Abstract

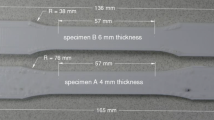

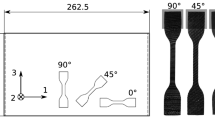

This work presents an experimental and mechanical study on the tensile response of 3D-printed thermoplastic polyurethane membranes, to be used as stretchable members of novel seismic isolators. The examined specimens have been 3D-printed by fused deposition modeling at the Rapid Prototyping Laboratory of the University of Salerno. Cyclic tests performed at different strain rates are employed to characterize the mechanical response of such members and the dependence of preconditioning effects on the recovery time and the initial pretension of the specimens. The presented results show a marked hysteretic response, the fast recovery of residual strains with time, and an appreciable increase of the tangent tensile modulus along the loading phase of the stress–strain curve with growing values of the applied strain rate.

Similar content being viewed by others

References

Kasmi, S., Ginoux, G., Labbé, E., Alix, S.: Multi-physics properties of thermoplastic polyurethane at various fused filament fabrication parameters. Rapid Prototyp. J. 28(5), 895–906 (2022)

Ali, M.M., Maddipatla, D., Narakathu, B.B., Chlaihawi, A.A., Emamian, S., Janabi, F., Bazuin, B.J., Atashbar, M.Z.: Printed strain sensor based on silver nanowire/silver flake composite on flexible and stretchable TPU substrate. Sens. Actuators, A 274, 109–115 (2018)

Kim, K., Park, J., Suh, J.H., Kim, M., Jeong, Y., Park, I.: 3D printing of multiaxial force sensors using carbon nanotube (CNT)/thermoplastic polyurethane (TPU) filaments. Sens. Actuators, A 263, 493–500 (2017)

Joshi, M., Adak, B., Butola, B.S.: Polyurethane nanocomposite based gas barrier films, membranes and coatings: a review on synthesis, characterization and potential applications. Prog. Mater Sci. 97, 230–282 (2018)

Pokharel, P., Pant, B., Pokhrel, K., Pant, H.R., Lim, J.G., Kim, H.Y., Choi, S.: Effects of functional groups on the graphene sheet for improving the thermomechanical properties of polyurethane nanocomposites. Compos. B Eng. 78, 192–201 (2015)

Jalaly, S., Vahdani, M., Shahabadi, M., Sadeghi, G.M.M.: Design, fabrication, and measurement of a polymer-based anti-reflection coating for improved performance of a solar panel under a specific incident angle. Sol. Energy Mater. Sol. Cells 189, 175–180 (2019)

Bao, J.J., Zou, B.K., Cheng, Q., Huang, Y.P., Wu, F., Xu, G.W., Chen, C.H.: Flexible and free-standing LiFePO4/TPU/SP cathode membrane prepared via phase separation process for lithium ion batteries. J. Membr. Sci. 541, 633–640 (2017)

Li, H., Oh, J.S., Sinha, T.K., Kim, J.K.: Synergistic influence of Keratin and TPU: An approach towards bioinspired artificial skin. Mater. Chem. Phys. 223, 196–201 (2019)

Bek, M., Betjes, J., von Bernstorff, B.S., Emri, I.: Viscoelasticity of new generation thermoplastic polyurethane vibration isolators. Phys. Fluids 29(12), 121614 (2017)

Drobny, J.G.: Handbook of Thermoplastic Elastomers. Elsevier, Norwich (2007)

Szycher, H.: Biostability of polyurethane elastomers: a critical review. J. Biomater. Appl. 3(2), 297–402 (1988)

Aurilia, M., Piscitelli, F., Sorrentino, L., Lavorgna, M., Iannace, S.: Detailed analysis of dynamic mechanical properties of TPU nanocomposite: The role of the interfaces. Eur. Polymer J. 47(5), 925–936 (2011)

Barick, A.K., Tripathy, D.K.: Thermal and dynamic mechanical characterization of thermoplastic polyurethane/organoclay nanocomposites prepared by melt compounding. Mater. Sci. Eng., A 527(3), 812–823 (2010)

Dan, C.H., Kim, Y.D., Lee, M., Min, B.H., Kim, J.H.: Effect of solvent on the properties of thermoplastic polyurethane/clay nanocomposites prepared by solution mixing. J. Appl. Polym. Sci. 108(4), 2128–2138 (2008)

Stan, F., Nicoleta-Violeta, S., Adriana-Madalina, C., Catalin, F.: 3D Printing of Flexible and Stretchable Parts Using Multiwall Carbon Nanotube/Polyester-Based Thermoplastic Polyurethane. Journal of Manufacturing Science and Engineering 143(5), (2021)

