Abstract

In mountainous terrain, landslide debris is a common occurrence around the world that can potentially result in catastrophic consequences to downstream residents and facilities. Arrays of baffles are increasingly used as energy dissipaters for the protection from debris flow due to their low cost and environmental impact. However, the development of a numerical tool for the rational design of such structures is still a challenge. In this work, a material point method computational framework is presented, using two contact models to describe the landslide debris movement and interaction with structures, respectively. Flume model experiments are adopted as calibration and good agreements are exhibited in flow kinematics between computed results and physical model tests. Simulations on an idealized scenario of landslide debris flow show how the baffle geometry/arrangement has key effects on the debris movement and deposition. The impact force in soil-structure interaction has also been studied, showing the ability of this method on evaluation force characteristics acted on baffle structures.

Similar content being viewed by others

References

Abe K, Soga K, Bandara S (2014) Material point method for coupled hydromechanical problems. J Geotech Geoenviron Eng 140(3):04013033

Bardenhagen SG, Brackbill JU, Sulsky D (2000) The material-point method for granular materials. Comput Methods Appl Mech Eng 187(3–4):529–541

Bi Y, Du Y, He S, Sun X, Wang D, Li X, Liang H, Wu Y (2018) Numerical analysis of effect of baffle configuration on impact force exerted from rock avalanches. Landslides 15(5):1029–1043

Bowles JE (1982) Foundation analysis and design, 3rd edn. McGraw-Hill, New York

Brackbill JU, Ruppel HM (1986) Flip: a method for adaptively zoned particle-in-cell calculations of fluid flows in two dimensions. J Comput Phys 65(2):314–343

C. E. Choi, G. R. Goodwin, C. W. W. Ng, D. K. H. Cheung, J. S. H. Kwan, W. K. Pun, (2016) Coarse granular flow interaction with slit structures. Géotechnique Letters 6 (4):267-274

Calvetti F, di Prisco CG, Vairaktaris E (2017) DEM assessment of impact forces of dry granular masses on rigid barriers. Acta Geotech 12:129–144

Choi CE, Ng CWW, Song D, Kwan JHS, Shiu HYK, Ho KKS, Koo RCH (2014) Flume investigation of landslide debris-resisting baffles. Can Geotech J 51(5):540–553

Choi CE, Ng CWW, Law RPH, Song D, Kwan JSH, Ho KKS (2015) Computational investigation of baffle configuration on impedance of channelized debris flow. Can Geotech J 52(2):182–197

Coetzee CJ, Vermeer PA, Basson AH (2005) The modelling of anchors using the material point method. Int J Numer Anal Meth Geomech 29(9):879–895

Cummins SJ, Brackbill JU (2002) An implicit particle-in-cell method for granular materials. J Comput Phys 180(2):506–548

D. Song, C. E. Choi, C. W. W. Ng, G. G. D. Zhou, (2018) Geophysical flows impacting a flexible barrier: effects of solid-fluid interaction. Landslides 15 (1):99-110

David L. George, Richard M. Iverson, (2014) A depth-averaged debris-flow model that includes the effects of evolving dilatancy. II. Numerical predictions and experimental tests. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences 470 (2170):20130820

Di Toro G, Han R, Hirose T, De Paola N, Nielsen S, Mizoguchi K, Ferri F, Cocco M, Shimamoto T (2011) Fault lubrication during earthquakes. Nature 471:494–498

Drucker DC, Prager W (1952) Soil mechanics and plastic analysis or limit design. Q Appl Math 10:157–165

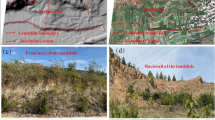

Fan X, Xu Q, Scaringi G, Dai L, Li W, Dong X, Zhu X, Pei X, Dai K, Havenith HB (2017) Failure mechanism and kinematics of the deadly June 24th 2017 Xinmo landslide, Maoxian, Sichuan, China. Landslides 14:2129–2146

Ferri F, Di Toro G, Hirose T, Han R, Noda H, Shimamoto T, Quaresimin M, de Rossi N (2011) Low- to high-velocity frictional properties of the clay-rich gouges from the slipping zone of the 1963 Vaiont slide, northern Italy. J Geophys Res 116:B09208

