Abstract

The single-step green synthesis has been successfully established to prepare a bi-phase structure of Zn/ZnO nanoparticles using laser ablation in a liquid medium. Nd: YAG laser with the wavelength of 1064 nm was employed to perform the laser ablation in pure water and Pometia pinnata (P. pinnata) leaf extract, with the leaf, were extracted in pure water and some concentration of ethanol. ZnO nanoparticles can be obtained via laser ablation in pure water, while the usage of P. pinnata leaf extract as the solution has caused the appearance of the bi-phase Zn/ZnO nanostructure. X-ray diffraction (XRD) pattern indicates the appearance of Zn peaks alongside with ZnO peaks with the inclusion of P. pinnata leaf extract. Transmission electron microscope (TEM) images show the change of shape from the rod-like shape into a spherical shape and smaller size spherical shape of Zn/ZnO nanoparticles in comparison with ZnO. Noticeable change of UV–visible spectrum emerges as the water was substituted by P. pinnata leaf extract. The zeta potential of Zn/ZnO prepared with P. pinnata extracted in water, with the value of − 18.9 V, reduces down to − 43.5 and − 41.1 for 20–40% of ethanol concentration, respectively. The as-prepared ZnO and Zn/ZnO colloidal samples were evaluated for their antibacterial activities against two strains Staphylococcus aureus (S. aureus) and Escherichia coli (E. coli). Zn/ZnO sample shows a more substantial antibacterial effect in comparison with pure ZnO, no bacteria alive after 12 and 24 h’ treatment for E. coli and S. aureus, respectively.

Similar content being viewed by others

1 Introduction

The bi-phase Zn/ZnO materials have been studied for its unique characteristic of metal–semiconductor combination and the junctions formed at the metal–semiconductor interface. The shape and size were varied from the simple nano-size [1,2,3,4,5,6,7] to microsize with a more complicated structure such as microspheres, micro-tubes, micro-belts and micro-urchins [8,9,10,11]. Zn/ZnO nanostructure has been applied as an active agent for disinfection and environmental sterilization which exhibited great potential. Jung et al. have successfully applied core/shell Zn/ZnO nanostructures for better photocatalytic function for dye degradation than single-phase ZnO nanostructures. The core/shell Zn/ZnO nanostructures can perform faster degradation on lindane, and it was 99.5% decomposed after 40-min photo-irradiation, in comparison with the pure ZnO [3]. Irradiation of the light with energy higher than the gap energy of ZnO has caused the formation of electrons and holes at conduction band (CB) and valence band (VB), respectively. At the interface of Zn/ZnO, the electrons can move to the Zn core such that the recombination can be prevented. In this case, the metal–semiconductor interface plays the role of an electron trap to reduce the recombination rate. The photo-generated hole and electrons will react with H2. Yi et al. show the performance of Zn/ZnO which can generate a high concentration of ROS to suppress the population of bacteria [6] and decompose some dyes [7] under UV, visible and dark condition. According to this work, the self-corrosion process occurred in the Zn/ZnO core/shell heterostructure has led to the production of the electron which then interacts with oxygen molecules to generate ROS. This process was also carried out in the dark without an external stimulus and special lighting condition [6,7].

The unique properties of bi-phase nanostructures, including Zn/ZnO, and its bright prospect for the environmental and medical application need to be supported with an appropriate synthesis technique. Laser ablation is one established method for nanostructures production [12,13,14,15] and surface modification [16,17,18]. On the widespread practice of laser ablation, Zn/ ZnO nanostructures can be formed in a single-step synthesis process [5,12,19,20,21]. Honda et al. have performed laser ablation in pure water and ethanol by varying pulse peak power and pulse width [12]. He found that higher energy and longer laser pulse prone to be more oxidated state and less likely to produce bi-phase Zn/ZnO nanostructure. The transformation of Zn metallic to pure ZnO can be interfered by using a surfactant such as SDS (sodium dodecyl sulphate) [5,19,21]. As the SDS was involved in the process, there was a competition between aqueous oxidation and surfactant protection of Zn clusters produced in the high temperature and high-pressure zinc plasma. The SDS concentration determined the content and speed of the surface adsorption of DS-ions, and hence the extent of the protective effect to the zinc clusters. The core/shell width was mentioned to be controllable by varying the concentration of SDS and laser power [5], in which the physical and chemical properties of these materials are tunable and dependent on the thickness of the shell layer. However, the usage of surfactant may limit the application of the produced nanoparticles, especially for environment and medicine, since SDS has been reported to leave a toxic effect to human and animals [22,23], hence its waste can be harmful to the environment.

The green technique which is environmentally friendly and requires less chemical substance on Zn/ZnO nanoparticles fabrication is highly demanded to support broader application on environmental, medical, food and pharmacology. Some researchers have demonstrated to involve natural resources on nanoparticle syntheses [24,25,26,27]. Zamiri et al. demonstrated that starch could be effectively used to both control particle size and stabilise ZnO nanoparticles in solution [28]. As reported by Chandran et al. and Toylamat et al., leaf extract consists of biological matter which was predicted to play a role as reductor and stabiliser for the nanoparticle formation [29,30]. Some leaf extracts like C. angustifolia and C. fistula, consisting of flavonoids, polyphenolic phytochemicals with inconsistent phenolic structures were found to have antioxidant function [31,32].

