Abstract

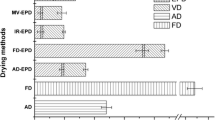

In this study, the production of green olive, chickpea and haricot bean added potato chips was investigated in order to produce a functional snack food appealing to consumers from all age groups. Chips were produced by hot air drying (75–85 °C), vacuum drying (75–85 °C, 250 mbar), and microwave drying (90 W and 180 W). The effective diffusion coefficient of chips was calculated as between 4.25 × 10−9- 4.38 × 10−8. When the drying behavior of samples was examined; vacuum drying, convectional drying and microwave drying fitted in Page and Modified Page models. Total acidity, pH, salt, protein, total phenolics and antioxidant activity analyses were conducted in chips and chips doughs. In olive added chips, the highest total phenolic content was determined in the sample produced by vacuum drying method at 85 °C. Moreover, for chickpea-olive added chips, the highest total phenolic content and antioxidant activity were determined in microwave dried (180 W) samples. In haricot bean and olive added chips, antioxidant activity showed differences according to drying methods. Chickpea and haricot bean addition into chips doughs were increased the protein content in dried samples.

Similar content being viewed by others

References

Ertop HE, Kultuk K, Coskun K, Canlı S (2016) Gıda endüstrisi yan ürünleri kullanımıyla cips üretimine yeni bir yaklaşım: Zenginleştirilmiş gluten cipsi. Akademik Gıda 14(4):398–406 (in Turkish)

Gergilioglu U (2016) Bazı OECD ülkeleri bağlamında obezite vergilerinin değerlendirilmesi. Ekonomik ve Sosyal Araştırmalar Dergisi 12(2):149–166 (in Turkish)

RESTEC Group (2018) U.S. Potato Chips Market Size, Share & Trends Analysis Report By Flavor (Flavored, Plain/Salted), By Distribution Channel (Supermarket, Convenience Stores), And Segment Forecasts, 2018–2025. ResearchAndMarkets.com Business Wire. https://www.researchandmarkets.com/research/d2nnr3/uspotatochips?w=4View. Accessed 31 May 2019

Ozer EA (2007) Ekstrüzyon yöntemi ile besleyici değeri yüksek çerez tipi fonksiyonel ürün geliştirme. Doktora Tezi, Çukurova Üniversitesi, Gıda Mühendisliği Anabilim Dalı, Adana (in Turkish)

Pedreschi F, Moyano P, Santis N, Pedreschi R (2007) Physical properties of pre-treated potato chips. J Food Eng 79(4):1474–1482

Granda C, Moreira RG, Tichy SE (2004) Reduction of acrylamide formation in potato chips by low-temperature vacuum frying. J Food Sci 69(8):405–411

Pineda, MT (2007) Fortification of baked and fried tortilla chips with mechanically expelled soy flour. M.A. Thesis, Texas A&M University, Faculty of Agricultural Sciences, United States

Palazoglu TK, Savran D, Gökmen V (2010) Effect of cooking method (baking compared with frying) on acrylamide level of potato chips. J Food Sci 75(1):25–29

Shyu SL, Hau LB, Hwang LS (2005) Effects of processing conditions on the quality of vacuum-fried carrot chips. J Sci Food Agric 85(11):1903–1908

Devseren E, Tomruk D, Koç M, Kaymak-Ertekin F (2016) Vakum altında kızartma işleminin gıda ve kızartma yağı kalitesi üzerine etkisi. Akademik Gıda 14(1):43–53

Ochoa-Martínez LA, Castillo-Vázquez K, Figueroa-Cárdenas JD, Morales-Castro J, Gallegos-Infante JA (2016) Quality evaluation of tortilla chips made with corn meal dough and cooked bean flour. Cogent Food Agric 2(1):1136017. https://doi.org/10.1080/23311932.2015.1136017

Makowska A, Zielińska-Dawidziak M, Niedzielski P, Michalak M (2018) Effect of extrusion conditions on iron stability and physical and textural properties of corn snacks enriched with soybean ferritin. Int J Food Sci Technol 53(2):296–303

