Abstract

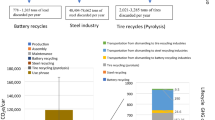

The ‘whole recycling method’, in which an end-of-life vehicle (ELV) is pressed and transferred to an electric furnace or converter, simultaneously recycles iron and treats automotive shredder residues. This contrasts with the usual practice of shredding ELVs to produce scrap. An advanced dismantling process is required to recycle pressed ELVs using a converter because the quality of scrap entering a converter is restricted (the copper content must be low). Here, life cycle assessments are performed to determine the amounts of greenhouse gases (GHGs) emitted recycling an ELV using the whole recycling method and using the shredding method. Recycling a pressed ELV in a converter was found to cause GHG emissions approximately 320 kg-CO2e lower than caused by the recycling of the pressed ELV in an electric furnace. Approximately, 120 kg-CO2e less GHGs were emitted when recycling in a converter than when using the shredding method. However, the amount of greenhouse gases reduced by a converter depends on the conditions used, such as the presence of a Linz–Donawitz converter gas recovery facility. It is hoped that incentives can be developed to improve scrap metal quality by encouraging automobile manufacturers to design for disassembly and recyclers to disassemble more ELV components.

Similar content being viewed by others

References

Sakai S, Yoshida H, Hiratsuka J, Vandecasteele C, Kohlmeyer R, Rotter VS, Passarini F, Santini A, Peeler M, Li J, Oh GJ, Chi NK, Bastian L, Moore S, Kajiwara N, Takigami H, Itai T, Takahashi S, Tanabe S, Tomoda K, Hirakawa T, Hirai Y, Asari M, Yano J (2013) An international comparative study of end-of-life vehicle (ELV) recycling systems. J Mater Cycles Waste Manage 16:1–20. doi:10.1007/s10163-013-0173-2

Castro MBG, Remmerswaal JAM, Reuter MA (2003) Life cycle impact assessment of the average passenger vehicle in the Netherlands. Int J Life Cycle Assess 8:297–304. doi:10.1007/BF02978922

Joung HT, Cho SJ, Seo YC, Kim WH (2007) Status of recycling end-of-life vehicles and efforts to reduce automobile shredder residues in Korea. J Mater Cycles Waste Manage 9:159–166. doi:10.1007/s10163-007-0181-1

Nourreddine M (2007) Recycling of auto shredder residue. J Hazard Mater 139:481–490. doi:10.1016/j.jhazmat.2006.02.054

Santini A, Passarini F, Vassura I, Serrano D, Dufour J, Morselli L (2012) Auto shredder residue recycling: mechanical separation and pyrolysis. Waste Manage 32:852–858. doi:10.1016/j.wasman.2011.10.030

Taylor R, Ray R, Chapman C (2013) Advanced thermal treatment of auto shredder residue and refuse derived fuel. Fuel 106:401–409. doi:10.1016/j.fuel.2012.11.071

Endoh S, Takahashi K, Lee JR, Ohya H (2006) Mechanical treatment of automobile shredder residue for its application as a fuel. J Mater Cycles Waste Manage 8:88–94. doi:10.1007/s10163-005-0140-7

Sakai SI, Noma Y, Kida A (2007) End-of-life vehicle recycling and automobile shredder residue management in Japan. J Mater Cycles Waste Manage 9:151–158. doi:10.1007/s10163-007-0180-2

Vermeulen I, Van Caneghem J, Block C, Baeyens J, Vandecasteele C (2011) Automotive shredder residue (ASR): reviewing its production from end-of-life vehicles (ELVs) and its recycling, energy or chemicals’ valorisation. J Hazard Mater 190:8–27. doi:10.1016/j.jhazmat.2011.02.088

Mancini G, Viotti P, Luciano A, Fino D (2014) On the ASR and ASR thermal residues characterization of full scale treatment plant. Waste Manage 34:448–457. doi:10.1016/j.wasman.2013.11.002

Boughton B (2007) Evaluation of shredder residue as cement manufacturing feedstock. Resour Conserv Recycl 51:621–642. doi:10.1016/j.resconrec.2006.11.006

Tian J, Chen M (2014) Sustainable design for automotive products: dismantling and recycling of end-of-life vehicles. Waste Manage 34:458–467. doi:10.1016/j.wasman.2013.11.005

Santini A, Morselli L, Passarini F, Vassura I, Di Carlo S, Bonino F (2011) End-of-Life Vehicles management: italian material and energy recovery efficiency. Waste Manage 31:489–494. doi:10.1016/j.wasman.2010.09.015

Tasala Gradin K, Luttropp C, Björklund A (2013) Investigating improved vehicle dismantling and fragmentation technology. J Cleaner Prod 54:23–29. doi:10.1016/j.jclepro.2013.05.023

Hiratsuka J, Sato N, Yoshida H (2014) Current status and future perspectives in end-of-life vehicle recycling in Japan. J Mater Cycles Waste Manag 16:21–30. doi:10.1007/s10163-013-0168-z

Ministry of Environment Japan (2015) Implementation status of automotive recycling: transfer report (in Japanese). Ministry of Environment of Japan. http://www.env.go.jp/recycle/car/pdfs/kouhyou_25d.pdf. Accessed 15 May 2015

