Abstract

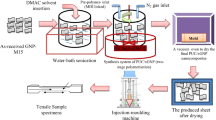

The present work investigates the combined effect of the addition of graphene nanoplatelets (GNPs) to the thermoplastic polyurethane copolymer (TPU) and thermal treatment evaluation of the resultant TPU/GNP nanocomposite. Thus, this factor can be evaluated through a variety of dynamic mechanical and thermal measurements. The TPUs as nanocomposites were synthesised by three different approaches of mixing (in situ polymerisation melt compounding and solution mixing) with different weight ratios. Various dispersion processes were employed to obtain better dispersed GNP and thus strong interaction, leading to an effective performance of the TPU/GNP system. X-Ray diffraction and Raman spectroscopy tests displayed the inter-spacing planar quality of GNP nanofillers. Dynamic mechanical analysis revealed that the storage modulus (Eʹ) of TPU nanocomposites how a significant performance particularly at 20 wt.%, 10 wt.% and 5 wt.% of GNP for in situ polymerisation melt compounding and solution mixing, respectively. The microphase-separated structure of TPU nanocomposite samples after thermal treatment (at 80 °C for 4 days) was investigated from for all dispersion methods. Consequently, the overall TPU crystallinity decreased after thermal treatment compared with untreated samples, presuming an ordering suppression of hard segments that involved with GNP. Dispersion and interaction of GNP can play a crucial role in enhancing the thermal and mechanical properties, and thus, a significant improvement for TPU nanocomposites. The tensile test showed significant enhancement with GNP incorporation before thermal treatment. On the contrary, a deterioration in tensile modulus and tensile strength resulted from thermal treatment. A modified Halpin–Tsai model was utilised to predict the mismatch between the empirical and theoretical results. It found a clear diversity in modulus of TPU/GNP samples, in particular at greater GNP content.

Similar content being viewed by others

References

Batista NL, Helal E, Kurusu RS, Moghimian N, David E, Demarquette NR, Hubert P (2018) Mass-produced graphene—HDPE nanocomposites: thermal, rheological, electrical, and mechanical properties. Polym Eng Sci 59(4):675–682. https://doi.org/10.1002/pen.24981

Menes O, Cano M, Benedito A, Giménez E, Castell P, Maser WK, Benito AM (2012) The effect of ultra-thin graphite on the morphology and physical properties of thermoplastic polyurethane elastomer composites. Compos Sci Technol 72(13):1595–1601. https://doi.org/10.1016/j.compscitech.2012.06.016

Huang A, Wang H, Ellingham T, Peng X, Turng L-S (2019) An improved technique for dispersion of natural graphite particles in thermoplastic polyurethane by sub-critical gas-assisted processing. Compos Sci Technol 182:107783. https://doi.org/10.1016/j.compscitech.2019.107783

Rothon RN (2002) Particulate fillers for polymers, rept. 141 edn, vol 12. iSmithers Rapra Publishing, Shrewsbury, United Kingdom

Xanthos M (2005) Functional fillers for plastics. Wiley-VCH Verlag GmbH & Co KGaA, Weinheim

Mittal V (2010) Optimization of polymer nanocomposite properties. Wiley-VCH Verlag GmbH & Co KGaA, Weinheim

Camargo PHC, Satyanarayana KG, Wypych F (2009) Nanocomposites: synthesis, structure, properties and new application opportunities. Mater Res 12(1):1–39

Albozahid M, Diwan AA, Habeeb SA (2021) The effect of addition graphite filler on mechanical properties of epoxy material. Egypt J Chem. https://doi.org/10.21608/ejchem.2021.73645.3638

Alexandre M, Dubois P (2000) Polymer-layered silicate nanocomposites: preparation, properties and uses of a new class of materials. Mater Sci Eng: A 28:1–63

Hussain F, Hojjati M, Okamoto M, Gorga RE (2006) Review article: polymer-matrix nanocomposites, processing, manufacturing, and application: an overview. J Compos Mater 40(17):1511–1575. https://doi.org/10.1177/0021998306067321

Naji HZN (2019) Fabricating of multiscale composite materials based on TPU reinforced by carbon fibre and graphene nanoplatelets (GNPs). University of Manchester

