Abstract

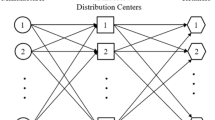

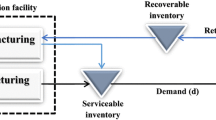

A closed-loop supply chain structure organises material and information flows from origin points to consumption points, including production, recycling, disposal, and other reverse logistic activities. Some integration problems arise with this structure including production, inventory, location, routing, distribution, collection, recycling, and routing. The integration problems that are facing scientific researchers include inventory routing, location routing, and location inventory. This study considers the integration problem of a closed-loop supply chain for the production, distribution, collection, and recycling quantities, along with the distribution and collection routes for each time period of a finite planning horizon. We refer to this problem as the “Closed-Loop Supply Chain Integrated Production-Inventory-Distribution-Routing Problem” (CLSC-PRP). A mathematical model is proposed that is the first to determine both quantities and routes for the CLSC-PRP simultaneously. As the problem is known to be NP-hard in terms of computational complexity, a simulated annealing-based decomposition heuristic is developed for solving large-scale CLSC-PRP instances. The results of the proposed mathematical model for the CLSC-PRP are compared with the results of the developed heuristic and two separate models that manage forward and backward production routing problems. An extensive comparative study indicated the following: (i) the proposed model was able to reduce the cost required for operating the total supply chain by an average of 12%, along with providing a positive impact on the environment and (ii) the proposed heuristic is able to generate solutions that are close to optimal in most cases.

Similar content being viewed by others

Data availability

The data used to support the findings of this study are available from the corresponding author (Y. Kuvvetli) upon request.

References

Blumberg DF (2004) Introduction to management of reverse logistics and closed loop supply chain processes. CRC Press, Boca Raton

E.P.A. (EPA) https://www.epa.gov/, USA, 2015. Accessed 14 May 2018

Lei L, Liu SG, Ruszczynski A, Park S (2006) On the integrated production, inventory, and distribution routing problem. IIE Trans 38:955–970

Chandra P, Fisher ML (1994) Coordination of production and distribution planning. Eur J Oper Res 72:503–517

Kaya O, Urek B (2016) A mixed integer nonlinear programming model and heuristic solutions for location, inventory and pricing decisions in a closed loop supply chain. Comput Oper Res 65:93–103

Glover F, Jones G, Karney D, Klingman D, Mote J (1979) An integrated production, distribution, and inventory planning system. Interfaces 9:21–35

Van Buer MG, Woodruff DL, Olson RT (1999) Solving the medium newspaper production/distribution problem. Eur J Oper Res 115:237–253

Russell R, Chiang W-C, Zepeda D (2008) Integrating multi-product production and distribution in newspaper logistics. Comput Oper Res 35:1576–1588

Fumero F, Vercellis C (1999) Synchronized development of production, inventory, and distribution schedules. Transp Sci 33:330–340

Bard JF, Nananukul N (2010) A branch-and-price algorithm for an integrated production and inventory routing problem. Comput Oper Res 37:2202–2217

Toptal A, Koc U, Sabuncuoglu I (2013) A joint production and transportation planning problem with heterogeneous vehicles. J Oper Res Soc 65:180–196

Boudia M, Louly MAO, Prins C (2007) A reactive GRASP and path relinking for a combined production–distribution problem. Comput Oper Res 34:3402–3419

Bard JF, Nananukul N (2009) The integrated production–inventory–distribution–routing problem. J Sched 12:257–280

Adulyasak Y, Cordeau J-F, Jans R (2012) Optimization-based adaptive large neighborhood search for the production routing problem. Transp Sci 48:20–45

Kuhn H, Liske T (2011) Simultaneous supply and production planning. Int J Prod Res 49:3795–3813

Shiguemoto AL, Armentano VA (2010) A tabu search procedure for coordinating production, inventory and distribution routing problems. Int Trans Oper Res 17:179–195

Armentano VA, Shiguemoto AL, Løkketangen A (2011) Tabu search with path relinking for an integrated production–distribution problem. Comput Oper Res 38:1199–1209

Fahimnia B, Luong L, Marian R (2012) Genetic algorithm optimisation of an integrated aggregate production–distribution plan in supply chains. Int J Prod Res 50:81–96

