Abstract

Caustic can be recovered from textile mercerization wastewaters by evaporation or membrane filtration. The main objective of this study was to evaluate and compare these two processes in environmental and economic terms, employing the methodology presented in the Integrated Pollution Prevention and Control (IPPC) Reference Document on Economics and Cross-Media Effects (ECM). Cross-media effects for caustic recovery alternatives were calculated on environmental themes including potentials of human toxicity (HTP), aquatic toxicity (ATP), global warming (GWP), acidification (AP), eutrophication (EP), ozone depletion (ODP), and photochemical ozone creation (POCP). For all the environmental themes, membrane filtration exhibited better environmental performance (lower environmental impact) than evaporation. Due to relatively dilute caustic solution to be obtained by membrane processes, ‘membrane filtration + evaporation’ option was also investigated. Findings showed that combination of membrane filtration and evaporation reduces the environmental benefits of membrane filtration alone. The cost-effectiveness values of evaporation and membrane filtration were calculated as 375–625 and 457–685 USD/ton caustic, respectively. Considering the mass of caustic recovered, unit total cost, net present value, internal rate of return, and payback period parameters, it was concluded that evaporation process is more cost-effective than membrane filtration with lower annual unit total cost and payback period. Evaporation may be preferred over membrane filtration in cases where concentrated caustic solution must be obtained for mercerization, although evaporation exhibits lower environmental performance. In cases where dilute caustic solution is adequate or the recovered dilute caustic is to be mixed with new concentrated caustic solution for further use in production processes, membrane filtration can be preferred over evaporation.

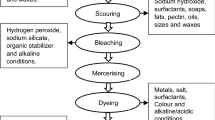

Graphical abstract

Similar content being viewed by others

Data availability

Enquiries about data availability should be directed to the authors.

Abbreviations

- AP:

-

Acidification potential

- ATP:

-

Aquatic toxicity potential

- BAT:

-

Best available techniques

- Béo :

-

Baumé

- BREF:

-

Best available techniques reference documents

- C 0 :

-

Cost at base year

- CED:

-

Cumulative energy demand

- CFC:

-

Chlorofluorocarbons

- CO2 :

-

Carbon dioxide

- COD:

-

Chemical oxygen demand

- EC:

-

European Commission

- ECM:

-

Economics and cross-media effects reference document

- ELV:

-

End of Life Vehicles Directive

- EP:

-

Eutrophication potential

- EU:

-

European Union

- GHG:

-

Greenhouse gas

- GWP:

-

Global warming potential

- HBFC:

-

Hydrobromofluorocarbons

- HCFC:

-

Hydrochlorofluorocarbons

- HTP:

-

Human toxicity potential

- IED:

-

Industrial Emissions Directive

- IPPC:

-

Integrated Pollution Prevention and Control

- IRR:

-

Internal rate of return

- MF:

-

Microfiltration

- n :

-

Estimated economic lifetime of the equipment

- NaOH:

-

Caustic

- NF:

-

Nanofiltration

- NH4 + :

-

Ammonium

- NO2 − :

-

Nitrite

- NO2 :

-

Nitrogen dioxide

- NO3 − :

-

Nitrate

- NPV:

-

Net present value

- ODP:

-

Ozone depletion potential

- PNEC:

-

Predicted no-effect concentration

- PO4 3 − :

-

Phosphate ion

- POCP:

-

Photochemical ozone creation potential

- r :

-

Interest (discount) rate per period

- SO2 :

-

Sulfur dioxide

- TSS:

-

Total suspended solids

- UF:

-

Ultrafiltration

- USD:

-

United States Dollar

References

Avdičević MZ, Košutić K, Dobrović S (2017) Effect of operating conditions on the performances of multichannel ceramic UF membranes for textile mercerization wastewater treatment. Environ Technol 38:65–77. https://doi.org/10.1080/09593330.2016.1186225

Bayar E (2015) Life cycle assessment of evaporative recovery of mercerization wastewater. Middle East Technical University, Science Institute, Department of Environmental Engineering, M.Sc. Thesis, Ankara, Turkey, p. 114p.