This paper works on using leaf extract as the solution to the laser ablation process. This single-step green technique was established to obtain Zn/ZnO nanostructures in a fast, simple and less chemical usage method. The Zn/ZnO product is also tested for its prospect as an antibacterial agent against two bacteria, Staphylococcus aureus (S. aureus) and Escherichia coli (E. coli). To the best of our knowledge, there is no previous research conducted on using leaf extract as the solution on the laser ablation process to produce Zn/ZnO nanostructures synthesis, and further exploring its potential as an antibacterial agent. One tropical plant was chosen for this purpose. Pometia pinnata (P. Pinnata) is a largely grown in Southeast Asia and the Pacific region. The woods and barks of this plant were studied for its beneficial usage as a powerful natural medicine [33,34]. A research conducted by Syarifah et al. have successfully performed the biosynthesis of ferric oxide nanoparticles by using P. pinnata leaf extract for magnetic application [35]. Therefore, it is sensible to apply P. pinnata leaf extract to produce bi-phase Zn/ZnO nanostructure via one-step green preparation using laser ablation technique and study its antibacterial properties.

2 Methods

2.1 Preparation of the Pometia pinnata extract

P. pinnata leaf extract (PPLE) used on the ablation process was collected from The University of Indonesia campus in February. They were surface cleaned with running tap water to remove debris and other contaminated organic contents, followed by double distilled water and air-dried at room temperature. About 10 g of finely cut leaves were kept in a beaker containing 100 mL of the solution and boiled for 30 min. The leaf was extracted with three different solutions in this experiment: double distilled water and ethanol–water with a concentration of 20–40%. The extract was cooled down and filtered with filter paper no.1, and the extract was stored at 4 °C for further use. A phytochemical screening analysis was performed for detecting the compound consisted of P. pinnata leaf extract. The extract was tested for phytochemical content qualitatively to determine the presence of alkaloids, terpenoids, flavonoids, saponins and phenols.[36,37].

2.2 Synthesis of ZnO and Zn/ZnO nanoparticles by laser ablation

Zinc oxide (ZnO) nanoparticles were prepared via laser ablation using a pulsed Q-Switched Nd: YAG laser from Quantel (Q-smart 850 mJ) with a wavelength of 1064 nm, the repetition rate of 10 Hz and pulse width energy of 6 ns. The laser fluence was 530 J/cm2, calculated by measuring the laser energy after the lens right before the ablation chamber and the focused beam's diameter. The synthesis of nanoparticles, a high-purity metallic zinc plate of 3 mm thick, and purity 99.5% (purchased from Nilaco corp.) was attached to a glass cell as the target and was rotated to avoid deep ablation trace. The experimental setup for laser ablation can be seen in Fig. 1. The Zn plate was placed in a cubic glass cell containing 5 ml of solution. The mass of the zinc target was measured before (m0) and after (mt) the ablation was performed and then m0 was subtracted by mt. This calculation was conducted to predict the zinc mass contained in the ZnO colloidal solution. There are four different laser ablation solutions, double distilled water, P. Pinnata leaf extract with 0% (pure water), 20–40% ethanol–water concentration. The laser ablation was performed at an irradiation time of 30 min for each different solution.

2.3 ZnO and Zn/ZnO nanoparticles characterization

After 30 min, the laser ablation was performed, the colloidal solution was identified by X-ray diffraction (XRD), ultraviolet–visible (UV–Vis) spectroscopy, photoluminescence (PL) spectroscopy, transmission electron microscope (TEM) and zeta potential. For XRD characterisation, the ZnO and Zn/ZnO nanoparticles colloid were transformed into powder by spreading the colloid into a petri dish and keeping it in an oven at 50 °C. XRD signals were recorded with a Shimadzu XRD-6000 X-ray diffractometer (Shimadzu, Tokyo, Japan) with Cu-Kα radiation (1.5406 Å) in the range of 2θ = 10°–90°. The UV–Vis optical absorbance of the ZnO and Zn/ZnO nanoparticles was recorded using JASCO V-570 UV/VIS spectrophotometer. The absorbance was measured to the as-prepared nanoparticle colloidal solution around 5 h after the ablation finished at room temperature. The photoluminescence spectra were studied using a photoluminescence setup equipped with femtosecond laser with a wavelength of 325 nm (fs—TOPAS Prime from Spectra-Physics) as the excitation source. Maya2000 Pro spectrometers from Ocean Insight was used as the detector for photoluminescence measurement. The Photoluminescence spectra were measured around 24 h after the samples were produced via laser ablation process. The structure and grain size were characterised using a Transmission electron microscope (TEM) FEI Tecnai G2 20S-Twin with an accelerating voltage of 200 kV. The samples were prepared for TEM experiments by depositing a drop of the ZnO-NP colloidal solution onto carbon-coated copper grids and left to air dry for one day at ambient temperature. The diameter of particle size was statistically measured to around 300 nanoparticles for each sample. Zeta potentials of the prepared samples were measured with a Zetasizer 3000HS photon correlation spectrometer (Malvern Instruments Ltd., Malvern, UK) at an applied voltage of 100 V.