The Mechanical Social Systems Foundation (2005) Study on optimized-dismantling system of automobile recycling (in Japanese). The Japan Research and development Center for Metals web. http://www.jrcm.or.jp/works_reports/16R11.pdf. Accessed 15 May 2015

JFE Techno-Research (2013) Survey of unutilized heat energy use and energy saving in steel industry (in Japanese). Ministry of Economy, Trade and Industry of Japan. http://www.meti.go.jp/meti_lib/report/2013fy/E003116.pdf. Accessed 15 May 2015

Toyotsu recycle Corporation (2015) Whole recycling: TH team standard (in Japanese). Toyotsu recycle web. http://www.toyotsurecycle.co.jp/ASR/all-th.html. Accessed 3 Jun 2015

Interview to an anonymous ELV dismantler. Interviewed 24 Sep 2015

Matsubae K, Nakajima K, Nakamura S, Nagasaka T (2011) Impact of the recovery of secondary ferrous materials from alternative ELV treatment methods on CO2 Emission: a waste input output analysis. ISIJ Int 51:151–157. doi:10.2355/isijinternational.51.151

Fuse M, Kashima S, Yagita H (2006) Input-output analysis of automobile recycling (in Japanese). J Life Cycle Assess, Jpn 2:65–72. doi:10.3370/lca.2.65

ISO (2006) ISO 14040. environmental management—life cycle assessment—principles and framework. International Organization for Standardization, Geneva

IPCC (2007) Climate Change 2007—the physical science basis: working group I contribution to the fourth assessment report of the IPCC (Climate Change 2007). Cambridge University Press, Cambridge

Oguchi M, Fuse M (2015) Regional and longitudinal estimation of product lifespan distribution: a case study for automobiles and a simplified estimation method. Environ Sci Technol 49:1738–1743. doi:10.1021/es505245q

Nikkan Jidosha Shimbun and Automobile Business Association of Japan (2003) Automotive Years Hand Book (in Japanese). Tokyo

Passarini F, Ciacci L, Santini A, Vassura I, Morselli L (2014) Aluminium flows in vehicles: enhancing the recovery at end-of-life. J Mater Cycles Waste Manage 16:39–45. doi:10.1007/s10163-013-0175-0

Yano J, Hirai Y, Okamoto K, Sakai S (2014) Dynamic flow analysis of current and future end-of-life vehicles generation and lead content in automobile shredder residue. J Mater Cycles Waste Manage 16:52–61. doi:10.1007/s10163-013-0166-1

Japan Environmental Management Association for Industry (2006) Development of technology to assess and verify product life cycle carbon dioxide emissions: development of life cycle assessment (LCA) method in relation to venous process (in Japanese). New Energy and Industrial Technology Development Organization (NEDO), Kawasaki

Mitsubishi UFJ Research and Consulting (2015) Experimental project on dismantling and shredding of end-of life vehicles (ELV) for reducing the content of inhibitor elements in automotive shredder reside (ASR), and for improving resource efficiency in automobile recycling system in Japan (in Japanese). Ministry of Environment of Japan. http://www.env.go.jp/recycle/car/pdfs/h26_report01_mat02.pdf. Accessed 15 May 2015

Yano J, Muroi T, Sakai S (2015) Rare earth element recovery potentials from end-of-life hybrid electric vehicle components in 2010–2030. J Mater Cycles Waste Manage. doi:10.1007/s10163-015-0360-4

West-Japan Auto Recycle (2015) Company profile. http://www.warc.co.jp/english/english.html. Accessed 29 Jun 2015

Tahara K, Onoye T, Kobayashi K, Yamagishi K, Tsuruta S, Nakano K (2010) Development of inventory database for environmental analysis (IDEA). In: Proceedings of the 9th International Conference Ecobalance. Tokyo, p 119

Nakano K, Narita N, Aoki R, Funazaki A, Yagita H (2006) Specification of environmental impact reduction processes on end of life vehicle through down-stream LCA (in Japanese). J Life Cycle Assess, Jpn 2:159–165. doi:10.3370/lca.2.159

Oda J, Akimoto K, Sano F, Tomoda T (2007) Diffusion of energy efficient technologies and CO2 emission reductions in iron and steel sector. Energ Econ 29:868–888. doi:10.1016/j.eneco.2007.01.003

Morihiro O, Manako K, Hirai Y, Sakai S (2012) Life cycle assessment for treatment and recycling of automobile shredder residue (ASR) (in Japanese). J Jpn Soc Mater Cycles Waste Manage 23:264–278. doi:10.3985/jjsmcwm.1101201

LCA forum of Japan (2013) JLCA database, 2013/3 ed. JLCA. http://lca-forum.org/. Accessed 29 Jun 2015

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Part of this study was funded by the West-Japan Auto Recycle Co., Ltd, but the company had no control over the interpretation, writing, or publication of this work.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Nakano, K., Shibahara, N. Comparative assessment on greenhouse gas emissions of end-of-life vehicles recycling methods. J Mater Cycles Waste Manag 19, 505–515 (2017). https://doi.org/10.1007/s10163-015-0454-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-015-0454-z