Buscher U, Lindner G (2007) Optimizing a production system with rework and equal sized batch shipments. Comput Oper Res 34:515–535

Kim T, Goyal SK (2011) Determination of the optimal production policy and product recovery policy: the impacts of sales margin of recovered product. Int J Prod Res 49:2535–2550

Zhang J, Liu X, Tu YL (2011) A capacitated production planning problem for closed-loop supply chain with remanufacturing. Int J Adv Manuf Technol 54:757–766

Kenné J-P, Dejax P, Gharbi A (2012) Production planning of a hybrid manufacturing–remanufacturing system under uncertainty within a closed-loop supply chain. Int J Prod Econ 135:81–93

Sifaleras A, Konstantaras I (2017) Variable neighborhood descent heuristic for solving reverse logistics multi-item dynamic lot-sizing problems. Comput Oper Res 78:385–392

Min H, Ko HJ, Park BI (2005) A Lagrangian relaxation heuristic for solving the multi-echelon, multi-commodity, close-loop supply chain network design problem. Int J Logist Syst Manage 1:382–404

Darvish M, Archetti C, Coelho LC (2019) Trade-offs between environmental and economic performance in production and inventory-routing problems. Int J Prod Econ 217:269–280

Kannan G, Sasikumar P, Devika K (2010) A genetic algorithm approach for solving a closed loop supply chain model: a case of battery recycling. Appl Math Model 34:655–670

Kim T, Goyal SK, Kim C-H (2013) Lot-streaming policy for forward–reverse logistics with recovery capacity investment. Int J Adv Manuf Technol 68:509–522

Sasikumar P, Haq AN (2011) Integration of closed loop distribution supply chain network and 3PRLP selection for the case of battery recycling. Int J Prod Res 49:3363–3385

Das K, Chowdhury AH (2012) Designing a reverse logistics network for optimal collection, recovery and quality-based product-mix planning. Int J Prod Econ 135:209–221

Das K, Rao PN (2015) Addressing environmental concerns in closed loop supply chain design and planning. Int J Prod Econ 163:34–47

Iassinovskaia G, Limbourg S, Riane F (2017) The inventory-routing problem of returnable transport items with time windows and simultaneous pickup and delivery in closed-loop supply chains. Int J Prod Econ 183:570–582

Qiu Y, Qiao J, Pardalos PM (2019) Optimal production, replenishment, delivery, routing and inventory management policies for products with perishable inventory. Omega 82:193–204

Miranda PL, Morabito R, Ferreira D (2019) Mixed integer formulations for a coupled lot-scheduling and vehicle routing problem in furniture settings. INFOR Inf Syst Oper Res. https://doi.org/10.1080/03155986.2019.1575686

Fang XJ, Du YA, Qiu YZ (2017) Reducing carbon emissions in a closed-loop production routing problem with simultaneous pickups and deliveries under carbon cap-and-trade. Sustainability 9:15

Li Y, Chu F, Chu C, Zhu Z (2019) An efficient three-level heuristic for the large-scaled multi-product production routing problem with outsourcing. Eur J Oper Res 272:914–927

Clarke G, Wright JW (1964) Scheduling of vehicles from a central depot to a number of delivery points. Oper Res 12:568–581

Kirkpatrick S (1984) Optimization by simulated annealing: quantitative studies. J Stat Phys 34:975–986

Chibante R (2010) Parameter identification of power semiconductor device models using metaheuristics. Sciyo, India

Kuvvetli Y (2016) Coordinated production–inventory–distribution routing problem on closed loop supply chain with recycling option. Industrial Engineering Department, Cukurova University, Adana, p 147

Acknowledgements

Yusuf Kuvvetli would like to extend thanks to the Scientific and Technological Research Council of Turkey (TÜBİTAK) for supporting his Ph.D. studies.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1

Notation of Mathematical Formulations

Indices

- \(i,j,v\) :

-

\({\text{Indices}}\;{\text{for}}\;{\text{nodes,}}\;{\text{where}}\; 0\;{\text{denotes}}\;{\text{the}}\;{\text{facility,}}\;{\text{recyler,}}\;{\text{and}}\;{\text{warehouse}}\)