Al-obad ZKM (2017) Designing PU resins for fibre composite applications. University of Manchester

Prisacariu C (2011) Polyurethane elastomers: from morphology to mechanical aspects. Springer, Vienna

Albozahid MAMa (2018) Design of novel high modulus TPUs for nanocomposite applications. University of Manchester, The UK

Albozahid M, Naji HZ, Alobad ZK, Saiani A (2021) Enhanced mechanical, crystallisation and thermal properties of graphene flake-filled polyurethane nanocomposites: the impact of thermal treatment on the resulting microphase-separated structure. J Polym Res. https://doi.org/10.1007/s10965-021-02660-5

Vakili H, Mohseni M, Makki H, Yahyaei H, Ghanbari H, González A, Irusta L (2020) Self-assembly of a patterned hydrophobic-hydrophilic surface by soft segment microphase separation in a segmented polyurethane: combined experimental study and molecular dynamics simulation. Polymer 195:122424. https://doi.org/10.1016/j.polymer.2020.122424

Li J-W, Tsai H-A, Lee H-T, Cheng Y-H, Chiu C-W, Suen M-C (2020) Synthesis and properties of side chain fluorinated polyurethanes and evaluation of changes in microphase separation. Prog Org Coat 145:105702. https://doi.org/10.1016/j.porgcoat.2020.105702

Albozahid M, Naji HZ, Alobad ZK, Saiani A (2021) Effect of OMMT reinforcement on morphology and rheology properties of polyurethane copolymer nanocomposites. J Elastom Plast. https://doi.org/10.1177/00952443211006160

Alobad ZK, Albozahid M, Naji HZ, Alraheem HS, Saiani A (2021) Influence of hard segments content on thermal, morphological and mechanical properties of homo and co-polyurethanes: a comparative study. Arch Mater Sci Eng 1(109):5–16. https://doi.org/10.5604/01.3001.0015.0510

Verma M (2015) Tailored graphene based polyurethane composites for efficient electrostatic dissipation and electromagnetic interference shielding applications. RSC Adv 5:97349–97358. https://doi.org/10.1039/C5RA17276D,10.1039/c5ra17276d

Nina MK, Lamba KAW, Cooper SL (1998) Polyurethanes in biomedical applications, 1st edn. CRC Press

Wang T, Yu W-C, Zhou C-G, Sun W-J, Zhang Y-P, Jia L-C, Gao J-F, Dai K, Yan D-X, Li Z-M (2020) Self-healing and flexible carbon nanotube/polyurethane composite for efficient electromagnetic interference shielding. Compos B Eng 193:108015. https://doi.org/10.1016/j.compositesb.2020.108015

Gahlout P, Choudhary V (2020) EMI shielding response of polypyrrole-MWCNT/polyurethane composites. Synth Met 266:116414. https://doi.org/10.1016/j.synthmet.2020.116414

Guo Y, Yan L, Zeng Z, Chen L, Ma M, Luo R, Bian J, Lin H, Chen D (2020) TPU/PLA nanocomposites with improved mechanical and shape memory properties fabricated via phase morphology control and incorporation of multi-walled carbon nanotubes nanofillers. Polym Eng Sci 60(6):1118–1128. https://doi.org/10.1002/pen.25365

Xiang D, Zhang X, Han Z, Zhang Z, Zhou Z, Harkin-Jones E, Zhang J, Luo X, Wang P, Zhao C, Li Y (2020) 3D printed high-performance flexible strain sensors based on carbon nanotube and graphene nanoplatelet filled polymer composites. J Mater Sci 55(33):15769–15786. https://doi.org/10.1007/s10853-020-05137-w

Quan H, Zhang B-Q, Zhao Q, Yuen RKK, Li RKY (2009) Facile preparation and thermal degradation studies of graphite nanoplatelets (GNPs) filled thermoplastic polyurethane (TPU) nanocomposites. Compos A Appl Sci Manuf 40(9):1506–1513. https://doi.org/10.1016/j.compositesa.2009.06.012

