Abstract

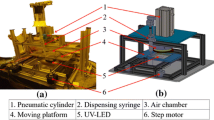

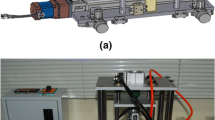

UV imprinting has been one of the most productive replication techniques due to its low imprinting pressure and temperature. The conventional UV resin is cured by direct irradiation from the bottom. Space management and energy consumption become problems as the areas are getting larger and larger. Another problem is the uniformity of imprinting pressure, which is higher near the center with conventional platen-pressuring imprinting. In this study, we develop an innovative side-emitting UV-curing gasbag-pressuring imprinting mechanism for large area microstructure replication. An imprinting system based on such integration has been designed and implemented. V-groove microstructures has been imprinted onto a PMMA plate with dimensions of 380 mm × 230 mm × 3 mm for light enhancement. The optical performance and the profile of microstructures have been verified.

Similar content being viewed by others

Reference

Chang J-H, Yang S-Y (2003) Gas pressurized hot embossing for transcription of micro-features. Microsyst Technol 10:76–80. https://doi.org/10.1007/s00542-003-0311-1

Chang N-W, Yang C-H, Yang S-Y (2017) Double-sided UV roller imprinting of microstructures on transparent plates. Microsyst Technol 23:5833–5839. https://doi.org/10.1007/s00542-017-3511-9

Cheng C, Ke K-C, Yang S-Y (2017) Application of graphene–polymer composite heaters in gas-assisted micro hot embossing. RSC Adv 7:6336–6344. https://doi.org/10.1039/C6RA27618K

Despa MS, Kelly KW, Collier JR (1999) Injection molding of polymeric LIGA HARMs. Microsyst Technol 6:60–66. https://doi.org/10.1007/s005420050176

Ebert D, Bhushan B (2016) Transparent, superhydrophobic, and wear-resistant surfaces using deep reactive ion etching on PDMS substrates. J Colloid Interface Sci 481:82–90. https://doi.org/10.1016/j.jcis.2016.07.035

Han K-S, Lee H, Kim D, Lee H (2009) Fabrication of anti-reflection structure on protective layer of solar cells by hot-embossing method. Sol Energy Mater Sol Cells 93:1214–1217. https://doi.org/10.1016/j.solmat.2009.01.002

He M, Yuan XC, Ngo NQ et al (2003) Simple reflow technique for fabrication of a microlens array in solgel glass. Opt Lett 28:731–733

Klaassen EH, Petersen K, Noworolski JM, et al (1995) Silicon fusion bonding and deep reactive ion etching a new technology for microstructures. In: The 8th international conference on solid-state sensors and actuators, 1995 and eurosensors IX. Transducers’95. pp 556–559

Lee J-H, Choi W-S, Lee K-H, Yoon J-B (2008) A simple and effective fabrication method for various 3D microstructures: backside 3D diffuser lithography. J Micromech Microeng 18:125015. https://doi.org/10.1088/0960-1317/18/12/125015

Matschuk M, Larsen NB (2013) Injection molding of high aspect ratio sub-100 nm nanostructures. J Micromech Microeng 23:025003. https://doi.org/10.1088/0960-1317/23/2/025003

Shih Y-M, Kao C-C, Ke K-C, Yang S-Y (2017) Imprinting of double-sided microstructures with rapid induction heating and gas-assisted pressuring. J Micromech Microeng 27:095012. https://doi.org/10.1088/1361-6439/aa7acd

Snakenborg D, Klank H, Kutter JP (2004) Microstructure fabrication with a CO2 laser system. J Micromech Microeng 14:182. https://doi.org/10.1088/0960-1317/14/2/003

Yoo Y-E, Kim T-H, Je T-J et al (2011) Injection molding of micro patterned PMMA plate. Trans Nonferrous Met Soc China 21:s148–s152. https://doi.org/10.1016/S1003-6326(11)61079-0

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, YY., Ke, KC. & Yang, SY. Fabrication of large-area V-groove microstructures using gasbag-pressuring edge-irradiating UV imprinting. Microsyst Technol 25, 811–817 (2019). https://doi.org/10.1007/s00542-018-4221-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-018-4221-7