- \(k\) :

-

\({\text{Index}}\;{\text{for}}\;{\text{vehicles}}\)

- \(t\) :

-

\({\text{Index}}\;{\text{for}}\;{\text{periods}}\)

- \(N_{c}\) :

-

\({\text{Set}}\;{\text{of}}\;{\text{consumption}}\;{\text{nodes}}\;N = N_{c} \cup \left\{ 0 \right\}\)

- \(K\) :

-

\({\text{Set}}\;{\text{of}}\;{\text{avaliable}}\;{\text{trucks}}\)

- \(T\) :

-

\({\text{Set}}\;{\text{of}}\;{\text{periods}}\;{\text{in}}\;{\text{the}}\;{\text{planning}}\;{\text{horizon}}\;T_{0} = T \cup \left\{ 0 \right\}\)

Parameters

- \(C_{k}\) :

-

\({\text{Capacity}}\;{\text{of}}\;{\text{vehicle}}\;k\;\left( {\text{unit}} \right)\)

- \(B ^{m} \left( {B ^{r} } \right)\) :

-

\({\text{Manufacturing}}\;\left( {\text{recycling}} \right)\;{\text{capacity}}\;\left( {\text{unit/period}} \right)\)

- \(q_{t}^{m} \left( {w_{t}^{r} } \right)\) :

-

\({\text{Raw}}\;{\text{material}}\;{\text{purchasing}}\;\left( {{\text{returned}}\;{\text{product}}\;{\text{collection}}} \right)\;{\text{cost}}\;{\text{for}}\;{\text{period}}\;t \;\left( {\text{money/unit}} \right)\)

- \(g_{i}^{m} \left( {g_{i}^{r} } \right)\) :

-

\({\text{Minimum }}\;{\text{new}}\;\left( {\text{returned}} \right)\;{\text{inventory}}\;{\text{level}}\;{\text{of}}\;{\text{node}}\;i\;\left( {\text{unit}} \right)\)

- \(a_{i}^{m} \left( {a_{i}^{r} } \right)\) :

-

\({\text{Maximum}}\;{\text{new}}\;\left( {\text{returned}} \right)\;{\text{inventory}}\;{\text{level}}\;{\text{of}}\;{\text{node}}\;i\;\left( {\text{unit}} \right)\)

- \(f_{k}\) :

-

\({\text{Fixed}}\;{\text{usage}}\;{\text{cost}}\;{\text{for}}\;{\text{vehicle}}\;k \;\left( {\text{money/period}} \right)\)

- \(c_{{}}^{v}\) :

-

\({\text{Variable}}\;{\text{cost}}\;{\text{for}}\;{\text{transportation}}\;\left( {\text{money/distance}} \right)\)

- \(s_{t}^{m} \left( {s_{t}^{r} } \right)\) :

-

\({\text{Production}}\;\left( {\text{recycling}} \right)\;{\text{setup }}\;{\text{cost}}\;{\text{for}}\;{\text{period }}\;t\; \left( {\text{money/period}} \right)\)

- \(c_{t}^{m} \left( {c_{t}^{r} } \right)\) :

-

\({\text{Variable}}\;{\text{production}}\;\left( {\text{recycling}} \right)\;{\text{cost}}\;{\text{for}}\;{\text{period}}\;t\; \left( {\text{money/period}} \right)\)

- \(h_{i}^{m} \left( {h_{i}^{m} } \right)\) :

-

\({\text{Holding}}\;{\text{cost}}\;{\text{for}}\;{\text{new}}\;\left( {\text{returned}} \right)\;{\text{product}}\;{\text{of}}\;{\text{node}}\;i\; ( {\text{money/}}\left( {{\text{unit}} \times {\text{period}}} \right)\)

- \(l_{ij}\) :

-

\({\text{Distance}}\;{\text{between }}\left( {i,j} \right)\;{\text{pair}}\;\left( {\text{distance}} \right)\)

- \(L\) :

-

\({\text{Maximum tour length in a period}}\)

- \(d_{it}^{m} \left( {d_{it}^{r} } \right)\) :

-

\({\text{New }}\left( {\text{returned}} \right)\,{\text{product demand of node }}i\; {\text{at period }}t \left( {\text{unit}} \right)\)

