Abstract

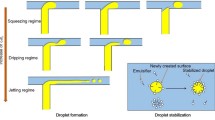

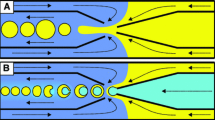

We report the results of a comparative study of microfluidic emulsification of liquids with different viscosities. Depending on the properties of the fluids and their rates of flow, emulsification occurred in the dripping and jetting regimes. We studied the characteristic features and typical dependence of the size and of the size distribution of droplets in each regime. For each liquid, we identified a range of hydrodynamic conditions promoting generation of highly monodisperse droplets. Viscosity played an important role in emulsification: highly viscous liquids were emulsified into larger droplets with lower polydispersity. Although it was not possible to provide a unified scaling for the volumes of the droplets, our results suggest that the break-up dynamics of the lower viscosity fluids resembles the rate-of-flow-controlled break-up, as reported earlier for the formation of bubbles in flow-focusing geometries [Garstecki P, Stone HA, Whitesides GM (2005) Phys Rev Lett 94:164501]. The results of this study can be helpful for a rationalized selection of liquids for the controlled formation of droplets with a predetermined size and with a narrow distribution of sizes.

Similar content being viewed by others

References

Anna SL, Bontoux N, Stone HA (2003) Formation of dispersions using “flow-focusing” in microchannels. Appl Phys Lett 82:364–363

Christopher GF, Anna SL (2007) Microfluidic methods for generating continuous droplet streams. J Phys D App Phys 40:R319–R336

Cohen I, Li H, Hougland JL, Mrksich M, Nagel SR (2001) Using selective withdrawal to coat microparticles. Science 292:265–267

Cramer C, Fischer P, Windhab EJ (2004) Drop formation in a co-flowing ambient fluid. Chem Eng Sci 59:3045–3058

Cygan ZT, Cabral JT, Beers KL, Amis EJ (2005) Microfluidic platform for the generation of organic-phase microreactors. Langmuir 21:3629–3634

De Menech M, Garstecki P, Jousse F, Stone HA (2007) Transition from squeezing to dripping in a microfluidic T-shaped junction. J Fluid Mech 595:141–162

Dendukuri D, Tsoi K, Hatton TA, Doyle PS (2005) Controlled synthesis of nonspherical microparticles using microfluidics. Langmuir 21:2113–2116

Dreyfus R, Tabeling P, Willaime H (2003) Ordered and disordered patterns in two-phase flows in microchannels. Phys Rev Lett 90:144505/1–144505/4

El-Ali J, Gaudet S, Gunther A, Sorger PK, Jensen KF (2005) Cell stimulus and lysis in a microfluidic device with segmented gas–liquid flow. Anal Chem 77:3629–3636

Freer EM, Wong H, Radke CJ (2005) Oscillating drop/bubble tensiometry: effect of viscous forces on the measurement of interfacial tension. J Colloid Interface Sci 282:128–132

Ganan-Calvo AM (1998) Generation of steady liquid microthreads and micron-sized monodisperse sprays in gas streams. Phys Rev Lett 80:285–288

Ganan-Calvo AM, Gordillo JM (2001) Perfectly monodisperse microbubbling by capillary flow focusing. Phys Rev Lett 87:274501

Garstecki P, Gitlin I, DiLuzio W, Whitesides GM, Kumacheva E, Stone HA (2004) Formation of monodisperse bubbles in a microfluidic flow-focusing device. Appl Phys Lett 85:2649–2651

Garstecki P, Fischbach MA, Whitesides GM (2005a) Design for mixing using bubbles in branched microfluidic channels. Appl Phys Lett 86:244108

Garstecki P, Fuerstman MJ, Whitesides GM (2005b) Nonlinear dynamics of a flow-focusing bubble generator: an inverted dripping faucet. Phys Rev Lett 94:234502/1–234502/4