Russo P, Acierno D, Marletta G, Destri GL (2013) Tensile properties, thermal and morphological analysis of thermoplastic polyurethane films reinforced with multiwalled carbon nanotubes. Eur Polym J 49(10):3155–3164. https://doi.org/10.1016/j.eurpolymj.2013.07.021

Xiang C, Cox PJ, Kukovecz A, Genorio B, Hashim DP, Yan Z, Peng Z, Hwang C-C, Ruan G, Samuel ELG, Sudeep PM, Konya Z, Vajtai XR, Ajayan PM, Tour JM (2013) Functionalized low defect graphene nanoribbons and polyurethane composite film for improved gas barrier and mechanical performances. ASCnano 7(11):10380–10386

Gavgani JN, Adelnia H, Gudarzi MM (2013) Intumescent flame retardant polyurethane/reduced graphene oxide composites with improved mechanical, thermal, and barrier properties. J Mater Sci 49(1):243–254. https://doi.org/10.1007/s10853-013-7698-6

Tayfun U, Kanbur Y, Abaci U, Guney HY, Bayramli E (2015) Mechanical, flow and electrical properties of thermoplastic polyurethane/fullerene composites: effect of surface modification of fullerene. Compos B Eng 80:101–107. https://doi.org/10.1016/j.compositesb.2015.05.013

Shamsi R, Mahyari M, Koosha M (2017) Synthesis of CNT-polyurethane nanocomposites using ester-based polyols with different molecular structure: mechanical, thermal, and electrical properties. J Appl Polym Sci. https://doi.org/10.1002/app.44567

Bera M, Maji PK (2017) Effect of structural disparity of graphene-based materials on thermo-mechanical and surface properties of thermoplastic polyurethane nanocomposites. Polymer 119:118–133. https://doi.org/10.1016/j.polymer.2017.05.019

Song H, Wang M, Wang Y, Zhang Y, Umar A, Guo Z (2017) Waterborne polyurethane/graphene oxide nanocomposites with enhanced properties. Sci Adv Mater. https://doi.org/10.1166/sam.2017.3118

Amirkiai A, Panahi-Sarmad M, Sadeghi GMM, Arjmand M, Abrisham M, Dehghan P, Nazockdast H (2020) Microstructural design for enhanced mechanical and shape memory performance of polyurethane nanocomposites: role of hybrid nanofillers of montmorillonite and halloysite nanotube. Appl Clay Sci 198:105816. https://doi.org/10.1016/j.clay.2020.105816

Gholizadeh A, Babaei A, Ziaratban M (2020) Analysis of dual role of nanographene on the microstructure-properties correlation of TPU/NG nanocomposite. Polym Adv Technol 32(3):1150–1161. https://doi.org/10.1002/pat.5162

Tripathi SN, Srinivasa Rao GS, Mathur AB, Jasra R (2017) Polyolefin/graphene nanocomposites: a review. RSC Adv 7:23615–23632. https://doi.org/10.1039/C6RA28392F

Mittal V, Kim JK, Pal K (2011) Recent advances in elastomeric nanocomposites. Springer, New York

Kim H, Miura Y, Macosko CW (2010) Graphene/polyurethane nanocomposites for improved gas barrier and electrical conductivity. Chem Mater 22(11):3441–3450. https://doi.org/10.1021/cm100477v

Rothon RN (2003) Particulate-filled polymer composites, 2nd edn. Rapra Technology Limited, Shrewsbury, UK

Lee S-H, Oh C-R, Lee D-S (2019) Large improvement in the mechanical properties of polyurethane nanocomposites based on a highly concentrated graphite nanoplate/polyol masterbatch. Nanomaterials. https://doi.org/10.3390/nano9030389

Albozahid M, Habeeb SA, Ismael Alhilo NA, Saiani A (2020) The impact of graphene nanofiller loading on the morphology and rheology behaviour of highly rigid polyurethane copolymer. Mater Res Express 7(12):125304. https://doi.org/10.1088/2053-1591/aba5ce

Saiani A (2004) Origin of multiple melting endotherms in a high hard block content polyurethane. 2. Structural investigation. Macromolecules 37:1411–1421

