Abstract

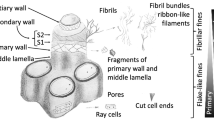

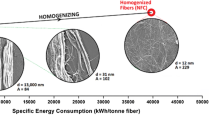

High-yield pulping of wood chips using low-consistency (LC) refining in combination with primary-stage high-consistency (HC) refining has previously been shown to produce paper with quality parameters (tensile strength and light-scattering coefficient) commonly targeted for newsprint with significantly less refining energy input than using only HC refining. However, questions remain on the differences in the refining action between the two refiner types and for high-yield pulping, the refiner energy demand is a crucial process parameter. Therefore, fines- and fiber-fraction development in HC and LC refining has been studied in detail using Bauer-McNett fractionation, and the respective tensile strengths of the different fractions have been compared. Quantitative and qualitative (morphological) characteristics of the isolated fine fractions have also been analyzed in detail using a newly developed automated fluorescence microscopy method and scanning electron microscopy. The results suggest the difference in LC/HC pulp properties (strength and optical) is partly derived from deviating fiber and fines morphologies and mass balances. The quality of the fines generated during HC and LC refining also differs. LC-refined pulps contain thinner fibrillar fines (thread-like) and HC-refined pulps broader fibrils such as lamellae-type fines. Flake-like fines from the outer fiber wall decreased in relative amount with energy input.

Similar content being viewed by others

References

Abitz P, Luner P (1989) The effect of refining on wet fibre flexibility and its relationship to sheet properties. In: Fundamentals of papermaking, transactions of the 9th fundamental research symposium, vol 1. Cambridge, UK, pp 67–86

Alince B, Lepoutre P (1980) Light scattering of coatings formed from polystyrene pigments particles. J Colloid Interface Sci 76(1):182–187

Andersson S (2011) Low consistency refining of mechanical pulp—process conditions and energy efficiency. Licentiate thesis, Mid-Sweden University, ISSN 1652-8948

Andersson S, Sandberg C (2011) Mill experiences from a 72″ LC refiner at Holmen paper Braviken mill. In: International mechanical pulping conference. Xi’an, China, pp 138–143

Andersson S, Sandberg C, Engstrand P (2012) Comparison of mechanical pulps from two stage HC single disc and HC double disc-LC refining. Appita J 65:57–62

Braaten KR (1997) The impact of fibre geometry, fibre splitting and fibrillation on the light scattering. In: International mechanical pulping conference. SPCI, Stockholm, Sweden, pp 349–353

Braaten KR (2000) Fibre and fibril properties versus light scattering and surface smoothness for mechanical pulps. Pulp Pap Can 101:122–127

Carpenter AE, Jones TR, Lamprecht MR, Clarke C, Kang IH, Friman O, Guertin DA, Chang JH, Lindquist RA, Moffat J, Golland P, Sabatini DM (2006) Cell profiler: image analysis software for identifying and quantifying cell phenotypes. Genome Biol 7:R100. doi:10.1186/gb-2006-7-10-r100

Fernando F, Daniel G (2008) Exploring scots pine fibre development mechanisms during TMP processing; impact of cell wall ultrastructure (morphological and topochemical) on negative behaviour. Holzforschung 62:597–607

Fernando D, Muhić D, Engstrand P, Daniel G (2011) Fundamental understanding of pulp property development during different TMP refining conditions using the application of new Simons’ stain method and fibre surface ultrastructure. Holzforschung 65:777–786

Fernando D, Gorski D, Sabourin M, Daniel G (2013) Characterization of fibre development in high and low consistency refining of mechanical pulp. Holzforschung 67(7):735–745

Görres J, Amiri R, Wood JR, Karnis A (1996) Mechanical pulp fines and sheet structure. J Pulp Pap Sci 22(12):J491–J496

Gorski D, Mörseburg K, Axelsson P, Engstrand P (2011) Peroxide-based ATMP refining of spruce: energy efficiency, fibre properties and pulp quality. Nord Pulp Pap Res J 26(1):47–63

Gorski D, Olson J, Luukkonen A, Sabourin M (2012a) Two-stage low-consistency refining of mechanical pulp. Appita J 65(3):244–249

Gorski D, Mörseburg K, Olson J, Luukkonen A (2012b) Fibre and fines quality development in pilot scale high and low consistency refining of ATMP. Nord Pulp Pap Res J 27:872–881