2.4 ZnO and Zn/ZnO nanoparticles antibacterial testing

The antibacterial properties of ZnO and Zn/ZnO nanoparticles were tested against two bacteria, Staphylococcus aureus (S. aures) ATCC 6538 and Escherichia coli (E. coli) ATCC 8739 as the representative of gram-positive and negative bacteria, respectively. The bacteria colony was counted with total plate counting (TPC) after the bacteria were treated with nanoparticles samples with the contact time of 0, 12 and 24 h. The bacteria and nanoparticles samples were serially diluted 10−1, 10−2 and 10−3, then 1 mL of each culture was diluted into 15 mL tryptone soya agar (TSA) and the initial concentration of bacteria was controlled around 106 cfu/mL for all samples. The bacteria concentration of each culture was plate counted after 24 h of incubation at 37 °C. Pure water and pometia pinnata leaf extract (PPLE) were used as a negative control sample for this antibacterial activities characterization. The antibacterial testing was performed thrice, and the average value of the antibacterial growth (log cfu/mL) was obtained.

3 Results and discussion

3.1 ZnO and Zn/ZnO nanoparticles produced via laser ablation in water and PPLE

In Fig. 2, the picture of our samples is presented. The colour of ZnO and Zn/ZnO nanoparticles suspension in different environments can be varied from white colour into dark brown colour as is shown in Fig. 2. The colour of as-prepared ZnO colloids is dark grey and dense. However, it exhibits white colour after the ageing several minutes, same as typical colloidal ZnO nanoparticles produced via laser ablation in pure water [38,39]. As we changed the environment into P. pinnata leaf extract (PPLE), the colour of colloidal has turned into brown to dark brown colour. The leaf was extracted using pure water and a mixture of water and ethanol. The ethanol addition on the plant extract provides brighter and clearer suspension than one of the pure water. The shiny appearance of the Zn/ZnO nanoparticles colloid with plant extract and ethanol is due to a good solubility and stability of the bimolecular of the extract in ethanol. Based on screening phytochemical analysis, PPLE consists of some phenolic compounds such as flavonoid, terpenoid, phenol and saponin. Some of those compounds were reported can perform as a potent reductor agent, capping agent and also stabilizer for metal or metal oxide nanoparticles synthesis [40,41,42,43]. P. pinnata is tropical tree species of the plant family Sapindaceae which is highly composed by flavonoid [44,45].

3.2 Optical properties of ZnO and Zn/ZnO nanoparticles

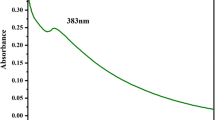

Figure 3a and b, respectively, shows the optical absorption spectra of the colloidal suspensions prepared in pure water, and PPLE with 0–20% ethanol–water concentration. The leaf extract was observed to have two peaks at around 250–300 nm, which are attributed to the natural compounds of PPLE. The ZnO curve has changed significantly after the pure water was substituted with PPLE extracted in ethanol 0% (E0%) and ethanol 20% (E20%). This substitution has induced the formation of Zn/ZnO and caused the blue-shifted of the absorbance curve of pure ZnO.

In Figure 3c, the absorbance of Zn/ZnO (with PPLE 0% ethanol) spectra was differentiated into several peaks, resulting in four prominent peaks 242 (green line), 285 (blue line), 324 (turquoise line), 370 (pink line) nm. Other peaks have been confirmed appears due to measurement tools, not belongs to the sample. Peaks at 242–285 nm are identical to those on original peak appeared on leaf extract E0% which are suggested might come from chemical compounds of PPLE. The peak at 370 nm is indicated belong to a compound of the extract because it was similar to a bump at 368 nm appears in Zn/ZnO sample with PPLE E20%. A peak at 324 nm was suggested as ZnO shell SPR peak, which is blue-shifted from the ZnO (absorbance peak at 342 nm) due to the presence of Zn in the core of the nanoparticle.

Figure 4a presents ZnO curve extracted from the full absorption spectra of ZnO sample produced in the pure water and Zn/ZnO sample produced in PPLE E0% and E20%. The blue-shifted of the ZnO absorbance peak can be seen more clearly. The blue-shift occurs due to weak oxidation of Zn nanoparticle due to PPLE and further the ethanol, which leads to the formation of Zn/ZnO core/shell structure. Soni et al. have performed the synthesis of Zn/ZnO core/shell nanoparticles by applying Polyethylene-Glycol (PEG) for slowing the oxidation rate of Zn. The same blue shifting also occurs as the Zn/ZnO core/shell nanostructure was formed. The mathematical calculation using Mie theory simulations of Zn/ZnO nanoparticle was conducted to study the thickness of oxidation level and its effect on the absorbance of Zn/ZnO nanoparticle. It was concluded that thicker oxidation layer (ZnO formation) the absorbance was shifted into higher wavelength (redshift). In this work, the absorbance peaks of ZnO plotted in Fig. 4a are in a good agreement with the simulation conducted by Soni et al. [20]. The oxidation appears as layer surrounding metallic zinc consist of the different dielectric function, resulting in a distinct absorbance peak of Zn/ZnO nanoparticle in comparison with single-phase ZnO.

