Abstract

Seawater toilet flushing, seawater intrusion in the sewerage, and discharge of sulfate-rich industrial effluents elevates sulfate content in wastewater. The application of sulfate-reducing bacteria (SRB) in wastewater treatment is very beneficial; as for example, it improves the pathogen removal and reduces the volume of waste sludge, energy requirement and costs. This paper evaluates the potential to apply biological sulfate reduction using acetate and propionate to saline sewage treatment in moderate climates. Long-term biological sulfate reduction experiments at 10 and 20 °C were conducted in a sequencing batch reactor with synthetic saline domestic wastewater. Subsequently, acetate and propionate (soluble organic carbon) conversion rate were determined in both reactors, in the presence of either or both fatty acids. Both acetate and propionate consumption rates by SRB were 1.9 times lower at 10 °C than at 20 °C. At 10 °C, propionate was incompletely oxidized to acetate. At 10 °C, complete removal of soluble organic carbon requires a significantly increased hydraulic retention time as compared to 20 °C. The results of the study showed that biological sulfate reduction can be a feasible and promising process for saline wastewater treatment in moderate climate.

Similar content being viewed by others

Introduction

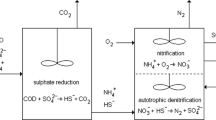

In recent years, several studies delineated the benefits of using seawater for toilet flushing (Chen et al. 2010). As a result of seawater integration in the sanitation chain, domestic wastewater becomes more saline and sulfate-rich; a salinity of 7.3 g/l and sulfate concentration of 500 mg/l is reached by a drinking water replacement of approximately 20 % by seawater. Recently, the Sulfate reduction Autotrophic denitrification and Nitrification Integrated (SANI) process has been developed to treat saline wastewater, which is sulfur cycle-based (Lau et al. 2006; Wang et al. 2009). Benefits of applying the SANI process to saline domestic wastewater treatment are substantial: high soluble organics [chemical oxygen demand (COD)] and N removal (>95 %), substantial decrease of volume of waste sludge (90 %), enhanced pathogens removal (2.2 log), and sustainability in terms of energy use (Tsang et al. 2009; Wang et al. 2009; Abdeen et al. 2010; Lu et al. 2012).

Lu et al. (2011) conducted a pilot study of the SANI process with real wastewater, achieving a COD removal of approximately 95 % under subtropical conditions (from the temperature perspective). Temperature is considered as a key parameter for (micro)biological processes, and consequently, it is interesting to investigate how the SANI process application, more precisely the sulfate reduction, part of it, can be extended to locations with moderate climate (sewage temperature between 10 and 20 °C). At temperatures below 30 °C, nitrification (Campos et al. 2002; Chen et al. 2003; Moussa et al. 2006) and autotrophic denitrification (Kleerebezem and Mendez 2002; Vaiopoulou et al. 2005; Zhang et al. 2009; Shao et al. 2011) processes have been studied frequently. Biological sulfate reduction, however, is limitedly investigated, only analyzed on short term (days), and fed with carbon sources nonspecific for domestic wastewater such as methanol and ethanol (Omil et al. 1997; Rabus et al. 2002; Sahinkaya 2009). For that reason, this study will focus on sulfate reduction by sulphate-reducing bacteria (SRB) at 10 and 20 °C, resembling winter and summer conditions in moderate climate, respectively, over the relatively long period (months) and including two soluble carbon sources: acetate and propionate.

Besides SRB performance at low(er) temperature, limited research is performed on the effect of salt and COD composition on sulfate removal from wastewater. In studies of Lau et al. (2006) and Wang et al. (2009) synthetic saline municipal wastewater was used with only one salt (NaCl), neglecting the existence of other naturally present ions in saline wastewater. Furthermore, both studies used acetate and glucose as COD source, while acetate and propionate are the main volatile fatty acids present in wastewater (Chen et al. 2004). Thus, to date, no biological sulfate reduction studies have focused on the combination of three typical characteristics of saline municipal wastewater in moderate climate countries: (1) composition of organics (acetate and propionate), (2) salt concentration (~7.2 g/l) composed of seawater ions, and (3) low(er) temperature range (10-20 °C). Therefore, this study focuses on the temperature effect on acetate and propionate consumption by SRB to investigate whether SRB can sufficiently remove organics from saline wastewater in moderate climate conditions (10–20 °C). Hereto, two laboratory, sulfate-reducing, sequencing batch reactors were operated at 10 and 20 °C. Long- and short-term effects of temperature on the metabolic conversions of SRB were studied. The microbial population composition was analyzed to provide further insight in the results obtained from the reactors' operation. Acetate and propionate were chosen as representatives of soluble organic substrate, since they are considered as the main organic substrate for SRB, obtainable either directly from the influent or through hydrolysis and fermentation processes taking place in the sewerage and treatment plant.

