Abstract

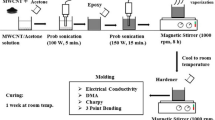

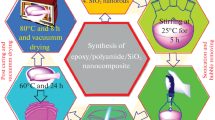

Carbon nanotube (CNT)/epoxy nanocomposites have a great potential of possessing many advanced properties. However, the homogenization of CNT dispersion is still a great challenge in the research field of nanocomposites. This study applied a novel dispersion agent, carboxymethyl cellulose (CMC), to functionalize CNTs and improve CNT dispersion in epoxy. The effectiveness of the CMC functionalization was compared with mechanical mixing and a commonly used surfactant, sodium dodecylbenzene sulfonate (NaDDBS), regarding dispersion, mechanical and corrosion properties of CNT/epoxy nanocomposites with three different CNT concentrations (0.1%, 0.3% and 0.5%). The experimental results of Raman spectroscopy, particle size analysis and transmission electron microscopy showed that CMC functionalized CNTs reduced CNT cluster sizes more efficiently than NaDDBS functionalized and mechanically mixed CNTs, indicating a better CNT dispersion. The peak particle size of CMC functionalized CNTs reduced as much as 54% (0.1% CNT concentration) and 16% (0.3% CNT concentration), compared to mechanical mixed and NaDDBS functionalized CNTs. Because of the better dispersion, it was found by compressive tests that CNT/epoxy nanocomposites with CMC functionalization resulted in 189% and 66% higher compressive strength, 224% and 50% higher modulus of elasticity than those with mechanical mixing and NaDDBS functionalization respectively (0.1% CNT cencentration). In addition, electrochemical corrosion tests also showed that CNT/epoxy nanocomposites with CMC functionalization achieved lowest corrosion rate (0.214 mpy), the highest corrosion resistance (201.031 Ω·cm2), and the lowest porosity density (0.011%).

Similar content being viewed by others

References

Cao, D.; Malakooti, S.; Kulkarni, V. N.; Ren Y.; Lu H. Nanoindentation measurement of core-skin interphase viscoelastic properties in a sandwich glass composite. Mech. Time-depend. Mater. 2021, 25, 353–363.

Cao, D.; Malakooti, S.; Kulkarni, V.N.; Ren Y.; Liu, Y.; Nie X.; Qian, D.; Griffith, D.T.; Lu, H. The effect of resin uptake on the flexural properties of compression molded sandwich composites. Wind Energy 2021, 25, 71–93.

Wang, X.; Xu, T.; Andrade, M.J.; Rampalli, I.; Cao, D.; Haque, M.; Roy, S.; Baughman, R.H.; Lu, H. The infterfacial shear strength of carbon nanotube sheet modified carbon fiber composites. Chall. Mech. Time-depend. Mater. 2021, 2, 25–32.

Adams, R.D.; Peppiatt, N. A. Stress analysis of adhesive-bonded lap joints. J. Strain Anal. Eng. Des. 1974, 9, 185–196.

Zhang, D.; Huang, Y. Influence of surface roughness and bondline thickness on the bonding performance of epoxy adhesive joints on mild steel substrates. Prog. Org. Coatings 2021, 153, 106135.

Fu, Y.X.; He, Z.X.; Mo, D.C.; Lu, S.S. Thermal conductivity enhancement with different fillers for epoxy resin adhesives. Appl. Therm. Eng. 2014, 66, 493–498.

Gu, H.; Ma, C.; Gu, J.; Guo, J.; Yan, X.; Huang, J.; Zhang, Q.; Guo, Z. An overview of multifunctional epoxy nanocomposites. J. Mater. Chem. C. 2016, 4, 5890–5906.

Dong, M.; Zhang, H.; Tzounis, L.; Santagiuliana, G.; Bilotti, E.; Papageorgiou, D. G. Multifunctional epoxy nanocomposites reinforced by two-dimensional materials: a review. Carbon N. Y. 2021, 185, 57–81.

Kumar, S.K.; Castro, M.; Saiter, A.; Delbreilh, L.; Feller, J. F.; Thomas, S.; Grohens, Y. Development of poly(isobutylene-co-isoprene)/reduced graphene oxide nanocomposites for barrier, dielectric and sensingapplications. Mater. Lett. 2013, 96, 109–112.

Nigam, V.; Setua, D. K.; Mathur, G. N. Failure analysis of rubber toughened epoxy resin. J. Appl. Polym. Sci. 2002, 87, 861–868.