Huang LI, Zhang M (2012) Trends in development of dried vegetable products as snacks. Dry Technol 30(5):448–461

Mihalcea LI, Bleoancă II, Mihai CM, Borda DD (2017) Osmotic pressure influence on the vegetable chips dehydration process. St Cerc St CICBIA 18(1):51–59

Wexler L, Perez AM, Cubero-Castillo E, Vaillant F (2016) Use of response surface methodology to compare vacuum and atmospheric deep-fat frying of papaya chips impregnated with blackberry juice. CYTA-J Food 14(4):578–586

Filiz BE (2015) Elma cipsinin bazı kalite ve antioksidan özelliklerine kurutma, ambalajlama ve depolamanın etkisi. Doktora Tezi, Süleyman Demiral Üniversitesi, Gıda Mühendisliği Anabilim Dalı, Isparta (in Turkish)

Kowalska H, Marzec A, Kowalska J, Samborska K, Tywonek M, Lenart A (2018) Development of apple chips technology. Heat Mass Transf 54(12):3573–3586

Turgay O, Cınar I (2009) Şekilli havuç cipsi üretiminde proses optimizasyonu. Akademik Gıda 7(5):26–31 (in Turkish)

Oghenechavwuko UE, Saka GO, Adekunbi TK, Taiwo AC (2013) Effect of processing on the physico-chemical properties and yield of gari from dried chips. J of Food Process Technol 4(8). https://doi.org/10.4172/2157-7110.1000255

Elkhalifa AOE, Hassan AM, Zei MEA (2014) Analytical quality and acceptability of baked and fried banana chips. J Hum Nutr Food Sci 2(6):1052

Wani SA, Sharma V, Kumar P (2017) Effect of processing parameters on quality attributes of fried banana chips. Int Food Res J 24(4):1407–1413

Vázquez-Durán A, Gallegos-Soto A, Bernal-Barragán H, López-Pérez M, Méndez- Albores A (2014) Physicochemical, nutritional and sensory properties of deep fat-fried fortified tortilla chips with broccoli (Brassica oleracea L. convar. italica Plenck) flour. J Food Nutr Res 53(4): 313–323

Shaviklo GR, Olafsdottir A, Sveinsdottir K, Thorkelsson G, Rafipour F (2011) Quality characteristics and consumer acceptance of a high fish protein puffed corn-fish snack. J Food Sci Technol 48(6):668–676

Olivares CYV (2010) Characterization of product quality attributes and thermal properties of potato chips during vacuum frying. M.A. Thesis, Texas A&M University, Faculty of Agricultural Sciences, United States

Tuta T, Palazoglu TK (2017) Effect of baking and frying methods on quality characteristics of potato chips. GIDA 42(1):43–49

Konuskan DB (2008) Hatay’da yetiştirilen Halhalı, Sarı Haşebi ve Gemlik zeytin çeşitlerinin bazı fiziksel özelliklerinin ve yağ verimlerinin belirlenmesi. Doktora Tezi, Çukurova Üniversitesi, Gıda Mühendisliği Anabilim Dalı, Adana (in Turkish)

Durucasu I (2004) Domat türü yeşil zeytinin tatlandırılması üzerine bir araştırma. GIDA 29(3):211–216 (in Turkish)

Gurbuz M, Ogut S (2018) Zeytin yaprağının potansiyel sağlık yararları. Türkiye Klinikleri J Health Sci 3(3):242–253 (in Turkish)

Coteli E, Karatas F (2017) Ateş Dikeninin (Pyracantha coccinea Roemer var. lalandi) kırmızı meyvelerindeki A, E, C vitamini, β-Karoten, Likopen, Glutatyon ve Malondialdehit miktarlarının araştırılması. Firat University J. Sci 29(1):41–46 (in Turkish)

Sayaslan A, Akarcay E, Tokatlı M (2016) Kavrulmuş mısır, buğday ve nohut (leblebi) çerezlerinin beslenme açısından önemli karbonhidrat fraksiyonları. Akademik Gıda 14(3):284–292 (in Turkish)