Cakir N, Alp E, Yetis U (2020) Assessing technologies for reducing dust emissions from sintermaking based on cross-media effects and economic analysis. Clean Technol Environ Policy 22:1909–1928. https://doi.org/10.1007/s10098-020-01933-9

Çavuşoğlu B, Ekmekyapar F (2019) Evaluation of caustic recovery in textile ındustry within the scope of best available techniques (BAT). Eur J Eng Appl Sci 2:6–10 https://dergipark.org.tr/tr/pub/ejeas/issue/47043/544837

European Commission (EC) (2003) Integrated Pollution Prevention and Control (IPPC) reference document on best available techniques for the textile industry. EC IPPC Bureau, Seville, Spain

European Commission (EC) (2006) Integrated Pollution Prevention and Control (IPPC) reference document on economics and cross-media effects. EC IPPC Bureau. Seville, Spain

Federal Institute for Occupational Safety and Health (BAuA) (2004) Technical Rules for Hazardous Substances (TGRS 900): German Occupational Exposure Limits. https://www.baua.de/EN/Service/Legislative-texts-and-technical-rules/Rules/TRGS/TRGS.html (Accessed on 14 April 2022)

Turkish Communique (2011) Integrated Pollution Prevention and Control in the Textile Industry Communiqué. Republic of Turkey Ministry of Environment and Urban, Official Gazette numbered 28142

Cui G, Bi M, Liu C (2021) Design and experimental validation of a six-effect multi-effect evaporation plant utilized in oilfield. Desalin Water Treat 217:111–126. https://doi.org/10.5004/dwt.2021.26891

European Chemicals Agency (ECHA) (2008) European Union Summary Risk Assessment Report Sodium Hydroxide. https://echa.europa.eu/documents/10162/917becd0-b0a4-4b68-8e5e-c2e466d8641a (Accessed on 10 April 2022)

Forster P, Ramaswamy V, Artaxo P, Berntsen T, Betts R, Fahey DW, Haywood J, Lean J, Lowe DC, Myhre G, Nganga J, Prinn R, Raga G, Schulz M, Van Dorland R (2007) Changes in atmospheric constituents and in radiative forcing in climate change 2007 The Physical Science Basis. Cambridge University Press, London

GHK and Bio Intelligence Service (GHK and BIS) (2006) A study to examine the benefits of the end-of-life vehicles directive and the costs and benefits of a revision of the 2015 targets for recycling, re-use and recovery under the ELV Directive. Final Report to DG Environment. Birmingham, USA.

Grigus M (2009) Caustic recovery using membrane filtration. ASME Citrus Engineering Symposium. Florida, Lake Alfred, pp 68–76

Gujarat Cleaner Production Centre (GCPC) (2017) Best available techniques implementation in Textile Sector. Gujarat Cleaner Production Centre, Industries & Mines Department, India. https://gcpcgujarat.org.in/publication (Accessed on 13.09.2022)

Haaz E, Fozer D, Nagy T, Valentinyi N, Andre A, Matyasi J, Balla J, Mizsey P, Toth AJ (2019) Vacuum evaporation and reverse osmosis treatment of process wastewaters containing surfactant material: COD reduction and water reuse. Clean Technol Environ Policy 21:861–870. https://doi.org/10.1007/s10098-019-01673-5

Halim SZ (2011) A study of the design parameters for evaporation of dilute caustic soda solution for application in the textiles mills in Bangladesh. Bangladesh University of Engineering and Technology, M.Sc. Thesis, Dhaka, Bangladesh, 87p.

Ibáñez-Forés V, Bovea MD, Azapagic A (2013) Assessing the sustainability of Best Available Techniques (BAT): methodology and application in the ceramic tiles industry. J Clean Prod 51:162–176. https://doi.org/10.1016/j.jclepro.2013.01.020

Ibrahim AY, Ghallab AO, Gadalla MA, Makary SS, Ashour FH (2017) Technical and economical/financial feasibility analyses of flared gas recovery in Egypt from oil and gas industry from international/national oil companies’ perspectives. Clean Technol Environ Policy 19:1423–1436. https://doi.org/10.1007/s10098-017-1340-2

Jyoti G, Khanam S (2014) Simulation of heat integrated multiple effect evaporator system. Int J Therm Sci 76:110–117. https://doi.org/10.1016/j.ijthermalsci.2013.08.016