FHWA (2006) Hydraulic design of energy dissipaters for culverts and channels. Hydraulic engineering circular no. 14. 3rd ed. report no. FHWA-NHI-06-086. United States Federal Highway Administration (FHWA), Springfield, Va

Homel M, Herbold EB (2016) Field-gradient partitioning for fracture and frictional contact in the material point method. Int J Numer Meth Eng 109(7):1013–1044

Huang P, Zhang X, Ma S, Huang X (2011) Contact algorithms for the material point method in impact and penetration simulation. Int J Numer Meth Eng 85(4):498–517

Jiang YJ, Towhata I (2013) Experimental study of dry granular flow and impact behavior against a rigid retaining wall. Rock Mech Rock Eng 46(4):713–729

Kazuo Mizoguchi, Takehiro Hirose, Toshihiko Shimamoto, Eiichi Fukuyama, (2007) Reconstruction of seismic faulting by high-velocity friction experiments: An example of the 1995 Kobe earthquake. Geophysical Research Letters 34 (1)

Law RPH, Choi CE, Ng CWW (2015) Discrete-element investigation of influence of granular debris flow baffles on rigid barrier impact. Can Geotech J 53(1):179–185

Lemiale V, Nairn J, Hurmane A (2010) Material point method simulation of equal channel angular pressing involving large plastic strain and contact through sharp corners. Comput Model Eng Sci 70(1):41–66

Leonardi A, Wittel FK, Mendoza M, Vetter R, Herrmann HJ (2016) Particle–fluid–structure interaction for debris flow impact on flexible barriers. Comp Aided Civ Inf Eng 31(5):323–333

Li X, Wu Y, He S, Su L (2016) Application of the material point method to simulate the post-failure runout processes of the Wangjiayan landslide. Eng Geol 212:1–9

Li X, Xie Y, Gutierrez M (2018) A soft–rigid contact model of MPM for granular flow impact on retaining structures. Comput Part Mech 5(4):529–537

Lian YP, Zhang X, Liu Y (2011) Coupling of finite element method with material point method by local multi-mesh contact method. Comput Methods Appl Mech Eng 200:3482–3494

Ma ZT, Zhang X, Huang P (2010) An object-oriented MPM framework for simulation of large deformation and contact of numerous grains. Comput Model Eng Sci 55(1):61–87

Ma J, Wang D, Randolph MF (2014) A new contact algorithm in the material point method for geotechnical simulations. Int J Numer Anal Meth Geomech 38(11):1197–1210

Mast CM, Arduino P, Miller GR, Mackenzie-Helnwein P (2014) Avalanche and landslide simulation using the material point method: flow dynamics and force interaction with structures. Comput Geosci 18:817–830

Mizuyama T (2008) Structural countermeasures for debris flow disasters. Int J Erosion Control Eng 1(2):38–43

Moriguchi S, Borja RI, Yashima A, Sawada K (2009) Estimating the impact force generated by granular flow on a rigid obstruction. Acta Geotech 4(1):57–71

Nairn JA (2013) Modeling imperfect interfaces in the material point method using multimaterial methods. Comput Model Eng Sci 1(1):1–15

Ng CWW, Choi CE, Kwan JSH, Shiu HYK, Ho KKS, Koo RCH (2012) Flume modeling of debris flow resisting baffles. In Proceedings of AGS seminar on natural terrain hazards mitigation measures, Hong Kong, HKSAR, 16 October 2012. The Association of Geotechnical and Geoenvironmental Specialists. pp. 16–21

Ng CWW, Choi CE, Song D, Kwan JSH, Koo RCH, Shiu HYK, Ho KKS (2015) Physical modelling of baffles influence on landslide debris mobility. Landslides 12(1):1–18

Ouyang C, Zhou K, Xu Q, Yin J, Peng D, Wang D, Li W (2017) Dynamic analysis and numerical modeling of the 2015 catastrophic landslide of the construction waste landfill at Guangming, Shenzhen, China. Landslides 14:705–718

Phuong NTV, van Tol AF, Elkadi ASK, Rohe A (2016) Numerical investigation of pile installation effects in sand using material point method. Comput Geotech 73:58–71

Richard M. Iverson, David L. George, (2014) A depth-averaged debris-flow model that includes the effects of evolving dilatancy. I. Physical basis. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences 470 (2170):20130819