Velankar S, Cooper SL (1998) Microphase separation and rheological properties of polyurethane melts. 1. Effect of block length. Macromolecules 31:9181–9192

Chu B (1992) Microphase separation kinetics in segmented polyurethanes: effects of soft segment length and structure. Macromolecules 25:5724–5729

Tjong SC, Mai YW (2010) Physical properties and applications of polymer nanocomposites. Woodhead Publishing Limited, Cornwall

Klonos P, Pissis P (2017) Effects of interfacial interactions and of crystallization on rigid amorphous fraction and molecular dynamics in polylactide/silica nanocomposites: a methodological approach. Polymer 112:228–243. https://doi.org/10.1016/j.polymer.2017.02.003

Alzari V, Sanna V, Biccai S, Caruso T, Politano A, Scaramuzza N, Sechi M, Nuvoli D, Sanna R, Mariani A (2014) Tailoring the physical properties of nanocomposite films by the insertion of graphene and other nanoparticles. Compos B Eng 60:29–35. https://doi.org/10.1016/j.compositesb.2013.12.011

Young RJ, Kinloch IA, Gong L, Novoselov KS (2012) The mechanics of graphene nanocomposites: a review. Compos Sci Technol 72(12):1459–1476. https://doi.org/10.1016/j.compscitech.2012.05.005

Pokharel P, Lee DS (2014) High performance polyurethane nanocomposite films prepared from a masterbatch of graphene oxide in polyether polyol. Chem Eng J 253:356–365. https://doi.org/10.1016/j.cej.2014.05.046

Nguyen DA, Lee YR, Raghu AV, Jeong HM, Shin CM, Kim BK (2009) Morphological and physical properties of a thermoplastic polyurethane reinforced with functionalized graphene sheet. Polym Int 58(4):412–417. https://doi.org/10.1002/pi.2549

Chandrasekaran S, Seidel C, Schulte K (2013) Preparation and characterization of graphite nano-platelet (GNP)/epoxy nano-composite: mechanical, electrical and thermal properties. Eur Polym J 49(12):3878–3888. https://doi.org/10.1016/j.eurpolymj.2013.10.008

Sadasivuni KK, Ponnamma D, Kumar B, Strankowski M, Cardinaels R, Moldenaers P, Thomas S, Grohens Y (2014) Dielectric properties of modified graphene oxide filled polyurethane nanocomposites and its correlation with rheology. Compos Sci Technol 104:18–25. https://doi.org/10.1016/j.compscitech.2014.08.025

Tsiotas AA (2012) The role of the chain extender on the phase behaviour and morphology of high hard block content thermoplastic polyurethanes: thermodynamics–Structures–Properties. PhD, The University of Manchester

Yanagihara Y, Osaka N, Murayama S, Saito H (2013) Thermal annealing behavior and structure development of crystalline hard segment domain in a melt-quenched thermoplastic polyurethane. Polymer 54(8):2183–2189. https://doi.org/10.1016/j.polymer.2013.02.005

Saiani A, Daunch WA, Verbeke H, Leenslag J-W, Higgins JS (2001) Origin of multiple melting endotherms in a high hard block content polyurethane. 1. Thermodynamic investigation. Macromolecules 34:9059–9068

Saiani A (2007) Origin of multiple melting endotherms in a high hard block content polyurethane: effect of annealing temperature. Macromolecules 40:7252–7262

Klinedinst DBY, Yilgör I, Yilgör E, Zhang M, Wilkes GL (2012) The effect of varying soft and hard segment length on the structure–property relationships of segmented polyurethanes based on a linear symmetric diisocyanate, 1,4-butanediol and PTMO soft segments. Polymer 53(23):5358–5366. https://doi.org/10.1016/j.polymer.2012.08.005

Korley LTJ, Pate BD, Thomas EL, Hammond PT (2006) Effect of the degree of soft and hard segment ordering on the morphology and mechanical behavior of semicrystalline segmented polyurethanes. Polymer 47(9):3073–3082. https://doi.org/10.1016/j.polymer.2006.02.093

He Y, Xie D, Zhang X (2014) The structure, microphase-separated morphology, and property of polyurethanes and polyureas. J Mater Sci 49(21):7339–7352. https://doi.org/10.1007/s10853-014-8458-y