Material and methods

Experimental set-up (long-term)

The long-term effect of temperature on biological sulfate reduction was investigated in two sequencing batch reactors. The 3 l dished bottom reactors (130-mm diameter and 250-mm height) were operated at 10 and 20 °C. Both reactors operated continuously in cycles of 6 h, in which 1.5 l was gradually added and 1 l broth remained in the reactor. The cycle consisted of 5 h and 20 min feed reaction phase (with gradually feeding only in the first 110 min), 20 min settling, and 20 min effluent withdrawal. During the feed reaction phase, besides temperature, the following parameters were controlled for both reactors: pH (7.6 ± 0.2) dissolved oxygen (DO; 0 %) and mixing (300 rpm). The solid retention time (SRT) was 15 days and the hydraulic retention time (HRT) was 9 h. Steady-state operation was achieved when, for at least 30 days, the cyclic behaviour of the reactor did not substantially change.

The reactor with temperature controlled at 20 °C operated continuously for 131 days. In the meantime, short-term temperature tests and full-cycle tests were conducted (see below). A schematic overview of different phases within this reactor is indicated in Fig. 1. The second reactor was operated continuously for 67 days at 10 °C, and had a similar approach as the one described in Fig. 1. After 14 days, no sulfate reduction was noticed and extra sludge (inoculum) was added to reactor. From day 29, the reactor operated stable for two SRT before cycle experiments were conducted.

The reactor operated at 10 °C was inoculated with activated sludge from wastewater treatment plant (WWTP) Amsterdam West (The Netherlands) and sediment from a pond in the ecological garden of KWR Watercycle Research Institute (Nieuwegein, The Netherlands). The inoculum of the reactor at 20 °C consisted solely of activated sludge from WWTP Amsterdam West. Every 2 weeks, the population in both systems was enriched by addition of new biomass (~5 % v/v) of composition similar to the inoculum of R10°C.

Synthetic media

The reactor was fed with synthetic saline wastewater with a COD/SO4 2- ratio of 0.6 g/g. Composition of synthetic wastewater (feed) was 2.68 mM NaCH3COO · 3H2O and 1.15 mM NaC3H5O2 (300 mg COD/l in total), 7.32 g/l aquarium salt corresponding to 500 mg SO4 2-/l (Reef Crystals™), 0.09 mM K2HPO4, 0.04 mM KH2PO4, 2.89 mM NH4Cl (40 mg N/l), 0.34 mM MgCl2 · 6H2O, 0.39 mM CaCl2 and 1 ml/l trace elements solution as described by Lau et al. (2006).

Cycle experiments

To obtain more detailed insight in substrate consumption by SRB, cycle experiments were performed using the reactor after stable operation of at least two SRT. These cycle experiments had three different feed combinations: (1) acetate and propionate, (2) only acetate, and (3) only propionate. The acetate and propionate concentration in the feed was equal to that fed to the long-term reactor as well as the present volatile suspended solids (VSS) content of the biomass in the reactor. The term VSS in this study means the dry weight minus the ash content of the biomass sample taken from the reactor. Contrary to continuous operation, in the cycle experiments, the feed was added as a pulse, followed by 5 h and 20 min reaction phase. Samples for acetate, propionate, and sulfur components were taken at 10, 50, 80, 110, 140, 170, 200, 260, and 320 min from the reactor.

Short-term temperature effect

For further investigation of the SRB kinetics, also short-term temperature effect experiments were performed using the biomass from the reactor operated at 20 °C in long term. The short-term temperature tests were performed at 10 and 30 °C, as this temperature range is representative for domestic wastewater treatment. Between day 47 and 75, the temperature in the reactor was changed twice for only one cycle, once to 10 °C, and once to 30 °C. The next short-term experiment was performed as soon as a new steady-state operation (similar to the operation before disturbance) was reached, as observed from the dynamic pattern of selected parameters (e.g., pH profile) in the reactor (in practice, 2 days were sufficient to return to steady-state operation). Samples of the reactor's effluent were analyzed for acetate, propionate, sulfate, and sulfide concentration.

Analytical methods

To avoid sulfide losses during sampling, 1 drop of 1 M NaOH was immediately added to the sample (Poinapen et al. 2009). The sulfide concentration was measured according to the methylene blue method (APHA 1995), while sulfate and COD were measured spectrofotometrically with standard test kits (Hach Lange 514 and 414, respectively). To measure the remaining soluble organic substrates (CODsubstrate), first, the sulfide was removed via ZnSO4 addition, whereafter the ZnS precipitates were filtered from the sample addition (Poinapen et al. 2009). Acetate and propionate samples were first filtered by a 0.45 μm glass fiber filter and analyzed with gas chromatography. The off-gas was sparged through an iron solution and checked for colour change to determine whether H2S was present (APHA 1995). For SRT determination of the system, total suspended solids (TSS) and VSS measurements were performed as described in standard methods (APHA 1995). Samples were taken from the reactor at t = 300 min (reactor completely filled) and from the effluent. The samples were filtered with 2.7 μm glass microfiber filters (Satorius, FT 3 1101 047) and incubated at 105 °C (for the measurement of TSS) followed by 550 °C (VSS).