The normalized absorbance of ZnO (a) and its bandgap curve (b) of ZnO and Zn/ZnO sample produced by laser ablation technique in pure water and P. pinnata leaf extract (PPLE) without ethanol (E0%) and with ethanol 20–40% (E20% and E40%) (a). This Gaussian curve was extracted from ZnO and Zn/ZnO PPLE absorption spectra

Further, the bandgap of pure ZnO and ZnO of Zn/ZnO sample were calculated by employing the Tauc plot method. The absorbance spectra in Fig. 4a were used to calculate the bandgap value of each sample, as shown in Fig. 4b. The optical energy gap of the nanoparticles was formulated in [46] where A is absorption, h is Planck’s constant, υ is light frequency, λ is wavelength, hυ is photon energy (eV), n = 1 and \({E}_{g}\) is energy gap. Below is the formula used to calculate the bandgap of ZnO nanoparticle.

and

where, A is a constant, Eg is the optical bandgap, h is Plank’s constant and α is the absorption coefficient. The plot of (αhv)2 versus Eg is presented in Fig. 4b. The calculated band gap energy is 3.18 eV for pure ZnO which is also reported in our previous work [47] and 3.22–3.25 eV for the ZnO of Zn/ZnO samples. The existence of the core and shell layer of Zn and ZnO influenced the bandgap energy, where ZnO nanoparticles tend to have higher bandgap energy.

The photoluminescence (PL) spectra are presented in Fig. 5a. The pure ZnO has a strong UV emission at around 396 nm and visible emission at around 550 nm. The emission peak at 396 nm indicates the emission from the edge of ZnO conduction band, which appears due to the holes–electrons recombination in the valence band and the conduction band of ZnO. The second peak of the colloid involving ZnO was observed at around 550 nm. The second peak was identified as green emission, and it was caused by defects and impurities formed in the ZnO structure. PPLE E0% shows UV emission at 400.7 nm and visible emission at 520 nm and 680.4 nm. Zn/ZnO PPLE E0% sample appears to show a combination of both emissions of ZnO and PPLE E0% and an additional of a bump around 400–500 nm indicates the occurrence of blue emission.

Figure 5 (b) shows peak fitting of Zn/ZnO photoluminescence spectra in PPLE E0% medium, where it can be divided into four peaks, 400.7 nm, 427.1 nm, 520.5 nm and 680.4 nm. The peak at 400.7 nm (3.09 eV) is very close to PPLE emission as well as pure ZnO emission. In comparison, 520.5 nm (2.38 eV) and 680 nm (1.82 eV) are very similar to the photoluminescence peak of PPLE as appeared in the photoluminescence spectra of pure PPLE E0%. The peak at 427.1 nm (2.90 eV) belongs to the zinc interstitial-level energy of ZnO, which is entirely a different feature from the conventional emissions owned by pure ZnO sample. A result obtained by Zeng et al. [19] shows an emission peak arises at 425 nm for Zn/ZnO sample, and it decreases sharply with the rise of annealing temperature up to 400 °C. Further, this particular emission disappears completely, and two other emission peaks at UV and green bands are rising strongly, which similar to those owned by pure ZnO [19]. Based on Bylander et al. finding, the defect energy level of zinc interstitial is considered to be 0.22 eV below the edge of the ZnO conduction band in the recombination levels of ZnO: Zn [48]. This finding is matching to the zinc interstitial level, 2.90 eV (427.1 nm), of Zn/ZnO sample in our work.

3.3 The structure of ZnO and Zn/ZnO nanoparticles

The XRD pattern for ZnO nanoparticles prepared in pure water and P. pinnata extract is shown in Fig. 6. The sample prepared in pure water exhibits strong diffraction peaks with the index of (100), (002), (101), (102), (110), (103), (200), (112) and (201), shows that the produced nanoparticles are ZnO with wurtzite crystalline structure with preferred orientations along (100), (002) and (101). This result is in a good agreement with JCPDS number 00-036-1451 [49] as the standard for ZnO XRD measurement for hexagonal wurtzite structure. Crystallite size along (100), (002) and (101) crystallographic plane for pure ZnO nanoparticles, as calculated by Debye Scherer formula, lies, respectively, on 20.0, 29.9 and 20.3 nm. There is no Zn peak found in the spectrum, indicating that the oxidation perfectly occurs in the ablation process. As the P. pinnata leaf extract (PPLE) extracted in pure water (E0%) employed as the solution, the strong Zn crystal peaks appear alongside with ZnO crystal peaks, which follows the pattern of pure metallic zinc standard of JCPDS 87-0713 [50]. The Zn peaks observed with the index of (100), (101) and (102) with a preferred orientation along (100). This phenomenon is because PPLE decelerates the oxidation rate of Zn by acting as a capping agent and providing a surface protective layer. However, the PPLE cannot completely stop the oxidation of the zinc; thus, both Zn and ZnO phase are formed together, resulting in Zn/ZnO bi-phase nanostructure.

In the PPLE with ethanol-rich media, ethanol–water 20–40% (E20% and E40%), the peak intensity of zinc phase appears stronger indicating higher contents of metallic Zn in comparison with its oxidized species. This result can be explained by the lower oxidation capability of ethanol in comparison with water, and this finding agrees well with the results of previous works by Goto et al. and Niu et al. [51,52]. The final structure of the nanoparticles is closely dependent on the solution condition and laser power on the competition between aqueous oxidation [5]. Inclusions of metallic zinc were often observed in laser-generated ZnO nanoparticles produced in ethanol or other organic liquids, as well as in their mixtures with water, implying a lack of enough oxygen during the laser ablation in the liquid process in such media [19,51].

