Abstract

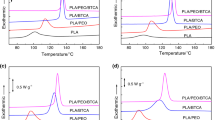

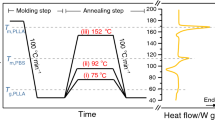

l-Lactide-rich poly(l-lactide) (LR-PLLA)/d-lactide-rich poly(d-lactide) (DR-PDLA) blends with moderate optical purity were prepared by conventional extrusion and followed by injection-molding process in this study. Thermal properties, crystalline structure, spherulite morphology, melt degradability, and thermal mechanical property were investigated by means of DSC, WAXD, POM, TG, and DMA. In comparison with LR-PLLA/DR-PDLA blends with higher optical purity, stereocomplex with less perfect structure was partially formed from the LR-PLLA/DR-PDLA blends with various compositions and showed lower melting temperature. Surprisingly, double melting peaks have appeared in blends with 40 or 50 wt% DR-PDLA. Annealing at higher temperature for blends with 50 wt% DR-PDLA resulted in three melting peaks. It is assumed that the optical purity would play a critical role, thus, producing limited amount of stereocomplex with less imperfect structure. Annealing would also induce the micro-phase separation behavior in LR-PLLA/DR-PDLA blends and significantly influence the thermal and degradable properties of blends.

Similar content being viewed by others

References

Dorgan JR, Lehermeier HJ, Cicero (2001) Polylactides: properties and prospects of an environmentally benign plastic from renewable resources. J Macromol Symp 175:55–66

Farrin J (2005) Biodegradable plastics from natural resources. Institute of Technology, Rochester

Fukushima K, Kimura Y (2006) Stereocomplexed polylactides (Neo-PLA) as high-performance bio-based polymers: their formation, properties, and application. Polym Int 55(6):626–642

Tsuji H, Ikada Y (1996) Crystallization from the melt of poly(lactide)s with different optical purities and their blends. Macromol Chem Phys 197(10):3483–3499

Ghosh S, Viana JC (2007) Effect of processing conditions on morphology and mechanical properties of injection-molded poly(l-lactic acid). Polym Eng Sci 47(7):1141–1147

Corradini P, Guerra G (1992) Polymorphism in polymers. Adv Polym Sci 100:182–217

Li HB, Huneault MA (2007) Effect of nucleation and plasticization on the crystallization of poly(lactic acid). Polymer 48(23):6855–6866

Haubruge HG, Daussin R, Jonas AM (2003) Epitaxial nucleation of poly(ethylene terephthalate) by talc: structure at the lattice and lamellar scales. Macromolecules 36(12):4452–4456

Ke T, Sun XZ (2003) Melting behavior and crystallization kinetics of starch and poly(lactic acid) composites. J Appl Polym Sci 89(5):1203–1210

Ikada Y, Tsuji H, Hyon SH (1987) Stereocomplex formation between enantiomeric poly(lactides). Macromolecules 20(4):904–906

Tsuji H, Ikada Y (2005) Poly(lactide) stereocomplexes: formation, structure, properties, degradation, and applications. Macromol Biosci 5(7):569–597

Brochu S, Barakat I (1995) Stereocomplexation and morphology of polylactides. Macromolecules 28(15):5230–5239

Schmidt SC, Hillmyer MA (2001) Polylactide stereocomplex crystallites as nucleating agents for isotactic polylactide. J Polym Sci B 39(3):300–313

He Y, Xu Y, Li SM (2008) Unique crystallization behavior of poly(l-lactide)/poly(d-lactide) stereocomplex depending on initial melt states. Polymer 49(26):5670–5675

Tsuji H, Ikada Y (1999) Stereocomplex formation between enantiomeric poly(lactic acids). I. Mechanical properties and morphology of solution-cast films. Polymer 40(24):6699–6708

Narladkar A, Balnois E, Grohens Y (2006) An AFM study of poly(l-lactic acid) and poly(d-lactic acid) macromolecules and their stereocomplexes at the solid-air interface. Macromol Symp 241:34–44

Zhang JM (2007) Investigation of phase transitional behavior of poly(l-lactide)/poly(d-lactide) blend used to prepare the highly-oriented stereocomplex. Macromolecules 40(4):1049–1054

Urayama H, Kanamori T, Fukushima K (2003) Controlled crystal nucleation in the melt-crystallization of poly(l-lactide)/poly(d-lactide) stereocomplex. Polymer 44(19):5635–5641

Sarasua JR, López Arraiza A (2005) Crystallinity and mechanical properties of optically pure polylactides and their blends. Polym Eng Sci 45(5):745–753

Sarasua JR, López Arraiza A (2005) Crystallization and thermal behavior of optically pure polylactides and their blends. J Mater Sci 40(8):1855–1862

Takasaki M, Ito H, Kikutani TJ (2003) Development of stereocomplex crystal of polylactide in high-speed melt spinning and subsequent drawing and annealing processes. J Macromol Sci Phys B 42(34):403–420

Wang YM, Mano JF (2008) Stereocomplexation and morphology of enantiomeric poly(lactic acid)s with moderate molecular weight. J Appl Polym Sci 107(3):1621–1627

Yasuniwa M, Iura K, Dan Y (2007) Melting behavior of poly(l-lactic acid): Effects of crystallization temperature and time. Polymer 48(18):5398–5407

Su ZZ, Wu CF (2009) Multiple melting behavior of poly(lactic acid) filled with modified carbon black. J Appl Polym Sci 47(20):1971–1980

Mano JF (2005) Influence of melting conditions on the thermal behavior of poly(l-lactic acid). Eur Polym J 41(10):2335–2342

He Y, Fan ZY (2007) DSC analysis of isothermal melt-crystallization, glass transition and melting behavior of poly(l-lactide). Eur Polym J 43(10):4431–4439

Wang Y, Mano JF (2005) Morphological contributions to glass transition in poly(l-lactic acid). Macromolecules 38(11):4712–4718

Lim L-T, Auras R (2008) Processing technologies for poly(lactic acid). Prog Polym Sci 33(8):820–852

Acknowledgment

This study is supported by the National Natural Science Foundation of China (No. 51173041), Shanghai Leading Academic Discipline Project (B502), and Shanghai Key Laboratory Project (08DZ2230500).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, H., Tang, S., Chen, J. et al. Thermal and phase-separation behavior of injection-molded poly(l-lactic acid)/poly(d-lactic acid) blends with moderate optical purity. Polym. Bull. 68, 1135–1151 (2012). https://doi.org/10.1007/s00289-011-0673-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-011-0673-y