TRFLP analyses

Microbial composition of the biomass present in the reactors operating at 10 and 20 °C and the two inoculum sources (WWTP Amsterdam West and a pond) were analyzed using terminal restriction fragment length polymorphism (TRFLP) and sequencing of the partial dsrA gene. DNA was isolated, straight after sampling, with the power-biofilm DNA isolation kit. After polymerase chain reaction (PCR) amplification with the primer set DSR1334R and DSR1Fmix (Table 1), TRFLP was performed as described in (Santillano et al. 2010). The PCR products after 70 cycles were cloned with the pGEM®-T Easy Vector kit. Colonies were picked and analyzed by Macrogen®.

Mass balances

For every set of analyses from the reactor and the cycle experiment, the sulfur and COD mass balance were checked. The sulfur balance included sulfate, sulfide, sulfite, and H2S in the off-gas, in which the S content of the biomass was considered negligible. For the COD balance, the acetate, propionate, sulfide, and biomass production were incorporated. For the cycle measurements, the concentration of each component at t = 0 min was calculated based on concentrations from the influent and effluent. The theoretical oxidation of propionate, both incomplete and complete, and acetate via biological sulfate reduction are stated in Eqs. 1, 2, and 3 including the energy yield of each reaction. The balances are presented as percentage recovery in the effluent as compared to influent composition.

Results

Long-term temperature effect

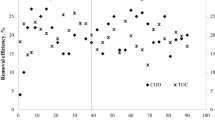

Directly after initiating the reactor at 20 °C, a gradual decrease in sulfate and COD concentration in the effluent was observed, indicating that SRB were active (Fig. 2). From day 32, the reactor operated stable for two SRT with an organic soluble COD removal efficiency of 98 %. Short-term experiments caused a temporary organic content increase of approximately 50 mg COD/l in the effluent. Fig. 2 demonstrates that the reactor needed around 20 days to stabilize again and obtain similar effluent values of 98 % COD removal as before the day when short-term experiments took place. Throughout stable operation and complete removal (>99 %) of both acetate and propionate was observed. The COD and sulfur balances were closed, 106 % and 91 %, respectively (Table 2), indicating no significant compounds were missed in the evaluation and that analytical procedures were performed correctly. The biomass concentration present in the reactor, which was set by a controlled SRT at 15 days, was 0.72 g VSS/l and 0.78 g TSS/l. Neither methane nor H2S was detected in the off-gas throughout the experiment.

The reactor operated at 10 °C achieved stable operation after 35 days (Fig. 3). In this reactor, COD removal was considerably less (30 %) compared to the reactor operated at 20 °C (Table 2), which resulted in a COD removal efficiency of 69 %. Table 2 indicates that the remaining (nonutilized) organic material consisted of solely acetate. Cycle experiments were conducted after a stable reactor operation of approximately two SRT. The execution of cycle experiments had no disturbing effect on the COD, sulfate and sulfide concentrations in the effluent. The average sulfur and COD balance closed for 98 % and 97 %, respectively. Neither CH4 nor H2S was detected in the off-gas of the reactor.

The results of the long-term reactor operation at 10 and 20 °C are presented in Table 2. The most important difference is practically complete removal of COD at 20 °C, while at 10 °C COD was only partially removed (69 %). In addition, also the VSS concentration in the reactor decreased from 0.72 to 0.50 when the temperature decreased from 20 to 10 °C. It should be noted that the yield (g VSS/g COD converted) was equal in the reactors (Table 2).

Flocculation

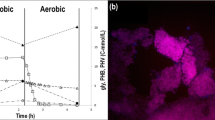

The reactors were inoculated with activated sludge and during operation of the sequencing batch reactor granules were formed in both reactors (see electronic supplement Fig. S1). The diameter of the granules were bigger at 20 °C than at 10 °C. Nonetheless, minimal settling velocity difference was observed between these two sludges, but granules from both reactors settled approximately 12 times faster than the inoculum sludge (data not shown).

Microbial population analysis

Besides comparison on effluent quality, growth, and flocculation, the SRB population composition present in the reactor at 10 and 20 °C were compared as well. Moreover, these samples were compared with the inoculum and with samples from sludge taken from a WWTP in winter and summer. The most prominent observation is the low similarity (25 %) between the two inoculum sources, which consequently increased the microbial diversity of the inoculum (Fig. 4). However, it should be noted that, in the sample from the ecological garden, less bands were visible than for other samples. After more than 45 days of operation in specified conditions, the population similarity with the original inoculum was only 7 %. In the reactor, temperature seems to have a major effect on the population change as the similarity was only 66 %.

Sequencing results demonstrated that the closest cultured relative to the dominant species was Desulfotalea arctica. The second most abundant species however differed between the two reactors; the second dominant strain in the reactor operated at 10 °C was related to Desulfobacter postgatei, while in the reactor at 20 °C, it was closest related to Desulfofustis glycolicus. A more diverse SRB population pattern was observed for both inoculum samples. Note, in Table 3 that only species with an abundance of at least two clones are indicated.

