Abstract

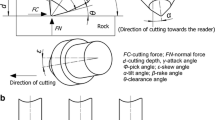

Chip geometry can play a crucial role in understanding the rock cutting efficiency in mechanical excavation. In this study, the shape and size distribution of chips produced in laboratory scale rock cutting tests and their relationship with cutting geometry and rock cuttability were analyzed. For this purpose, a series of small-scale linear rock cutting tests (SSLRCT) were carried out with a simple chisel tool in unrelieved mode at cutting depth of 1, 2, 3, and 4 mm to determine the cuttability of four rock types (sandstone, marl, salt, and coal) and two synthetic (dental plaster and concrete) specimens. The size distribution of all cuttings collected from the grooves in different samples was determined by sieve analysis. The results were used to create a comprehensive particle size analysis, including a Rosin–Rammler plot (d′), coarseness index (CI), median (d50) and Krumbein mean particle size (dMPS). Also, the chips remained on the 4-mesh sieve and greater were chosen for chip shape analysis. The results obtained from chip analysis indicated that 85.6% of selected chips were fragmented in very platy and very bladed shape. Also, the analysis results showed that an inverse exponential correlation exists between specific energy and particle size indicators including CI, dMPS, d50, and d′ as anticipated based on rock fragmentation and grinding theories. Furthermore, a strong inverse correlation was found between specific energy and representative chip volume. The findings highlight the relationship of rock cutting efficiency with chip shape and size.

Similar content being viewed by others

References

Abu Bakar MZ, Gertsch LS (2012) Disc cutting tests on dry and saturated sandstone: muck as a performance estimator. In: Proceedings of the SME annual meeting, Seattle, pp 1–7

Abu Bakar MZ, Gertsch LS (2013) Evaluation of saturation effects on drag pick cutting of a brittle sandstone from full scale linear cutting tests. Tunn Undergr Space Technol 34:124–134. https://doi.org/10.1016/j.tust.2012.11.009

Altindag R (2003) Estimation of penetration rate in percussive drilling by means of coarseness index and mean particle size. Rock Mech Rock Eng 36(4):323–332. https://doi.org/10.1007/s00603-003-0002-3

Altindag R (2004) Evaluation of drill cuttings in prediction of penetration rate by using coarseness index and mean particle size in percussive drilling. Geotech Geol Eng 22(3):417–425. https://doi.org/10.1023/B:GEGE.0000025043.92979.48

Asbury B, Cigla M, Balci C (2002) Design methodology, testing and evaluation of a continuous miner cutterhead for dust reduction in underground coal mining. In: SME annual meeting. Arizona, pp 1–8

ASTM C136/C136 M-14 (2014) Standard test method for sieve analysis of fine and coarse aggregates. Am Soc Test Mater. https://doi.org/10.1520/C0136_C0136M-14

ASTM D2938-95 (1995) Standard test method for unconfined compressive strength of intact rock core specimens. Annual Book of ASTM Standards, American Society for Testing and Materials, West Conshohocken

ASTM D3967-95 (1995) Standard test method for splitting tensile strength of intact rock core specimens. Annual Book of ASTM Standards, American Society for Testing and Materials, West Conshohocken

ASTM D4543-08 (2008) Standard practices for preparing rock core as cylindrical test specimens and verifying conformance to dimensional and shape tolerances. Annual Book of ASTM Standards, American Society for Testing and Materials, West Conshohocken

Balci C, Bilgin N (2007) Correlative study of linear small and full-scale rock cutting tests to select mechanized excavation machines. Int J Rock Mech Min Sci 44(3):468–476. https://doi.org/10.1016/j.ijrmms.2006.09.001

Barker JS (1964) A laboratory investigation of rock cutting using large picks. Int J Rock Mech Min Sci 1(4):519–534. https://doi.org/10.1016/0148-9062(64)90059-2

