Abstract

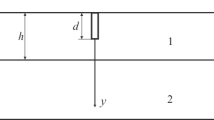

Ceramic coatings are ideal materials for thermal protection systems such as the thermal shield of the space shuttle. In a high-temperature environment, material properties of ceramics strongly depend on the temperature. The severe mismatch of material properties between the ceramic coating and the substrate can result in progressive mechanical failure of thermal protection system. This paper investigates delamination and buckling behaviors between a temperature-dependent ceramic coating and a porous substrate. The shear stress intensity factor at the tips of the delamination crack and buckling region are derived. Based on the stress intensity factor, the critical temperature of the coating buckling from the substrate is obtained. A fitting formula of the critical buckling temperature with respect to the length-to-thickness ratio of the coating, and the buckling region is obtained. It is found that the effect of the temperature dependence of material properties on delamination and buckling is more significant for higher temperatures than for lower temperatures. The critical temperatures of delamination and buckling are overestimated if the temperature dependence of material properties is neglected. The critical temperatures of delamination and buckling increase with the porosity of the substrate.

Similar content being viewed by others

References

Kravchuk, L.V., Buiskikh, K.P., Gusarova, I.A., et al.: Methods for the simulation of the aerodynamic heating conditions of the structural elements of space shuttles. Strength Mater. 50, 565–574 (2018)

Wang, Y., Chen, Z.F., Yu, S.J., et al.: Improved sandwich structured ceramic matrix composites with excellent thermal insulation. Compos. Part B Eng. 129, 180–186 (2017)

Green, D.J., Colombo, P.: Cellular ceramics: intriguing structures, novel properties and innovative applications. Mater. Res. Soc. Bull. 28, 296–300 (2003)

Vogt, U., Gorbar, M., Dimopoulos-Eggenschwiler, P., et al.: Improving the properties of ceramic foams by a vacuum infiltration process. J. Eur. Ceram. Soc. 30, 3005–3011 (2010)

Jiang, M., Wang, X.H., Pak, J.J.: Formation of low-melting-point inclusions in Al-deoxidized steel refined by high-basicity calcium aluminate slag in \(\text{ ZrO }_2\) crucible experiments. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 45, 1248–1259 (2014)

Glaser, P.E., Arthur, D.: Thermal insulation systems, Technical report NASA SP-5027, 82-83 (1967)

Fesmire, J.E., Coffman, B.E., Meneghelli, B.J., et al.: Spray-on foam insulations for launch vehicle cryogenic tanks. Cryogenics 52, 251–261 (2012)

Sun, Z.Q., Lu, C., Fan, J.M., et al.: Porous silica ceramics with closed-cell structure prepared by inactive hollow spheres for heat insulation. J Alloys Compd. 662, 157–164 (2016)

Liang, C.Y., Wang, Z.F., Wu, L.N., et al.: Light and strong hierarchical porous SiC foam for efficient electromagnetic interference shielding and thermal insulation at elevated temperatures. ACS Appl. Mater. Interfaces 9, 29950–29957 (2017)

Xu, D., Jiang, H.Y., Ming, L.: Synthesis of monolithic alumina-silica hollow microspheres and their heat-shielding performance for adiabatic materials. Ceram. Int. 44, 1545–1555 (2018)

Sharafat, S., Ghoniem, N., Williams, B., et al.: Cellular foams a potential innovative solid breeder material for fusion applications. Fusion Sci. Technol. 47, 886–890 (2005)

Uhlířová, T., Nečina, V., Pabst, W.: Modeling of Young’s modulus and thermal conductivity evolution of partially sintered alumina ceramics with pore shape changes from concave to convex. J. Eur. Ceram. Soc. 38, 3004–3011 (2018)

Pabst, W., Uhlířová, T., Gregorová, E., et al.: Young’s modulus and thermal conductivity of closed-cell, open-cell and inverse ceramic foams-model-based predictions, cross-property predictions and numerical calculations. J. Eur. Ceram. Soc. 38, 2570–2578 (2018)

Zhang, Y.X., Wang, B.L.: Thermal shock resistance analysis of a semi-infinite ceramic foam. Int. J. Eng. Sci. 62, 22–30 (2013)

