Abstract

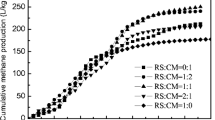

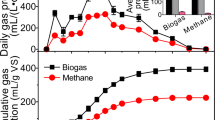

The kinetics of anaerobic co-digestion of poultry litter and wheat straw has not been widely reported in the literature. Since endogenous decay and yield coefficients are two basic parameters for the design of anaerobic digesters, they are currently estimated only by continues experiments. In this study, numerical integration was employed to develop a novel strategy to estimate endogenous decay and yield coefficients using initial and final liquid data combined with methane volumes produced over time in batch experiments. To verify this method, the kinetics of batch anaerobic co-digestion of poultry litter and wheat straw at different TS and VS levels was investigated, with the corresponding endogenous decay and (non-observed) yield coefficients in the exponential periods determined to be between 0.74 × 10−3 and 6.1 × 10−3 d−1, and between 0.0259 and 0.108 g VSS (g VS)−1, respectively. A general Gompertz model developed early for bio-product could be used to simulate the methane volume profile in the co-digestion. The same model parameters obtained from the methane model combined with the corresponding yield coefficients could also be used to describe the VSS generation and VS destruction.

Similar content being viewed by others

Abbreviations

- b:

-

Fitted constant in the Gompertz model (dimensionless)

- c:

-

Fitted constant in the Gompertz model (d)

- e:

-

Base of the natural logarithm (dimensionless)

- gmp :

-

Maximum bio-product rate (i.e., at the deflection point of P vs. t curve) (mL d−1)

- K:

-

Maximum rate constant in the Monod model (d−1)

- KS :

-

Half-saturation rate coefficient in the Monod model (g)

- kd :

-

Endogenous decay coefficient (d−1)

- m:

-

Sample size

- P:

-

Cumulated biogas volume (mL)

- P i :

-

Value of point i calculated from the models

- P m :

-

Maximum gas volume (mL)

- P0 :

-

Fitted constant in the Gompertz model (mL)

- pi :

-

Observed value of point i

- \(\overline{p}\) :

-

Mean of the observed data

- R 2 :

-

Coefficients of determination

- S:

-

Substrate mass in the digester represented by the volatile solid (VS) (g)

- SSres :

-

Sums of squares of residuals

- SStol :

-

Total sum of squares of deviations

- t:

-

Digestion time (d)

- X:

-

Microbial mass represented by the suspended volatile solid (VSS) (g)

- YX/S :

-

Yield coefficient of microbial mass to substrate mass (g VSS (g VS)−1)

- \({\text{Y}}_{{{\text{X}}/{\text{P}}}} = {\text{Y}}_{{{\text{S}}/{\text{X}}}} /{\text{Y}}_{{{\text{P}}/{\text{S}}}}\) :

-

Yield coefficient of microbial mass to methane volume (g VSS mL−1)

- λ :

-

Lag time, which is defined as the t axis intercept of the tangent through the inflection point (d)

- µ m :

-

Maximum specific growth rate (d−1)

- c:

-

Calculated datum

- fc:

-

Final calculated datum

- fe:

-

Final experimental datum

- i :

-

Index of the observed points

- ob:

-

Observed datum

- 0:

-

Initial datum

References

Scharbor J (2011) Poultry litter: is it fertilizer or pollution? Change Agent 42–43

Edwards DR, Daniel TC (1992) Environmental impacts of on-farm poultry waste-disposal: a review. Bioresour Technol 41(1):9–33

Shih JCH (1987) Ecological benefits of anaerobic digestion. Poult Sci 66(6):946–950

Chastain JP, Coloma-del Valle A, Moore KP (2012) Using broiler litter as an energy source: energy content and ash composition. Appl Eng Agric 28(4):513–522

Priyadarsan S, Annamalai K, Sweeten J, Mukhtar S, Holtzapple M (2004) Fixed-bed gasification of feedlot manure and poultry litter biomass. Trans ASAE 47(5):1689–1696

Bolan NS, Szogi A, Chuasavathi T, Seshadri B, Rothrock M, Panneerselvam P (2010) Uses and management of poultry litter. World’s Poult Sci J 66(04):673–698

Turnell J, Faulkner R, Hinch G (2007) Recent advances in Australian broiler litter utilisation. World’s Poult Sci J 63(02):223–231

Henihan AM, Leahy MJ, Leahy J, Cummins E, Kelleher B (2003) Emissions modeling of fluidised bed co-combustion of poultry litter and peat. Bioresour Technol 87(3):289–294

De Jong W, Di Nola G, Venneker B, Spliethoff H, Wójtowicz M (2007) TG-FTIR pyrolysis of coal and secondary biomass fuels: determination of pyrolysis kinetic parameters for main species and NO × precursors. Fuel 86(15):2367–2376

Singh K, Lee K, Worley J, Risse LM, Das KC (2010) Anaerobic digestion of poultry litter: a review. Appl Eng Agric 26(4):677–688

Kelleher B, Leahy J, Henihan A, O’dwyer T, Sutton D, Leahy M (2002) Advances in poultry litter disposal technology–a review. Bioresour Technol 83(1):27–36

Horan N, Fletcher L, Betmal S, Wilks S, Keevil C (2004) Die-off of enteric bacterial pathogens during mesophilic anaerobic digestion. Water Res 38(5):1113–1120