Bilgin N (1977) Investigations into the mechanical cutting characteristics of some medium and high strength rocks. PhD thesis, University of Newcastle upon Tyne, UK

Bilgin N, Copur H, Balci C (2012) Effect of replacing disc cutters with chisel tools on performance of a TBM in difficult ground conditions. Tunn Undergr Space Technol 27(1):41–51

Bilgin N, Copur H, Balci C (2014) Mechanical excavation in mining and civil industries. CRC Press Taylor & Francis Group, Boca Raton. https://doi.org/10.1017/CBO9781107415324.004

Blott SJ, Pye K (2008) Particle shape: a review and new methods of characterization and classification. Sedimentology. https://doi.org/10.1111/j.1365-3091.2007.00892.x

Boggs Jr S (2014) Principles of sedimentology and stratigraphy, Fifth Edit. Pearson Education

Bruland A (1998) Hard rock tunnel boring. PhD thesis, Department of Building and Construction Engineering, Norwegian University of Science and Technology (NTNU), Trondheim, Norway

Brunsing, T., & Goodman, R. E. (1979). Hard Rock Excavating By Prestressed Rock Cutting. In 20th US Symposium on Rock Mechanics (USRMS). American Rock Mechanics Association

Cook N, Joughin N, Weibols G (1968) Rock-cutting and its potentialities as a new method of mining. J S Afr Inst Min Metall 68(10):435–454

Copur H (2010) Linear stone cutting tests with chisel tools for identification of cutting principles and predicting performance of chain saw machines. Int J Rock Mech Min Sci 47(1):104–120

Copur H, Balci C, Tumac D, Bilgin N (2011) Field and laboratory studies on natural stones leading to empirical performance prediction of chain saw machines. Int J Rock Mech Min Sci 48(2):269–282

Copur H, Balci C, Bilgin N, Tumac D, Avunduk E (2012) Predicting cutting performance of chisel tools by using physical and mechanical properties of natural stones. In: ISRM International Symposium-EUROCK 2012. International Society for Rock Mechanics, Stockholm

Dalziel JA (1967) Coal cutting research–friction and blunting: their effects on the performance of a model cutter jib. Colliery Eng 476–486

Dobkins JE, Folk RL (1970) Shape development on Tahiti-nui. J Sediment Res 40(4):1167–1203

Dogruoz C, Bolukbasi N (2014) Effect of cutting tool blunting on the performances of various mechanical excavators used in low-and medium-strength rocks. Bull Eng Geol Env 73(3):781–789

Evans I (1958) Theoretical aspects of coal ploughing. In: Mechanical properties of non-metallic brittle materials, pp 451–468. Butterworths, London

Evans I (1965) The force required to cut coal with blunt wedges. In: International journal of rock mechanics and mining sciences and geomechanics abstracts, vol 2, pp 1–12. Elsevier

Evans I (1972) Line spacing of picks for effective cutting. In: International journal of rock mechanics and mining sciences and geomechanics abstracts, vol 9, pp 355–361. Elsevier

Evans I, Pomeroy CD (1966) The strength, fracture and workability of coal. Pergamon Press, Oxford

Evenden MP, Edwards JS (1985) Cutting theory and coal seam assessment techniques and their application to shearer design. Min Sci Technol 2(4):253–270

Fowell RJ, Hekimoglu OZ (1987) Drag tools employed on shearer drums and roadheaders. In: 10th Turkish Mining Congress of Ankara, pp 529–550

Gertsch L, Fjeld A, Nilsen B, Gertsch R (2000) Use of TBM muck as construction material. Tunn Undergr Space Technol. https://doi.org/10.1016/S0886-7798(01)00007-4

Goktan RM (1995) Prediction of drag bit cutting force in hard rocks. In: Proceedings of the 3rd international symposium on mine mechanization and automation, Golden, Colorado, pp 10–31