Shi B, Zhang Y, Zhang W (2019) Run-out of the 2015 Shenzhen landslide using the material point method with the softening model. B Eng Geol Environ 78:1225–1236

Sulsky D, Schreyer HL (1996) Axisymmetric form of the material point method with applications to upsetting and Taylor impact problems. Comput Methods Appl Mech Eng 139:409–429

Sulsky D, Chen Z, Schreyer HL (1994) A particle method for history-dependent materials. Comput Methods Appl Mech Eng 118:179–196

Sulsky D, Zhou SJ, Schreyer HL (1995) Application of a particle-in-cell method to solid mechanics. Comput Physics Commun 87:236–252

Teufelsbauer H, Wang Y, Chiou MC, Wu W (2009) Flow–obstacle interaction in rapid granular avalanches: DEM simulation and comparison with experiment. Granul Matter 11(4):209–220

Togo T, Shimamoto T, Dong JJ, Lee CT, Yang CM (2014) Triggering and runaway processes of catastrophic Tsaoling landslide induced by the 1999 Taiwan Chi-Chi earthquake, as revealed by high-velocity friction experiments. Geophys Res Lett 41:1907–1915

Wang D, Chen Z, He S, Liu Y, Tang H (2018) Measuring and estimating the impact pressure of debris flows on bridge piers based on large-scale laboratory experiments. Landslides 15(7):1331–1345

Wieckowski Z, Youn S, Yeon J (1999) A particle-in-cell solution to the silo discharging problem. Int J Numer Meth Eng 45(9):1203–1225

Xu X, Jin F, Sun Q, Soga K, Gordon GDZ (2019) Three-dimensional material point method modeling of runout behavior of the Hongshiyan landslide. Can Geotech J 56:1318–1337

Yerro A, Alonso EE, Pinyol NM (2015) The material point method for unsaturated soils. Geotechnique 65(3):201–217

YuZhang Bi, SiMing He, YanJun Du, XinPo Sun, XinPo Li, (2019) Effects of the configuration of a baffle–avalanche wall system on rock avalanches in Tibet Zhangmu: discrete element analysis. Bulletin of Engineering Geology and the Environment 78 (4):2267-2282

Zhang DZ, Zou Q, VanderHeyden WB, Ma X (2008) Material point method applied to multiphase flows. J Comput Phys 227:3159–3173

Zhang X, Lian Y, Liu Y, Zhou X (2013) The material point method. Tsinghua University Press, Beijing [In Chinese]

Funding

The work in this paper was performed while the author was supported by the National Natural Science Foundation of China through grant (41877291, 41472293). These supports are greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Appendix. MPM computational cycle

Appendix. MPM computational cycle

A computational cycle of the MPM solution generally consists of four steps.

- 1.

In each time step, particle mass and momenta along with other quantities needed for algorithms are extrapolated to nodes on the mesh grid. The mass of an arbitrary node i is given by

where Sip is the shape function of node i for particle p, mp is the mass of a material point.

The nodal momentum is given by

where vp is velocity of the material point.

- 2.

The particle strains are calculated based on the nodal velocity field, and are used to update the particle stresses by the constitutive model. Then the nodal internal force and external force (neglecting surface tractions) at the ith grid node are calculated by

where bp is the body force acting on the pth particle, Vp is the particle volume, σp is the Cauchy stress at the particle, and ΔSip is the gradient of the ith grid shape function over the pth particle domain. From the forces, the updated nodal velocities are computed,

In Eq. (5), the updated velocity, \( {\overline{\boldsymbol{v}}}_i^{n+1} \), neglects the effect of contact forces. As described in the following section, contact forces modify the velocity field to compute a corrected \( {\mathrm{v}}_i^{n+1} \) from \( {\overline{\boldsymbol{v}}}_i^{n+1} \).

- 3.

The updated grid velocity field is used to compute the updated velocity at the particle

-

4.

Update material point positions by

After the update, background mesh can be discarded or reused for the next time step in its initial, undistorted form. The previously mentioned procedure is repeated for each incremental step.

Rights and permissions

About this article

Cite this article

Li, X., Yan, Q., Zhao, S. et al. Investigation of influence of baffles on landslide debris mobility by 3D material point method. Landslides 17, 1129–1143 (2020). https://doi.org/10.1007/s10346-020-01346-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10346-020-01346-1