Abstract

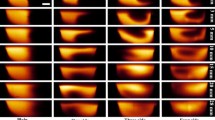

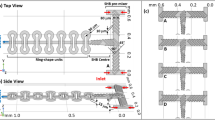

Micro-mixing is an important research area for various applications in sensing and diagnostics. In this paper, we present a performance comparison of several different passive micromixer designs based on the idea of staggered herringbone mixers (SHM). The working principle in such designs includes the formation of centers of flow rotation thus leading to multiple laminations with decreasing sizes of the lamellae as the flow passes over staggered structures. We have realized different layout designs of staggered herringbones inside micro-channels and compared their mixing performance. An overall reduction in mixing time and length has been observed as the degree of asymmetry within these structures is increased. The layouts of these staggered structures are based on herringbone bilayers wherein these layers are positioned on the top and bottom walls of a micro-channel. Fluorescence microscopy and computational fluid dynamics (CFD) based modeling have been used to observe the extent of mixing and understand the reasons behind the enhanced mixing effects. We have further varied the degree of asymmetry of the herringbone bilayers and investigated mixing as a function of the asymmetry. We have developed a novel microfabrication strategy to realize these micro-devices using an inexpensive non-photolithographic technique which we call micro-replication by double inversion (MRDI). The paper basically attempts to develop an overall understanding of the mixing process by letting two fluids flow pass over a variety of asymmetric structures.

Similar content being viewed by others

References

Ansari MA, Kim KY (2007) Shape optimization of a micromixer with staggered herringbone groove. Chem Eng Sci 62:6687–6695

Auroux PA (2002) Micro total analysis systems. 2. Analytical standard operations and applications. Anal Chem 74:2637–2652

Branebjerg J, Gravesen P, Krog JP (1996) Fast mixing by lamination. In: Proceedings of the IEEE micro electro mechanical systems, San Diego, USA 441–446

Chaudhury R (2009) Bilayared staggered herringbone micromixers, Master’s thesis. Department of Mechanical Engineering Faculty, Indian Institute of Technology, Kanpur

Chung CK, Shih TR (2008) Effect of geometry on fluid mixing of the rhombic micromixers. Microfluid Nanofluidics 4:419–425

de Mello A, Wooton R (2002) But what is it good for? Applications of microreactor technology for the fine chemical industry. Lab chip 2:7N–13N

Erbacher C, Bessoth FG, Busch M, Verpoorte E, Manz A (1999) Towards integrated continuous-flow chemical reactors. Mikrochim Acta 131:19–24

Hardt S, Schönfeld F (2003) Laminar mixing in interdigital micromixers with different mixing chambers—Part 2: Numerical simulations. AIChE J 49:578–584

He B, Burke BJ, Zhang X, Zhang R, Regnier FE (2001) A picoliter-volume mixer for microfluidic analytical systems. Anal Chem 73:1942–1947

Hessel V, Zimmerman WB (2006) Investigation of the convective motion through a staggered herringbone micro-mixer at low Reynolds number flow. Chem Eng Sci 61:2977–2985

Hessel V, Löwe H, Schönfeld F (2005) Micromixers: a review on passive and active mixing principles. Chem Eng Sci 60:2479–2501

Howell PB, Mott DR, Fertig S, Kaplan CR, Golden JP, Ran ES, Ligler FS (2005) Microfluidic mixer with grooves placed on top and bottom of the channel. Lab chip 5:524–530

Johnson TJ, Ross D, Locascio LE (2002) Rapid microfluidic mixing. Anal Chem 75:45–51

Kakuta M, Hinsmann P, Manz A, Lendl B (2003a) Time-resolved Fourier transform infrared spectrometry using a microfabricated continuous flow mixer: application to protein conformation study on the example of ubiquitin. Lab chip 3:82–85

Kakuta M, Jayawickrama DA, Wolters AM, Manz A, Jonathan V, Sweedler JV (2003b) Micromixer-based time-resolved NMR: applications to ubiquitin protein conformation. Anal Chem 75:956–960

Kang TG, Singh MK, Kwon TH, Anderson PD (2008) Chaotic mixing using periodic and aperiodic sequences of mixing protocols in a micromixer. Microfluid Nanofluidics 4:589–599