Gong QM, Zhao J, Jiang YS (2007) In situ TBM penetration tests and rock mass boreability analysis in hard rock tunnels. Tunn Undergr Space Technol 22(3):303–316. https://doi.org/10.1016/j.tust.2006.07.003

Heydari S, Khademi Hamidi J, Monjezi M, Eftekhari A (2019) An investigation of the relationship between muck geometry, TBM performance and operational parameters: a case study in Golab II water transfer tunnel. Tunnelling and Underground Space Technology

Hood M, Alehossein H (2000) A development in rock cutting technology. Int J Rock Mech Min Sci 37:297–305. https://doi.org/10.1016/S1365-1609(99)00107-0

Horiba S (2012) A guidebook to particle size analysis. Horiba Instruments, Inc, pp 1–29

Hurt KG, Evans I (1980) A laboratory study of rock cutting using point attack tools. In: The 21st US Symposium on Rock Mechanics (USRMS). American Rock Mechanics Association

Ip CK (1986) Laboratory water jet assisted drag tool rock cutting studies at high traverse speeds. PhD thesis, University of Newcastle upon Tyne, UK

Krumbein WC (1934) Size frequency distributions of sediments. J Sedim Petrol 4(2):65–77. https://doi.org/10.1306/D4268EB9-2B26-11D7-8648000102C1865D

Krumbein WC (1941) Measurement and geological significance of shape and roundness of sedimentary particles. SEPM J Sedim Res. https://doi.org/10.1306/D42690F3-2B26-11D7-8648000102C1865D

Martin JA, Fowell RJ (1997) Factors governing the onset of severe drag tool wear in rock cutting. Int J Rock Mech Min Sci 34(1):59–69. https://doi.org/10.1016/S1365-1609(97)80033-0

Mc Feat-Smith I (1975) Correlation of Rock Properties and Tunnel Machine Performance in Selected Sedimentary Rocks. PhD thesis, University of Newcastle upon Tyne

Mellor M (1977) Mechanics of cutting and boring. Part 4. Dynamics and energetics of parallel motion tools. Cold Regions Research and Engineeering LAB, Hanover

Mohammadi M, Khademi Hamidi J, Rostami J, Goshtasbi K (2017) Laboratory investigation into the effect of groove deepening on the performance of drag tools in mechanized excavation. In: 12th Iranian and 3rd Regional Tunnelling Conference. Tehran, Iran (in persian)

Morrell RJ, Wilson RJ (1983) Toward development of a hard-rock mining machine-drag cutter experiments in hard abrasive rocks. US Bureau of Mines Report Investigation, RI, p 8784

Nishimatsu Y (1972) The mechanics of rock cutting. In: International journal of rock mechanics and mining sciences and geomechanics abstracts, vol 9, pp 261–270. Elsevier

Pan Y, Liu Q, Liu J, Liu Q, Kong X (2018) Full-scale linear cutting tests in Chongqing Sandstone to study the influence of confining stress on rock cutting efficiency by TBM disc cutter. Tunn Undergr Space Technol 80:197–210. https://doi.org/10.1016/j.tust.2018.06.013

Pomeroy CD, Foote P (1960) A laboratory investigation of the relation between ploughability and the mechanical properties of coal. Colliery Eng 37(1):146–154

Potts ELJ, Shuttleworth P (1958) A study of ploughability of coal with special reference to the effects of blade shape, direction of planning to the cleat, planning speed and influence of water infusion. Trans Inst Min Eng 117:519–553

Powers MC (1953) A new roundness scale for sedimentary particles. SEPM J Sedim Res. https://doi.org/10.1306/D4269567-2B26-11D7-8648000102C1865D

Rispoli A, Ferrero AM, Cardu M, Farinetti A (2017) Determining the particle size of debris from a tunnel boring machine through photographic analysis and comparison between excavation performance and rock mass properties. Rock Mech Rock Eng 50(10):2805–2816. https://doi.org/10.1007/s00603-017-1256-5

