Abstract

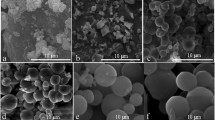

This study investigates the production of spherical carbons from cellulose under sub- and supercritical ethanol conditions with and without the addition of a potassium hydroxide (KOH) catalyst. Different temperatures (200 and 280 °C), residence times (0.5, 1, 2, and 4 h), and KOH concentrations (5, 10, and 20 wt% of cellulose) were used for the carbonization process. Carbon spheres could only be obtained under supercritical ethanol conditions (at 280 °C and 9.5 MPa). Supercritical ethanol decreases the oxygen content by a significant amount, thereby increasing the heating value. Morphological studies show that the carbons are essentially spherical of different sizes depending on the operating conditions (such as the presence of a catalyst and time). For the first time, we showed that spherical carbons can be obtained under supercritical ethanol conditions. This is a useful result as, for instance, ethanol can be produced from cellulose, and this opens the possibility for the development of a green and simple procedure to synthesize carbon spheres that may have many different applications including gas separation, catalysis, and energy storage.

Similar content being viewed by others

References

Alper K, Tekin K, Karagöz S (2015) Pyrolysis of agricultural residues for bio-oil production. Clean Technol Environ Policy 17:211–223

Brown TM, Duan P, Savage PE (2010) Hydrothermal liquefaction and gasification of Nannochloropsis sp. Energy Fuels 24:3639–3646

Budarin V, Clark JH, Hardy JJ, Luque R, Milkowski K, Tavener SJ, Wilson AJ (2006) Starbons: new starch-derived mesoporous carbonaceous materials with tunable properties. Angew Chem 118:3866–3870

Falco C, Baccile N, Titirici M-M (2011) Morphological and structural differences between glucose, cellulose and lignocellulosic biomass derived hydrothermal carbons. Green Chem 13:3273–3281

Fan J et al (2013) Direct microwave-assisted hydrothermal depolymerization of cellulose. J Am Chem Soc 135:11728–11731

Heilmann SM, Jader LR, Sadowsky MJ, Schendel FJ, von Keitz MG, Valentas KJ (2011) Hydrothermal carbonization of distiller’s grains. Biomass Bioenergy 35:2526–2533

Jamari SS, Howse JR (2012) The effect of the hydrothermal carbonization process on palm oil empty fruit bunch. Biomass Bioenergy 47:82–90

Maroušek J (2013) Two-fraction anaerobic fermentation of grass waste. J Sci Food Agric 93:2410–2414

Maroušek J (2014a) Economically oriented process optimization in waste management. Environ Sci Pollut Res 21:7400–7402

Maroušek J (2014b) Significant breakthrough in biochar cost reduction. Clean Technol Environ Policy 16:1821–1825. doi:10.1007/s10098-014-0730-y

Maroušek J, Hašková S, Zeman R, Váchal J, Vaníčková R (2014a) Processing of residues from biogas plants for energy purposes. Clean Technol Environ Policy 17:797–801

Maroušek J, Zeman R, Vaníčková R, Hašková S (2014b) New concept of urban green management. Clean Technol Environ Policy 16:1835–1838

Nethaji S, Sivasamy A (2014) Removal of hexavalent chromium from aqueous solution using activated carbon prepared from walnut shell biomass through alkali impregnation processes. Clean Technol Environ Policy 16:361–368. doi:10.1007/s10098-013-0619-1

Parshetti GK, Kent Hoekman S, Balasubramanian R (2013) Chemical, structural and combustion characteristics of carbonaceous products obtained by hydrothermal carbonization of palm empty fruit bunches. Bioresour Technol 135:683–689

Peterson AA, Vogel F, Lachance RP, Fröling M, Antal MJ Jr, Tester JW (2008) Thermochemical biofuel production in hydrothermal media: a review of sub-and supercritical water technologies. Energy Environ Sci 1:32–65

Ryu J, Suh Y-W, Suh DJ, Ahn DJ (2010) Hydrothermal preparation of carbon microspheres from mono-saccharides and phenolic compounds. Carbon 48:1990–1998

Sevilla M, Fuertes AB (2009a) Chemical and structural properties of carbonaceous products obtained by hydrothermal carbonization of saccharides. Chem-A Eur J 15:4195–4203

Sevilla M, Fuertes AB (2009b) The production of carbon materials by hydrothermal carbonization of cellulose. Carbon 47:2281–2289

Stemann J, Putschew A, Ziegler F (2013) Hydrothermal carbonization: process water characterization and effects of water recirculation. Bioresour Technol 143:139–146

Tay T, Ucar S, Karagöz S (2009) Preparation and characterization of activated carbon from waste biomass. J Hazard Mater 165:481–485

Tekin K (2015) Hydrothermal conversion of russian olive seeds into crude bio-oil using CaO catalyst derived from waste mussel shells. Energy Fuels. doi:10.1021/acs.energyfuels.5b00724

Tekin K, Akalın MK, Bektaş S, Karagöz S (2013a) Hydrothermal wood processing using borax decahydrate and sodium borohydride. J Anal Appl Pyrol 104:68–72

Tekin K, Karagöz S, Bektaş S (2013b) Effect of sodium perborate monohydrate concentrations on product distributions from the hydrothermal liquefaction of scotch pine wood. Fuel Process Technol 110:17–23

Tekin K, Karagöz S, Bektaş S (2014) A review of hydrothermal biomass processing. Renew Sustain Energy Rev 40:673–687

Titirici M-M (2012) Hydrothermal carbons: synthesis, characterization, and applications. In: novel carbon adsorbents. Elsevier, Amsterdam

Titirici MM, Thomas A, Yu S-H, Müller J-O, Antonietti M (2007) A direct synthesis of mesoporous carbons with bicontinuous pore morphology from crude plant material by hydrothermal carbonization. Chem Mater 19:4205–4212

Titirici M-M, White RJ, Falco C, Sevilla M (2012) Black perspectives for a green future: hydrothermal carbons for environment protection and energy storage. Energy Environ Sci 5:6796–6822

Venkatesan G, Senthilnathan U, Rajam S (2014) Cadmium removal from aqueous solutions using hybrid eucalyptus wood based activated carbon: adsorption batch studies. Clean Technol Environ Policy 16:195–200. doi:10.1007/s10098-013-0628-0

Zengin A, Akalin MK, Tekin K, Erdem M, Tay T, Karagoz S (2012) Preparation and characterization of activated carbons from waste melamine coated chipboard by NaOH activation. Ekoloji 21:123–128

Acknowledgments

We acknowledge Prof. Magdalena Titirici for her valuable suggestions. We thank Dr. K. Vasanth Kumar for the discussions during the revision of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tekin, K., Pileidis, F.D., Akalin, M.K. et al. Cellulose-derived carbon spheres produced under supercritical ethanol conditions. Clean Techn Environ Policy 18, 331–338 (2016). https://doi.org/10.1007/s10098-015-1014-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-015-1014-x