Prolongo SG, Moriche R, Jiménez-Suárez A, Sánchez M, Ureña A (2014) Advantages and disadvantages of the addition of graphene nanoplatelets to epoxy resins. Eur Polym J 61:206–214. https://doi.org/10.1016/j.eurpolymj.2014.09.022

Cai D, Jin J, Yusoh K, Rafiq R, Song M (2012) High performance polyurethane/functionalized graphene nanocomposites with improved mechanical and thermal properties. Compos Sci Technol 72(6):702–707. https://doi.org/10.1016/j.compscitech.2012.01.020

Lin J, Zhang P, Zheng C, Wu X, Mao T, Zhu M, Wang H, Feng D, Qian S, Cai X (2014) Reduced silanized graphene oxide/epoxy-polyurethane composites with enhanced thermal and mechanical properties. Appl Surf Sci 316:114–123. https://doi.org/10.1016/j.apsusc.2014.07.058

Kaveh P, Mortezaei M, Barikani M, Khanbabaei G (2014) Low-temperature flexible polyurethane/graphene oxide nanocomposites: effect of polyols and graphene oxide on physicomechanical properties and gas permeability. Polym-Plast Technol Eng 53(3):278–289. https://doi.org/10.1080/03602559.2013.844241

Lee YR, Raghu AV, Jeong HM, Kim BK (2009) Properties of waterborne polyurethane/functionalized graphene sheet nanocomposites prepared by an in situ method. Macromol Chem Phys 210(15):1247–1254. https://doi.org/10.1002/macp.200900157

Khan U, May P, O’Neill A, Coleman JN (2010) Development of stiff, strong, yet tough composites by the addition of solvent exfoliated graphene to polyurethane. Carbon 48(14):4035–4041. https://doi.org/10.1016/j.carbon.2010.07.008

Gresil M, Wang Z, Poutrel QA, Soutis C (2017) Thermal diffusivity mapping of graphene based polymer nanocomposites. Sci Rep 7(1):5536. https://doi.org/10.1038/s41598-017-05866-0

Hosseini-Sianaki T, Nazockdast H, Salehnia B, Nazockdast E (2015) Microphase separation and hard domain assembly in thermoplastic polyurethane/multiwalled carbon nanotube nanocomposites. Polym Eng Sci 55(9):2163–2173. https://doi.org/10.1002/pen.24101

Alshammari BA (2014) Processing, structure and properties of poly (ethylene terephthalate)/carbon micro- and nano-composites. PhD, The University of Manchester

Jirakrttidul K (2013) Structure-property relationships in polyurethane-carbon particle nanocomposites. PhD, the University of Manchester

Thakur S, Karak N (2014) Ultratough, ductile, castor oil-based, hyperbranched, polyurethane nanocomposite using functionalized reduced graphene oxide. ACS Sustain Chem Eng 2(5):1195–1202. https://doi.org/10.1021/sc500165d

Chung YC, Khiem ND, Chun BC (2014) Characterization of a polyurethane copolymer covalently linked to graphite and the influence of graphite on electric conductivity. J Compos Mater 49(14):1689–1703. https://doi.org/10.1177/0021998314539366

Huang M (2014) Two-way shape memory property and its structural origin of cross-linked poly(3-caprolactone). Royal Soc Chem 4:55483–55494. https://doi.org/10.1039/C4RA09385B

Choi JT, Kim DH, Ryu KS, Lee H-I, Jeong HM, Shin CM, Kim JH, Kim BK (2011) Functionalized graphene sheet/polyurethane nanocomposites: effect of particle size on physical properties. Macromol Res 19(8):809–814. https://doi.org/10.1007/s13233-011-0801-4

Lei L, Xia Z, Zhang L, Zhang Y, Zhong L (2016) Preparation and properties of amino-functional reduced graphene oxide/waterborne polyurethane hybrid emulsions. Prog Org Coat 97:19–27. https://doi.org/10.1016/j.porgcoat.2016.03.011

