Abstract

In this study, to produce adipic acid, mutant strains of Candida tropicalis KCTC 7212 deficient of AOX genes encoding acyl-CoA oxidases which are important in the β-oxidation pathway were constructed. Production of adipic acid in the mutants from the most favorable substrate C12 methyl laurate was significantly increased. The highest level of production of adipic acid was obtained in the C. tropicalis ΔAOX4::AOX5 mutant of 339.8 mg L−1 which was about 5.4-fold higher level compared to the parent strain. The C. tropicalis ΔAOX4::AOX5 mutant was subjected to fed-batch fermentation at optimized conditions of agitation rate of 1000 rpm, pH 5.0 and methyl laurate of 3% (w/v), giving the maximum level of adipic acid of 12.1 g L−1 and production rate of 0.1 g L−1 h−1.

Similar content being viewed by others

References

Polen T, Spelberg M, Bott M (2012) Toward biotechnological production of adipic acid and precursors from biorenewables. J Biotechnol 167:75–84. https://doi.org/10.1016/j.jbiotec.2012.07.008

Castellan A, Bart JCJ, Cavallaro S (1991) Industrial production and use of adipic acid. Catal Today 9:237–254. https://doi.org/10.1016/0920-5861(91)80049-F

Draths KM, Frost JW (1994) Environmentally compatible synthesis of adipic acid from D-glucose. J Am Chem Soc 116:399–400. https://doi.org/10.1021/ja00114a003

Sun J, Raza M, Sun X, Yuan Q (2018) Biosynthesis of adipic acid via microaerobic hydrogenation of cis, cis-muconic acid by oxygen-sensitive enoate reductase. J Biotechnol 280:49–54. https://doi.org/10.1016/j.jbiotec.2018.06.304

Niu W, Draths KM, Frost JW (2002) Benzene-free synthesis of adipic acid. Biotechnol Prog 18:201–211. https://doi.org/10.1021/bp010179x

Zhao M, Huang D, Zhang X, Koffas MAG, Zhou J, Deng Y (2018) Metabolic engineering of Escherichia coli for producing adipic acid through the reverse adipate degradation pathway. Metab Eng 47:254–262. https://doi.org/10.1016/j.ymben.2018.04.002

Picataggio S, Beardslee T (2012) Biological methods for preparing adipic acid. United States patent US 8241879 B2. https://patentimages.storage.googleapis.com/13/14/dd/0ccf0788f9b566/US8778658.pdf

Skoog E, Shin JH, Saez-Jimenez V, Mapelli V, Olsson L (2018) Biobased adipic acid—the challenge of developing the production host. Biotechnol Adv 36:2248–2263. https://doi.org/10.1016/j.biotechadv.2018.10.012

Buzás Z, Dallmann K, Szajáni B (1989) Influence of pH on the growth and ethanol production of free and immobilized Saccharomyces cerevisiae cells. Biotechnol Bioeng 34:882–884. https://doi.org/10.1002/bit.260340620

Raj K, Partow S, Correia K, Khusnutdinova AN, Yakunin AF, Mahadevan R (2018) Biocatalytic production of adipic acid from glucose using engineered Saccharomyces cerevisiae. Metab Eng Commun 6:28–32

Ayhan D (2007) Importance of biodiesel as transportation fuel. Energ policy 35:4661–4670. https://doi.org/10.1016/j.enpol.2007.04.003

Gietz RD, Schiestl RH (2007) High-efficiency yeast transformation using the LiAc/SS carrier DNA/PEG method. Nat protoc 2:31–34. https://doi.org/10.1038/nprot.2007.13

Hong WK, Kim CH, Heo SY, Luo LH, Oh BR, Rairakhwada D, Seo JW (2011) 1,3-Propandiol production by engineered Hansenula polymorpha expressing dha genes from Klebsiella pneumoniae. Bioprocess Biosyst Eng 34:231–236. https://doi.org/10.1007/s00449-010-0465-z

Matsubara C, Nishikawa Y, Yoshida Y, Takamura K (1983) A spectrophotometric method for the determination of free fatty acid in serum using acyl-coenzyme A synthetase and acyl-coenzyme A oxidase. Anal Biochem 130:128–133. https://doi.org/10.1016/0003-2697(83)90659-0

Kawaguchi A, Tsubotani S, Seyama Y, Yamakawa T, Osumi T, Hashimoto T, Kikuchi T, Ando M, Okuda S (1980) Stereochemistry of dehydrogenation catalyzed by acyl-CoA oxidase. J Biochem 88:1481–1486. https://doi.org/10.1016/0003-2697(83)90659-0

Okabe H, Uji Y, Nagashima K, Noma A (1980) Enzymic determination of free fatty acids in serum. Clin Chem 26:1540–1543

Poosch MS, Yamazaki RK (1986) Determination of peroxisomal fatty acyl-CoA oxidase activity using a lauroyl-CoA-based fluorometric assay. BioChim Biophys Acta 884:585–593

Park JM, Oh BR, Kang IY, Heo SY, Seo JW, Park SM, Hong WK, Kim CH (2017) Enhancement of 2,3-butanediol production from Jerusalem artichoke tuber extract by a recombinant Bacillus sp. strain BRC1 with increased inulinase activity. J Ind Microbiol Biotechnol 44:1107–1113. https://doi.org/10.1007/s10295-017-1932-1

