Abstract

The effect of potassium on carbon adsorption and deposition on the Co(0001) surface was studied on the basis of theoretical calculations. Thermodynamically, the surface Cn species is expected, and C2 dimer may be a critical elementary unit. With the increase of carbon coverage, a fraction of the carbon atoms may diffuse into the subsurface. But kinetically, the formation of Cn species is more favorable, and there is no driving force for carbon to migrate into the subsurface. As the surface carbon concentration increases, the adsorbed carbon atoms turn into carbon chains and then into graphene sheets parallel to the surface. Potassium promoter has little effect on the most stable adsorption configurations of carbon atoms but increases the adsorption energy of carbon species, which can be explained by the decreasing of the surface work function resulting from the electron effect of potassium promoter. The potassium promotes carbon deposition and carbonization of the cobalt surface to a certain extent. These results could support some useful information for the carbon deposition and cobalt carbide formation.

Similar content being viewed by others

Introduction

As a widely used promoter, alkali metal promoters have important effects on species adsorption, catalytic activity, phase change, and product distribution in Fischer-Tropsch synthesis (FTS) [1]. Studies have shown that a cobalt-based catalyst in a moderate amount of added alkali additives can reduce the intensity of surface acidity and increase the CO adsorption, but little impact on the absorption ability of the H2, so that leads to increased 1-olefin selectivity, product of olefin/paraffin ratio increased, at the same time increased the selectivity of long-chain hydrocarbons and CO2, but add too much promoter will reduce its catalytic activity [2,3,4,5]. Recently, Li et al. [6] found that without adding Na, the activity phase of cobalt-based catalyst in FTS is the Fcc-cobalt phase, when adding Na and gradually increase the concentration of Na, the Fcc-cobalt phase transfers into nanometer Co2C phase prism structure, namely Na added to promote the formation of Co2C phase, and found that nano prism Co2C phase at 250 °C still exists, namely Na promoter increased Co2C phase stability.

It can be seen that the addition of alkali metal promoters plays a key role in the regulation of active components and the carbonization of the cobalt metal phase and products of cobalt-based catalysts. How do the alkali metal promoters affect the catalyst properties and the surface reaction? Owing to the difficulty indirect observation of the structural changes and the complexity of the catalytic systems, the working mechanisms of potassium promoter in many heterogeneous catalysts remain controversial. In view of this problem, researchers put forward a variety of different explanations. In order to study the effect of alkali promotion, co-adsorption systems involving alkali atoms have been extensively used in experiment and theory. The generally accepted mechanisms of alkali metal promoter are enhanced surface electronic polarizability [7, 8], substrate-mediated electron transfer [9], as well as direct bonding between alkali and adsorbates [10, 11].

In the present work, the effect of K promoter on carbonization of cobalt surface would be studied. Numerous studies for carbonization of cobalt surface have been reported. Theoretical studies [12,13,14,15,16,17] have shown that on the cobalt surface isolated carbon is easily polymerized, and a more stable graphene structure is formed with the increasing of carbon coverage. Kong et al. [17] showed that carbon diffuse to the step position easily of forming p4g surface carbide and is superior to the growth of small graphene island. Saib et al. [12] found that in the FTS, carbon oligomers are easily formed. These oligomers are the precursors to polymeric carbon and graphene. Ramírez-caballero et al. [15] found that with the surface carbon concentration increases, the adsorbed carbon on the cobalt surface transforms into carbon chains, which then turn into graphene sheets parallel to the surface. For carbon on the cobalt surface, it tends to participate in the reconstruction or form polymeric carbon, Corral et al. [16] found that at low Anderson-Schulz-Flory distribution (ASF) coefficient, the Co(111) surface undergoes a strong reconstruction associated with the insertion of C in subsurface sites, and at high ASF coefficient, the Co(111) surface is covered by oligomeric C species which may be seen as either long-chain alkane or graphene precursors.

