Abstract

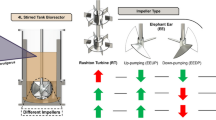

The computational fluid dynamics (CFD) software package Fluent was utilized to simulate the flow field of Escherichia coli (E. coli) BL21 fermentation in a 50 L automatic bioreactor for producing α-cyclodextrin glycosyltransferase (α-CGTase) in this study. 4-down-pumping propeller (4DPP), 6-curved-blade disc turbine (6CBDT), and Rushton turbine (RT) were assembled to form eight impeller combinations (C1–C8). Through flow field simulating, four referential impeller combinations, in which C6, C7, and C8 were three layers stirring blades and C1 as a control, were selected to carry out batch fermentation experiments (TC1, TC6, TC7, and TC8) for validation. The correlation analysis between simulation results and experimental measurements indicated that TC6 (tank equipped with C6 impeller combination) exhibited lower enzymatic activity though it had the better mixing effect, fastest oxygen uptake rate (OUR), and maximum specific growth rate (µ) in the initial stage, which was just to the contrary in TC8. It was revealed by next fed-batch fermentation experiments in TC6 and TC8 that TC6 was considered as excellent flow field properties brought about the higher µ of E. coli BL21 and fast acetic acid (HAc) accumulation, which resulting in a serious inhibition on α-CGTase expression and this negative effect could not be removed. As a result, there should be a threshold of HAc accumulation rate which brought about a terrible inhibitory effect on α-CGTase expression. Moreover, the yield of α-CGTase activity reached 231.38 U mL− 1 in TC8, which elevated 31.74% compared to that obtained in TC1.

Similar content being viewed by others

References

Tonkova A (1998) Bacterial cyclodextrin glucanotransferase. Enzyme Microb Technol 22(8):678–686

Li Z, Wang M, Wang F, Gu Z, Du G, Wu J, Chen J (2007) γ-Cyclodextrin: a review on enzymatic production and applications. Appl Microb Biotechnol 77(2):245–255

Macaev F, Boldescu V (2015) Cyclodextrins in asymmetric and stereospecific synthesis. Symmetry 7(4):1699–1720

Bautista V, Esclapez J, Pérezpomares F, Martínezespinosa RM, Camacho M, Bonete MJ (2012) Cyclodextrin glycosyltransferase: a key enzyme in the assimilation of starch by the halophilic archaeon Haloferax mediterranei. Extremophiles 16(1):147–159

Mahat MK, Illias RM, Rahman RA, Rashid NAA, Mahmood NAN, Hassan O, Aziz SA, Kamaruddin K (2004) Production of cyclodextrin glucanotransferase (CGTase) from alkalophilic Bacillus sp. TS1-1: media optimization using experimental design. Enzyme Microb Technol 35(5):467–473

Rosso AM, Ferrarotti SA, Krymkiewicz N, Nudel BC (2002) Optimisation of batch culture conditions for cyclodextrin glucanotransferase production from Bacillus circulans DF 9R. Microb Cell Fact 1(1):1–9

Kim MH, Lee JK, Kim HK, Sohn CB, Oh TK (1999) Overexpression of cyclodextrin glycosyltransferase gene from Brevibacillus brevis in Escherichia coli by control of temperature and mannitol concentration. Biotechnol Tech 13(11):765–770

Kriaa M, Ayadi DZ, Jemli S, Sahnoun M, Bejar S, Kammoun R (2012) Improvement of cyclodextrin glycosyltransferase (CGTase) production by recombinant Escherichia coli pAD26 immobilized on the cotton. Biologia 67(6):1049–1055

Ramli N, Abd-Aziz S, Alitheen NB, Hassan MA, Maeda T (2013) Improvement of cyclodextrin glycosyltransferase gene expression in Escherichia coli by insertion of regulatory sequences involved in the promotion of RNA transcription. Mol Biotechnol 54(3):961–968

Ahmed SU, Ranganathan P, Pandey A (2010) Computational fluid dynamics modeling of gas dispersion in multi impeller bioreactor. J Biosci Bioeng 109(6):588–597

Kerdouss F, Bannari A, Proulx P, Bannari R, Skrga M, Labrecque Y (2008) Two-phase mass transfer coefficient prediction in stirred vessel with a CFD model. Comput Chem Eng 32(8):1943–1955

Garcia-Ochoa F, Gomez E (2009) Bioreactor scale-up and oxygen transfer rate in microbial processes: an overview. Biotechnol Adv 27(2):153

Enfors SO, Jahic M, Rozkov A, Xu B, Hecker M, Jürgen B, Krüger E, Schweder T, Hamer G, O’Beirne D (2001) Physiological responses to mixing in large scale bioreactors. J Biotechnol 85(2):175–185

Liu XL (2014) Analysis of acetic acid metabolism from recombinant E. coli his 3.1. Value Eng 12:294–297