Sydlik, S. A.; Lee, J. H.; Walish, J. J.; Thomas, E. L.; Swager, T. M. Epoxy functionalized multi-walled carbon nanotubes for improved adhesives. Carbon N. Y. 2013, 59, 109–120.

Wang, Z. Y.; Sun, X.; Wang, Y.; Liu, J. D.; Zhang, C.; Zhao, Z. B.; Du, X. Y. Fabrication of high-performance thermally conductive and electrically insulating polymer composites with siloxane/multi-walled carbon nanotube core-shell hybrids at low filler content. Polymer 2022, 262, 125430.

Zhang, D.; Huang, Y. The bonding performances of carbon nanotube (CNT)-reinforced epoxy adhesively bonded joints on steel substrates. Prog. Org. Coatings 2021, 159, 106407.

Singh, N. P.; Gupta, V. K.; Singh, A. P. Graphene and carbon nanotube reinforced epoxy nanocomposites: a review. Polymer 2019, 180, 121724.

Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58.

Kil, T.; Jin, D. W.; Yang, B.; Lee, H. K. A comprehensive micromechanical and experimental study of the electrical conductivity of polymeric composites incorporating carbon nanotube and carbon fiber. Compos. Struct. 2021, 268, 114002.

Guo, Y.K.; Li, H.; Zhao, P.X.; Wang, X.F.; Astruc, D.; Shuai, M. Thermo-reversible MWCNTs/epoxy polymer for use in self-healing and recyclable epoxy adhesive. Chinese J. Polym. Sci. 2017, 35, 728–738.

Zhang, D.; Huang, Y.; Chia, L. Effects of carbon nanotube (CNT) geometries on the dispersion characterizations and adhesion properties of CNT reinforced epoxy composites. Compos. Struct. 2022, 296, 115942.

Parveen, S.; Rana, S.; Fangueiro, R. A review on nanomaterial dispersion, microstructure, and mechanical properties of carbon nanotube and nanofiber reinforced cementitious composites. J. Nanomater. 2013, 2013, 710175.

Thess, A.; Lee, R.; Nikolaev, P.; Dai, H.; Petit, P.; Robert, J. Crystalline ropes of metallic carbon nanotubes. Science 1996, 273, 483–487.

Gao, E.; Lu, W.; Xu, Z. Strength loss of carbon nanotube fibers explained in a three-level hierarchical model. Carbon N. Y. 2018, 138, 134–142.

Zhang, D.; Huang, Y.; Wang, Y. Bonding performances of epoxy coatings reinforced by carbon nanotubes (CNTs) on mild steel substrate with different surface roughness. Compos. Part A Appl. Sci. Manuf. 2021, 147, 106479.

Ma, P.C.; Siddiqui, N.A.; Marom, G.; Kim, J.K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: a review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367.

Yu, Z.; Di, H.; Ma, Y.; Lv, L.; Pan, Y.; Zhang, C.; He, Y. Fabrication of graphene oxide-alumina hybrids to reinforce the anti-corrosion performance of composite epoxy coatings. Appl. Surf. Sci. 2015, 351, 986–996.

Rennhofer, H.; Zanghellini, B. Dispersion state and damage of carbon nanotubes and carbon nanofibers by ultrasonic dispersion: a review. Nanomaterials 2021, 11, 1469.

Andrews, R.; Jacques, D.; Minot, M.; Rantell, T. Fabrication of carbon multiwall nanotube/polymer composites by shear mixing. Macromol. Mater. Eng. 2002, 287, 395–403.

Yang, H.; Yang, Y.; Liu, Y.; He, D.; Bai, J. Multi-scale study of CNT and CNT-COOH reinforced epoxy composites: dispersion state, interfacial interaction vs mechanical properties. Compos. Interfaces 2021, 28, 381–393.

Korayem, A.H.; Barati, M.R.; Chen, S.J.; Simon, G.P.; Zhao, X.L.; Duan, W.H. Optimizing the degree of carbon nanotube dispersion in a solvent for producing reinforced epoxy matrices. Powder Technol. 2015, 284, 541–550.

Dassios, K. G.; Alafogianni, P.; Antiohos, S. K.; Leptokaridis, C.; Barkoula, N. M.; Matikas, T. E. Optimization of sonication parameters for homogeneous surfactant assisted dispersion of multiwalled carbon nanotubes in aqueous solutions. J. Phys. Chem. C. 2015, 119, 7506–7516.