Temperature effect on SRB kinetics

In order to determine the effect of temperature on kinetics, cycle experiments were performed at both temperatures and three different feed compositions. The feed composition consisted of (1) acetate and propionate, (2) only propionate, and (3) only acetate. The results are presented in Fig. 5A–F. The sulfur and COD balances of these cycle experiments were calculated with satisfactory accuracy of 102 % and 97 %, respectively.

Effect of substrate type on the conversion in a sequencing batch reactor cycle at 10 (A, C, F) and 20 °C (B, D, E) Sulfate (▼), sulfide (Δ), acetate (●), and propionate (○) concentrations over a sequencing batch reactor cycle while pulse fed by three types of substrate composition: (1) acetate and propionate, (2) solely propionate, and (3) acetate

In the reactor operated at 20 °C and fed with acetate and propionate, acetate consumption was observed approximately 1 h after the start of the experiment and as soon as propionate was fully oxidized. Acetate was fully oxidized after approximately 260 min (Fig. 5B). In the reactor containing sludge fed with solely acetate at 20 °C, acetate oxidation started directly and was completed after 200 min (Fig. 5F). In the cycle with solely propionate in the feed, the propionate consumption profile was similar to that in case of mixed acetate and propionate feed, but the observed acetate concentration in the reactor increased to 0.75 mM during the first hour of this cycle.

Based on the Fig. 5A–F, it can be concluded that the acetate and propionate concentration declined more slowly at 10 °C during cycle operation than at 20 °C. In contrast to what occurred at 20 °C, acetate consumption started immediately from the beginning of the cycle with SRB fed with acetate and propionate. Although propionate oxidation occurred more slowly at 10 °C (in 260 min) than at 20 °C (in 110 min), there was also no difference in kinetics observed between cases with mixed feed composition at 10 °C. It is remarkable that, when fed with exclusively propionate, acetate is produced at 20 °C, while no increase in acetate concentration is observed at 10 °C (Fig. 5C and D).

Conversion rates

To quantify the effect of temperature on acetate and propionate consumption, conversion rates were calculated. Three sludge specific conversion rates were defined: propionate (q HPr), acetate in the presence of propionate (q HAc,a), and acetate in the absence of propionate (q HAc,b). A temperature decrease from 20 to 10 °C resulted in lower conversion rates for both acetate and propionate (Table 4). Remarkably, a decrease in temperature had an equal effect on acetate (79.23/41.09 g COD/g VSS-1 h-1) and propionate (81.76/42.22 g COD/g VSS-1 h-1) consumption rate, both decreased by factor 1.9. In both reactors, the acetate conversion was slower in the presence of propionate (q HAc,a) than in the absence of propionate (q HAc,b). As soon as propionate was fully consumed at 10 °C, the acetate conversion rate was similar to the acetate conversion in a test fed with solely acetate, while at 20 °C, it was slower than in the case when SRB were fed with solely acetate. The propionate conversion rate was not affected by the presence of acetate at both temperatures (Table 4). At both 10 and 20 °C, the conversion rates of acetate and propionate were different in terms of mmol substrate per hour per biomass, but when expressed in units of mg COD, the conversion rate is very similar.

Short-term temperature effect

The effect of a short-term (cycle) temperature change is represented in Fig. 6. An increase of temperature for 6 h from 20 to 30 °C had marginal effect on COD removal efficiency (Fig. 6). In contrast, the COD removal efficiency was affected when the temperature was changed from 20 to 10 °C or from 20 to 30 °C. At 10 °C, a higher percentage of propionate than acetate was oxidized. A typical winter temperature of wastewater in moderate climates is 10 °C, and as these short-term experiments revealed a decrease in COD removal efficiency, a long-term experiment was conducted at 10 °C.

Cycle operation

To compare the profiles of a pulse-fed batch with the actual situation, a cycle of the sequencing batch reactor is shown (Figs. 7 and 8). The feed was gradually added during the feed and reaction phase, but at the same time, sulfate reduction and COD oxidation occurred. Fig. 7 shows the concentration of acetate and propionate in mixed liquor over a cycle, compared to the theoretical concentration in a mixed liquor if no conversion would occur. Propionate consumption started directly after initiating the feed procedure, resulting in a low propionate concentration (<0.06 mM) throughout the cycle. On the contrary, acetate had a higher actual presence than what has been added over the first 150 min of the cycle. Within 2 h after ceasing the feed procedure, the acetate concentration dropped to zero. The sulfate and sulfide profiles of this cycle showed almost linear decrease or increase of concentration, respectively (Fig. 8).

Discussion

To the best of our knowledge, this is the first study focusing on performance of SRB at temperatures below 30 °C fed with acetate and propionate. A comprehensible difference in COD removal efficiency was observed between the reactors operated at 10 and 20 °C (Table 2). Reasons for the COD removal decrease at 10 °C will be discussed regarding the effluent quality (COD removal efficiency), biomass growth, population diversity, and SRB kinetics.

