Abstract

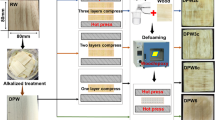

To improve the structure and basic performance, carbon fibre-reinforced woodceramics with a laminated structure were prepared by using liquefied wood and carbon powder as matrix materials and carbon fibre as a reinforcing material through structure and process designs with the establishment of a unit structure model thereof. Basic performance tests indicated that the sintering temperature and content of liquefied wood played important roles. The apparent density first reduced, later increased and then decreased with increasing sintering temperature; the apparent porosity decreased with increasing liquefied wood content. Scanning electron microscopy showed that the woodceramics presented a clear laminated structure and tight joints between glassy carbon (GC) and the embedded carbon fibres. There was an interface layer found between the amorphous carbon and GC. Meanwhile, it still partially retained the natural structural characteristics of wood. Raman spectrum detection verified that raising the sintering temperature could increase the number of graphite crystallites and the orderliness of their arrangement. Transmission electron microscopy showed that the specimens formed at higher temperatures presented clear lattice fringes. In addition, the laminated structure and the application of reinforced carbon fibre greatly enhanced the bending strength, elastic modulus, and fracture toughness.

Similar content being viewed by others

References

Akagaki T, Hokkirigawa K, Okabe T, Saito K (1999) Friction and wear of woodceramics under oil and water lubricated sliding contacts. J Porous Mater 6:197–204

Clegg JK, Alford NM (1990) A simple way to make tough ceramics. Nature 347(10):455–457

Dudek M, Socha R (2014) Direct electrochemical conversion of the chemical energy of raw waste wood to electrical energy in tubular direct carbon solid oxide fuel cells. Int J Electrochem Sci 9:7414–7430

Fang GW, Gao XG, Song YD (2013) Interface slip distribution of unidirectional fibre-reinforced ceramic matrix composites. Acta Mater Compos Sinica 30(4):101–107

Frank O, Mohr M, Mautzsch J, Thomsen C et al (2011) Raman 2D-band splitting in grapheme: theory and experiment. ACS Nano 5(3):2231–2239

Greil P, Lifka T, Kaindl A (1998a) Biomorphic cellular silicon carbide ceramics from wood: I. Processing and microstructure. J Eur Ceram Soc 18(14):1961–1973

Greil P, Lifka T, Kaindl A (1998b) Biomorphic cellular silicon carbide ceramics from wood: II. Mechanical properties. J Eur Ceram Soc 18(14):1975–1983

Guo XH, Cai QH, Wang CG, Huang Y (2000) A mechanics analysis of strengthening-toughening design of multilayer structure ceramics. Actc Mech Solida Sinica 21(4):314–324

Hirose T, Fan TX, Okabe T, Yoshimura M (2001) Effect of carbonization temperature on the basic properties of woodceramics impregnated with liquefied wood. J Mater Sci 36(16):4145–4149

Hirose T, Zhao BY, Okabe T, Yoshimura M (2002) Effect of carbonization temperature on the basic properties of woodceramics made from carbonized bamboo fibre and liquefied wood. Mater Sci 37(16):3453–3458

Huang ZK, Lü QF, Lin QL, Chen XS (2012) Microstructure, properties and lignin-based modification of wood–ceramics from rice husk and coal tar pitch. J Inorg Organomet Polym Mater 22(5):1113–1121

Iizuka H, Fushitani M, Okabe T, Saito K (1999) Mechanical properties of wood-ceramics: a porous carbon material. J Porous Mater 6(3):175–184

Ishimaru K, Hata T, Bronsveld P, Nishizawa T, Nishizawa T, Imamura Y (2007) Characterization of sp2− and sp3− bonded carbon in wood charcoal. J Wood Sci 53(5):442–448

Kercher AK, Nagle DC (2003) Microstructural evolution during charcoal carbonization by X-ray diffraction analysis. Carbon 41(1):15–27

Krstic Z, Krstic VD (2009) Fracture toughness of concentric Si3N4-based laminated structures. J Eur Ceram Soc 29(9):1825–1829

Kwon JH, Park SB, Ayrilmis N, Oh SW, Kim NH (2013) Effect of carbonization temperature on electrical resistivity and physical properties of wood and wood-based composites. Compos Part B Eng 46(3):102–107

Lu CH, Chen X (2003) Advance in novel wood composites based on the mesoporous structures of wood. Polym Mater Sci Eng 19(6):32–36

Nishimiya K, Hata T, Imamura Y, Ishihara S (1998) Analysis of chemical structure of wood charcoal by X-ray photoelectron spectroscopy. J Wood Sci 44(1):56–61