Wood JA, Tan HT, Collins HM, Yap K, Khor SF, Lim WL, Xing X, Bulone V, Burton RA, Fincher GB, Tucker MR (2018) Genetic and environmental factors contribute to variation in cell wall composition in mature desi chickpea (Cicer arietinum L.) cotyledons. Plant Cell Environ 41(9):2195–2208

Tekatlı M, Kılınc C, Cınkır MA (2017) Bazı kışlık nohut (Cicer arietinum L.) hatlarında bazı tarımsal karakterlerin ve karakterler arası ilişkilerin belirlenmesi. Tarla Bitkileri Merkez Araştırma Enstitüsü Dergisi 26(Özel sayı): 138–141 (in Turkish)

Demirbas A, Karakoy T, Durukan H, Erdem H (2017) The impacts of the biochar addition in different doses on yield and nutrient uptake of the chickpea plant (Cicer arietinum L.) under the conditions with and without incubation. Fresenius Environ Bull 26(12A):8328–8336

Maqbool K, Naik HR, Hussain SZ, Rather AH (2017) Influence of soaking and germination on physico-chemical composition and functional properties of chickpea (var. SKUAST-233) flour. Int J Chem Stud 5(5):1048–1054

Ceran F, Onder M (2017) Farklı zamanlarda ekilen nohut çeşitlerinin (Cicer arietinum L.) bazı tarımsal özelliklerinin belirlenmesi. Selçuk Tar Bil Der 3(1):25–29 (in Turkish)

Sozen O, Ozcelik H, Bozoglu H (2014) Doğu Karadeniz Bölgesi yerel fasulye (Phaseolus vulgaris L.) populasyonlarının karakterizasyonu ve morfolojik değişkenliğin ortaya konulması. BİBAD 7(1):29–36 (in Turkish)

Ayalew AM (2011) Factors affecting adoption of improved haricot bean varieties and associated agronomic practices. M.Sc. Thesis, Department of Plant and Horticultural Sciences, Hawassa University, Hawassa, Ethiopia

Kahraman A (2008) Konya bölgesinde yetiştirilen bodur kuru fasulye (Phaseolus vulgaris L.) populasyonlarının genetik farklılıklarının ve bazı kalite özelliklerinin belirlenmesi. Selçuk Üniversitesi, Tarla Bitkileri Anabilim Dalı, Yüksek Lisans Tezi, Konya (in Turkish)

Kutlu N, İsci A, Demirkol OS (2015) Gıdalarda ince tabaka kurutma modelleri. GIDA 40(1):39–46 (in Turkish)

Avhad MR, Marchetti JM (2016) Mathematical modelling of drying kinetics of hass avocado seeds. Ind Crop Prod 91:76–87

Bengsston GB, Rahman MS, Stanley R, Perera CO (1998) Effect of Specific Pretreatment on the Drying Behaviour of Apple Rings, The New Zealand Institute of Food Science and Technology and The Nutrition Society of New Zealand Conference, 1–3 July, Nelson, New Zealand

Sarsavadiva PN, Sawhney RL, Pangavhane DR, Sing SP (1999) Drying behaviour of brined onion slices. J Food Eng 40(3):219–226

Yaldiz O, Ertekin C (2001) Thin layer solar drying of some vegetables. Dry Technol 19(3–4):583–597

Doymaz I (2007) The kinetics of forced convective air-drying of pumpkin slices. J Food Eng 79(1):243–248

AOAC (1985) Official methods of analysis 14th edn, Association of Official Analytical Chemists, Washington, DC

AOAC (1990) Official methods of analysis 15th edn, Association of Official Analytical Chemists, Washington, DC

AOAC (1975) Official methods of analysis 12th edn, Association of Official Agricultural Chemists, Washington, DC

AOAC (2005) Official methods of analysis 18th edn, Association of Official Analytical Chemists, Gaithersburg, Md

Yen G, Chen H (1995) Antioxidant activity of various tea extracts in relation to their antimutagenicity. J Agr Food Chem 43(1):27–32

Apak R, Guclu K, Ozyurek M, Karademir SE (2004) Novel total antioxidant capacity index for dietary polyphenols and vitamins C and E, using their cupric ion reducing capability in the presence of Neocuproine: CUPRAC method. J Agr Food Chem 52(26):7970–7981

