Abstract

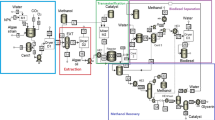

Biodiesel is a notable alternative to the widely used petroleum-derived diesel fuel since it can be generated by domestic natural sources such as soybeans, rapeseeds, coconuts, and even recycled cooking oil, and thus reduces dependence on diminishing petroleum fuel from foreign sources. The advantages of biodiesel as diesel fuel are its portability, ready availability, renewability, higher combustion efficiency, lower sulfur and aromatic content, higher cetane number, and higher biodegradability. The main disadvantages of biodiesel as diesel fuel are its higher viscosity, lower energy content, higher cloud point and pour point, higher nitrogen oxide emission, lower engine speed and power, injector coking, engine compatibility, high price, and higher engine wear. Therefore, biodiesel production is confronted with two main tasks: cost reduction and ecological restrictions. Also, beside these objectives, the social involvements of biodiesel production and use must not be neglected. The best decisions regarding all these aspects imply solving optimization problems. Biodiesel is defined as a mixture of fatty acid alkyl esters which are commonly produced from triglycerides and alcohol through trans-esterification reaction in the presence of alkali catalysts. In this work, canola oil and methanol were used in this research as the feedstocks, and potassium hydroxide and potassium methoxide were used as different formulations of catalysts. A laboratory-scale continuous-flow reactive distillation column system was simulated at optimum conditions by Aspen HYSYS Software. The homogeneous alkali and acid catalyzed were applied to the system. The non-catalytic reaction, where the absence of catalyst simplifies the purification procedures and the products can be easily separated. The critical operating conditions and high consumption of methanol and energy make it uneconomical. Based on the optimization of energy integration and methanol recovery strategies, optimization strategies were assessed for saving energy and recovery methanol.

Similar content being viewed by others

Abbreviations

- a :

-

Activity

- k :

-

Rate constant (mol s−1)

- \(K_{\text{a}}\) :

-

Chemical equilibrium constant

- K sorp :

-

Equilibrium sorption constants

- m :

-

Mass (g)

- n :

-

Mole value of an any component (mole)

- Q :

-

Heat duty (kW)

- r :

-

Reaction rate (gmol L−1s−1)

- R :

-

Gas law constant (J mol−1 K−1)

- t :

-

Time (s)

- T :

-

Temperature (K)

- V :

-

Volume (L)

- x :

-

Liquid phase mole fraction

References

Aspen (2003) HYSYS 3.2 installation guide. USA: Aspen Technology

Cetinkaya M, Karaosmanoglu F (2004) Optimization of base-catalyzed transesterification reaction of used cooking oil. Energy & Fuels 18(6):1888–1895. doi:10.1021/ef049891c

Csikos R, Laky J, Peterfy L (1980) Production of methyl tert-butyl ether from the c-4 fraction of gasoline pyrolysis. Chem Ing Techol 52:594–595. doi:10.1002/cite.330520712

Fletcher R, Reeves CM (1964) Function minimization by conjugate gradients. Comput J 7:149–154

Ghadge SV, Raheman (2006) Process optimization for biodiesel production from mahua (Madhuca indica) oil using response surface methodology. Bioresour Technol 97(3):379–384. doi:10.1016/j.biortech.2005.03.014

Hennig P and Kiefel M (2012) Quasi-Newton methods: a new direction, Proceedings of the 29th International Conference on Machine Learning, Edinburgh, Scotland, UK

Hofman V, Wiesenborn D, Rosendahl M (2006) Biodiesel use in engines NDSU, USA, Accessed 10 April 2014

Ignat RM, Kiss AA (2013) Optimal design, dynamics and control of a reactive DWC for biodiesel production. Chem Eng Res Des 91:1760–1767. doi:10.1016/j.cherd.2013.02.009

Kiss AA (2013a) Novel applications of dividing-wall column technology to biofuel production processes. J Chem Technol Biotechnol 88:1387–1404. doi:10.1002/jctb.4108

Kiss AA (2013b) Advanced distillation technologies—design, control and applications. John Wiley & Sons, West Sussex

Kiss AA, Bildea CS (2012) A review of biodiesel production by integrated reactive separation technologies. J Chem Technol Biotechnol 87:861–879. doi:10.1002/jctb.3785

Kralj AK (2008) Heat integration between two biodiesel processes using a simple method. Energy Fuels 22(3):1972–1979. doi:10.1021/ef700710y

Liew WH, Hassim MH, Ng Denny KS (2014) Sustainability assessment for biodiesel production via fuzzy optimisation during research and development (R&D) stage. Clean Technol Environ Policy 16:1431–1444. doi:10.1007/s10098-014-0763-2

Lim S, Teong LK (2010) Recent trends, opportunities and challenges of biodiesel in Malaysia: an overview. Renew Sustain Energy Rev 14:938–954. doi:10.1016/j.rser.2009.10.027