COD removal efficiency

A long-term temperature decrease from 20 to 10 °C resulted in a 31 % lower COD removal efficiency (Table 2). As propionate was completely consumed at both temperatures, it can be stated that the decrease in COD removal is caused by an incomplete removal of acetate at 10 °C. A 10 °C short-term temperature exposure to sludge adapted to 20 °C revealed a similar acetate removal efficiency (Fig. 6), implying that acetate consumption is not improved after long-term adaptation of biomass. This is supported by the observation of the same dominant SRB strain at both temperatures.

The excess of acetate in the effluent of the reactor operated at 10 °C might be explained by one (combination of) the following reasons: (1) propionate is incompletely oxidized, resulting in an additional formation of acetate to the amount present in the feed, (2) SRB favor the consumption of propionate over acetate, (3) acetate oxidation is more strongly inhibited than that of propionate at lower temperature, and (4) the reactor is fed with relatively higher amount of acetate (227 mg COD/l) than propionate (171 mg COD/l). These hypotheses are further elaborated and discussed below.

In the typical slow-feeding procedure as applied to the reactor at 20 °C (Fig. 7), a higher acetate concentration was measured than the theoretically calculated amount that should be present in the reactor (if no utilization took place). In general, two types of SRB have been reported in the literature: those that degrade organic compounds incompletely to acetate, and those that degrade organic compounds completely to carbon dioxide (Widdel 1988; Henze et al. 2008). An incomplete propionate oxidation into acetate would explain the formation of acetate during the cycle. In pulse-fed cycle tests using solely propionate at 20 °C, a distinct acetate production was observed, similar to the detected acetate during the slow-feed procedure cycle (Figs. 5 and 7), which supports the hypothesis that propionate was incompletely oxidized to acetate. Hence, it seems possible to have incomplete propionate removal by one SRB species and acetate removal by another. This hypothesis is supported by the fact that Laanbroek et al. (1984) revealed for the majority of species present in the microbial population (Table 3) have an incomplete conversion of propionate into acetate.

For propionate, the consumption rates were similar between batches fed with a mixture of acetate and propionate and with solely propionate. For acetate, however, the rate was lower in the presence of propionate than it its absence (Table 4), as acetate consumption initiates after the complete oxidation of propionate within the cycle (Fig. 7). Also the preference for substrate by SRB might be the reason for the decrease of only the acetate removal efficiency at 10 °C. Since propionate is not completely oxidized to acetate, this is probably a result of a similar amount of acetate produced and consumed in the same period. Moreover, because the rate of acetate and propionate consumption is practically equal at each temperature (Table 4), it is assumed that there is no preference of substrate by the SRB population present in the reactor. Hence, substrate preference seems not to be the reason for an sole acetate presence in the effluent at 10 °C.

The effect of a temperature decrease from 20 to 10 °C is similar for conversion rates of both acetate and propionate (Table 4), as the ratios between these conversions at 10 and 20 °C, in case of single substrate feed, were similar (1.93 mmol.x-1 h-1 ± 0.01). This suggests that temperature decrease slows down the consumption of both organics. The temperature affects the sulfate reduction as a result of the substrate conversion.

Improved COD removal at 10 °C

In the reactor operated at 10 °C, a COD removal efficiency of only 69 % was observed (Table 2), while COD oxidation occurred throughout the cycle. This implied that incomplete COD removal is linked to the maximal specific oxidation rate [41.6 mg CODsubstrate/(h g VSS)] and biomass concentration present in the reactor (0.50 g VSS/l), which was kept constant by maintaining the SRT of 15 days. To improve the COD removal efficiency at 10 °C, the HRT was increased. Initially, the HRT was 9 h, but after an increase to 12 h, the COD removal efficiency increased to 89 % (data not shown). The additional removal of 80 mg/l COD is directly related to the maximal specific oxidation rate within the reactor. Obviously, the overall amount of COD removed per day was not affected.

An alternative aiming to improve the COD consumption is to increase the COD removal per day. Therefore, the biomass concentration in the reactor needed to be elevated, which would be achieved by increasing the SRT. As a result, the specific rate remains similar, but the system converts more COD per unit of time. This hypothesis is strengthened by the fact that the biomass concentration determines strongly the COD removal efficiency in these two reactors. In both reactors, the SRT was controlled at 15 days, resulting in VSS concentration of 0.50 g VSS/l at 10 °C and 0.72 g VSS/l at 20 °C. Both reactors were fed with 300 mg COD/l, which was 100 % utilized at 20 °C and for only 69 % at 10 °C (Table 2). The ratio between COD removal efficiency (69/100) is equal to the VSS concentration (0.50/0.72). Hence, it seems that the present VSS concentration in the reactor is determined by the operating temperature which affects the COD consumption rate.