Suárez DC, Kilikian BV (2000) Acetic acid accumulation in aerobic growth of recombinant Escherichia coli. Process Biochem 35(9):1051–1055

Shi D, Zhang Q, Wen J, Song X, Hong H (2013) CFD simulation of gas-inducing reactor and its application in yeast production. J Nanjing Univ Technol (Natural Sci Ed) 35(4):72–77

Um BH, Hanley TR (2008) A CFD model for predicting the flow patterns of viscous fluids in a bioreactor under various operating conditions. Korean J Chem Eng 25(5):1094–1102

Li X, Zhang J, Tan YL, Li ZH, Yu XF, Xia JY, Chu J, Ge YQ (2013) Effects of flow field on the metabolic characteristics of Streptomyces lincolnensis in the industrial fermentation of lincomycin. J Biosci Bioeng 115(1):27–31

Duan S, Yuan G, Zhao Y, Ni W, Luo H, Shi Z, Liu F (2013) Simulation of computational fluid dynamics and comparison of cephalosporin C fermentation performance with different impeller combinations. Korean J Chem Eng 30(5):1097–1104

Korte G, Rinas U, Kracke-Helm HA, Schügerl K (1991) Simulation of cell growth, substrate consumption and product formation with recombinant Escherichia coli. Appl Microbiol Biotechnol 35(2):189–199

Nishio Y, Ogishima S, Ichikawa M, Yamada Y, Usuda Y, Masuda T, Tanaka H (2013) Analysis of l-glutamic acid fermentation by using a dynamic metabolic simulation model of Escherichia coli. BMC Syst Biol 7(1):1–12

Konstantinov K, Kishimoto M, Seki T, Yoshida T (1990) A balanced DO-stat and its application to the control of acetic acid excretion by recombinant Escherichia coli. Biotechnol Bioeng 36(7):750–758

Zhu J (1981) Biochemistry experiment. Shanghai Scientific and Technical Publishers, Shanghai

Lejeune A, Sakaguchi K, Imanaka T (1989) A spectrophotometric assay for the cyclization activity of cyclomaltohexaose (α-cyclodextrin) glucanotransferase. Anal Biochem 181(1):6–11

Kim JH, Lim JS, Kim CH, Kim SW (2005) Morphology and kinetics studies on cephalosporin C production by Cephalosporium acremonium M25 in a 30-l bioreactor using a mixture of inocula. Lett Appl Microbiol 40(5):307–311

Sommerfeld M, Decker S (2004) State of the art and future trends in CFD simulation of stirred vessel hydrodynamics. Chem Eng Technol 27(3):215–224

Monod J (1978) The growth of bacterial cultures. Selected Papers Mol Biol Jacques Monod 3(6):139–162

Sandén AM, Prytz I, Tubulekas I, Förberg C, Le H, Hektor A, Neubauer P, Pragai Z, Harwood C, Ward A (2003) Limiting factors in Escherichia coli fed-batch production of recombinant proteins. Biotechnol Bioeng 81(2):158–166

Xia JY, Wang YH, Zhang SL, Chen N, Yin P, Zhuang YP, Chu J (2009) Fluid dynamics investigation of variant impeller combinations by simulation and fermentation experiment. Biochem Eng J 43(3):252–260

Montante G, Magelli F (2004) Liquid Homogenization characteristics in vessels stirred with multiple rushton turbines mounted at different spacings: CFD Study and comparison with experimental data. Chem Eng Res Design 82(9):1179–1187

Bandaiphet C, Prasertsan P (2006) Effect of aeration and agitation rates and scale-up on oxygen transfer coefficient, k(L)a in exopolysaccharide production from Enterobacter cloacae WD7. Carbohyd Polym 66(2):216–228

Çalık P, Çalık G, Özdamar TH (2000) Oxygen-transfer strategy and its regulation effects in serine alkaline protease production by Bacillus licheniformis. Biotechnol Bioeng 69(3):301–311

Haq IU, Ali S, Qadeer MA (2005) Influence of dissolved oxygen concentration on intracellular pH for regulation of Aspergillus niger growth rate during citric acid fermentation in a stirred tank bioreactor. Int J Biol Sci 1(1):34–41

Jahoda M, Tomášková L, Moštěk M (2009) CFD prediction of liquid homogenisation in a gas–liquid stirred tank. Chem Eng Res Design 87(4):460–467

Acknowledgements

This work was supported by Natural Science Foundation of Hubei province (No. 2015CFA150), and thanks the research team for their sincere cooperation and selfless dedication.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Li, X., Xu, CQ., Luo, YD. et al. Influence of the flow field on α-cyclodextrin glycosyltransferase production by Escherichia coli BL21. Bioprocess Biosyst Eng 41, 819–829 (2018). https://doi.org/10.1007/s00449-018-1916-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-018-1916-1