Lameh M, Al-Mohannadi DM, Linke P (2022) Minimum marginal abatement cost curves (Mini-MAC) for CO2 emissions reduction planning. Clean Technol Environ Policy 24:143–159. https://doi.org/10.1007/s10098-021-02095-y

McKone TE, Hertwich EG (2001) The human toxicity potential and a strategy for evaluating model performance in life cycle impact assessment. Int J Life Cycle Assess 6(2):106–109. https://doi.org/10.1007/BF02977846

Organization for Economic Co-operation and Development (OECD) (2002) SIDS initial assessment report for SIAM 14 Sodium Hydroxide. https://hpvchemicals.oecd.org/ui/handler.axd?id=4d5cda68-5a7d-4ab6-85ec-20a0fd6592ca (Accessed on 10 April 2022)

Organization for Economic Co-operation and Development (OECD) (2022a) Inflation (CPI) (indicator). https://data.oecd.org/price/inflation-cpi.htm (Accessed on 14 April 2022a)

Organization for Economic Co-operation and Development (OECD) (2022b) Gross domestic product (GDP) (indicator). https://data.oecd.org/gdp/gross-domestic-product-gdp.htm (accessed on 14 April 2022b)

Ozturk E, Koseoglu H, Karaboyacı M, Yigit NO, Yetis U, Kitis M (2016) Minimization of water and chemical use in a cotton/polyester fabric dyeing textile mill. J Clean Prod 130:92–102. https://doi.org/10.1016/j.jclepro.2016.01.080

Paździor K, Bilińska L, Ledakowicz S (2019) A review of the existing and emerging technologies in the combination of AOPs and biological processes in industrial textile wastewater treatment. Chem Eng J 376:120597. https://doi.org/10.1016/j.cej.2018.12.057

Sealed Power Corporation (SPX) (2008) Evaporator handbook. SPX Corporation. http://www.apvhemisan.com/uploads/images/Evaporator_Handbook_10003_01_08_2008_US.pdf (Accessed on 15 April 2022)

Son EJ, Choe EK, Kim JW (2000) Nanofiltration membrane technology for caustic soda recovery. Textle Chem Color Am Dyest Report 32:46–52

Sorour MA (2015) Optimization of multiple effect evaporators designed for fruit juice concentrate. Am J Energy Eng 3:6–11. https://doi.org/10.11648/j.ajee.s.2015030201.12

Tomić T, Kremer I, Schneider DR (2022) Economic efficiency of resource recovery-analysis of time-dependent changes on sustainability perception of waste management scenarios. Clean Technol Environ Policy 24:543–562. https://doi.org/10.1007/s10098-021-02165-1

Tsegay G (2018) Optimization and recovery of caustic soda from the mercerization process: Almeda textile factory. Addis Ababa University, Technology Institute, Department of Chemical and Bio-Engineering, M.Sc. Thesis, Ethiopia, p. 70p

Turkish Statistical Institute (TSI) (2022) Consumer price index, December 2021. https://data.tuik.gov.tr/ (Accessed on 14 April 2022)

U.S. Environmental Protection Agency (USEPA) (2014) Global greenhouse gas emissions data. https://www.epa.gov/ghgemissions/global-greenhouse-gas-emissions-data (Accessed on 10 April 2022)

Varol C (2008) Caustic recovery from highly alkaline denim mercerizing wastewaters using membrane technology. Middle East Technical University, Science Institute, Department of Environmental Engineering, M.Sc. Thesis, Ankara, Turkey, p. 97p

Yang J, Park C, Lee D, Kim S (2007) Recovery of caustic soda in textile mercerization by combined membrane filtration. Nanotechnology Conference and Trade Show-NSTI Nanotech 2007. Tech Proc 4:660–663

Zhang Y, Shao S, Yu W, Yang F, Xu X (2014) Study on recycling alkali from the wastewater of textile mercerization process by nanofiltration. Ieri Procedia 9:71–76. https://doi.org/10.1016/j.ieri.2014.09.043

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by MB, EO and MK. The first draft of the manuscript was written by MB, EO and MK. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Balkan, M., Ozturk, E. & Kitis, M. Economic and cross-media effect analyses of best available techniques for caustic recovery from mercerization textile wastewater. Clean Techn Environ Policy 25, 1043–1058 (2023). https://doi.org/10.1007/s10098-022-02424-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-022-02424-9