For the study of carbon deposition on cobalt surface, Tan et al. [17] found the surface carbide phase and polyaromatic carbon phase in the catalyst after the reaction using XPS and HRTEM. Using situ magnetometer and X-ray diffraction (XRD), Claeys et al. [18] investigated the formation and stability of cobalt carbide in the FTS process and they confirmed the formation of cobalt carbide; however, the effect of the amount of cobalt carbonized on the deactivation of the actual FTS condition can be ignored. Ehrensperger et al. [19] found that the change of morphology of Co-based catalysts in the FTS process has little effect on the reaction. Dong et al. [20] found that their catalytic performance strongly depended on the ratio of Co2C to Co by comparing the unsupported (Co-Co2C) and activated carbon-supported (Co-Co2C/AC) catalysts. Then, the density functional theory (DFT) calculation showed that the interface between Co and Co2C plays an important role in the reaction. Cobalt is used for olefin adsorption and activation to form surface carbon-bearing species, while Co2C is used for CO molecule adsorption, activation, and insertion. Through experimental characterization and theoretical calculation, Zhong et al. [21] found that the preferentially exposed crystal planes promoted olefin formation and inhibited methane formation in the process of syngas conversion, which made cobalt carbide nanoparticles become a new catalyst system for direct converting syngas into lower olefins.

To gain systematic insight into the effect of K promoter on carbonization of cobalt surface, we chose the most stable Hexagonal Close Packing (Hcp) Co(0001) surfaces to study [22]. Firstly, we calculated the adsorption of carbon atoms under different coverages to analyze the distribution of carbon atoms on the cobalt surfaces. Then, the barriers of C atoms from the most stable adsorption sites to other sites and the carbon atoms coupling reactions were calculated. Meanwhile, the effect of alkali promoter on the carbon adsorption and the microdynamics behavior of carbon atoms were considered. These results could support some useful information for the carbon deposition and cobalt carbide formation.

Computational methods and model

All calculations were done using the DFT method implemented in the Vienna ab initio simulation package (VASP) [23, 24]. The electron exchange-correlation energy was treated within the generalized gradient approximation in the Revise Perdew–Burke–Ernzerhof form (GGA-RPBE) [25]. The electron-ionic interaction was presented by the project-augmented-wave (PAW) method [26]. An energy cut-off of 400 eV and a second-order Methfessel-Paxton [27] electron smearing with σ = 0.05 eV were used to ensure accurate energies with errors due to smearing of less than 1 meV per unit cell. The convergence criterion for the electronic self-consistent iteration and force was set to 10−4 eV and 0.02 eV/Å, respectively. The nudged elastic band (NEB) method was used to examine the energy profiles along the selected diffusion pathways.

For the Hcp–Co(0001) surface, the reciprocal space is sampled with 15 × 15 × 15 k-point grid generated automatically using the Monkhorst-Pack method [28]. The optimized lattice constants (a = b = 2.507 Å and c = 4.069 Å) agree well with the experimental (a = b = 2.507 Å, c = 4.061 Å [29]) and computed (a = b = 2.56 Å, c = 4.14 Å [30]; a = b = 2.507 Å, c = 4.069 Å [31]) values.

We used a five-layer slab to model the Co(0001) surface; where the top three layers were relaxed, and the bottom two layers were kept in their bulk sites within (2 × 2) unit cell. The spacing between the periodically repeated slabs was 10 Å. We used k-meshes of 3 × 3 × 1. The coverage (θC) is defined as the number of the adsorbates over the number of the first layer Co atoms.

As shown in Fig. 1, we considered all the high symmetry adsorption sites on the Co(0001) surface, the top (t) site, the bridge (b) site, the shallow hole (sh) site, the deep hole (dh) site, and the hexahedral vacancy (S) site in the subsurface. The adsorption of carbon on the Co surface is indicated by the symbol F, including coupled adsorption (Fn) and dispersed adsorption (nF).