Han S, Chun BC (2014) Preparation of polyurethane nanocomposites via covalent incorporation of functionalized graphene and its shape memory effect. Compos A Appl Sci Manuf 58:65–72. https://doi.org/10.1016/j.compositesa.2013.11.016

Wurm A, Ismail M, Kretzschmar B, Pospiech D, Schick C (2010) Retarded crystallization in polyamide/layered silicates nanocomposites caused by an immobilized interphase. Macromolecules 43(3):1480–1487. https://doi.org/10.1021/ma902175r

Karevan M, Kalaitzidou K (2013) Formation of a complex constrained region at the graphite nanoplatelets-polyamide 12 interface. Polymer 54(14):3691–3698. https://doi.org/10.1016/j.polymer.2013.05.019

Koutsoumpis S, Raftopoulos KN, Oguz O, de Christine MP, de Menceloglu YZ, Pissis P (2017) Dynamic glass transition of the rigid amorphous fraction in polyurethane-urea/SiO2 nanocomposites. Soft Matter 13:4580–4590. https://doi.org/10.1039/C7SM00397H,10.1039/c7sm00397h

Weon JI, Sue HJ (2005) Effects of clay orientation and aspect ratio on mechanical behavior of nylon-6 nanocomposite. Polymer 46(17):6325–6334. https://doi.org/10.1016/j.polymer.2005.05.094

Russo P, Lavorgna M, Piscitelli F, Acierno D, Di Maio L (2013) Thermoplastic polyurethane films reinforced with carbon nanotubes: the effect of processing on the structure and mechanical properties. Eur Polym J 49(2):379–388. https://doi.org/10.1016/j.eurpolymj.2012.11.008

Hodgkinson JM (2000) Mechanical testing of advanced fibre composites, 1st edn. Woodhead Publishing Limited, Cambridge, England

Liu M, Zhang C, Tjiu WW, Yang Z, Wang W, Liu T (2013) One-step hybridization of graphene nanoribbons with carbon nanotubes and its strong-yet-ductile thermoplastic polyurethane composites. Polymer 54(12):3124–3130. https://doi.org/10.1016/j.polymer.2013.04.013

Ramezanzadeh B, Ghasemi E, Mahdavian M, Changizi E, Mohamadzadeh Moghadam MH (2015) Characterization of covalently-grafted polyisocyanate chains onto graphene oxide for polyurethane composites with improved mechanical properties. Chem Eng J 281:869–883. https://doi.org/10.1016/j.cej.2015.07.027

Pokharel P, Choi S, Lee DS (2015) The effect of hard segment length on the thermal and mechanical properties of polyurethane/graphene oxide nanocomposites. Compos A Appl Sci Manuf 69:168–177. https://doi.org/10.1016/j.compositesa.2014.11.010

Yadav SK, Cho JW (2013) Functionalized graphene nanoplatelets for enhanced mechanical and thermal properties of polyurethane nanocomposites. Appl Surf Sci 266:360–367. https://doi.org/10.1016/j.apsusc.2012.12.028

Wu C, Huang X, Wang G, Wu X, Yang K, Li S, Jiang P (2012) Hyperbranched-polymer functionalization of graphene sheets for enhanced mechanical and dielectric properties of polyurethane composites. J Mater Chem 22(14):7010. https://doi.org/10.1039/c2jm16901k

Appel A-K, Thomann R, Mülhaupt R (2012) Polyurethane nanocomposites prepared from solvent-free stable dispersions of functionalized graphene nanosheets in polyols. Polymer 53(22):4931–4939. https://doi.org/10.1016/j.polymer.2012.09.016

Zhou K, Gui Z, Hu Y, Jiang S, Tang G (2016) The influence of cobalt oxide–graphene hybrids on thermal degradation, fire hazards and mechanical properties of thermoplastic polyurethane composites. Compos A Appl Sci Manuf 88:10–18. https://doi.org/10.1016/j.compositesa.2016.05.014

Vallés C (2014) Few layer graphene–polypropylene nanocomposites: the role of flake diameter. Royal Soc Chem 173:379–390. https://doi.org/10.1039/C4FD00112E