Benzie IFF, Strain JJ (1996) Ferric reducing ability of plasma (FRAP) as a measure of antioxidant power: the FRAP assay. Anal Biochem 239(1):70–76

Gao, Y (2014) Antioxidant activities and phenolic acids in different raw and boiled potatoes and sweet potatoes. M.A. Thesis, Louisiana State University, Faculty of Agricultural Sciences, United States

Montedoro G, Servili M, Baldioli M, Miniati E (1992) Simple and hydrolysable phenolic compounds in virgin olive oil: their extraction, separation, and quantitative and semiquantitative evaluation by HPLC. J Agr Food Chem 40(9):1571–1576

Xu XQ, Tran VH, Palmer M, White K, Salisbury P (1999) Chemical and physical analyses and sensory evaluation of six deep frying oils. J Am Oil Chem Soc 76(9):1091–1099

Tunde-Akintunde TY, Afon AA (2010) Modeling of hot-air drying of pretreated cassava chips. Agric Eng Int CIGR J 12(2):34–41

Zhang F, Zhang M, Mujumdar AS (2011) Drying characteristics and quality of restructured wild cabbage chips processed using different drying methods. Dry Technol 29(6):682–688

Madamba PS, Driscoll RH, Buckle KA (1996) Thin layer drying characteristics of garlic slices. J Food Eng 29(1):75–97

Doymaz I (2004) Pretreatment effect on sun drying of mulberry fruits (Morus alba L.). J Food Eng 65(2):205–209

Kingsly RP, Goyal RK, Manikantan MR, Ilyas SM (2007) Effects of pretreatments and drying air temperature on drying behaviour of peach slice. Int J Food Sci Technol 42(1):65–69

Darvishi H, Asl AR, Asghari A, Gazori GNHA (2013) Mathematical modeling, moisture diffusion, energy consumption and efficiency of thin layer drying of potato slices. J Food Process Technol 4(3):215. https://doi.org/10.4172/2157-7110.1000215

Falade KO, Solademi OJ (2010) Modelling of air drying of fresh and blanched sweet potato slices. Int J Food Sci Technol 45(2):278–288

Ajala AS, Aboiye AO, Popoola JO, Adeyanju JA (2012) Drying characteristics and mathematical modelling of cassava chips. Chem Process Eng Res 4:1–9

Belayneh M, Workneh TS, Belew D (2014) Physicochemical and sensory evaluation of some cooking banana (Musa spp.) for boiling and frying process. J Food Sci Technol 51(12):3635–3646

Albuquerque TG, Sanches-Silva A, Santos L, Costa HS (2012) An update on potato crisps contents of moisture, fat, salt and fatty acids (including trans-fatty acids) with special emphasis on new oils/fats used for frying. Int J Food Sci Nutr 63(6):713–717

Zugravu CA, Parvu M, Patrascu D, Stoian-Pantea A (2012) Savory snacks and chips in Romania: are salt load and daily intake arguments for a reformulation effort? J Agroaliment Processes Technol 18(1):8–12

Catalkaya G, Ceylan FD, Yuce H, Ozcelik B (2016) Mor Lahana, Havuc ve Brokoli İçeren Fonksiyonel Sebze Cipsi Üretimi ve Antioksidan Özeliklerinin Araştırılması. Gıda, Metabolizma ve Saglık: Biyoaktif Bilesenler ve Doğal Katkılar Kongresi. Bildiri Ozetleri: 134. 28 Kasım 2016, İTU Teknokent, İstanbul (in Turkish)

Kaur S, Aggarwal P (2017) Development of maize-potato tortilla chips: a nutritious and low fat snack food. J Pharmacogn Phytochem 6(4):153–161

Dogan N, Dogan C, Hayoglu I (2017) Pleurotus ostreatus mantarının cips üretiminde kullanımı. Harran Tarım ve Gıda Bilimleri Dergisi 21(2):133–142 (in Turkish)

Chhabra N, Kaur A, Kaur S (2017) Development of composite tortilla chips: an approach with improved quality. J Pharm Innov 6(9):514–520