Carbon adsorption energy (Eads) on-surface and into subsurface for different coverages was defined as equation (1), where n is the number of adsorbed C atoms per unit cell, Eslab + nC is total energy of the slab with adsorbed C atoms in its equilibrium geometry, Eslab is the energy of the clean slab, and EC is the energy of the free carbon atom, respectively. The free C atom was calculated in a (15 × 15 × 15) cell under the consideration of spin-polarization. Thus, Eads is referenced to isolated C atoms in the gas phase and a pure Co slab; the more negative the Eads, the stronger the adsorption. The average adsorption energy of per carbon atom is defined as Eads(C) = Eads/n and used for direct comparison.

The transformation barrier (Ea) and reaction energy (Er) for the diffusion of carbon atom on the surface and into subsurface are calculated according to equations (2) and (3), where EIS, ETS, and EFS are the energies of the corresponding initial state (IS), transition state (TS), and the final state (FS), respectively.

For studying the factors governing the stability of the Cn configurations, the energies of each part in the calculated system were considered.

Results and discussion

Adsorption of carbon atoms

To gain insight into the location and distribution of the carbon atoms at different coverage on the surface and the subsurface, we considered a large number of systems with the carbon coverage from 0.25 to 1 ML on the (2 × 2) unit cell. Energy diagram for the consideration different distributions of carbon atoms and Cn species are shown in Fig. 2. In view of the migration, the carbon atoms adsorbed on the surface may interact with each other, so we calculated C-C coupling and the growing of Cn clusters, as well as the migration into the subsurface.

At first, we computed the adsorption of the surface species on the Co(0001) surface. We considered all the possible adsorption sites. Table 1 summarize the adsorption energies as well as the structure parameters of single carbon atom (θ = 0.25 ML) in the different adsorption site. The adsorption structures and energies as well as the structure parameters for high coverage carbon adsorption (θ = 0.50, 0.75, and 1.0 ML, respectively) are shown in the supporting information. The considered adsorption structures under different carbon coverage are also shown in the supporting information.

On the Co(0001) surface, the most stable adsorption site of one carbon atom can be initially considered as the sh site (− 6.38 eV), which is similar as reported in the references as shown in Table 1. Adsorption at dh site (− 6.21 eV) is 0.17 eV higher than that at the sh site. For carbon absorbed at the S site (− 6.22 eV) in the subsurface, it is 0.16 eV higher than that at the most stable on-surface site. Then, during the optimization process, the carbon which initially sites at the bridge site will move to the sh site, and the carbon which initially sites at the top site will move to the dh site.

At 0.50 ML, the most stable configuration is the C2 species. The substable configuration is one carbon on-surface with one carbon diffuse into the subsurface, which is endothermic by 0.48 eV relative to the C2 species, and the configurations for separate adsorption of carbon atoms on the surface or on the subsurface is endothermic by 1.00 and 1.08 eV, respectively, which is also not favored energetically.

At 0.75 ML, as shown in Fig. 2, the configuration of C3 trimer and the configuration with C2 species and one carbon diffuse into subsurface have the same adsorption energy (− 20.07 eV), so the formation of Cn species and the configuration with C2 dimer and one carbon diffuse into subsurface are competitive. And other considered configurations are less stable energetically. These results indicated that a fraction of the carbon atoms may diffuse into the subsurface when the carbon coverage above 0.50 ML. In addition, the configuration with C2 species and one carbon diffuse into subsurface has been partially deformed (Figure S1). There is a significant increase in the distance between cobalt atoms.

At 1.00 ML, the configuration with C2 dimer and two subsurface carbon atoms are most stable energetically. The configurations of C3 species with one carbon in the subsurface and the configuration of C4 species have similar energies (− 26.78 vs. − 26.82 eV), but these are not favored energetically relative to the most stable one. And other considered configurations are not favored energetically.

