wang, H.Y., Jiang, Q.C., Zhao, Y.Q.: Fabrication of TiB2 and TiB2–TiC particulates reinforced magnesium matrix composites. Mater. Sci. Eng. A 372, 109–114 (2004)

Mattern, A., Huchler, B., Staudenecker, D., Oberacker, R., Nagel, A., Hoffmann, M.J.: Preparation of interpenetrating ceramic–metal composites. J. Eur. Ceram. Soc. 24, 3399–3408 (2004)

Zhou, W., Hu, W., Zhang, D.: Study on the making of metal-matrix interpenetrating phase composites. Scr. Mater. 39(12), 1743–1748 (1998)

Zeschkya, J., Goetz-Neunhoeffer, F., Neubauer, J., Jason Lo, S.H., Kummer, B., Scheffler, M., Greil, P.: Preceramic polymer derived cellular ceramics. Compos. Sci. Technol. 63, 2361–2370 (2003)

Konopka, K., Olszówka-Myalska A., Szafran, M.: Ceramic–metal composites with an interpenetrating network. Mater. Chem. Phys. 81, 329–332 (2003)

Lu, L., Lai, M.O., Froyen, L.: Structure and properties of Mg metal–metal composite. Key Eng. Mater. 230(2), 287–290 (2002)

Lange, F.F., Miller, K.T.: Open-cell, low-density ceramics fabricated from reticulated polymer substrates. Adv. Ceram. Mater. 2, 827–831 (1987)

Zeschky, J., Goetz-Neunhoeffer, F., Neubauer, J., Jason Lo S.H., Kummer, B., Scheffler, M., Greil, P.: Preceramic polymer derived cellular ceramics. Compos. Sci. Technol. 63, 2361–2370 (2003)

Hashim, J., Looney, L., Hashmi, M.S.J.: Metal matrix composites: Production by the stir casting method. J. Mater. Process. Technol. 92–93, 1–7 (1999)

Mortensen, A.: Mechanical and Physical Behaviour of Metals and Ceramic Compounds. p. 141. Riso National Laboratory, Roskilde, Denmark (1988)

Jiang, Q.C., Wang, H.Y., Guan, Q.F., et al.: Effect of the temperature of molten magnesium on the thermal explosion synthesis reaction of Al–Ti–C system for fabricating TiC/Mg composite[J]. Adv. Eng. Mater. 10, 722–725 (2003)

Ho, K.F., Gupta, M., Srivatsan, T.S.: The mechanical behavior of magnesium alloy AZ91 reinforced with fine copper particulates. Mater. Sci. Eng. A 369, 302–308 (2004)

Ames, W., Alpas, A.T.: Wear mechanisms in hybrid composites of graphite-20 Pct SiC in A356 aluminum alloy (Al-7 Pct Si-0.3 Pct Mg). Met. Mater. Trans. A 26A, 85–98 (1995)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shouren, W., Haoran, G., Jingchun, Z. et al. Interpenetrating Microstructure and Properties of Si3N4/Al–Mg Composites Fabricated by Pressureless Infiltration. Appl Compos Mater 13, 115–126 (2006). https://doi.org/10.1007/s10443-006-9015-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-006-9015-x