Garstecki P, Stone HA, Whitesides GM (2005c) Mechanism for flow-rate controlled breakup in confined geometries: a route to monodisperse emulsions. Phys Rev Lett 94:164501

Garstecki P, Fuerstman MJ, Stone HA, Whitesides GM (2006) Formation of droplets and bubbles in a microfluidic T-junction - scaling and mechanism of break-up. Lab Chip 6:437–446

Guillot P, Colin A (2005) Stability of parallel flows in a microchannel after a T junction. Phys Rev E 72:066301

Hudson SD, Cabral JT, Goodrum WJ, Beers KL, Amis EJ (2005) Microfluidic interfacial tensiometry. Appl Phys Lett 87:081905

Jensen K, Lee A (2004) The science and applications of droplets in microfluidic devices—Foreword. Lab Chip 4:31N–32N

Jeong WJ, Kim JY, Choo J, Lee EK, Han CS et al (2005) Continuous fabrication of biocatalyst immobilized microparticles using photopolymerization and immiscible liquids in microfluidic systems. Langmuir 21:3738–3741

Khan SA, Gunther A, Schmidt MA, Jensen KF (2004) Microfluidic synthesis of colloidal silica. Langmuir 20:8604–8611

Lewis PC, Graham RR, Nie ZH, Xu SQ, Seo M, Kumacheva E (2005) Continuous synthesis of copolymer particles in microfluidic reactors. Macromolecules 38:4536–4538

Li W, Nie ZH, Zhang H, Paquet C, Seo M, Garstecki P, Kumacheva E (2007) Screening of the effect of surface energy of microchannels on microfluidic emulsification. Langmuir 23:8010–8014

Liao YC, Franses EI, Basaran OA (2006) Deformation and breakup of a stretching liquid bridge covered with an insoluble surfactant monolayer. Phys Fluids 18:022101

Link DR, Anna SL, Weitz DA, Stone HA (2004) Geometrically mediated breakup of drops in microfluidic devices. Phys Rev Lett 92:054503

Loscertales IG, Barrero A, Guerrero I, Cortijo R, Marquez M, Ganan-Calvo AM (2002) Micro/nano encapsutation via electrified coaxial liquid jets. Science 295:1695–1698

Nie ZH, Li W, Seo M, Xu SQ, Kumacheva E (2006) Janus and ternary particles generated by microfluidic synthesis: Design, synthesis, and self-assembly. J Am Chem Soc 128:9408–9412

Nie ZH, Xu SQ, Seo M, Lewis PC, Kumacheva E (2005) Polymer particles with various shapes and morphologies produced in continuous microfluidic reactors. J Am Chem Soc 127:8058–8063

Nisisako T, Torii T, Higuchi T (2002) Droplet formation in a microchannel network. Lab Chip 2:24–26

Nisisako T, Torii T, Higuchi T (2004) Novel microreactors for functional polymer beads. Chem Eng Sci 101:23–29

Probstein RF. (1989) Physicochemical hydrodynamics: an introduction. Butterworth Publishers, London

Seo M, Nie ZH, Xu SQ, Lewis PC, Kumacheva E (2005a) Microfluidics: From dynamic lattices to periodic arrays of polymer disks. Langmuir 21:4773–4775

Seo M, Nie ZH, Xu SQ, Mok M, Lewis PC et al (2005b) Continuous microfluidic reactors for polymer particles. Langmuir 21:11614–11622

Serra C, Berton N, Bouquery M, Prat L, Hadziioannou G (2007) A predictive approach of the influence of the operating parameters on the size of polymer particles synthesized in a simplified microfluidic system. Langmuir 23:7745–7750

Song H, Tice JD, Ismagilov RF (2003) A microfluidic system for controlling reaction networks in time. Angew Chem Int Ed Engl 42:768–772

Sugiura S, Nakajima M, Itou H, Seki M (2001) Synthesis of polymeric microspheres with narrow size distributions employing microchannel emulsification. Macromol Rapid Commun 22:773–778