TEM images in Fig. 7a and b show unidentical size and shape of produced ZnO and Zn/ZnO nanoparticles produced by the ablation process. The shape of ZnO nanoparticles is non-uniform, and it is a mixture of sphere and rod, while Zn/ZnO shows the more uniform spherical shape of nanoparticles. The shape of ZnO nanoparticles produced in pure water is known to be a complex function of numerous variables, including laser and medium parameter. The absence of capping agent leads to the growth and the formation of a non-uniform shape of nanoparticles as appeared in Fig. 7a. An intensive laser ablation to the metal target has increased the temperature of the medium and emerged the nanoparticle growth along the longitudinal axis, which then produces a rod shape of the ZnO nanoparticle [12]. The non-existence of capping agent and the growth of nanoparticle is also the reason for the non-uniform size of ZnO nanoparticles which is varied from 5 to 80 nm, as presented in Fig. 7c. On the other hand, the Zn/ZnO nanoparticle prepared in PPLE E0% appears to be spherical as appeared in Fig. 7b with smaller and more uniform size, 5–40 nm, than those of ZnO nanoparticles. The leaf extract contributes to the appearance of the fraction of metallic zinc phase, as the effect of the low oxidating ability. The leaf extract plays the role of a capping agent. The inclusion of metallic Zn contributes to the more inert, low aggregation possibility and less re-crystallization in comparison with pure ZnO. This circumstance is also responsible for our findings of the spherical shape and smaller size of Zn/ZnO nanoparticles in comparison with ZnO with the spherical and rod shape.

The chemical formula 3–5 above are generally applied for the formation of ZnO nanoparticle via laser ablation technique [5]. The oxidation of the metallic zinc is specially formulated with formula 4 and 5. Perfect oxidation of metallic zinc to ZnO is highly possible if pure water (H2O) was used as the medium. Some previous works on Zn/ZnO formation in liquid mentioned that the oxidation power were highly influenced by laser ablation parameters [5,12], the higher temperature and high-pressure plasma would be formed after the interaction of laser light with matter.

The mechanism of the Zn/ZnO bi-phase nanoparticles formation has been proposed by some previous studies [5,12,19]; however, the formation of bi-phase Zn/ZnO formation caused by plant extract is still unclear. After the laser hit the zinc target, the produced zinc clusters will have a direct encounter with the plant extract, which consist of its natural compounds might induce some chemical reactions and capping effects. Some possible mechanism can be proposed for these phenomena. (1) The PPLE compounds can play the role of bioreductor [29,30], hence in the formula (3) it can work with the electron (e−) for reducing Zn2+ ions, thus producing Zn atoms and further Zn cluster. (2) The PPLE compounds act as a surface protective layer. Some of the natural extracts were reported to be a capping agent of nanoparticles synthesis [53]. This role of PPLE can slow down the metallic zinc oxidizing process. (3) The ethanol–water with the concentration of 20–40% used in the PPLE extract has reduced the oxidation potential of the ablation system; thus, the metallic zinc is more dominating in the synthesis product. This result is proven by stronger Zn crystal peaks of Zn/ZnO sample produced in PPLE with ethanol-rich medium than thus in PPLE with pure water. Ethanol has an oxidation potential of 0.05–0.7 V [53] which is much lower oxidation potential than water (1.229 V). The usage of ethanol (20 and 40%) has reduced the oxidation potential of the ablation system; thus, the metallic zinc is more dominating in the synthesis product. This result is proven by stronger Zn crystal peaks of Zn/ZnO sample produced in ethanol-rich medium. Such XRD evolution indicated the possible changes in the composition and structure of the products.

Further analysis has been conducted to confirm an evolution of surface-charged property of particles by zeta potential measurement of colloidal ZnO nanoparticles from water, P. pinnata leaf extract and extract with ethanol as the solution. As indicated in Table 1, the entire samples are negatively charged. The charge density shows the value of − 24.8 mV and change to − 18.9 mV by using P. pinnata leaf as the solution. The ethanol–water concentration of 20–40% has significantly decreased the charge property, to − 43.5 mV and − 41.5 mV, respectively. Ethanol existence on the nanoparticles production is a benefit for the stability of nanoparticles, in which nanoparticles with zeta potential values of + 30 mV or smaller than − 30 mV typically have high degrees of stability [54]. The high value confirms the repulsion among the particles and thereby increases in the stability of the formulation. On the other hand, the zeta potentials became less negative when the concentration of ethanol is 40% (E40%) in comparison with those in 20% ethanol (E20%) concentration. We measured the mass of zinc contained in the solution during laser synthesis. It was found the Zn/ZnO nanoparticle colloidal sample with E40% has 10–15% higher zinc concentration in comparison with those in E20%. The higher ethanol concentration has some effect on increasing the groove width, groove depth and size of heat-affected zinc target, as explained by Tangwarodomnukun et al. [55]. The solution containing a higher concentration of nanoparticles has shifted into lower zeta potential. As the content of the solution is rising, the electrical double layer is pressured, and the zeta potential decreases.