USDA (2014) Wheat Production Report for Arkansas Washington DC: United States Department of Agriculture

Blanch H, Clark D (1996) Biochemical engineering. Marel Dekkar Inc, New York, p 174

Ramdani A, Dold P, Déléris S, Lamarre D, Gadbois A, Comeau Y (2010) Biodegradation of the endogenous residue of activated sludge. Water Res 44(7):2179–2188

Speitel GE, DiGiano FA (1988) Determination of microbial kinetic coefficients through measurement of initial rates by radiochemical techniques. Water Res 22(7):829–835

Arutchelvan V, Kanakasabai V, Elangovan R, Nagarajan S, Muralikrishnan V (2006) Kinetics of high strength phenol degradation using Bacillus brevis. J Hazard Mater 129(1):216–222

Singh KS, Viraraghavan T (2002) Effect of temperature on bio-kinetic coefficients in UASB treatment of municipal wastewater. Water Air Soil Pollut 136(1–4):243–254

Kumaran P, Paruchuri Y (1997) Kinetics of phenol biotransformation. Water Res 31(1):11–22

Terzis E (1994) Anaerobic treatment of industrial wastewater containing organic solvents. Water Sci Technol 29(9):321–329

Timur H, Özturk I (1999) Anaerobic sequencing batch reactor treatment of landfill leachate. Water Res 33(15):3225–3230

Nacheva PM, Chavez GM, Chacon JM, Chuil AC (2009) Treatment of cane sugar mill wastewater in an upflow anaerobic sludge bed reactor. Water Sci Technol 60(5):1347–1352

Shen J, Zhu J (2016) Optimization of methane production in anaerobic co-digestion of poultry litter and wheat straw at different percentages of total solid and volatile solid using a developed response surface model. J Environ Sci Health Part A 51(4):325–334

Shen J, Zhu J. (2015a) Effects of total solid, volatile solid, ammonia and ratio of carbon to nitrogen on methane production in Anaerobic Co-digestion of poultry litter and wheat straw. 2015 ASABE Annual International Meeting New Orleans, LA: ASABE; Paper number 152187836

Pandey A, Soccol CR, Rodriguez-Leon JA, Nigam P (2001) Solid state fermentation in biotechnology: fundamentals and applications. Asiatech Publishers, New Delhi

Zwietering M, Jongenburger I, Rombouts F, Van’t Riet K (1990) Modeling of the bacterial growth curve. Appl Environ Microbiol 56(6):1875–1881

Lay JY, Li YY, Noike T (1998) Developments of bacterial population and methanogenic activity in a laboratory-scale landfill bioreactor. Water Res 32(12):3673–3679

Van Ginkel S, Sung SW, Lay JJ (2001) Biohydrogen production as a function of pH and substrate concentration. Environ Sci Technol 35(24):4726–4730

Mu Y, Yu HQ, Wang G (2007) A kinetic approach to anaerobic hydrogen-producing process. Water Res 41(5):1152–1160

Costa J, Barbosa S, Alves M, Sousa D (2012) Thermochemical pre-and biological co-treatments to improve hydrolysis and methane production from poultry litter. Bioresour Technol 111:141–147

Li Y, Zhang R, Chen C, Liu G, He Y, Liu X (2013) Biogas production from co-digestion of corn stover and chicken manure under anaerobic wet, hemi-solid, and solid state conditions. Bioresour Technol 149:406–412

Kafle GK, Kim SH, Sung KI (2013) Ensiling of fish industry waste for biogas production: a lab scale evaluation of biochemical methane potential (BMP) and kinetics. Bioresour Technol 127:326–336

Wu X, Zhu J, Miller C (2013) Kinetics study of fermentative hydrogen production from liquid swine manure supplemented with glucose under controlled pH. J Environ Sci Health Part B Pestic Food Contam Agric Wastes 48(6):477–485

Zhu J, Zheng Y, Xu F, Li Y (2014) Solid-state anaerobic co-digestion of hay and soybean processing waste for biogas production. Bioresour Technol 154:240–247

Shen J, Zhu J. (2015b) Modeling Cumulative methane volume produced in Anaerobic Co-digestion of poultry litter and wheat straw using developed novel general gompertz models. 2015 ASABE Annual International Meeting New Orleans. LA: ASABE; Paper number 152187873

Webb AR, Hawkes FR (1985) THE anaerobic-digestion of poultry manure—variation of gas yeild with influent concentration and ammonium-nitrogen levels. Agric Wastes 14(2):135–156

Abbassi-Guendouz A, Brockmann D, Trably E, Dumas C, Delgenès J-P, Steyer J-P et al (2012) Total solids content drives high solid anaerobic digestion via mass transfer limitation. Bioresour Technol 111:55–61

Eddy M (1999) Wastewater engineering-treatment, disposal, and reuse, 3rd edn. McGraw Hill Publishing Company Ltd, New York, p 810

Acknowledgments

This work is financially supported by the USDA National Institute of Food and Agriculture, Hatch project 1003122, and the Arkansas Agricultural Experiment Station.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shen, J., Zhu, J. Kinetics of batch anaerobic co-digestion of poultry litter and wheat straw including a novel strategy of estimation of endogenous decay and yield coefficients using numerical integration. Bioprocess Biosyst Eng 39, 1553–1565 (2016). https://doi.org/10.1007/s00449-016-1630-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-016-1630-9