Hammar L-Å, Htun M, Svensson B (1997) A two-stage refining process to save energy for mechanical pulps. In: International mechanical pulping conference, SPCI. Stockholm, Sweden, pp 257–262

Hammar L-Å, Salmén L, Sandberg C, Sundström L (2009) The effect of process conditions on pulp quality development in low consistency refining of mechanical pulp. In: International mechanical pulping conference, SPCI. Sundsvall, Sweden, pp 182–185

Heikkurinen A, Levlin JE, Paulapuro H (1991) Principles and methods in pulp characterization—basic fibre properties. Pap Puu Pap Timber 73:411–417

Hill J, Sabourin M, Aichinger J, Johansson L, Gorski D, Axelsson P (2010) Combining selective bleaching chemistries and ATMP technology for low energy mechanical pulping at higher brightness. In: 7th International seminar fundamental mechanical pulping, Nanjing, China

Johansson L, Hill J, Gorski D, Axelsson P (2011) Improvement of energy efficiency of TMP process by selective wood disintegration and targeted application of chemicals. Nord Pulp Pap Res J 26(1):31–46

Lamprecht MR, Sabatini DM, Carpenter AE (2007) Cell profiler: free, versatile software for automated biological image analysis. Biotechniques 42(1):71–75

Lindblad G, Iversen T, Bergenblad H, Rigdahl M (1989) Light scattering ability of coatings as a tool to protect paper and board against photo-oxidation. Nord Pulp Pap Res J 4(4):253–257

Luukko K, Paulapuro H (1999) Mechanical pulp fines; effect of particle size and shape. Tappi J 82(2):95–101

Luukko K, Kajola-Kemppainen P, Paulapuro H (1997) Characterization of mechanical pulp fines by image analysis. Appita J 50(5):387–392

Luukkonen A, Olson JA, Martinez DM (2010a) Low consistency refining of mechanical pulp, effect of gap, speed and power. J Pulp Pap Sci 36:28–34

Luukkonen A, Olson JA, Martinez DM (2010b) Low consistency refining of mechanical pulp: a methodology to relate operating conditions to paper properties. J Pulp Pap Sci 36:107–111

Paavilainen L (1993) Conformability, flexibility and collapsibility of sulphate pulp fibers. Pap Puu Pap Timb 75:689–702

Ross WD (1971) Theoretical computation of light scattering power: comparison between TiO2 and air bubbles. J Paint Technol 43(563):50–66

Rundlöf M, Höglund H, Htun M, Wågberg L (1995) Effects of fines quality on paper properties-new aspects. In: International mechanical pulping conference. Ottawa, Canada, pp 109–118

Sabourin M, Aichinger J, Wiseman N (2003) Effect of increasing wood chip defibration on thermomechanical and chemi-thermomechanical refining efficiency. In: International mechanical pulping conference. Quebec City, Canada, pp 163–170

Sabourin M, Antensteiner P, Luukkonen A (2011) Aggressive low consistency refining in thermomechanical pulping: energy consumption and fibre development. In: International mechanical pulping conference. China Light Industry Press, Xi`an, China, pp 248–252

Stone JE, Scallan AM (1965) A study of cell wall structure by nitrogen adsorption. Pulp Pap Mag Can 66:T407–T414

Acknowledgments

This study has partly been conducted within the framework of CRUW (cooperative research on the ultrastructure of wood, which is a VINNOVA and Forest industry financed competence center at the Swedish University of Agricultural Sciences), and we thank the CRUW mechanical pulp group for valuable discussions. We also thank UBC Pulp and Paper Centre (especially George Soong and Christine Seville) and the staff of the Andritz pilot plant in Springfield (where the first-stage pulp used was performed). Dr. Jens Heymer (AFT), Dr. Antti Luukkonen (Andritz) and Dr. Marc Sabourin (Andritz) are acknowledged for their support during the pilot trials. D.G acknowledges financial support from Gålöstiftelsen, Hans Werthén Fonden and Jansons Legat.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hafrén, J., Fernando, D., Gorski, D. et al. Fiber- and fine fractions-derived effects on pulp quality as a result of mechanical pulp refining consistency. Wood Sci Technol 48, 737–753 (2014). https://doi.org/10.1007/s00226-014-0636-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-014-0636-1