Wang HJ, Le Dall MT, Wach Y, Laroche C, Belin JM, Gaillardin C, Nicaud JM (1999) Evaluation of acyl coenzyme A oxidase (Aox) isozyme function in the n-alkane-assimilating yeast Yarrowia lipolytica. J Bacteriol 181:5140–5148

Mlı́čková K, Luo Y, d'Andréa S, Peč P, Chardot T, Nicaud JM (2004) Acyl-CoA oxidase, a key step for lipid accumulation in the yeast Yarrowia lipolytica. J Mol Catal B Enz 28:81–85. https://doi.org/10.1016/j.molcatb.2004.01.007

Haddouche R, Delessert S, Sabirova J, Neueglise C, Poirier Y, Nicaud JM (2010) Roles of multiple acyl-CoA oxidases in the routing of carbon flow towards β-oxidation and polyhydroxyalkanoate biosynthesis in Yarrowia lipolytica. FEMS Yeast Res 10:917–927. https://doi.org/10.1111/j.1567-1364.2010.00670.x

Kim S, Kim KS (2018) Crystal structure of acyl-CoA oxidase 3 from Yarrowia lipolytica with specificity of short-chain acyl-CoA. J Microbiol Biotechnol 28:597–605. https://www.ncbi.nlm.nih.gov/pubmed/29429324

Picataggio S, Deanda K, Mielenz J (1991) Determination of Candida tropicalis acyl coenzyme A oxidase isozyme function by sequential gene disruption. Mol Cell Biol 11:4333–4339

Li Q, Du W, Liu D (2008) Perspectives of microbial oils for biodiesel production. Appl Microbiol Biot 80:749–756. https://doi.org/10.1007/s00253-008-1625-9

Rossi M, Buzzini P, Cordisco L, Amaretti A, Sala M, Raimondi S, Ponzoni C, Pagnoni UM, Matteuzzi D (2009) Growth, lipid accumulation, and fatty acid composition in obligate psychrophilic, facultative psychrophilic, and mesophilic yeasts. FEMS Microbiol Ecol 69:363–372. https://doi.org/10.1111/j.1574-6941.2009.00727.x

Zhu LY, Zong MH, Wu H (2008) Efficient lipid production with Trichosporon fermentans and its use for biodiesel preparation. Bioresource Technol 99:7881–7885. https://doi.org/10.1016/j.biortech.2008.02.033

Ageitos JM, Vallejo JA, Veiga-Crespo P, Villa TG (2011) Oily yeasts as oleaginous cell factories. Appl Microbiol Biot 90:1219–1227. https://doi.org/10.1007/s00253-011-3200-z

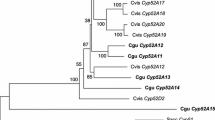

Craft DL, Madduri KM, Eshoo M, Wilson CR (2003) Identification and characterization of the CYP52 family of Candida tropicalis ATCC 20336, important for the conversion of fatty acids and alkanes to α, ω-dicarboxylic acids. Appl Environ Microbiol 69:5983–5991. https://doi.org/10.1128/AEM.69.10.5983-5991.2003

Song JW, Lee JH, Bornscheuer UT, Park JB (2014) Microbial synthesis of medium-chain α, ω-dicarboxylic acids and ω-aminocarboxylic acids from renewable long-chain fatty acids. Adv Synth Catal 356:1782–1788. https://doi.org/10.1002/adsc.201300784

Wentzel A, Ellingsen TE, Kotlar HK, Zotchev SB, Throne-Holst M (2007) Bacterial metabolism of long-chain n-alkanes. Appl Microbiol Biot 76:1209–1221. https://doi.org/10.1007/s00253-007-1119-1

Curran KA, Leavitt JM, Karim AS, Alper HS (2013) Metabolic engineering of muconic acid production in Saccharomyces cerevisiae. Metab Eng 15:55–66. https://doi.org/10.1016/j.ymben.2012.10.003

Leavitt JM, Wagner JM, Tu CC, Tong A, Liu Y, Alper HS (2017) Biosensorenabled directed evolution to improve muconic acid production in Saccharomyces cerevisiae. Biotechnol J 12:1600687. https://doi.org/10.1002/biot.201600687

Acknowledgements

This work was supported by grants from the Korea Research Foundation (KRF) for Basic Research Promotion (2017R1A2B4006016) and by the Advanced Biomass R&D Center (ABC) of Global Frontier Project.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.Below is the link to the electronic supplementary material.

449_2019_2202_MOESM1_ESM.tif

Supplementary Fig. 1. Analysis of adipic acid production by the C. tropicalis AOX4-deficient (ΔAOX4) mutant using LC/MS/MS at culture 72 h. The fragmentor voltage and the collision energy were 70 V and 5 V. A, cultured sample with methyl laurate (145.0 to 101.0) and B, adipic acid standard (145.0 to 101.0) (TIF 851 kb)

449_2019_2202_MOESM2_ESM.tif

Supplementary Fig. 2. HPLC analysis of adipic acid production by A, wild-type C. tropicalis; B, AOX4-deficient (ΔAOX4) mutant; C, adipic acid standard. methyl laurate, open inverted triangles; adipic acid, closed inverted triangles (TIF 657 kb)

Rights and permissions

About this article

Cite this article

Ju, JH., Oh, BR., Heo, SY. et al. Production of adipic acid by short- and long-chain fatty acid acyl-CoA oxidase engineered in yeast Candida tropicalis. Bioprocess Biosyst Eng 43, 33–43 (2020). https://doi.org/10.1007/s00449-019-02202-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-019-02202-w