These results indicated that the C2 dimer formation is preferred on the surface and a fraction of the carbon atoms diffuses into the subsurface with the increasing of the carbon coverage; however, it can be seen from Figure S1 that the most stable configuration has been reconstructed.

To better understand the variation of carbon adsorption stability between different coverage levels, a summary of some stable adsorption structures for each coverage gives a detailed thermodynamic distribution of C on the surface and subsurface within the range of 0.25 ≤ θc ≤ 1.00 ML (Fig. 2). At low coverage, the adsorption both on the surface and subsurface are possible. At 0.50 ML, the most stable configuration is the C2 dimer. With the C coverage is up to 0.75 ML, the formation of Cn species and the configuration with C2 dimer and one carbon in subsurface are competitive. At 1.00 ML, the most stable configuration has C2 dimer and two subsurface carbon atoms. These discussions indicated that, thermodynamically, at low C coverage the surface Cn species is expected, and C2 dimer maybe a critical elementary unit, while at high C coverage, a fraction of the carbon atoms may diffuse into the subsurface on the Co(0001) surface.

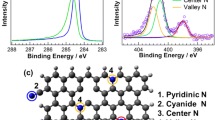

In order to understand whether carbon atoms tend to chain or ring polymerization, we used the four-layer p(5*5) lattice model to relax the two layers above and fix the two layers below (Figs. 3 and 4). The coverage was less than 0.75 ML. For the six carbon atoms, the most stable adsorption configuration was the single chain form (− 6.78 eV), and the average adsorption energy was 0.18 eV lower than that of the circular configuration (− 6.60 eV). With the carbon coverage increasing, the adsorption energy of chain configuration does not change obviously, while that of ring form increases obviously. As shown in Fig. 3, the adsorption stability of the chain cluster is stronger than that of the ring form, and the energy gap between the chain cluster and the ring form decreases gradually with the increasing of carbon coverage. Thus, as the surface carbon concentration increases, the carbon adsorbed on the cobalt surface turns into carbon chains and then into graphene sheets parallel to the surface. It is also considered a precursor to long-chain alkanes or graphene.

Then, the effect of potassium on carbon adsorption was considered. The stable adsorption configuration after potassium doping was calculated. The energies and the optimized structures for different coverage carbon adsorption are shown in Fig. 5. Figure 6 gives the average adsorption energies of the most stable adsorption configuration before and after doping K promoter at 0.25–1.00 ML. The most stable configurations after doping K promoter are similar as those on the pure surface, while some dispersed adsorbed carbon atoms were coupled to form more compact configurations. For the deformable configurations, the movement of the surface atoms was inhibited. Among them, C2 dimer combined with two subsurface carbon atoms changes significantly. But the presence of potassium increases the adsorption energy under any coverage, that is, the presence of potassium increases the stability of the carbon adsorption.

However, so far these discussions only considered the thermodynamic results, the activation energies for the Cn formation and that of the diffusion into the subsurface must be considered for the overall process.

Kinetics of the formation for Cn species and carbide formation

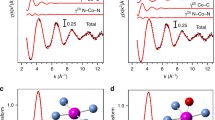

To analyze the micro-kinetic properties of the initial stage of the carbon deposition and carburization, the activation barriers of the carbon transfer and C-C coupling to C2 dimer were calculated. Both the transfer on the surface and transfer into the subsurface were considered at 0.25 and 0.5 ML, respectively. The reaction barriers and reaction energy for the transformation of carbon atom on the Co(0001) surface are shown in Table 2.

At 0.25 ML, in Fig. 7, the energy of C adsorption on the sh site was set as zero. For the transfer of a surface C atom from sh site via the transition state at the bridge site to the less stable dh site has an energy barrier of 0.39 eV and is endothermic by 0.17 eV. While for the vertical transfer into the subsurface, the carbon atom also first migrates to the dh site, then transfers into the subsurface S site. The energy barrier is 1.78 eV and is endothermic by 0.01 eV. The carbon atom transfers are easier on the surface than that transfer into the subsurface.