Jia, X. L.; Zhang, Q.; Huang, J. Q.; Zheng, C.; Qian, W. Z.; Wei, F. The direct dispersion of granular agglomerated carbon nanotubes in bismaleimide by high pressure homogenization for the production of strong composites. Powder Technol. 2012, 217, 477–481.

Shokrieh, M.M.; Rafiee, R. Investigation of nanotube length effect on the reinforcement efficiency in carbon nanotube based composites. Compos. Struct. 2010, 92, 2415–2420.

Haque, A.; Ramasetty, A. Theoretical study of stress transfer in carbon nanotube reinforced polymer matrix composites. Compos. Struct. 2005, 71, 68–77.

Park, K.C.; Hayashi, T.; Tomiyasu, H.; Endo, M.; Dresselhaus, M.S. Progressive and invasive functionalization of carbon nanotube sidewalls by diluted nitric acid under supercritical conditions. J. Mater. Chem. 2005, 15, 407–411.

Gabriel, G.; Sauthier, G.; Fraxedas, J.; Moreno-Mañas, M.; Martínez, M.T.; Miravitlles, C.; Casabó, J. Preparation and characterisation of single-walled carbon nanotubes functionalised with amines. Carbon N. Y. 2006, 44, 1891–1897.

Ma, P. C.; Kim, J. K.; Tang, B. Z. Functionalization of carbon nanotubes using a silane coupling agent. Carbon N. Y. 2006, 44, 3232–3238.

Han, B.; Yu, X. Effect of surfactants on pressure-sensitivity of CNT filled cement mortar composites. Front. Mater. 2014, 1, 1–5.

Carilli, C. L.; Lewis, G. F.; Djorgovski, S. G.; Mahabal, A.; Cox, P.; Bertoldi, F.; Omont, A. A molecular Einstein ring: Imaging a starburst disk surrounding a quasi-stellar object. Science 2003, 300, 773–775.

Imtiaz, S.; Siddiq, M.; Kausar, A.; Muntha, S.T.; Ambreen, J.; Bibi, I. A review featuring fabrication, properties and applications of carbon nanotubes (CNTs) reinforced polymer and epoxy nanocomposites. Chinese J. Polym. Sci. 2018, 36, 445–461.

Chen, Y.; Wei, W.; Zhu, Y.; Luo, J.; Liu, X. Noncovalent functionalization of carbon nanotubes via co-deposition of tannic acid and polyethyleneimine for reinforcement and conductivity improvement in epoxy composite. Compos. Sci. Technol. 2019, 170, 25–33.

Qi, Z.; Tan, Y.; Wang, H.; Xu, T.; Wang, L.; Xiao, C. Effects of noncovalently functionalized multiwalled carbon nanotube with hyperbranched polyesters on mechanical properties of epoxy composites. Polym. Test. 2017, 64, 38–47.

Monthioux, M.; Smith, B. W.; Burteaux, B.; Claye, A.; Fischer, J. E.; Luzzi, D. E. Sensitivity of single-wall carbon nanotubes to chemical processing: an electron microscopy investigation. Carbon N. Y. 2001, 39, 1251–1272.

Cha, J.; Jin, S.; Shim, J. H.; Park, C. S.; Ryu, H. J.; Hong, S. H. Functionalization of carbon nanotubes for fabrication of CNT/epoxy nanocomposites. Mater. Des. 2016, 95, 1–8.

Chen, B.; Chen, J.; Li, J. Y.; Tong, X.; Zhao, H. C.; Wang, L. P. Oligoaniline assisted dispersion of carbon nanotubes in epoxy matrix for achieving the nanocomposites with enhanced mechanical, thermal and tribological properties. Chinese J. Polym. Sci. 2017, 35, 446–454.

Rahman, M. S.; Hasan, M. S.; Nitai, A. S.; Nam, S.; Karmakar, A. K.; Ahsan, M. S.; Shiddiky, M. J. A.; Ahmed, M. B. Recent developments of carboxymethyl cellulose. Polymers 2021, 13, 1345.

Minami, N.; Kim, Y.; Miyashita, K.; Kazaoui, S. Nalini, B. Cellulose derivatives as excellent dispersants for single-wall carbon nanotubes as demonstrated by absorption and photoluminescence spectroscopy. Appl. Phys. Lett. 2006, 88, 093123.