3.4 Antibacterial activities of ZnO and Zn/ZnO nanoparticles against Escherichia coli and Staphylococcus aureus

Antibacterial activities of ZnO and Zn/ZnO nanoparticles, synthesized in pure water extract of P. pinnata leaf extract (PPLE), against Escherichia coli (E. coli) and Staphylococcus aureus (S. aureus) can be seen in Fig. 8. Three rounds of the anti-bacteria experiment were performed, and the average value of the bacteria population was obtained (log cfu/mL). The result is in good consistency with an error of around 5–10%. The laser medium, water and PPLE were also evaluated for their antibacterial properties as an additional analysis. S. aureus and E. coli were chosen to represent gram-positive and gram-negative bacteria, respectively. ZnO nanoparticles show moderate antibacterial activities towards both bacteria, even though the reduction rate is different for S. aureus and E. coli due to differences in cell wall compounds, cell structure, metabolism or penetration level of nanoparticles [56]. There is no viable S. aureus were detected after 24-h in contact with ZnO nanoparticles. Zn/ZnO nanoparticles exhibit massive improvement in its antibacterial activities for both strain, although Zn/ZnO nanoparticles have shown more rapid reduction towards S. aureus, where no bacteria found alive after 12-h treatment time. There are no viable E. coli and S. aureus was found at a 24-h treatment time of Zn/ZnO nanoparticles. There are no antibacterial activities showed for both medium solution, pure water and PPLE. However, the PPLE shows a greater enhancement of microbial number in comparison with pure water. Plant extract is enriched by organic compound consisted of carbon, oxygen, nitrogen, iron, etc., which is essential for cell nutrient and required for bacteria growth [57,58]. The intake of the nutrient will rapidly increase the number of bacteria due to the cells multiply exponentially [57].

ZnO nanostructure was described to possess several antimicrobial mechanisms, reactive oxygen species (ROS) generation, zinc ion release and nanoparticle internalization towards bacteria [59,60]. ROS is only generated under suitable light irradiation. Optical properties of ZnO and Zn/ZnO indicated wide bandgap energy, 3.18–3.25 eV, indicating both ZnO and Zn/ZnO normally can only be activated under ultraviolet (UV) light irradiation [61]. Our study conducted ambient laboratory room with a visible light source, hence ROS is less likely to be generated under lighting irradiation. However, Yi et al. showed another perspective of ROS generation through the self-corrosive process of Zn/ZnO nanoparticles regardless of the lighting condition [6]. The electron was donated from Zn to ZnO layers by self-corrosive mechanism, which further interacted with oxygen molecules to produce ROS [6]. The O2− and H2O2 are surprisingly generated in a high concentration such that the antibacterial activities of Zn/ZnO are powerful [6]. There is a possibility that the same process also occurred in our Zn/ZnO nanoparticles sample. However, a further antibacterial study needs to be conducted to apply a particular lighting condition for ZnO photo-activating, such as a UV irradiation and a dark condition.

Metal ion release is also reported as one primary antimicrobial mechanism of metal and metal oxides [62]. However, this mechanism has left some space for debate since some research, conducted by Baek et al. and Jiang et al., did not show significant bactericidal number following metal ions diffuse in the medium. Li et al. presented their work by varying aqueous media with different components showing the chemical complex of the bacteria has a substantial impact on the dissolved Zn2+ ions [63,64]. Our antibacterial tests were performed in tryptic soy agar (TSA) medium, which also consists of phosphate as a buffer in the media. Phosphate (PO43-) anions strongly interact with Zn2+ cations suspecting to form Zn3(PO4)2, which was also observed by Li et al. [64]. This formation has directed into weak bactericidal effect on ZnO nanoparticles. Yi et al. found that the Zn2+ release is not a predominant factor of ZnO and Zn/ZnO antibacterial activities, since the amount of Zn2+ leached from ZnO and Zn/ZnO samples are much less than the minimum inhibitory concentration (MIC) of Zn2+ [6].

Another mechanism is the internalization of nanoparticles structure into the bacteria, which is reported to be significant activities on reducing bacteria population. Several conditions are required to be controlled to create a direct interaction between bacteria and nanoparticles, such as the size and the surface charge of nanoparticles [65,66]. As we can see in Fig. 7c and d, the size of Zn/ZnO nanoparticles is smaller than ZnO. The bacteria provide a better intake of smaller nanoparticles than the bigger ones. Raghupathi et al. show ZnO nanoparticles with the size of 8 and 25 nm resulted in a bactericidal rate of 92% and 60%, respectively [65]. The surface potential of the produced ZnO and Zn/ZnO nanoparticles were negatively charged, and the surface charge of the nanoparticles highly influence the nanoparticle-bacteria interaction. Positively charge ZnO nanoparticle has an excellent antibacterial effect towards both gram-positive and negative bacteria [66]. On the other hand, negatively charge ZnO nanoparticles tend to show better antibacterial activities towards gram-positive bacteria than the negatives ones [66], despite higher ZnO concentration needed for bacteria inhibition. The two kinds of bacteria have different membrane structure with negative surface potential; nonetheless, gram-positive bacteria have a less negative potential. This phenomenon is the reason why the ZnO and Zn/ZnO nanoparticle has a stronger attraction towards S. aureus (gram-positive bacteria) than E. coli (gram-negative bacteria), resulting in stronger antibacterial activities on S. aureus than E. coli. The attraction of ZnO or Zn/ZnO provides better contact of nanoparticles with the bacteria structure, exhibits destabilization by inducing surface tension and ROS production of the membrane which can destruct the DNA and other vitals of bacteria [59].