- \(\alpha\) :

-

\({\text{production rate}}\)

- \(\beta\) :

-

\({\text{Maximum }}\;{\text{recycling }}\;{\text{ratio}}\)

- \(\gamma\) :

-

\({\text{Coefficient}}\;{\text{of}}\;{\text{calculating}}\;{\text{the}}\;{\text{returned}}\;{\text{product}}\;{\text{regarding}}\;{\text{recycling}}\;{\text{quantities}}\)

Decision Variables

- \(p_{t} \left( {p_{t}^{r} } \right)\) :

-

\({\text{Production }}\left( {\text{recycling}} \right) {\text{quantity at period }}t\; \left( {\text{unit}} \right)\)

- \(p_{t}^{m}\) :

-

\({\text{Purshased}}\;{\text{raw}}\;{\text{material}}\;{\text{quantity}}\;{\text{at}}\; {\text{period }}\;t \;\left( {\text{unit}} \right)\)

- \(Y _{t}^{m} \left( {Y _{t}^{r} } \right)\) :

-

\(\left\{ {\begin{array}{*{20}l} {1,} \hfill & {{\text{if}}\;{\text{new}}\;\left( {{\text{returned}}} \right)\;{\text{product}}\;{\text{is}}\;{\text{produced}}\;\left( {{\text{recycled}}} \right)\; }\\ &{ {\text{at}}\;{\text{period}}\;t} \hfill \\ {0,} \hfill & {{\text{otherwise}}} \hfill \\ \end{array} } \right.\)

- \(I_{it}^{m} \left( {I_{it}^{r} } \right)\) :

-

\({\text{New }}\;\left( {\text{returned}} \right) \;{\text{inventory}}\; {\text{level}}\; {\text{on}}\; {\text{node}}\; i\; {\text{at}}\; {\text{period }}\;t \;\left( {\text{unit}} \right)\)

- \(Q_{ikt}^{m} \left( {Q_{ikt}^{r} } \right)\) :

-

\({\text{New }}\left( {\text{returned}} \right)\,\,{\text{product delivery }}\left( {\text{pick up}} \right) {\text{amount to }}\left( {\text{from}} \right)\;{\text{node }}i {\text{at period }}t {\text{with vehicle }}k \left( {\text{unit}} \right)\)

- \(X_{ijkt}^{m} \left( {X_{ijkt}^{r} } \right)\) :

-

\(N{\text{ew }}\left( {\text{returned}} \right) {\text{product load on travelling }}\left( {i,j} \right) {\text{pair at period }}t\;{\text{with vehicle }}k\;\left( {\text{unit}} \right)\)

- \(Z_{\text{ijkt}}\) :

-

\(\left\{ {\begin{array}{*{20}l} {{\text{1,}}} \hfill & {{\text{if~}}\;{\text{a~}}\;{\text{delivery~}}\;{\text{made}}\;{\text{~to}}\;{\text{~}}\left( {i,j} \right)\;{\text{~pair~}}\;{\text{at}}\;{\text{~period}}\;{\text{~}}t\; } \\ & { {\text{~with~}}\;{\text{vehicle}}\;{\text{~}}k} \hfill \\ {{\text{0,}}} \hfill & {{\text{otherwise}}} \hfill \\ \end{array} } \right.\)

- \(U_{\text{kt}}\) :

-

\(\left\{ {\begin{array}{*{20}l} { 1 , } \hfill & {{\text{if vehicle }}k\,\,{\text{is used on period }}t} \hfill \\ { 0 ,} \hfill & {\text{otherwise}} \hfill \\ \end{array} } \right.\)

Appendix 2

Parameter setting case problem instanceIn this parameters setting test instance, a 7-day planning problem is considered, and the dataset is briefly described in Table 9. Distribution activities are carried out by different capacities of vehicles (72.09 ton), and during the planning horizon, eight different points demand new products or collection requests for recycling. The distances between cities are generated randomly.

Rights and permissions

About this article

Cite this article

Kuvvetli, Y., Erol, R. Coordination of production planning and distribution in closed-loop supply chains. Neural Comput & Applic 32, 13605–13623 (2020). https://doi.org/10.1007/s00521-020-04770-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-020-04770-5