Mrad R, Rouphael M, Maroun RG, Louka N (2014) Effect of expansion by “intensification of vaporization by decompression to the vacuum” (IVDV) on polyphenol content, expansion ratio, texture and color changes of Australian chickpea. Food Sci Technol 59(2P1):874–882

Yi J, Zhou L, Bi J, Liu X, Qinqin C, Wu X (2016) Influences of microwave pre-drying and explosion puffing drying induced cell wall polysaccharide modification on physicochemical properties, texture, microstructure and rehydration of pitaya fruit chips. Food Sci Technol 70:271–279

Yi J, Zhou L, Bi J, Chen Q, Liu X, Wu X (2016) Impacts of pre-drying methods on physicochemical characteristics, color, texture, volume ratio, microstructure and rehydration of explosion puffing dried pear chips. J Food Process Pres 40(5):863–873

Vasconcellos J, Conte-Junior C, Silva D, Pierucci AP, Paschoalin V, Alvares TS (2016) Comparison of total antioxidant potential, and total phenolic, nitrate, sugar, and organic acid contents in beetroot juice, chips, powder, and cooked beetroot. Food Sci Biotechnol 25(1):79–84

Chen J, Chai W, Xu B (2014) Food properties of ready-to-eat flavored ginseng chips as affected by food formulation and food processing. Int J Sci 3(10):16–28

Nazzaro F, Cardinale F, Cozzolino A, Granese T, Fratianni F (2014) Polyphenol composition and antioxidant activity of different potentially functional kale-based snacks. Food Nutr Sci 5(12):1145–1152

Mazurek S, Szostak R, Kita A, Kucharska AZ, Sokoł-Letowska A, Hamouz K (2017) Determination of antioxidant activity and polyphenols content in chips by Raman and IR spectroscopy. Food Anal Methods 10(12):3964–3971

Nems A, Peksa A, Kucharska AZ, Sokoł-Letowska A, Kita A, Drozdz W, Hamouz K (2015) Anthocyanin and antioxidant activity of snacks with coloured potato. Food Chem 172:175–182

Yalcın G (2017) Trace element content and antioxidant capacity of gluten-free snacks produced for coeliac disease patients. Marmara Pharm J 21(3):598–602

Rudra SG, Jakhar N, Nishad J, Saini N, Sen S, Bhardhwaj R, Jaiswal S, Suneja P, Singh S, Kaur C (2015) Extrusion conditions and antioxidant properties of sorghum, barley and horse gram based snack. Vegetos: Int J Plant Res 2(1):171–182 (72)

Liu C, Zhao Y, Li X, Jia J, Chen Y, Hua Z (2014) Antioxidant capacities and main reducing substance contents in 110 fruits and vegetables eaten in China. Food Nutr Sci 5:293–307

Boateng J, Verghese M, Walker LT, Ogutu S (2008) Effect of processing on antioxidant contents in selected dry beans (Phaseolus spp. L.). Food Sci Technol 41(9):1541–1547

Makris DP, Rossiter JT (2001) Domestic processing of onion bulbs (Allium cepa) and asparagus spears (Asparagus officinalis): effect on flavonol content and antioxidant status. J Agric Food Chem 49(7):3216–3222

Mastura YH, Hasnah H, Dang TN (2017) Total phenolic content and antioxidant capacity of beans: organic vs inorganic. Int Food Res J 24(2):510–517

Cui ZW, Li CY, Song CF, Song Y (2008) Combined microwave-vacuum and freeze drying of carrot and apple chips. Dry Technol 26(12):1517–1523

Baltacıglu C, Esin A (2013) Crisp production from Jerusalem artichoke (Helianthus tuberosus L.) and investigation of quality parameters. Akademik Gıda 11(2):14–20

Garayo J, Moreira R (2002) Vacuum frying of potato chips. J Food Eng 55(2):181–191

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Halil, T., Tamer, C.E., Suna, S. et al. Investigations of some quality parameters and mathematical modeling of dried functional chips. Heat Mass Transfer 56, 1099–1115 (2020). https://doi.org/10.1007/s00231-019-02757-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-019-02757-0