4 Conclusion

One-step green method to prepare bi-phase structure Zn/ZnO has been performed by using P. pinnata leaf extract (PPLE) as the solution on laser ablation technique. The leaf extract and ethanol-rich medium contribute to the appearance of the fraction of metallic zinc phase, for its role as a capping agent. The inclusion of metallic Zn has resulted in more inert, low aggregation possibility and less re-crystallization in comparison with pure ZnO. This circumstance is also responsible for our findings of the spherical shape and smaller size of Zn/ZnO nanoparticles in comparison with ZnO with the rod shape. The antibacterial activities of ZnO and Zn/ZnO sample was tested on Escherichia coli (E. coli), and Staphylococcus aureus (S. aureus) under normal ambient laboratory light, showing Zn/ZnO has more significant antibacterial activity on both bacteria. In this work, internalization of the nanoparticle is proposed as a major mechanism due to the change of surface potential change and the smaller size of Zn/ZnO nanoparticles in comparison with pure ZnO.

References

P.X. Gao, C.S. Lao, Y. Ding, Z.L. Wang, Adv. Funct. Mater. 16, 53 (2006)

X.Y. Zhang, J.Y. Dai, C.H. Lam, H.T. Wang, P.A. Webley, Q. Li, H.C. Ong, Acta Mater. 55, 5039 (2007)

H.J. Jung, R. Koutavarapu, S. Lee, J.H. Kim, H.C. Choi, M.Y. Choi, J. Environ. Sci. (China) 74, 107 (2018)

M. Trejo, P. Santiago, H. Sobral, L. Rendon, U. Pal, C. Shell, Cryst. Growth Des. 9, 7 (2010)

H. Zeng, Z. Li, W. Cai, B. Cao, P. Liu, S. Yang, J. Phys. Chem. B 111, 51 (2007)

G. Yi, X. Li, Y. Yuan, Y. Zhang, Environ. Sci NANO 6, 68 (2019)

G. Yi, G. Agarwal, Y. Zhang, J. Phys. Chem. C 123, 19230 (2019)

O. Lupan, L. Chow, G. Chai, H. Heinrich, Chem. Phys. Lett. 465, 249 (2008)

K.M. Sulieman, X. Huang, J. Liu, M. Tang, Nanotechnology 17, 4950 (2006)

Q.L. Ma, R. Xiong, B.G. Zhai, Y.M. Huang, Micro. Nano Lett. 8, 491 (2013)

D.M. Tang, G. Liu, F. Li, J. Tan, C. Liu, G.Q. Lu, H.M. Cheng, J. Phys. Chem. C 113, 11035 (2009)

M. Honda, T. Goto, T. Owashi, A.G. Rozhin, S. Yamaguchi, T. Ito, S.A. Kulinich, Phys. Chem. Chem. Phys. 18, 23628 (2016)

V. Amendola, M. Meneghetti, Phys. Chem. Chem. Phys. 11, 3805 (2009)

C.N.M.C. Sportelli, M. Izzi, A. Volpe, M. Clemente, R.A. Picca, A. Ancona, P.M. Lugarà, G. Palazzo, Antibiotics 7, 1 (2020)

M.P. Navas, R.K. Soni, N. Tarasenka, N. Tarasenko, Appl. Surf. Sci. 414, (2017)

K. Xu, C. Zhang, R. Zhou, R. Ji, M. Hong, Opt. Express 24, 10352 (2016)

H. Yang, K. Xu, C. Xu, D. Fan, Y. Cao, W. Xue, J. Pang, Nanoscale. Res. Lett. 14, 333 (2019)

K. Xu, H. Yan, C.F. Tan, Y. Lu, Y. Li, G.W. Ho, R. Ji, M. Hong, Adv. Opt. Mater. 6, 1 (2018)

H. Zeng, G. Duan, Y. Li, S. Yang, X. Xu, W. Cai, Adv. Funct. Mater. 20, 561 (2010)

R.K. Soni, M.P. Navas, J. Nanoeng, Nano Manufact. 3, 341 (2013)

S.C. Singh, R.K. Swarnkar, R. Gopal, Bull. Mater. Sci. 33, 21 (2010)

C.M. Messina, C. Faggio, V.A. Laudicella, M. Sanfilippo, F. Trischitta, A. Santulli, Aquat. Toxicol. 157, 94 (2014)

A.J.S. Rocha, V. Gomes, P.V. Ngan, M.J.A.C.R. Passos, R.R. Furia, Ecotoxicol. Environ. Saf. 68, 397 (2007)

G. Sangeetha, S. Rajeshwari, R. Venckatesh, Mater. Res. Bull. 46, 2560 (2011)

N. Ain Samat, R. Md Nor, Ceram. Int. 39, 1 (2013)

S. He, Z. Guo, Y. Zhang, S. Zhang, J. Wang, N. Gu, Mater. Lett. 61, 3984 (2007)

B. Xue, D. He, S. Gao, D. Wang, K. Yokoyama, L. Wang, Int. J. Nanomedicine 11, 1899 (2016)

R. Zamiri, A. Zakaria, H.A. Ahangar, M. Darroudi, A.K. Zak, G.P.C. Drummen, J. Alloys Compd. 487, (2013)

T.M. Tolaymat, A.M. El Badawy, A. Genaidy, K.G. Scheckel, T.P. Luxton, M. Suidan, Sci. Total Environ. 408, 999 (2010)

S.P. Chandran, Biotechnol. Prog. 22, 577 (2006)

A.Q. Laghari, S. Memon, A. Nelofar, A.H. Laghari, Am. J. Anal. Chem. 02, 871 (2011)

D. Suresh, P.C. Nethravathi, H. Udayabhanu, H.N. Rajanaika, S.C. Sharma, Mater. Sci. Semicond. Process. 31, 446 (2015)

A. Suedee, S. Tewtrakul, P. Panichayupakaranant, Pharm. Biol. 51, 1256 (2013)

L. Voutquenne, P. Guinot, O. Thoison, T. Sevenet, C. Lavaud, Phytochemistry 64, 781 (2003)

S. Syarifah, C. Imawan, W. Handayani, D. Djuhana, A.I.P. Conf, Proc. 2023, 020054 (2018)

J.B. Harborne, Phytochemical Methods (Chapman and Hall, New York, 1980).

