Abstract

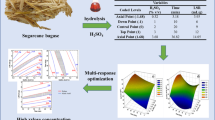

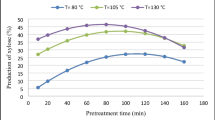

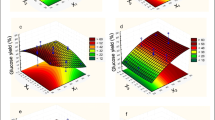

The goal of this work is to evaluate the influence of different pretreatments in the kinetics of enzymatic hydrolysis of sugarcane bagasse and to propose a reliable methodology to easily perform sensitivity analysis and updating kinetic parameters whenever necessary. A kinetic model was modified to represent the experimental data of the batch enzymatic hydrolysis of sugarcane bagasse pretreated with alkaline hydrogen peroxide. The simultaneous estimation of kinetic parameters of the mathematical model was performed using the Pikaia genetic algorithm using batch hydrolysis experimental data obtained with different enzymatic loads. Subsequently, Plackett–Burman designs were used to identify the kinetic parameters with the higher influence on the dynamic behavior of the process variables, which were re-estimated to describe experimental data of the hydrolysis of bagasse pretreated with phosphoric acid + sodium hydroxide. The methodology was accurate and straightforward and can be used whenever there are changes in pretreatment conditions and/or fluctuations in biomass composition in different harvests.

Similar content being viewed by others

Abbreviations

- B :

-

Concentration of cellobiose (g/L)

- C :

-

Concentration of cellulose (g/L)

- enzc :

-

Cellulase activity concentration (FPU/L)

- enzg :

-

β-Glucosidase activity concentration (CBU/L)

- G :

-

Concentration of glucose (g/L)

- k 1 :

-

Maximum specific rate of cellulose hydrolysis to cellobiose (h−1)

- k 2 :

-

Specific rate of cellobiose hydrolysis to glucose (g/(CBU h))

- K 1 :

-

Lumped specific rate of cellulose hydrolysis to cellobiose (h−1)

- K 2 :

-

Lumped specific rate of cellobiose hydrolysis to glucose (g/(L h))

- K eq :

-

Cellulase adsorption saturation constant (FPU/L)

- K L :

-

Constant for β-glucosidase adsorption to lignin (L/g)

- K m :

-

Cellobiose saturation constant for β-glucosidase (g/L)

- K 1B :

-

Inhibition constant of cellulase by cellobiose (g/L)

- K 1G :

-

Inhibition constant of cellulase by glucose (g/L)

- K 2G :

-

Inhibition constant of β-glucosidase by glucose (g/L)

- L :

-

Concentration of lignin (g/L)

- r 1 :

-

Volumetric rate of cellulose hydrolysis to cellobiose (g/(L h))

- r 2 :

-

Volumetric rate of cellobiose hydrolysis to glucose (g/(L h))

- t :

-

Time (h)

- λ :

-

Rate of decrease in cellulose specific surface area (h−1)

References

Soni SK, Batra N, Bansal N, Soni R (2010) BioResour 5(2):741–748

Kaar WE, Holtzapple MT (2000) Biomass Bioenerg 18:189–199

Rabelo SC, Maciel Filho R, Costa AC (2009) Appl. Biochem Biotechnol 153:139–150

Rabelo SC, Maciel Filho R, Costa AC (2008) Appl. Biochem Biotechnol 144:87–100

Rivera EAC, Rabelo SC, Garcia DR, Maciel Filho R, Costa AC (2010) J Chem Technol Biotechnol 85:983–992

Rabelo SC, Fonseca NAA, Fuentes LLG, Andrade RR, Maciel Filho R, Costa AC (2011) J Biomass Bioenerg 35:2600–2607

Teramoto Y, Lee SH, Endo T (2009) Bioresour Technol 100(20):4783–4789

Zhang J, Zhang B, Zhang J, Lin L, Liu S, Ouyang P (2010) Biotechnol Adv 28(5):613–619

Rueda SMG (2010) Master thesis, State University of Campinas, Campinas, Brazil

Vásquez MP, Da Silva J, De Souza MBJ, Pereira NJ (2007) Appl Biochem Biotechnol 137–140:141–153

Bezerra RMF, Dias AA (2004) Appl Biochem Biotechnol 112:173–184

Drissen RET, Maas RHW, Maarel MJECVD, Kabel MA, Schols HA, Tramper J (2007) Biocatal. Biotransfor. 25:419–429