Lujan JM, Tormos B, Salvador FJ, Gargar K (2009) Comparative analysis of a DI diesel engine fuelled with biodiesel blends during the European MVEG-A cycle: preliminary study (I). Biomass Bioenergy 33(6–7):941–947. doi:10.1016/j.biombioe.2009.02.004

Marousek J, Itoh S, Higa O, Kondo Y et al (2012) The use of underwater high-voltage discharges to improve the efficiency of Jatropha curcas L. biodiesel production. Biotechnol Appl Biochem 59:451–456. doi:10.1002/bab.1045

Marousek J, Itoh S, Higa O, Kondo Y, Ueno M et al (2013) Enzymatic hydrolysis enhanced by pressure shockwaves opening new possibilities in Jatropha curcas L. processing. J Chem Technol Biotechnol 88:1650–1653. doi:10.1002/jctb.4014

Martins MI, Pires RF, Alves MJ, Horib CE, Reis MHM, Cardoso VL (2013) Transesterification of soybean oil for biodiesel production using hydrotalcite as basic catalyst. Chem Eng Trans 32:817–822. doi:10.3303/CET1332137

Mazidi SK, Sadeghi MT, Marvast MA (2013) Optimization of Fischer–Tropsch process in a fixed-bed reactor using non-uniform catalysts. Chem Eng Technol 36:62–72. doi:10.1002/ceat.201200268

Mokhtarani B, Musavi J, Parvini M, Mafi M, Sharifi A, Mirzaei M (2013) Ternary (liquid–liquid) equilibria of nitrate based ionic liquid plus alkane plus benzene at 298.15 K: experiments and correlation. Fluid Phase Equilib 341:35–41. doi:10.1016/j.Fluid.12.025

Noshadi I, Amina NAS, Parnas RS (2012) Continuous production of biodiesel from waste cooking oil in a reactive distillation column catalyzed by solid heteropoly acid: optimization using response surface methodology (RSM). Fuel 94:156–164. doi:10.1016/j.fuel.2011.10.018

Piemonte V, Paola LD, Gentile A, Masciocchi B, Russo V, Iaquaniello G (2014) Biodiesel production from microalgae: ionic liquid process simulation. Chem Eng Trans 39:379–384. doi:10.3303/CET1439064

Pirola C, Manenti F, Galli F, Bianchi CL, Boffito DC, Corbetta M (2014) Heterogeneously catalyzed free fatty acids esterification in (monophasic liquid)/solid packed bed reactors (PBR). Chem Eng Trans 37:553–558. doi:10.3303/CET1437093

Pöpken T, Götze L, Gmehling J (2000) Reaction kinetics and chemical equilibrium of homogeneously and heterogeneously catalyzed acetic acid esterification with methanol and methyl acetate hydrolysis. Ind Eng Chem Res 39:2601–2611. doi:10.1021/ie000063q

Rehfinger A, Hoffmann U (1990) Kinetics of methyl tertiary butyl ether liquid-phase synthesis catalyzed by ion exchange resin I. Intrinsic rate expression in liquid-phase activities. Chem Eng Sci 45:1605–1617. doi:10.1016/0009-2509(90)80013-5

Rossi CRS, Cardozo-Filho L, Guirardello R (2012) Parameter estimation and thermodynamic model fitting for components in mixtures for bio-diesel production. Clean Technol Environ Policy 14:435–442. doi:10.1007/s10098-012-0463-8

Schimizu S, Hirai C (1986) Kinetic study of liquid-phase esterification with sulfonic acid cation-exchange resin of the macroreticular Type I. Heterogeneous-pseudohomogeneous resin catalysts. Bull Chem Soc Jpn 59:7–11. doi:10.1246/bcsj.59.7

Shieh CJ, Liao HF, Lee CC (2003) Optimization of lipase-catalyzed biodiesel by response surface methodology. Bioresour Technol 88(2):103–106. doi:10.1016/S0960-8524(02)00292-4

Steinigeweg S, Gmehling J (2003) Esterification of a fatty acid by reactive distillation. Ind Eng Chem Res 42:3612–3619. doi:10.1021/ie020925i

Tiwari AK, Kumar A, Raheman H (2007) Biodiesel production from jatropha oil (Jatropha curcas) with high free fatty acids: an optimized process. Biomass Bioenergy 31(8):569–575. doi:10.1016/j.biombioe.2007.03.003

Wang WG, Lyons DW, Clark NN, Gautam M, Norton PM (2000) Emissions from nine heavy trucks fueled by diesel and biodiesel blend without engine modification. Environ Sci Technol 34(6):933–939. doi:10.1021/es981329b

Xuan W, Leung DY (2011) Optimization of biodiesel production from camelina oil using orthogonal experiment. Appl Energy 88:3615–3624. doi:10.1016/j.apenergy.2011.04.041

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Karacan, S., Karacan, F. Steady-state optimization for biodiesel production in a reactive distillation column. Clean Techn Environ Policy 17, 1207–1215 (2015). https://doi.org/10.1007/s10098-015-0964-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-015-0964-3