Yousefi N, Gudarzi MM, Zheng Q, Lin X, Shen X, Jia J, Sharif F, Kim J-K (2013) Highly aligned, ultralarge-size reduced graphene oxide/polyurethane nanocomposites: mechanical properties and moisture permeability. Compos A Appl Sci Manuf 49:42–50. https://doi.org/10.1016/j.compositesa.2013.02.005

Jing Q, Liu W, Pan Y, Silberschmidt VV, Li L, Dong Z (2015) Chemical functionalization of graphene oxide for improving mechanical and thermal properties of polyurethane composites. Mater Des 85:808–814. https://doi.org/10.1016/j.matdes.2015.07.101

Li X, Deng H, Li Z, Xiu H, Qi X, Zhang Q, Wang K, Chen F, Fu Q (2015) Graphene/thermoplastic polyurethane nanocomposites: surface modification of graphene through oxidation, polyvinyl pyrrolidone coating and reduction. Compos A Appl Sci Manuf 68:264–275. https://doi.org/10.1016/j.compositesa.2014.10.016

Chou T-W (1992) Microstructural design of fiber composites. Cambridge University Press, Cambridge

Coleman JN, Khan U, Blau WJ, Gun’ko YK (2006) Small but strong: a review of the mechanical properties of carbon nanotube–polymer composites. Carbon 44(9):1624–1652. https://doi.org/10.1016/j.carbon.2006.02.038

Fornes TD, Paul DR (2003) Modeling properties of nylon 6/clay nanocomposites using composite theories. Polymer 44(17):4993–5013. https://doi.org/10.1016/s0032-3861(03)00471-3

Li Y, Hu K, Jiao H, Liu X, Wang Q, Pan G, Zhang X, Wang T (2015) In situpolymerization, thermal, damping, and mechanical properties of multiwalled carbon nanotubes/polyisobutylene-based polyurethane nanocomposites. Polym Compos 36(1):198–203. https://doi.org/10.1002/pc.22930

Li Z, Young RJ, Wilson NR, Kinloch IA, Vallés C, Li Z (2016) Effect of the orientation of graphene-based nanoplatelets upon the Young’s modulus of nanocomposites. Compos Sci Technol 123:125–133. https://doi.org/10.1016/j.compscitech.2015.12.005

Yung KC (2006) Modeling young’s modulus of polymer-layered silicate nanocomposites using a modified Halpin-Tsai micromechanical model. J Reinf Plast Compos 25(8):847–861. https://doi.org/10.1177/0731684406065135

Shokrieh MM, Moshrefzadeh-Sani H (2016) On the constant parameters of Halpin-Tsai equation. Polymer 106:14–20. https://doi.org/10.1016/j.polymer.2016.10.049

Wilkinson AN, Man Z, Stanford JL, Matikainen P, Clemens ML, Lees GC, Liauw CM (2007) Tensile properties of melt intercalated polyamide 6–Montmorillonite nanocomposites. Compos Sci Technol 67(15–16):3360–3368. https://doi.org/10.1016/j.compscitech.2007.03.024

Terrones M, Martín O, González M, Pozuelo J, Serrano B, Cabanelas JC, Vega-Díaz SM, Baselga J (2011) Interphases in graphene polymer-based nanocomposites: achievements and challenges. Adv Mater 23(44):5302–5310. https://doi.org/10.1002/adma.201102036

Galpaya D, Wang M, Liu M, Motta N, Waclawik E, Yan C (2012) Recent advances in fabrication and characterization of graphene-polymer nanocomposites. Graphene 01(02):30–49. https://doi.org/10.4236/graphene.2012.12005

Acknowledgements

The author is grateful to Materials Department at University of Kufa, faculty of Engineering, to their unlimited support to fulfil this study.

Funding

The financial support from the Ministry of Higher Education and Scientific Research of Iraq (Grant No. 1033).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Albozahid, M., Naji, H.Z., Alobad, Z.K. et al. TPU nanocomposites tailored by graphene nanoplatelets: the investigation of dispersion approaches and annealing treatment on thermal and mechanical properties. Polym. Bull. 79, 8269–8307 (2022). https://doi.org/10.1007/s00289-021-03898-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-021-03898-1