Population shift due to temperature change

A TRFLP analysis was conducted in order to investigate the temperature (10 and 20 °C) effect on SRB communities in saline domestic wastewater fed reactors. An inoculum mixture was used to start up the reactor. The SRB population between the two inoculum sources had a similarity of 25 %. The similarity between both inoculums and the population in the reactors was even lower (15 %). The reactor culture was much less diverse then the inoculum due to the selection of the best adopted organisms to the reactor conditions. The TRFLP profile of positive control samples of DSMZ 1240 and DSMZ 480 demonstrated that a pure culture can result in single or multiple bands (data not shown). Therefore, some precaution has to be made when number of bands is related to number of species. The sequencing of the bands indicated the uniqueness of the species. Low sequence similarity values were observed with related species in the database, which indicates that a SRB, which was not cultivated afore, is dominant in this reactor. The closest cultured species related to the dominant species in both reactors is D. arctica. This psychrophilic strain has been isolated from cold arctic marine sediments in 1999 (Knoblauch et al. 1999). Knoblauch et al. (1999) stated that this strain has an optimal growth rate of 10 to 18 °C and a salinity, with a mixture of salts, of ~1 %, which is also typical for saline municipal wastewater. However, both closest related cultured relatives, D. arctica and D. postgatei, of the two strains that were detected in the reactors, have been documented to be able to oxidize acetate, although not propionate (Widdel and Pfennig 1981; Knoblauch et al. 1999). Clearly, the conditions in the reactor were selected for a yet unknown SRB which needs further attention in the future.

Recommendations for application

Seasonal temperature fluctuation

Seasonal temperature in sewage and WWTPs in moderate climates usually fluctuate between 10 °C (winter) and 20 °C (summer). Winter and summer samples for WWTP Amsterdam West showed a high similarity in SRB population as well as the sludge from the reactor operated at 10 and 20 °C. Therefore, one can expect a relative stable SRB community despite seasonal temperature variations. A stable SRB community is beneficial for the application of SRB in the wastewater treatment in moderate climates.

COD content

Chen et al. (2004) reported that the main volatile fatty acids (VFA) present in wastewater are acetate and propionate in an average carbon molar ratio of 0.7 to 0.3. The acetate and propionate concentrations can vary significantly López-Vázquez et al. (2008). As the present study shows that the sulfate reduction rate using acetate and propionate is practically equal, it was concluded that the VFA composition in wastewater has no effect on the oxidation rates (mg COD/l g VSS) of SRB. Therefore, the expected fluctuations of acetate and propionate levels seems not to be relevant for process design.

Flocculation

An approach to reduce expenses within a WWTP is the application of granular sludge which is a powerful technique to reduce large-area requirement and aeration costs (de Kreuk et al. 2005). Sludge present in both reactors, inoculated with activated sludge, formed granules during operation of sequencing batch reactor (see electronic supplement Fig. S1) which is beneficial for its application. The fact that a larger floc diameter for sludge operated at 20 than 10 °C is probably due to the increased biomass concentration (Table 2). Nonetheless, the settling velocity did not differ, resulting in an equal settling time which, in cases of different settling properties of flocs dominantly populated with certain organisms, can be used as a selection mechanism.

Competition SRB and methanogens

In the biological sulfate reduction reactor at 20 °C, the organics were completely removed (Table 2). Since no measurable amount of methane was produced, it was assumed that SRB formed the dominant population in the reactor. This assumption was confirmed by the fact that no autofluorescent microorganisms like methanogens (Doddema and Vogels 1978) were observed in the sludge. Moreover, FISH analyses with the Archaeal-specific probe Arch915 resulted in detection of Archaeal methanogens neither (data not shown).

In the reactor operated at 10 °C, the COD removal efficiency was only 69 %, while the COD/SO4 2- ratio was lower than 0.67. In the presence of excessive sulfate (COD/SO4 2- < 0.67), SRB usually outcompete methanogens (Harada et al. 1994; Mizuno et al. 1994; Oude Elferink et al. 1994; Omil et al. 1998). Also, in this reactor, no methanogens were observed, although COD was not fully oxidized and methanogens adapted to low temperatures were present in the inoculum. This suggests that methanogens cannot outcompete SRB in a saline and sulfate-rich wastewater treatment system at 10 °C under these specific conditions. This result is in accordance with the study of Lu et al. (2011), which had similar salt, sulfate and COD concentrations, but operated at 25 °C. Vallero et al. (2004), however, reported that at temperatures below 30 °C, propionate was oxidized by SRB, while acetate was oxidized by methanogens. But the observation that an increase in salinity affected methanogens more than SRB (Vallero et al. 2004) supports the detected dominance of SRB in the present reactor. As SRB are the dominant population, minimal methanogens activity might be expected in sludge exposed to saline and sulfate-rich wastewater, despite the excess of COD in the effluent, it is clearly considered beneficial for its application in wastewater treatment.

Modeling

The sulfate reduction rate in batches at 10 and 20 °C are independent from the type of substrate acetate or propionate (Table 4). It can be concluded that sulfate reduction is the rate-limiting conversion in the biomass. As given the specific rates and the yield, the maximal growth rate can be calculated, it is proposed to establish the kinetics based on sulfate reduction rate instead of the growth rate for sequencing batch reactors.