A. Pandey, S. Tripathi, C.A. Pandey, J. Pharmacogn. Phytochem. JPP 115, 115 (2014)

S.I. Al-nassar, F.I. Hussein, K.M. Adel, Integr. Med. Res. 8, 4026 (2019)

J. N. J. Low, W. Y. Wong, W. Rashmi, A. A. H. Kadhum, J. Eng. Sci. Technol. 5, (2017)

S. Jain, M.S. Mehata, Sci. Rep. 7, 1 (2017)

Z.R. Mashwani, M.A. Khan, T. Khan, A. Nadhman, Adv. Colloid. Interface. Sci. 234, 132 (2016)

N. Matinise, X.G. Fuku, K. Kaviyarasu, N. Mayedwa, M. Maaza, Appl. Surf. Sci. 406, (2017)

J.Y. Song, B.S. Kim, Bioprocess Biosyst. Eng. 32, 79 (2009)

M. Díaz, C. Rossini, Insecticides-Advances, in Integrated Pest Management, ed. by F. Perveen (IntechOpen, Rijeka, 2012), pp. 287–300

M. Getie, T. Gebre-Mariam, R. Rietz, R.H.H. Neubert, Pharmazie 57, 320 (2002)

V. Kumar, J. Prakash, J. Pal, K. Hwa, C. Swart, Colloid. Surfaces. B Biointerfaces. 159, 191 (2017)

N. Yudasari, M.M. Suliyanti, C. Imawan, Adv. Nat. Sci. Nanosci. Nanotechnol. 11, 025003 (2020)

D.M. Bylander, L. Kleinman, Phys. Rev. B 41, 7868 (1990)

M.S. Yadav, N. Singh, S.M. Bobade, Ionics 24, (2018)

D.K. Ma, J.L. Jiang, J.R. Huang, D.P. Yang, P. Cai, L.J. Zhang, S.M. Huang, Chem. Commun. 46, 4556 (2010)

T. Goto, M. Honda, S.A. Kulinich, Y. Shimizu, T. Ito, Jpn. J. Appl. Phys. 54, 070305 (2015)

K.Y. Niu, J. Yang, S.A. Kulinich, J. Sun, H. Li, X.W. Du, J. Am. Chem. Soc. 132, 28 (2010)

F. Vigier, C. Coutanceau, F. Hahn, E.M. Belgsir, C. Lamy, J. Electroanal. Chem. 563, 81 (2004)

G.W. Lu, P. Gao, in Non-invasive Drug Delivery Systems, ed. by V.S. Kulkarni (Elsevier, Burlington, 2010), pp. 59–91

V. Tangwarodomnukun, H.Y. Chen, Mater. Manuf. Process. 30, 685 (2015)

S. Suwanboon, P. Amornpitoksuk, P. Bangrak, A. Sukolrat, N. Muensit, J. Ceram. Process. Res. 11, 547 (2010)

C.E. Boyd, Water Quality an Introduction, 2nd edn. (Springer, New York, 2000).

A.N. Glazer, H. Nikaido, Microbial Biotechnology (W H Freeman, New York, 1995).

A. Sirelkhatim, S. Mahmud, A. Seeni, N.H.M. Kaus, L.C. Ann, S.K.M. Bakhori, H. Hasan, D. Mohamad, Nano-Micro Lett. 7, 219 (2015)

K.S. Siddiqi, A. Rahman, Tajuddin, A. Husen, Nanoscale Res. Lett. 13, 141 (2018)

H.W.K. Qi, B. Cheng, J.J. Yu, Alloys. Compd. 727, 792 (2017)

A. Raghunath, E. Perumal, Int. J. Antimicrob. Agents 49, 2 (2017)

Y. Baek, Y. An, Sci. Total Environ. 409, 1603 (2011)

M. Li, L. Zhu, D. Lin, Environ. Sci. Technol. 45, 5 (2011)

K.R. Raghupathi, R.T. Koodali, A.C. Manna, Langmuir 27, 4020 (2011)

M. Arakha, M. Saleem, B.C. Mallick, S. Jha, Scie. Rep. 5, 9578 (2015)

Acknowledgements

This work was fully supported by “Hibah Tugas Akhir Mahasiswa Doktor Universitas Indonesia 2018” with the registration number of 1333/UN2.R3.1/HKP.05.00/2018.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yudasari, N., Wiguna, P.A., Handayani, W. et al. The formation and antibacterial activity of Zn/ZnO nanoparticle produced in Pometia pinnata leaf extract solution using a laser ablation technique. Appl. Phys. A 127, 56 (2021). https://doi.org/10.1007/s00339-020-04197-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-020-04197-8