Zhang, Y.X., Wang, B.L., Li, J.E.: The thermal shock resistance analysis of ceramic foams. J. Am. Ceram. Soc. 96, 2615–2622 (2013)

Zhang, G.X., Wang, H.L., Shen, S.P.: A chemomechanical coupling model for stress analysis of oxide scale growing between ceramic coating and substrate. ACTA Mech. 228, 3173–3183 (2017)

Yalkin, H.E., Icten, B.M., Alpyildiz, T.: Enhanced mechanical performance of foam core sandwich composites with through the thickness reinforce core. Compos. Part B Eng. 79, 383–391 (2015)

Triantou, K., Mergia, K., Florez, S., et al.: Thermo-mechanical performance of an ablative/ceramic composite hybrid thermal protection structure for re-entry applications. Compos. Part B Eng. 82, 159–165 (2015)

Hou, X.B., Zhang, R.B., Fang, D.: Novel whisker-reinforced \(\text{ Al }_{{2}} \text{ O }_{{3}}\)–\(\text{ SiO }_{{2}}\) aerogel composites with ultra-low thermal conductivity. Ceram. Int. 43, 9547–9551 (2017)

Shariyat, M.: A nonlinear Hermitian transfinite element method for transient behavior analysis of hollow functionally graded cylinders with temperature-dependent materials under thermo-mechanical loads. Int. J. Press. Vessel. Pip. 86, 280–289 (2009)

Argeso, H., Eraslan, A.N.: On the use of temperature-dependent physical properties in thermomechanical calculations for solid and hollow cylinders. Int. J. Therm. Sci. 47, 136–143 (2008)

Deng, Y., Li, W.G., Shao, J.X., et al.: Modeling the temperature-dependent non-steady state first matrix cracking stress for fiber ceramic matrix composites. J. Alloys Compd. 740, 987–996 (2018)

Han, J.C., Wang, B.L.: Thermal shock resistance of ceramics with temperature-dependent material properties at elevated temperature. Acta Mater. 59, 1373–1382 (2011)

Deng, Y., Li, W.G., Zhang, X., et al.: Characterization model of thermal shock resistance for fiber reinforced brittle matrix composites over a wide range of cooling environment temperatures. Ceram. Int. 44, 5518–5523 (2018)

Wang, B.L., Cui, Y.J.: Transient interlaminar thermal stress in multi-layered thermoelectric materials. Appl. Therm. Eng. 119, 207–214 (2017)

Tao, C., Fu, Y.M.: Thermal buckling and postbuckling analysis of size-dependent composite laminated microbeams based on a new modified couple stress theory. ACTA Mech. 228, 1711–1724 (2017)

Kumar, R., Ramachandra, L.S., Banerjee, B.: Semi-analytical approach for thermal buckling and postbuckling response of rectangular composite plates subjected to localized thermal heating. ACTA Mech. 228, 1767–1791 (2017)

Zhang, A.B., Wang, B.L.: Temperature and electric potential fields of an interface crack in a layered thermoelectric or metal/thermoelectric material. Int. J. Therm. Sci. 104, 396–403 (2016)

Zhang, A.B., Wang, B.L., Pang, D.D., et al.: Influence of leg geometry configuration and contact resistance on the performance of annular thermoelectric generators. Energy Convers. Manag. 166, 337–342 (2018)

Lou, J., He, L.W., Du, J.K., et al.: Buckling and post-buckling analyses of piezoelectric hybrid microplates subject to thermo-electro-mechanical loads based on the modified couple stress theory. Compos. Struct. 153, 332–344 (2016)

Cui, Y.J., Wang, B.L., Wang, P.: Analysis of thermally induced delamination and buckling of thin-film thermoelectric generators made up of pn-junctions. Int. J. Mech. Sci. 149, 393–401 (2017)

Lou, J., He, L.W., Wu, H.P., et al.: Pre-buckling and buckling analyses of functionally graded microshells under axial and radial loads based on the modified couple stress theory. Compos. Struct. 142, 226–237 (2016)

Tanigawa, Y., Matsumoto, M., Akai, T.: Optimization of material composition to minimize thermal stresses in nonhomogeneous plate subjected to unsteady heat supply. Jpn. Soc. Mech. Eng. Int. J. Ser. A 40, 84–93 (1997)