Conclusion

The decrease in sulfate reduction rate as a result of temperature decrease from 20 to 10 °C was similar for acetate and propionate consumption. The conversion of propionate proceeds as a partial conversion to acetate first, followed by acetate oxidation. As the consumption rate of acetate and propionate was similar in terms of mgCOD/h g-1 biomass, it is assumed that fluctuations in acetate and propionate concentrations in the influent have marginal effect on biological sulfate reduction. SRB can perform well considering COD removal (>95 %) in conditions specific to saline domestic wastewater and moderate climate, as an increase of the HRT resulted in complete COD removal of the reactor operated at 10 °C. Therefore, SRB can be applied in moderate climates successfully.

References

Abdeen S, Di W, Hui L, Chen G-H, van Loosdrecht MCM (2010) Fecal coliform removal in a sulfate reducing autotrophic denitrification and nitrification integrated (SANI) process for saline sewage treatment. Water Sci Technol 62(11):2564–2570

APHA (1995) Standard methods for the examination of water and wastewater, 19th edn. ISBN:0-87553-223-3

Campos JL, Mosquera-Corral A, Sánchez M, Méndez R, Lema JM (2002) Nitrification in saline wastewater with high ammonia concentration in an activated sludge unit. Water Res 36(10):2555–2560

Chen G-H, Wong M-T, Okabe S, Watanabe Y (2003) Dynamic response of nitrifying activated sludge batch culture to increased chloride concentration. Water Res 37(13):3125–3135

Chen Y, Randall AA, McCue T (2004) The efficiency of enhanced biological phosphorus removal from real wastewater affected by different ratios of acetic to propionic acid. Water Res 38(1):27–36

Chen G–H, Brdjanovic D, Ekama GA, van Loosdrecht MCM (2010) Seawater as Alternative water resource. Proceedings of the 7th IWA leading edge technology conference on water and wastewater treatment, Arizona, USA, June 2–4

de Kreuk MK, Heijnen JJ, van Loosdrecht MCM (2005) Simultaneous COD, nitrogen, and phosphate removal by aerobic granular sludge. Biotechnol Bioeng 90(6):761–769

Doddema HJ, Vogels GD (1978) Improved identification of methanogenic bacteria by fluorescence microscopy. Appl Environ Microbiol 36(5):752–754

Harada H, Uemura S, Momonoi K (1994) Interaction between sulfate-reducing bacteria and methane-producing bacteria in UASB reactors fed with low strength wastes containing different levels of sulfate. Water Res 28(2):355–367

Henze M, Van Loosdrecht MCM, Ekama GA, Brdjanovic D (2008) Biological wastewater treatment: principles, modelling and design. IWA Publishing. ISBN: 1843391880

Kleerebezem R, Mendez R (2002) Autotrophic denitrification for combined hydrogen sulfide removal from biogas and post-denitrifcation. Water Sci Technol 45(10):349–356

Knoblauch C, Sahm K, Jorgensen BB (1999) Psychrophilic sulfate-reducing bacteria isolated from permanently cold arctic marine sediments: description of Desulfofrigus oceanense gen. nov., sp.nov., Desulfofrigus fragile sp.nov., Desulfofabe gelida gen. nog., sp. nov., Desulfotalea psychophilia gen. nov., sp. nov. and Desulfotalea arctica sp. nov. Int J Syst Bacteriol 49:1631–1643

Laanbroek HJ, Geerligs HJ, Sijtsma L, Veldkamp H (1984) Competition for sulfate and ethanol among Desulfobacter, Desulfobulbus, and Desulfovibrio species isolated from intertidal sediments. Appl Environ Microbiol 47(2):329–334

Lau GN, Sharma KR, Chen G-H, van Loosdrecht MCM (2006) Integration of sulphate reduction, autotrophic denitrification and nitrification to achieve low-cost excess sludge minimisation for Hong Kong sewage. Water Sci Technol 53(3):227–235

López-Vázquez CM, Hooijmans CM, Brdjanovic D, Gijzen HJ, van Loosdrecht MCM (2008) Factors affecting the microbial populations at full-scale enhanced biological phosphorus removal (EBPR) wastewater treatment plants in The Netherlands. Water Res 42(10–11):2349–2360

Loy A, Kusel K, Lehner A, Drake HL, Wagner M (2004) Microarray and functional gene analyses of sulfate-reducing prokaryotes in low-sulfate, acidic fens reveal cooccurrence of recognized genera and novel lineages. Appl Environ Microbiol 70(12):6998–7009

Lu H, Wu D, Tang DTW, Chen G-H, van Loosdrecht MCM, Ekama GA (2011) Pilot scale evaluation of SANI process for sludge minimization and greenhouse gas reduction in saline sewage treatment. Water Res 63(10):2149–2154

Lu H, Ekama GA, Wu D, Feng J, van Loosdrecht MCM, Chen G-H (2012) SANI® process realizes sustainable saline sewage treatment: steady state model-based evaluation of the pilot-scale trial of the process. Water Res 46(2):475–490