Kim DS, Lee SW, Kwon TH, Lee SS (2004) A barrier embedded chaotic micromixer. J Micromech Microeng 14:798–805

Kirtland JD, Siegel CR, Stroock AD (2009) Interfacial mass transport in steady three-dimensional flows in microchannels. New J Phys 11:075028

Knapp MR (2001) Commercialized and emerging Lab-on-a-Chip applications in micro total analysis systems. Kluwer Academic Publishers, Dordrecht, pp 7–9

Lee SW, Kim DS, Lee SS, Kwon TH (2006) A split and recombination micromixer fabricated in a PDMS three-dimensional structure. J Micromech Microeng 16:1067–1072

Li C, Chen T (2005) Simulation and optimization of chaotic micromixer using lattice Boltzmann method. Sens Actuators B Chem 106:871–877

Lynn NS, Dandy DS (2007) Geometrical optimization of helical flow in grooved micromixers. Lab Chip 7:580–587

Melin J, Gimenez G, Roxhed NW, van der Wijngaart W, Stemme G (2003) In: Proceedings of the 7th International conference on micro total analysis systems, Lake Tahoe, California, 167–170

Mengeaud V, Josserand J, Girault HH (2002) Mixing processes in a zigzag microchannel: finite element simulation and optical study. Anal Chem 74:4279–4286

Michael GO, Juan GS, Ronald JA, Hassan A, Beebe DJ (2002) Passive mixing in a three-dimensional serpentine microchannel. J Microelectromech Syst 9:190–197

Nguyen NT, Wu ZG (2005) Micromixers: a review. J Micromech Microeng 15:R1–R16

Ottino JM, Wiggins S (2004) Introduction: mixing in microfluidics. Philos Trans R Soc Lond A 362:923–935

Stroock AD, McGraw GJ (2004) Investigation of the staggered herringbone mixer with a simple analytical model. Philos Trans R Soc Lond A 362:971–986

Stroock AD, Dertinger SK, Ajdari A, Mezic I, Stone HA, Whitesides GM (2002a) Chaotic mixer for microchannels. Science 295:647–651

Stroock AD, Dertinger SK, Whitesides GM, Ajdari A (2002b) Patterning flows using grooved surfaces. Anal Chem 74:5306–5312

Vargas-Bernal R (2006) In: Proceedings of robotics and automotive mechanics conference 2:176–181

Wang H, Iovenitti P, Harvey E, Masood S (2003) Numerical investigation of mixing in micro-channels with patterned grooves. J Micromech Microeng 13:801–808

Wiles C, Watts P, Haswell SJ, Pombo-Villar E (2001) The aldol reaction of silanol ethers within a micro reactor. Lab chip 1:100–101

Wiles C, Watts P, Haswell SJ, Pombo-Villar E (2002) 1, 4-Addition of enolates to α, β-unsaturated ketones within a micro reactor. Lab chip 2:62–64

Yang ID, Chen YF, Hsu HT, Tseng FG, Chieng CC (2003) International conference on miniaturized chemical and biochemical analysis systems, Squaw Valley, CA, US, 1005–1009

Yang JT, Huang KJ, Lin YC (2005) Geometric effects on fluid mixing in passive grooved micromixers. Lab Chip 5:1140–1147

Acknowledgment

The authors gratefully acknowledge the financial support from the Department of biotechnology, Government of India and the Dean of Research and Development, Indian Institute of Technology, Kanpur for supporting this work. They also gratefully acknowledge Professor Shubhra Gangopadhyay and Professor Keshab Gangopadhyay; University of Missouri, Columbia, Professor Rashid Bashir; University of Illinois at Urbana Champaign, Professor P K Panigrahi, Professor Gautam Biswas and Professor S K Choudhary at Department of Mechanical Engineering, IIT, Kanpur for their help, advice and valuable suggestions.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Choudhary, R., Bhakat, T., Singh, R.K. et al. Bilayer staggered herringbone micro-mixers with symmetric and asymmetric geometries. Microfluid Nanofluid 10, 271–286 (2011). https://doi.org/10.1007/s10404-010-0667-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-010-0667-3