At 0.50 ML, the energy of 2C was set as zero. For C2 formation, one carbon transfer from dh site to sh site, then form C2 dimer. These two processes are shown in Fig. 8, and they need an energy barrier of 0.75 eV and 0.14 eV, and the reaction energy is 0.54 eV and − 1.54 eV, respectively. While for the transfer of one carbon into the subsurface, the barrier has 2.13 eV and this reaction is exothermic by 0.04 eV. The high barrier indicates that the migration of carbon into the subsurface is not favorable kinetically at 0.50 ML.

Then, the effect of K for the transformation was considered. The similar processes were calculated with the pure surface. The potential energy surfaces are shown in Fig. 7. For the transfer of surface C atom from sh site to dh site has an energy barrier of 0.41 eV and is endothermic by 0.15 eV. In the transition state TS’, the C atom site at the bridge position is similar to on the pure surface. At 0.50 ML, for C2 formation, this reaction also needs two steps, one carbon transferring from dh sit to sh site then forming C2 dimer. They have an energy barrier of 0.75 and 0.14 eV, and the reaction energy is 0.41 eV and − 1.41 eV, respectively. For the transformation into the subsurface, the barrier is up to 1.92 eV, indicating that this reaction is not favorable kinetically. So kinetically, the formation of Cn species is more favorable, and there is no driving force for carbon to migrate from surface to subsurface. All these considered reactions have a slightly lower energy barrier after doping K than those on the pure surface, but this effect is not obvious.

Work function

To further explain the effect of potassium on the adsorption of carbon, we calculated the work function of the most stable adsorption configuration at different coverage before and after the addition of potassium. The work function, which reflects the minimum energy required for a surface to lose electrons, is thought to be directly related to surface reactivity [33]. The smaller the surface function, the easier it is to give away electrons, whereas the larger the surface function, the harder it is to give away electrons.

As shown in Table 3, the surface work function decreases at all the considered coverage after adding potassium. The reduced values are 0.31, 1.92, 1.26, and 1.34 eV, respectively. This result indicates that the electron effect of the potassium promoter makes it easier to give away electrons from the surface, which well explains the enhanced adsorption of surface carbon after adding potassium. The potassium promotes carbon deposition and carbonization of the cobalt surface to a certain extent.

Conclusions

In the present work, we have investigated the adsorption and deposition of carbon atoms on the Co(0001) surface on the basis of density functional theory calculations. The energetic aspects of carbon adsorption and transfer on the surface or into the subsurface have been carried out with the carbon coverage from 0.25 to 1 ML on the (2 × 2) unit cell on the cobalt surfaces.

Thermodynamically, the most stable adsorption position of carbon is the sh site, and the subsurface adsorption has similar adsorption energy. At 0.50 ML, the most stable configuration is C2 dimer. At 0.75 ML, the configuration of C3 trimer and the configuration with C2 species and one carbon in the subsurface have the similar adsorption energy. At 1.00 ML, the most stable configuration has C2 dimer and two subsurface carbon atoms. However, from the kinetic point of view, the carbon transfers easier on the surface than into the subsurface, and the C2 formation is more favored than carbon transfer into the subsurface, at the same time, the carbon transferring from on-surface into the subsurface needs high energy barrier and is endothermic, and there is no driving force for this process. As the surface carbon concentration increases, the adsorbed carbon atoms turn into carbon chains, and then into graphene sheets parallel to the surface. It is also considered a precursor to long-chain alkanes or graphene.

The most stable adsorption configurations of carbon atoms at different coverages after doping K promoters are similar to those on the pure surface. But the presence of potassium on the surface increases the adsorption energy of the adsorbed species under any coverage, that is, the presence of potassium increases the stability of the carbon adsorption configurations. The surface work function decreases results from the electron effect of the potassium promoter. The potassium promotes carbon deposition and carbonization of the cobalt surface to a certain extent. These results could support some useful information for the carbon deposition and cobalt carbide formation.