Mizuno O, Li YY, Noike T (1994) Effects of sulfate concentration and sludge retention time on the interaction between methane production and sulfate reduction for butyrate. Water Sci Technol 30(8):45–54

Moussa MS, Sumanasekera DU, Ibrahim SH, Lubberding HJ, Hooijmans CM, Gijzen HJ, van Loosdrecht MCM (2006) Long term effects of salt on activity, population structure and floc characteristics in enriched bacterial cultures of nitrifiers. Water Res 40(7):1377–1388

Omil F, Bakker CD, Pol LWH, Lettinga G (1997) Effect of pH and low temperature shocks on the competition between sulphate reducing bacteria and methane producing bacteria in UASB reactors. Environ Technol 18(3):255–264

Omil F, Lens P, Visser A, Hulshoff Pol LW, Lettinga G (1998) Long-term competition between sulfate reducing and methanogenic bacteria in UASB reactors treating volatile fatty acids. Biotechnol Bioeng 57(6):676–685

Oude Elferink SJWH, Visser A, Hulshoff Pol LW, Stams AJM (1994) Sulfate reduction in methanogenic bioreactors. FEMS Microbiol Rev 15(2–3):119–136

Poinapen J, Ekama G, Wentzel MC (2009) Biological sulphate reduction with primary sewage sludge in an upflow anaerobic sludge bed (UASB) reactor: Part 2. Modification of simple wet chemistry analytical procedures to achieve COD and S mass balances. Water SA 35(5):525–534

Rabus R, Brüchert V, Amann J, Könneke M (2002) Physiological response to temperature changes of the marine, sulfate-reducing bacterium Desulfobacterium autotrophicum. FEMS Microbiol Ecol 42(3):409–417

Sahinkaya E (2009) Microbial sulfate reduction at low (8°C) temperature using waste sludge as a carbon and seed source. Int Biodeterior Biodegrad 63(3):245–251

Santillano D, Boetius A, Ramette A (2010) Improved dsrA-based terminal restriction fragment length polymorphism analysis of sulfate-reducing bacteria. Appl Environ Microbiol 76(15):5308–5311

Shao M-F, Zhang T, Fang HH-P, Li X (2011) The effect of nitrate concentration on sulfide-driven autotrophic denitrification in marine sediment. Chemosphere 83(1):1–6

Tsang WL, Wang J, Lu H, Li S, Chen G-H, van Loosdrecht MCM (2009) A novel sludge minimized biological nitrogen removal process for saline sewage treatment. Water Sci Technol 59(10):1893–1899

Vaiopoulou E, Melidis P, Aivasidis A (2005) Sulfide removal in wastewater from petrochemical industries by autotrophic denitrification. Water Res 39(17):4101–4109

Vallero MVG, Sipma J, Lettinga G, Lens PNL (2004) High-rate sulfate reduction at high salinity (up to 90 mS.cm-1) in mesophilic UASB reactors. Biotechnol Bioeng 86(2):226–235

Wagner M, Roger AJ, Flax JL, Brusseau GA, Stahl DA (1998) Phylogeny of dissimilatory sulfite reductases supports an early origin of sulfate respiration. J Bacteriol 180(11):2975–2982

Wang J, Lu H, Chen G-H, Lau GN, Tsang WL, van Loosdrecht MCM (2009) A novel sulfate reduction, autotrophic denitrification, nitrification integrated (SANI) process for saline wastewater treatment. Water Res 43(9):2363–2372

Widdel, F (1988) The dissimilatory sulfate and sulfur reducing bacteria. In: Balows A, Truper HG, Dworkin M., Harder W, Schleiferk H (eds), The prokaryotes, 2nd edn. Springer; 1992. pp 583–664

Widdel F, Pfennig N (1981) Studies on dissimilatory sulfate-reducing bacteria that decompose fatty acids I. Isolation of new sulfate-reducing bacteria enriched with acetate from saline environments. Description of Desulfobacter postgatei gen. nov., sp. nov. Arch Microbiol 129:395–400

Zhang M, Zhang T, Shao MF, Fang HHP (2009) Autotrophic denitrification in nitrate-induced marine sediment remediation and Sulfurimonas denitrificans-like bacteria. Chemosphere 76(5):677–682

Zverlov V, Klein M, Lucker S, Friedrich MW, Kellermann J, Stahl DA, Loy A, Wagner M (2005) Lateral gene transfer of dissimilatory (bi)sulfite reductase revisited. J Bacteriol 187(6):2203–2208

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 98 kb)

Rights and permissions

About this article

Cite this article

van den Brand, T.P.H., Roest, K., Brdjanovic, D. et al. Temperature effect on acetate and propionate consumption by sulfate-reducing bacteria in saline wastewater. Appl Microbiol Biotechnol 98, 4245–4255 (2014). https://doi.org/10.1007/s00253-013-5482-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-013-5482-9

), acetate (

), acetate ( ), and propionate (

), and propionate ( ) at 10 and 30 °C in a stable reactor operated at 20 °C

) at 10 and 30 °C in a stable reactor operated at 20 °C