Huo, W.L., Zhang, X.Y., Chen, Y.G., et al.: Novel mullite ceramic foams with high porosity and strength using only fly ash hollow spheres as raw material. J. Eur. Ceram. Soc. 38, 2035–2042 (2018)

Lu, T.J., Fleck, N.A.: The thermal shock resistance of solids. Acta Mater. 46, 4755–4768 (1998)

Muskhelishvili, N.I.: Some Basic Problem of the Mathematical Theory of Elasticity, pp. 391–413. Noordhoff, Groningen (1953)

Zhang, A.B., Wang, B.L.: Explicit solutions of an elliptic hole or a crack problem in thermoelectric materials. Eng. Fract. Mech. 151, 11–21 (2016)

Cui, Y.J., Wang, B.L., Wang, K.F., et al.: Fracture mechanics analysis of delamination buckling of a porous ceramic foam coating from elastic substrate. Ceram. Int. 44, 17986–17991 (2018)

Li, B., Li, C.X., Wei, C.L.: Surface effects on the posting of nanowires. Chin. Phys. Lett. 28, 046202 (2011)

Wang, K.F., Wang, B.L., Zhang, C.W.: Surface energy and thermal stress effect on nonlinear vibration of electrostatically actuated circular micro-/nanoplates based on modified couple stress theory. Acta Mech. 228, 129–140 (2016)

Xue, Q.C., Zhang, J.C., He, J., et al.: Control performance and robustness of pounding tuned mass damper for vibration reduction in SDOF structure. Shock Vib. 2016, 1–15 (2016)

Khoramishad, H., Ebrahimijmal, M., Fasihi, M.: The effect of grapheme oxide nano-platelets on fracture behavior of adhesively bonded joints. Fatigue Fract. Eng. Mater. Struct. 40, 1905–1916 (2017)

Acknowledgements

This research was supported by Research Innovation Fund of Shenzhen City of China (Project Nos. JCYJ20170413104256729, JCYJ20170811160538023), the National Natural Science Foundation of China (Project Nos. 11972137, 11972133, 11602072 11502101 and 11672084), Guangdong Basic and Applied Basic Research Foundation (Project No. 2019A1515011348). KFW also acknowledges the Project (2020057) supported by Natural Scientific Research Innovation Foundation in Harbin Institute of Technology.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A

Appendix A

With the substitution of Eq. (7) into Eq. (6), one can obtain the following equation:

By introducing an intermediate variable \(\xi \) which satisfies \(\zeta =\hbox {cos}\xi \), \(0\le \xi \le \pi \), the Chebyshev polynomials of the first kind can be expressed as \(V_{j}(\xi )=\hbox {cos}(j\xi )\). Thus, the second integral at the left hand side of Eq. (A1) reduces to \(\int _{\arccos \bar{{x}}}^0 {\frac{\cos (j\xi )}{\sqrt{1-\cos ^{2}(\xi )} }} \hbox {d}\cos (\xi )=\frac{1}{j}\sin \left( {j\arccos (\bar{{x}})} \right) \). In addition, the Chebyshev polynomials of the first kind and the second kind hold \(\pi U_{j-1} (\bar{{x}})=\int _{-1}^1 {V_{j} (\zeta )/(\bar{{x}}-\zeta )/\sqrt{1-\zeta ^{2}} } \hbox {d}\zeta ,j\ge 1\). Thus, Eq. (A1) can be rewritten as

The Chebyshev polynomials of the second kind can be expressed in terms of the trigonometric functions as \(U_{j-1} (\bar{{x}})=\sin \left( {j\arccos (\bar{{x}})} \right) /\sin \left( {\arccos (\bar{{x}})} \right) \). Therefore, Eq. (A2) reduces to

Rights and permissions

About this article

Cite this article

Cui, Y.J., Li, J.E., Wang, B.L. et al. Thermally induced delamination and buckling of a ceramic coating with temperature-dependent material properties from porous substrate at high temperatures. Acta Mech 231, 2143–2154 (2020). https://doi.org/10.1007/s00707-020-02624-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-020-02624-8