Liu, L.C., Liang, W.C., Chen, C.M.: Manufacture of recyclable thermoplastic polyurethane (TPU)/Silicone blends and their mechanical properties. Manufact. Lett. 31, 1–5 (2022)

Qi, H.J., Boyce, M.C.: Stress-strain behavior of thermoplastic polyurethanes. Mech. Mater. 37(8), 817–839 (2005)

Sain, T., Meaud, J., Yeom, B., Waas, A.M., Arruda, E.M.: Rate dependent finite strain constitutive modeling of polyurethane and polyurethane-clay nanocomposites. Int. J. Solids Struct. 54, 147–155 (2015)

Sui, T., Salvati, E., Ying, S., Sun, G., Dolbnya, I.P., Dragnevski, K., Prisacariu, C., Korsunsky, A.M.: Strain softening of nano-scale fuzzy interfaces causes Mullins effect in thermoplastic polyurethane. Sci. Rep. 7(1), 1–9 (2017)

Chen, H., Trivedi, A.R., Siviour, C.R.: Application of linear viscoelastic continuum damage theory to the low and high strain rate response of thermoplastic polyurethane. Exp. Mech. 60(7), 925–936 (2020)

Kim, K., Park, J., Suh, J.H., Kim, M., Jeong, Y., Park, I.: 3D printing of multiaxial force sensors using carbon nanotube (CNT)/thermoplastic polyurethane (TPU) filaments. Sens. Actuators, A 263, 493–500 (2017)

Christ, J.F., Aliheidari, N., Pötschke, P., Ameli, A.: Bidirectional and stretchable piezoresistive sensors enabled by multimaterial 3D printing of carbon nanotube/thermoplastic polyurethane nanocomposites. Polymers 11(1), 11 (2019)

Kim, M., Jaebong Jung, J., Sungmook, J., Young, H.M., Dae-Hyeong, K., Ji, H.K.: Piezoresistive behaviour of additively manufactured multi-walled carbon nanotube/thermoplastic polyurethane nanocomposites. Materials 12(16), 2613 (2019)

Fraternali, F., Singh, N., Amendola, A., Benzoni, G., Milton, G.W.: A biomimetic sliding-stretching approach to seismic isolation. Nonlinear Dyn. 106(4), 3147–3159 (2021)

Fraternali, F., Singh, N., Amendola, A., Benzoni, G., Milton, G. W.: The 3D print job that keeps quake damage at bay. Nature, Research Highlight, 600(7887), 10 (2021)

Dorfmann, A., Ogden, R.W.: A pseudo-elastic model for loading, partial unloading and reloading of particle-reinforced rubber. Int. J. Solids Struct. 40(11), 2699–2714 (2003)

Dorfmann, A., Ogden, Ray W.: A constitutive model for the Mullins effect with permanent set in particle-reinforced rubber. Int. J. Solids Struct. 41(7), 1855–1878 (2004)

Mohotti, D., Ali, M., Ngo, T., Lu, J., Mendis, P.: Strain rate dependent constitutive model for predicting the material behaviour of polyurea under high strain rate tensile loading. Mater. Design 53, 830–837 (2014)

Saedniya, M., Talaeitaba, S.B.: Numerical modeling of elastomeric seismic isolators for determining force-displacement curve from cyclic loading. Int. J. Adv. Struct. Eng. 11(3), 361–376 (2019)

Reese, S., Govindjee, S.: A theory of finite viscoelasticity and numerical aspects. Int. J. Solids Struct. 35(26–27), 3455–3482 (1998)

Amendola, A., Fraternali, F.: Incremental auxetic response of composite lattices under isotropic prestress. Compos. Struct. 191, 145–153 (2018)

Miniaci, M., Mazzotti, M., Amendola, A., Fraternali, F.: Effect of prestress on phononic band gaps induced by inertial amplification. Int. J. Solids Struct. 216, 156–166 (2021)

Acknowledgements

The great technical support received by Giuseppe Marchese and Antonella Serra (Proplast - Consorzio per la Promozione della Cultura Plastica, Via Roberto di Ferro, 86 - 15122 Alessandria—Italy) during the execution of laboratory tests is gratefully acknowledged.

Funding

This study was funded by Italian Ministry of University and Research PRIN 2017 Grant 2017J4EAYB.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

de Castro Motta, J., Qaderi, S., Farina, I. et al. Experimental characterization and mechanical modeling of additively manufactured TPU components of innovative seismic isolators. Acta Mech 235, 1637–1648 (2024). https://doi.org/10.1007/s00707-022-03447-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-022-03447-5