Philippidis GP, Hatzis C (1997) Biotechnol Progr 13:222–231

Kadam KL, Rydholm EC, Mcmillan JD (2004) Biotechnol Progr 20:698–705

Zheng Y, Pan Z, Zhang R, Jenkins BM (2009) Biotechnol Bioeng 102:1558–1569

Khodaverdi M, Jeihanipour A, Karimi K, Taherzadeh MJ (2012) J Ind Microbiol Biotechnol 39:429–438

Shen J, Agblevor FA (2008) Chem Eng Commun 195:1107–1121

Pettersson PO, Eklund R, Zacchi G (2002) Appl Biochem Biotechnol 98–100:733–746

Kim JK, Oh BR, Shin HJ, Eom CY, Kim SW (2008) Process Biochem 43:1308–1312

Zhou J, Wang YH, Chu J, Luo LZ, Zhuang YP, Zhang SL (2009) Bioresour Technol 100:819–825

Zhu L (2005) Ph.D thesis, Texas A&M University, College Station, USA

Garcia DR (2010) Master thesis, State University of Campinas, Campinas, Brazil

Sluiter A, Hames B, Ruiz R, Sluiter J, Templeton D (2005) National Renewable Energy Laboratory. Available from: http://www.nrel.gov/biomass/pdfs/42622.pdf. Accessed July 2009a

Sluiter A, Ruiz R, Scarlata J, Sluiter J, Templeton D (2005) National Renewable Energy Laboratory. Available from: http://www.nrel.gov/biomass/pdfs/42619.pdf. Accessed July 2009b

Sluiter A, Hames B, Ruiz R, Scarlata J, Sluiter J, Templeton D (2008) National Renewable Energy Laboratory. Available from: http://www.nrel.gov/biomass/pdfs/42618.pdf. Accessed Jan 2010

Hyman D, Sluiter D, Crocker D, Johnson J, Sluiter J, Black S, Scarlata C (1996). National Renewable Energy Laboratory. Available from: http://www.nrel.gov/biomass/pdfs/42617.pdf. Accessed Dec 2009

Ghose TK (1987) Pure Appl Chem 59:257–268

Adney B, Baker J (1996) Chemical analysis and testing task—laboratory analytical procedure. National Renewable Energy Laboratory (NREL), LAP-006

Wood TM, Bhat KM (1988) In: Wood WA, Kellog ST (eds) Methods for measuring cellulase activities, vol. 160: methods in enzymology. Academic Press, San Diego, pp 87–116

Philippidis GP, Spindler DD, Wyman CE (1992) Appl Biochem Biotechnol 34–35:543–556

Philippidis GP, Smith TK, Wyman CE (1993) Biotechnol Bioeng 41:846–853

Charbonneau P, Knapp B (1996) User’s Guide to PIKAIA 1.0, NCAR Technical note 418+IA. Nacional Center for Atmospheric Research, Boulder

Nandasana DA, Kumar S (2008) Biochem Eng J 38:277–284

Smets I, Bernaerts K, Sun J, Marchal K, Vanderleyden J, Impe JV (2002) Biotechnol Bioeng 80(2):195–200

Andrade RR, Rivera EAC, Atala DIP, Maciel Filho R, Maugeri Filho F, Costa AC (2009) Bioprocess Biosyst Eng 32:673–680

Beres DL, Hawkins DM (2001) Ecol Model 141:171–183

Andrade RR (2007) Master thesis, State University of Campinas, Campinas, Brazil

Atala DIP, Costa AC, Maugeri Filho F, Maciel Filho R (2001) Appl. Biochem Biotechnol 91–93:353–366

Rivera EAC, Costa AC, Andrade RR, Atala DIP, Maugeri Filho F, Maciel Filho R (2007) Biochem. Eng J 36:157–166

Mantovaneli ICC, Rivera EAC, Costa AC, Maciel Filho R (2007) Appl Biochem Biotechnol 136:817–834

Acknowledgments

The authors acknowledge Fundação de Amparo à Pesquisa do Estado de São Paulo (FAPESP) process number 2009/02424-7 and Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Neto, J.M., dos Reis Garcia, D., Rueda, S.M.G. et al. Study of kinetic parameters in a mechanistic model for enzymatic hydrolysis of sugarcane bagasse subjected to different pretreatments. Bioprocess Biosyst Eng 36, 1579–1590 (2013). https://doi.org/10.1007/s00449-013-0930-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-013-0930-6