Sugiura S, Nakajima M, Seki M (2002a) Effect of channel structure on microchannel emulsification. Langmuir 18:5708–5712

Sugiura S, Nakajima M, Seki M (2002b) Prediction of droplet diameter for microchannel emulsification. Langmuir 18:3854–3859

Takeuchi S, Garstecki P, Weibel DB, Whitesides GM (2005) An axisymmetric flow-focusing microfluidic device. Adv Mater 17:1067–1072

Tan YC, Cristini V, Lee AP (2006) Monodispersed microfluidic droplet generation by shear focusing microfluidic device. Sens Actuators B 114:350–356

Thorsen T, Roberts RW, Arnold FH, Quake SR (2001) Dynamic pattern formation in a vesicle-generating microfluidic device. Phys Rev Lett 86:4163–4166

Tice JD, Song H, Lyon AD, Ismagilov RF (2003) Formation of droplets and mixing in multiphase microfluidics at low values of the Reynolds and the capillary numbers. Langmuir 19:9127–9133

Utada AS, Lorenceau E, Link DR, Kaplan PD, Stone HA, Weitz DA (2005) Monodisperse double emulsions generated from a microcapillary device. Science 308:537–541

Ward T, Faivre M, Abkarian M, Stone HA (2005) Microfluidic flow focusing: Drop size and scaling in pressure versus flow-rate-driven pumping. Electrophoresis 26:3716–3724

Xia YN, Whitesides GM (1998) Soft lithography. Angew Chem Int Ed Engl 37:551–575

Xu QY, Nakajima M (2004) The generation of highly monodisperse droplets through the breakup of hydrodynamically focused microthread in a microfluidic device. Appl Phys Lett 85:3726–3728

Xu SQ, Nie ZH, Seo M, Lewis P, Kumacheva E et al (2005) Generation of monodisperse particles by using microfluidics: Control over size, shape, and composition. Angew Chem Int Ed Engl 44:724–728

Zhang DF, Stone HA (1997) Drop formation in viscous flows at a vertical capillary tube. Phys Fluids 9:2234–2242

Zhang H, Tumarkin E, Peerani R, Nie Z, Sullan RMA et al (2006) Microfluidic production of biopolymer microcapsules with controlled morphology. J Am Chem Soc 128:12205–12210

Zhang XG (1999) Dynamics of drop formation in viscous flows. Chem Eng Sci 54:1759–1774

Zheng B, Ismagilov RF (2005) A microfluidic approach for screening submicroliter volumes against multiple reagents by using preformed arrays of nanoliter plugs in a three-phase liquid/liquid/gas flow. Angew Chem Int Ed Engl 44:2520–2523

Zheng B, Roach LS, Ismagilov RF (2003) Screening of protein crystallization conditions on a microfluidic chip using nanoliter-size droplets. J Am Chem Soc 125:11170–11171

Acknowledgments

This work was supported by the US Department of Energy under award DE-FG02-00ER45852 and Canada Research Chair Grant. P.G. acknowledges financial support from the Foundation for Polish Science and the support from the Ministry of Science and Higher Education of Poland for the years 2006–2009. We thank for Prof. David James and Ryan Grau (University of Toronto) for helping us in rheology experiments.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

The volume of an undeformed spherical droplet is given by V = 4/3 πR 3 where R is the radius of the droplet. The volume of the droplet segment is given by Vs = 1/3 πh′2 (3R-h′) where h is the height of the segment. The volume of the disk with height h (h = 2R − h′) is thus equal to (π/12)[2D 3 − (D − h)2 (2D + h)] where D is the diameter of the disk.

Rights and permissions

About this article

Cite this article

Nie, Z., Seo, M., Xu, S. et al. Emulsification in a microfluidic flow-focusing device: effect of the viscosities of the liquids. Microfluid Nanofluid 5, 585–594 (2008). https://doi.org/10.1007/s10404-008-0271-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-008-0271-y