References

Ribeiro MC, Jacobs G, Davis BH, Cronauer DC, Kropf AJ, Marshall CL (2010) Fischer−Tropsch synthesis: an in-situ TPR-EXAFS/XANES investigation of the influence of Group I alkali promoters on the local atomic and electronic structure of carburized iron/silica catalysts. J Phys Chem C 114:7895–7903

Borg Ø, Hammer N, Enger BC, Myrstad R, Lindvåg OA, Eri S, Skagseth TH, Rytter E (2011) Effect of biomass-derived synthesis gas impurity elements on cobalt Fischer–Tropsch catalyst performance including in situ sulphur and nitrogen addition. J Catal 279:163–173

Chen LA, Song GX, Fu YC, Shen JY (2012) The effects of promoters of K and Zr on the mesoporous carbon supported cobalt catalysts for Fischer–Tropsch synthesis. J Colloid Interface Sci 368:456–461

Xiang YZ, Kruse N (2016) Tuning the catalytic co hydrogenation to straight- and long-chain aldehydes/alcohols and olefins/paraffins. Nat Commun 7:13058–13063

Lillebø AH, Patanou E, Yang J, Blekkan E, Holmen A (2013) The effect of alkali and alkaline earth elements on cobalt based Fischer–Tropsch catalysts. Catal Today 215:60–66

Li ZJ, Zhong LS, Fu F, An YL, Dai YY, Yang YZ, Lin TJ, Li SG, Wang H, Gao P, Sun YH, He MY (2017) Effects of sodium on the catalytic performance of CoMn catalysts for Fischer–Tropsch to olefin reactions. ACS Catal 7:3622–3631

Stolbov S, Rahman TS (2006) Alkali-induced enhancement of surface electronic polarizibility. Phys Rev Lett 96:186801–186,804

Rahman TS, Stolbov S, Mehmood F (2007) Alkali-induced effects on metal substrates and coadsorbed molecules. Appl Phys A Mater Sci Process 87:367–374

Dry ME, Shingles T, Boshoff LJ, Oosthuizen GJ (1969) Heats of chemisorption on promoted iron surfaces and the role of alkali in Fischer-Tropsch synthesis. J Catal 15:190–199

Liu ZP, Hu P (2001) Liu Z P, Hu P. An insight into alkali promotion: a density functional theory study of CO dissociation on K/Rh (111). J Am Chem Soc 123:12596–12,604

Politano A, Agostino RG, Formoso V, Chiarello G (2008) Short-range interactions in Na coadsorption with CO and O on Ni (111). Chem Phys Chem 9:1189–1194

Saib A, Moodley D, Ciobîcă I, Hauman M, Sigwebela B, Weststrate C, Niemantsverdriet J, Van de Loosdrecht J (2010) Fundamental understanding of deactivation and regeneration of cobalt Fischer–Tropsch synthesis catalysts. Catal Today 154:271–282

Swart JC, Ciobîcă IM, van Santen RA, van Steen E (2008) Intermediates in the formation of graphitic carbon on a flat FCC-Co (111) surface. J Phys Chem C 112:12899

Swart JCW, van Steen E, Ciobícă IM, van Santen RA (2009) Interaction of graphene with FCC–Co (111). Phys Chem Chem Phys 11:803

Ramírez-Caballero GE, Burgos JC, Balbuena PB (2009) Growth of carbon structures on stepped (211) Co surfaces. J Phys Chem C 113:15658

Valero MC, Raybaud P (2014) Stability of carbon on cobalt surfaces in Fischer–Tropsch reaction conditions: a DFT study. J Phys Chem C 118:22479

Tan KF, Xu J, Chang J, Borgna A, Saeys M (2010) Carbon deposition on Co catalysts during Fischer–Tropsch synthesis: a computational and experimental study. J Catal 274:121

