Abstract

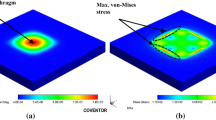

Polysilicon based pressure sensors use a silicon dioxide layer for isolation of piezoresistors from bulk. This helps in reducing the leakage current compared to the p–n junction isolation in silicon piezoresistors. They are also more cost effective than silicon-on-insulator (SOI) based sensors for high temperature applications. This paper reports the design, fabrication process and characterization of a polysilicon piezoresistive pressure sensor with wet bulk micromachined diaphragm. Novel meander shaped polysilicon piezoresistors are placed at optimized locations, found using finite element method (FEM) simulations, to experience high stress. The effect of clamping conditions of the diaphragm on the piezoresistors placement is shown through FEM simulations and the piezoresistor shapes are designed to keep the metal lines outside the diaphragm structure for better reliability. After fabrication and dicing, the mechanical characterization of the sensor is performed using laser doppler vibrometer (LDV) for determining the first mode resonance frequency and transient response of the sensor diaphragm. A first mode resonant frequency of 306.6 kHz and a response time of 0.56 ms are obtained. The sensor is then packaged inside a customized jig and tested with pressure load for determining the static and temperature characteristics of the sensor in the pressure range of 0–30 Bar. The sensor is tested at three different temperatures, viz. −5, 25 and 55 °C. A sensitivity of 3.35–3.73 mV/Bar, non-linearity of less than 0.3 %, and a hysteresis of less than 0.1 % are obtained for all the test temperatures.

Similar content being viewed by others

References

Bao M (2005) Analysis and design principles of MEMS devices. Elsevier, Amsterdam

Barlian AA, Park W-T, Mallon JR Jr, Rastegar AJ, Pruitt BL (2009) Review: semiconductor piezoresistance for microsystems. Proc IEEE 97:513–552

Eaton WP, Smith JH (1997) Micromachined pressure sensors: review and recent developments. Smart Mat Struc 6:530–539

Esashi M, Sugiyama S, Ikeda K, Wang Y, Miyashita H (1998) Vacuum-sealed silicon micromachined pressure sensors. Proc IEEE 86:1627–1639

French PJ (2002) Polysilicon: a versatile material for microsystems. Sens Actuator A 99:3–12

Gong S-C, Lee C (2001) Analytical solutions of sensitivity for pressure microsensors. IEEE Sensors J 1:340–344

Guo S, Eriksen H, Childress K, Fink A, Hoffman M (2009) High temperature smart-cut SOI pressure sensor. Sens Actuators A 154:255–260

Herrera-May AL, Soto-Cruz BS, López-Huerta F, Aguilera Cortés LA (2009) Electromechanical analysis of a piezoresistive pressure micro-sensor for low-pressure biomedical applications. Revista Mexicana De Física 55:14–24

Kanda Y (1982) A graphical representation of the piezoresistance coefficients in silicon. IEEE Trans Electron Devices 29:64–70

Kumar SS, Pant BD (2012) Design of piezoresistive MEMS absolute pressure sensor. SPIE, UK 8549

Kumar SS, Pant BD (2014) Design principles and considerations for the ‘ideal’ silicon piezoresistive pressure sensor: a focused review. Microsyst Technol 20:1213–1247

Li X, Liu Q, Pang S, Xu K, Tang H, Sun C (2012) High-temperature piezoresistive pressure sensor based on implantation of oxygen into silicon wafer. Sens Actuators A 179:277–282

Liu X, Lu X, Chuai R, Shi C, Suo C (2009) Polysilicon nanofilm pressure sensor. Sens Actuators A 154:42–45

Maier-Schneider D, Maibach J, Obermeier E (1995) A new analytical solution for the load-deflection of square membranes. J Microelectromech Syst 4:238–241

Malhaire C, Barbier D (2003) Design of a polysilicon-on-insulator pressure sensor with original polysilicon layout for harsh environment. Thin Solid Films 427:362–366

Mukhiya R, Bagolini A, Bhattacharyya TK, Lorenzelli L, Zen M (2011) Experimental study and analysis of corner compensation structures for CMOS compatible bulk micromachining using 25 wt% TMAH. Microelectron J 42:127–134

Senturia SD (2001) Microsystem Design. Kluwer, Boston

Sivakumar K, Dasgupta N, Bhat KN, Natarajan K (2006) Sensitivity enhancement of polysilicon piezo-resistive pressure sensors with phosphorous diffused resistors. J Phys 34:216–221

Smith CS (1954) Piezoresistance effect in germanium and silicon. Phys Rev 94:42–49

Tanasković D, Djurić Z, Lazić Z (1995) Influence of impurity distribution on thermal coefficients of resistivity and piezoresistivity of diffused layers of silicon, 20th Int. Conf. on Microelectron. (MIEL’95), pp 573–576

Wei J, Sarro PM, Due TC (2010) A piezoresistive sensor for pressure monitoring at inkjet nozzle, IEEE Sensors conf., pp 2093–2096

Xiansong F, Suying Y, Shuzhi H, Wei Z, Yiqiang Z, Shengcai Z, Weixin Z (2004) Simulation and test of a novel SOI high temperature pressure sensor, 7th Int. Conf. on solid-state and integrated circuits tech, pp 1824–1827

Zhang Y-H, Yang C, Zhang Z–H, Lin ZH–W, Liu L–T, Ren T–L (2007) A novel pressure microsensor with 30-μm-thick diaphragm and meander-shaped piezoresistors partially distributed on high-stress bulk silicon region. IEEE Sensors J 7:1742–1748

Acknowledgments

Authors would like to acknowledge the generous support of the Director, CSIR-CEERI, Pilani. The authors would also like to thank all the scientific and technical staff of MEMS and Microsensors Group at CSIR-CEERI, Pilani. The financial support by Council of Scientific and Industrial Research (CSIR) through PSC-201: MicroSenSys project is gratefully acknowledged. The authors would also like to thank Dr. S.C. Bose and Mr. M. Santosh from IC design group for their help in sensor characterization. The authors would also like to acknowledge the Centre for Nano Science and Engineering (CeNSE) at the Indian Institute of Science (IISc), Bangalore for providing the LDV characterization facility for mechanical characterization.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, S.S., Pant, B.D. Polysilicon thin film piezoresistive pressure microsensor: design, fabrication and characterization. Microsyst Technol 21, 1949–1958 (2015). https://doi.org/10.1007/s00542-014-2318-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-014-2318-1