Rosin P, Rammler E (1933) The laws governing the fineness of powdered coal. J Inst Fuel 7:29–36

Rostami J, Gertsch R, Gertsch L (2002) Rock fragmentation by disc cutter: a critical review and an update. In: Proceedings, North American Rock Mechanics Symposium (NARMS). Tunneling Association of Canada (TAC) meeting, Toronto

Roxborough FF (1973) Cutting rocks with picks. Min Eng 445–455

Roxborough FF (1987) The role of some basic rock properties in assessing cuttability. In: Seminar on tunnels: wholly engineered structures. The Institute of Engineers Australia and AFCC

Roxborough FF, Rispin A (1973) A laboratory investigation into the application of picks for mechanized tunnel boring in the lower chalk. Min Eng 133(1):13

Roxborough FF, King P, Pedroncelli EJ (1981) Tests on the cutting performance of a continuous miner. J S Afr Inst Min Metall 81:9–26

Sneed ED, Folk RL (1958) Pebbles in the Lower Colorado River, Texas a study in particle morphogenesis. J Geol 66(2):114–150. https://doi.org/10.1086/626490

Spencer A, Machin J, Jackson E (2007) Rock cutting With the T750 super trencher. Unmanned Intervention, New Orleans, p 30

Tiryaki B, Dikmen AC (2006) Effects of rock properties on specific cutting energy in linear cutting of sandstones by picks. Rock Mech Rock Eng 39(2):89–120

Tumac D, Copur H, Balci C, Er S, Avunduk E (2018) Investigation into the effects of textural properties on cuttability performance of a chisel tool. Rock Mech Rock Eng 51(4):1227–1248

Tuncdemir H, Bilgin N, Copur H, Balci C (2008) Control of rock cutting efficiency by muck size. Int J Rock Mech Min Sci 45(2):278–288. https://doi.org/10.1016/j.ijrmms.2007.04.010

Udden JA (1898) The mechanical composition of wind deposits. Lutheran Augustana book concern, printers

Ulusay R, Hudson JA (2007) The complete ISRM suggested methods for rock characterization, testing and monitoring: 1974–2006. Commission on Testing Methods. International Society of Rock Mechanics, Compilation Arranged by the ISRM Turkish National Group, Ankara, p 628

Vesilind PA (1980) The Rosin-Rammler particle size distribution. Resour Recov Conserv 5(3):275–277. https://doi.org/10.1016/0304-3967(80)90007-4

Wadell H (1932) Volume, shape, and roundness of rock particles. J Geol 40(5):443–451. https://doi.org/10.1093/ajh/hpw148

Wentworth CK (1922) A scale of grade and class terms for clastic sediments. J Geol 30(5):377–392

Whittaker D (1962) Effect of pick shape on cutting forces. Colliery Guardian 205(5288):242–244

Yasar S, Yilmaz AO (2017) Rock cutting tests with a simple-shaped chisel pick to provide some useful data. Rock Mech Rock Eng 50(12):3261–3269

Yasar S, Yilmaz AO (2018) Drag pick cutting tests: a comparison between experimental and theoretical results. J Rock Mech Geotech Eng 10(5):893–906

Yilmaz NG, Yurdakul M, Goktan RM (2007) Prediction of radial bit cutting force in high-strength rocks using multiple linear regression analysis. Int J Rock Mech Min Sci. https://doi.org/10.1016/j.ijrmms.2007.02.005

Zingg T (1935) Beitrag zur schotteranalyse. ETH Zurich

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mohammadi, M., Khademi Hamidi, J., Rostami, J. et al. A Closer Look into Chip Shape/Size and Efficiency of Rock Cutting with a Simple Chisel Pick: A Laboratory Scale Investigation. Rock Mech Rock Eng 53, 1375–1392 (2020). https://doi.org/10.1007/s00603-019-01984-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-019-01984-5