Abstract

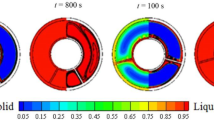

One of the drawbacks in latent thermal energy storage system is the slow charging and discharging time due to the low thermal conductivity of the phase change materials (PCM). This study numerically investigated the PCM melting process inside a finned tube to determine enhanced heat transfer performance. The influences of fin length and fin numbers were investigated. Also, two different fin orientations, a vertical and horizontal type, were examined, using two different simulation methods, constrained and unconstrained. The unconstrained simulation, which considers the density difference between the solid and liquid PCM showed approximately 40 % faster melting rate than that of constrained simulation. For a precise estimation of discharging performance, unconstrained simulation is essential. Thermal instability was found in the liquid layer below the solid PCM, which is contrary to the linear stability theory, due to the strong convection driven by heat flux from the coil wall. As the fin length increases, the area affected by the fin becomes larger, thus the discharging time becomes shorter. The discharging performance also increased as the fin number increased, but the enhancement of discharging performance by more than two fins was not discernible. The horizontal type shortened the complete melting time by approximately 10 % compared to the vertical type.

Similar content being viewed by others

Abbreviations

- a :

-

Wavenumber (1/m)

- C :

-

Mushy zone constant (kg/m3 s)

- c p :

-

Specific heat (J/kg K)

- f :

-

Volume fraction

- g :

-

Gravitational acceleration (m/s2)

- h :

-

Sensible heat (J/kg)

- H :

-

Enthalpy (J/kg)

- k :

-

Thermal conductivity (W/m K)

- l :

-

Length (m)

- L :

-

Latent heat (J/kg)

- p :

-

Pressure (Pa)

- Pr:

-

Prandtl number ν/α

- Ra :

-

Rayleigh number gβ(T w − T m )l 3/να

- S :

-

Source term

- Ste :

-

Stefan number c p (T w − T m )/L

- t :

-

Time (s)

- T :

-

Temperature (K)

- u, v :

-

Velocity components (m/s)

- x, y :

-

Coordinates (m)

- α :

-

Thermal diffusivity (m2/s)

- β :

-

Thermal expansion (1/K)

- μ :

-

Dynamic viscosity (kg/m s)

- ν :

-

Kinematic viscosity (m2/s)

- ρ :

-

Density (kg/m3)

- c :

-

Characteristic

- f :

-

Fin

- h :

-

Hot

- H :

-

Horizontal

- i :

-

Initial

- l :

-

Liquid

- m :

-

Melting

- s :

-

Solid

- ref :

-

Reference

- w :

-

Wall

- V :

-

Vertical

References

Trp A, Lenic K, Frankovic B (2006) Analysis of the influence of operating conditions and geometric parameters on heat transfer in water-paraffin shell-and-tube latent thermal energy storage unit. Appl Therm Eng 26:1830–1839

Hosseini MJ, Ranjbar AA, Sedighi K, Rahimi MA (2012) Combined experimental and computational study on the melting behavior of a medium temperature phase change storage material inside shell and tube heat exchanger. Int Commun Heat Mass 39:1416–1424

Lacroix M (1993) Study of the heat transfer behavior of a latent heat thermal energy storage unit with a finned tube. Int J Heat Mass Transf 36:2083–2092

Erek A, Ilken Z, Acar MA (2005) Experimental and numerical investigation of thermal energy storage with a finned tube. Int J Energ Res 29:283–301

Ismail KAR, Henriquez JR, Moura LFM, Ganzarolli MM (2000) Ice formation around isothermal radial finned tubes. Energ Convers Manage 41:585–605

Zhang Y, Faghri A (1996) Heat transfer enhancement in latent heat thermal energy storage system by using the internally finned tube. Int J Heat Mass 39:3165–3173

Yimer B, Adami M (1997) Parametric study of phase change thermal energy storage systems for space application. Energ Convers Manag 38:253–262

Liu C, Groulx D (2014) Experimental study of the phase change heat transfer inside a horizontal cylindrical latent heat energy storage system. Int J Therm Sci 82:100–110

Sciacovelli A, Gagliardi F, Verda V (2015) Maximization of performance of a PCM latent heat storage system with innovative fins. Appl Energy 137:707–715

Sparrow EM, Geiger GT (1986) Melting in a horizontal tube with the solid either constrained or free to fall under gravity. Int J Heat Mass Transf 29:1007–1019

Hong SW, Lee YT, Chung JD (2015) Restrictions on the analytic approach of unconstrained melting inside a spherical capsule. J Mech Sci Technol 29:5035–5042

Tan FL (2008) Constrained and unconstrained melting inside a sphere. Int Commun Heat Mass 35:466–475

Kozak Y, Rozenfeld T, Ziskind G (2014) Close-contact in vertical annular enclosures with a non-isothermal base: theoretical modeling and application to thermal storage. Int J Heat Mass Transf 72:114–127

Sharifi N, Bergman TL, Faghri A (2011) Enhancement of PCM melting in enclosures with horizontally-finned internal sufaces. Int J Heat Mass Transf 54:4182–4192

Swaminathan CR, Voller VR (1992) A general enthalpy method for modeling solidification processes. Metall Mater Trans B 23:651–664

Hosseinizadeh SF, Darzi AAR, Tan FL, Khodadadi JM (2013) Unconstrained melting inside a sphere. Int J Therm Sci 63:55–64

Chung JD, Lee JS, Yoo H (1997) Thermal instability during the melting process in an isothermally heated horizontal cylinder. Int J Heat Mass Transf 40:3899–3907

Chandrasekhar S (1961) Hydrodynamic and Hydro-magnetic stability, Dover edn. Dover Publication, New York

Sridharan P (2013) Aspect ratio effect on melting and solidification during thermal energy storage. Dissetation, University of South Florida

Acknowledgments

This research is supported by Korea Institute of Energy Technology Evaluation and Planning (KETEP) granted financial resource from the Ministry of Trade, Industry and Energy of Korea (No. 20132010101780).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, M.H., Duong, X.Q. & Chung, J.D. Performance enhancement of fin attached ice-on-coil type thermal storage tank for different fin orientations using constrained and unconstrained simulations. Heat Mass Transfer 53, 1005–1015 (2017). https://doi.org/10.1007/s00231-016-1875-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-016-1875-5