Zhang, D.; Huang, Y. Dispersion characterizations and adhesion properties of epoxy composites reinforced by carboxymethyl cellulose surface treated carbon nanotubes. Powder Technol. 2022, 404, 117505.

Chia, L.; Huang, Y.; Lu, P.; Bezbaruah, A. N. Surface modification of carbon nanotubes using carboxymethyl cellulose for enhanced stress sensing in smart cementitious composites. IEEE Sens. J. 2021, 21, 15218–15229.

Creus U, J.; Mazille, H.; Idrissi, H. Porosity evaluation of protective coatings onto steel, through electrochemical techniques. Surf. Coat. Technol. 2000, 130, 224–232.

Ranganatha, S.; Venkatesha, T. V.; Vathsala, K. Development of electroless Ni-Zn-P/nano-TiO2 composite coatings and their properties. Appl. Surf. Sci. 2010, 256, 7377–7383.

Mazaheri, H.; Allahkaram, S. R. Deposition, characterization and electrochemical evaluation of Ni-P-nano diamond composite coatings. Appl. Surf. Sci. 2012, 258, 4574–4580.

Pizzutto, C. E.; Suave, J.; Bertholdi, J.; Pezzin, S. H.; Coelho, L. A. F.; Amico, S. C. Study of epoxy/CNT nanocomposites prepared via dispersion in the hardener. Mater. Res. 2011, 14, 256–263.

Jojibabu, P.; Zhang, Y. X.; Rider, A. N.; Wang, J.; Gangadhara Prusty, B. Synergetic effects of carbon nanotubes and triblock copolymer on the lap shear strength of epoxy adhesive joints. Compos. Part B Eng. 2019, 178, 107457.

Bourchak, M.; Juhany, K. A.; Salah, N.; Ajaj, R.; Algarni, A.; Scarpa, F. Determining the tensile properties and dispersion characterization of CNTs in epoxy using Tem and Raman spectroscopy. Mech. Compos. Mater. 2020, 56, 215–226.

Jorio, A.; Saito, R. Raman spectroscopy for carbon nanotube applications. J. Appl. Phys. 2021, 129, 021102.

Mallakpour, S.; Soltanian, S. Surface functionalization of carbon nanotubes: fabrication and applications. RSC Adv. 2016, 6, 109916–109935.

Cha, J.; Jun, G. H.; Park, J. K.; Kim, J. C.; Ryu, H. J.; Hong, S. H. Improvement of modulus, strength and fracture toughness of CNT/Epoxy nanocomposites through the functionalization of carbon nanotubes. Compos. Part B Eng. 2017, 129, 169–179.

Shokrian, M. D.; Shelesh-Nezhad, K.; Najjar, R. Effect of CNT dispersion methods on the strength and fracture mechanism of interface in epoxy adhesive/Al joints. J. Adhes. Sci. Technol. 2019, 33, 1394–1409.

Chen, X.; Beyerlein, I. J.; Brinson, L. C. Curved-fiber pull-out model for nanocomposites. Part 1: bonded stage formulation. Mech. Mater. 2009, 41, 279–292.

Ramezanzadeh, B.; Bahlakeh, G.; Ramezanzadeh, M. Polyaniline-cerium oxide (PAni-CeO2) coated graphene oxide for enhancement of epoxy coating corrosion protection performance on mild steel. Corros. Sci. 2018, 137, 111–126.

Jeon, H. R.; Park, J. H.; Shon, M. Y. Corrosion protection by epoxy coating containing multi-walled carbon nanotubes. J. Ind. Eng. Chem. 2013, 19, 849–853.

Moradi, M. H.; Aliofkhazraei, M.; Toorani, M.; Golgoon, A.; Rouhaghdam, A. S. SiAlON-epoxy nanocomposite coatings: corrosion and wear behavior. J. Appl. Polym. Sci. 2016, 133, 43855.

Acknowledgments

This work was financially supported by the National Science Foundation (No. CMMI-1750316). The findings and opinions expressed in this study are those of the authors only and do not necessarily reflect the views of the sponsors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Conflict of Interests

The authors declare no interest conflict.

Rights and permissions

About this article

Cite this article

Zhang, DW., Chia, L. & Huang, Y. Effect of Carboxymethyl Cellulose (CMC) Functionalization on Dispersion, Mechanical, and Corrosion Properties of CNT/Epoxy Nanocomposites. Chin J Polym Sci 41, 1277–1286 (2023). https://doi.org/10.1007/s10118-023-2928-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-023-2928-0