Okabe T, Saito K, Hokkirigawa K (1996) New porous carbon materials, woodceramics: development and fundamental properties. J Porous Mater 2(3):207–213

Ozao R, Okabe T, Arii T, Nishimoto Y, Cao Y, Whitely N, Pan WP (2005) Gas and mercury adsorption properties of woodceramics made from chicken waster. Energy Fuels 19(4):1729–1734

Ozao R, Nishimoto Y, Pan WP, Okabe T (2006) Thermoanalytical characterization of carbon/carbon hybrid material, Apple Woodceramics. Thermochim Acta 440(1):75–80

Qian JM, Jin ZH, Wang JP (2004) Structure and basic properties made from phenolic resin-basswood powder composite. Mater Sci Eng, A 368(1):71–79

Rajan VP, Zok FW (2013) Remediation of a constitutive model for ceramic composite laminates. Compos part A Appl Sci Manuf 52(9):80–88

Sieber H, Rambo CR, Cao J, Vogli E, Greil P (2002) Manufacturing of porous oxide ceramics by replication of wood morphologies. Key Eng Mater 206–213:2009–2012

Suda T, Kondo N, Okabe T, Saito K (1999) Electrical properties of woodceramics. J Porous Mater 6(3):255–258

Sun DL, Yu XC, Liu WJ, Sun DB (2010) Laminated wood-ceramics prepared from beech veneer and phenol formaldehyde resin. Wood Fibre Sci 42(4):474–479

Sun DL, Yu XC, Wang R (2013) Characterization of woodceramics prepared from liquefied corncob and poplar powder. Asian J Chem 25(1):373–376

Sun DB, Ren SJ, Zhong ZY, Sun DL (2014) Effects of carbonization temperature on the structure changes of woodceramics prepared from liquefied poplar. Wood Process Machinery 16(2):7–9

Takasaki A, Iijima S, Yamane T, Okabe T (2012) Hydrogen Adsorption by Woodceramics Produced from Biomass. J Shanghai Jiaotong University 17(3):330–333

Tomasini EP, Halac EB, Reinoso M, Di Liscia EJ, Maier MS (2012) Micro-Raman spectroscopy of carbon-based black pigments. J Raman Spectrosc 43(11):1671–1675

Treusch O, Hofenauer A, Tröger F, Fromm J, Wegener G (2004) Basic properties of specific wood-based materials carbonized in a nitrogen atmosphere. Wood Sci Technol 38(5):323–333

Tu JH, Zhang LB, Peng JH et al (2005) Fabrication mechanism and structure of glass-like carbons derived from phenolic resin. Carbon Technol 27(3):21–29

Vyshnyakova K, Yushin G, Pereselentseva L, Gogotsi Y (2006) Formation of porous SiC ceramics by pyrolysis of wood impregnated with silica. Int J Appl Ceram Technol 3(6):485–490

Xue T, Meng JG, Jin ZH (2012) Study on the carbonization mechanism of common paper template cellulose and preparation of porous wooden ceramic. Mater Rev 26(12):101–103

Yu XC, Sun DL, Sun DB, Xu Z, Li XS (2012) Basic properties of woodceramics made from bamboo powder and epoxy resin. Wood Sci Technol 46(1):23–31

Zhang L, Krstic VD (1995) High toughness silicon carbide/graphite laminar composite by slip casting. Theor Appl Fract Mech 24(1):13–19

Zhang D, Xie XQ, Fan TX, Okabe T, Hirose T (2002) Morphology and damping characteristics of woodceramics. J Mater Sci 37(20):4457–4463

Zhang D, Sun BH, Fan TX (2004) Preparation and micromechanism analyse of Morph-genetic materials. Sci China Ser E 34(7):721–729

Zhang HY, Tan ML, Hhan J et al (2008) Spectroscopic characterization of boron doped tetrahedral amorphous carbon. J Inorg Mater 23(1):180–184

Zhou WH, Yu YS, Xiong XL (2010) Basic properties of woodceramics made from furane resin/bamboo powder composite. Adv Mater Res 160:1569–1574

Acknowledgments

The authors gratefully acknowledge the financial support from the National Natural Science Foundation of China (No. 31270611). We also greatly appreciate the comments and insights provided by the reviewers of this article.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, Dl., Hao, Xf., Yu, Xc. et al. Preparation and characterisation of carbon fibre-reinforced laminated woodceramics. Wood Sci Technol 50, 581–597 (2016). https://doi.org/10.1007/s00226-016-0802-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-016-0802-8