Claeys M, Dry E, Van Steen ME, Du Plessis E, Van Berge PJ, Saib AM, Moodley DJ (2014) In situ magnetometer study on the formation and stability of cobalt carbide in Fischer–Tropsch synthesis. J Catal 318:193

Ehrensperger M, Wintterlin J (2014) In situ high-pressure high-temperature scanning tunneling microscopy of a Co (0 0 0 1) Fischer–Tropsch model catalyst. J Catal 319:274

Dong W, Liu J, Zhu H, Ding Y, Pei Y, Liu J, Du H, Jiang M, Liu T, Su H, Li W (2014) Co–Co2C and Co–Co2C/AC catalysts for hydroformylation of 1-hexene under low pressure: experimental and theoretical studies. J Phys Chem C 118:19114

Zhong L, Yu F, An Y, Zhao Y, Sun Y, Li Z, Lin T, Lin Y, Qi X, Dai Y, Hu J, Jin S, Shen Q, Wang H, Gu L (2016) Cobalt carbide nanoprisms for direct production of lower olefins from syngas. Nature 538:84

Liu JX, Su HY, Sun DP, Zhang BY, Li WX (2013) Crystallographic dependence of CO activation on cobalt catalysts: HCP versus FCC. J Am Chem Soc 135:16284–16,287

Kresse G, Furthmüller J (1996) Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput Mater Sci 6:15

Kresse G, Furthmüller J (1996) Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys Rev B 54:11169

Vanderbilt D (1990) Soft self-consistent pseudopotentials in a generalized eigenvalue formalism. Phys Rev B 41:7892

Blöchl PE (1994) Projector augmented-wave method. Phys Rev B 50:17953

Methfessel MPAT, Paxton AT (1989) High-precision sampling for Brillouin-zone integration in metals. Phys Rev B 40:3616

Monkhorst HJ, Pack JD (1976) Special points for Brillouin-zone integrations. Phys Rev B 13:5188

Lide DR, Kehiaian HV (1994) CRC handbook of thermophysical and thermochemical data[M]. Crc Press

Cheng J, Gong XQ, Hu P, Lok CM, Ellis P, French S (2008) A quantitative determination of reaction mechanisms from density functional theory calculations: Fischer–Tropsch synthesis on flat and stepped cobalt surfaces. J Catal 254:285

Liu SL, Li YW, Wang J, Jiao H (2016) Mechanisms of H2O and CO2 formation from surface oxygen reduction on Co(0001). J Phys Chem C 120:19265–19,270

Burghgraef H, Jansen APJ, Van Santen RA (1995) Methane activation and dehydrogenation on nickel and cobalt: a computational study. Surf Sci 324:345–356

Vayenas CG, Bebelis S, Ladas S (1990) Dependence of catalytic rates on catalyst work function. Nature 343:625–627

Funding

This work was supported by the National Natural Science Foundation of China (No. 21803052), and Natural Science Foundation of Shandong province (No. ZR2018LB017). The grants are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary materials

ESM 1

Average adsorption energies of the most stable adsorption configurations before and after doping K (Table S1 and S2); Structures of the considered carbon adsorption at different coverage as well as the average adsorption energies (eV/C) on the Co(0001) surface (Figure S1); The geometries and relative energy of the initial state and the final state as well as the transition state for carbon atom transfer from the most stable site to other sites (Figure S2, S3); Chain and ring structures with different carbon atom number as well as the average adsorption energies (eV/C) in the presence of potassium (Figure S4). (DOCX 2516 kb).

Rights and permissions

About this article

Cite this article

Zhang, Z., Liu, S., Hou, X. et al. Effect of potassium on carbon adsorption on the Co(0001) surface. J Mol Model 26, 134 (2020). https://doi.org/10.1007/s00894-020-04390-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00894-020-04390-9