Abstract

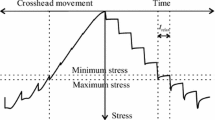

In the process of wood drying inevitable stresses are induced. This often leads to checking and undesired deformations that may greatly affect the quality of the dried product. The purpose of this study was to propose a new rheological model representation capable to predict the evolution of stresses and deformations in wood cantilever as applied to wood drying. The rheological model considers wood shrinkage, instantaneous stress–strain relationships, time induced creep, and mechano-sorptive creep. The constitutive law is based on an elasto–viscoplastic model that takes into account the moisture content gradient in wood, the effect of external load, and a threshold viscoplastic (permanent) strain which is dependent on stress level and time. The model was implemented into a numerical program that computes stresses and strains of wood cantilever under constant load for various moisture content conditions. The results indicate that linear and nonlinear creep behavior of wood cantilever under various load levels can be simulated using only one Kelvin element model in combination with a threshold-type viscoplastic element. The proposed rheological model was first developed for the identification of model parameters from cantilever creep tests, but it can be easily used to simulate drying stresses of a piece of wood subjected to no external load. It can therefore predict the stress reversal phenomenon, residual stresses and maximum stress through thickness during a typical drying process.

Similar content being viewed by others

References

Allegretti O, Rémond R, Perré P (2003) A new experimental device for non-symmetrical drying tests. Experimental and numerical results for free and constrained samples. In: Proceedings of the 8th international IUFRO wood drying conference. Brasov, Romania, pp 65–70

Bingham EC (1922) Fluidity and plasticity. McGraw-Hill, New York

Dahlblom O, Petersson H, Omarsson S (2001) Full 3-D FEM-simulations of drying distortions in spruce boards based on experimental studies. In: Proceedings of the 7th international IUFRO wood drying conference. Tsukuba, Japan, pp 246–251

Dinwoodie JM, Paxton BH, Bonfield PW, Mundy JS (1995) Fatigue and creep in chipboard. Part 2. The influence of slow cyclic fatigue on the creep behavior of chipboard at a range of stress levels and moisture contents. Wood Sci Technol 29:64–76

Fortin Y, Naderi N, Laforest P, Cloutier A (1999) Viscoelastic and mechano-sorptive creep measurements of spruce wood in the longitudinal direction under kiln drying conditions. In: Proceedings of the 6th international IUFRO wood drying conference. Stellenbosch, South Africa, pp 225–226

Foudjet A, Bremond C (1989) Creep of four tropical hardwoods from Cameroon. Wood Sci Technol 23:335–341

Guitard D (1987) Mécanique du matériau bois et composites. Eds.; CEPADUES: Toulouse, France, 238 pp

Hanhijärvi A (2000) Deformation properties of Finnish spruce and pine wood in tangential and radial directions in association to high temperature drying. Part 3. Experimental results under drying conditions (mechano-sorptive creep). Holz Roh- Werkst 58:63–71

Haque MN, Langrish TAG, Keep LB, Keey RB (2000) Model fitting for visco-elastic creep of Pinus radiata during kiln drying. Wood Sci Technol 34:447–457

Kingston RST, Budgen B (1972) Some aspects of the rheological behavior of wood. Part 4. Non-linear behavior at high stresses in bending and compression. Wood Sci Technol 6:230–238

Mårtensson A (1994) Mechano-sorptive effects in wooden material. Wood Sci Technol 28:437–449

Mårtensson A, Svensson S (1997) Stress–strain relationship of drying wood. Part 1. Development of a constitutive model. Holzforschung 51:472–478

Miller DG, George P (1974) A method of measuring creep and recovery due to flexural loads of short duration. Wood Sci 7(2):153–159

Moutee M, Laghdir A, Fafard M, Fortin Y (2002) A three-dimensional mathematical model of the hygro-thermo-mechanical behavior of wood during drying. In: Proceedings of forest product society conference “Quality Drying: The Key to Profitable Manufacturing”. Montreal, Canada, pp 179–184

Moutee M, Fafard M, Fortin Y, Laghdir A (2005) Modeling the creep behavior of wood cantilever loaded at free end during drying. Wood Fiber Sci 37(3):521–534

Ormarsson S, Dahlblom O, Petersson H (1999) A numerical study of the shape stability of sawn timber subjected to moisture variation. Part 2. Simulation of drying board. Wood Sci Technol 33:407–423

Pang S (2001) Modeling of stresses and deformation of Radiata Pine lumber during drying. In: Proceedings of the 7th international IUFRO wood drying conference. Tsukuba, Japan, pp 238–245

Perré P, Passard J (2004) A physical and mechanical model able to predict the stress field in wood over a wide range of drying conditions. Dry Technol 22(1–2):27–44

Ranta-Maunus A (1990) Impact of mechano-sorptive creep to the long-term strength timber. Holz Roh-Werkst 48:67–71

Ranta-Maunus A (1992)Determination of drying stress in wood when shrinkage is prevented: test method and modeling. In: Proceedings of the 3rd international IUFRO wood drying conference. Vienna, Austria, pp 139–144

Ranta-Maunus A (1993) Rheological behaviour of wood in directions perpendicular to the grain. Mater Struct 26:362–369

Rice RW, Youngs RL (1990) The mechanism and development of creep during drying of red oak. Holz Roh-Werkst 48:73–79

Salin JG (1989) Prediction of checking, surface discoloration and final moisture content by numerical methods. In: Kayihan F, Johnson JA, Smith WR (eds) Upgrading wood quality through drying technology. International Union of Forestry Research Organisations, Washington, pp. 222–225

Salin JG (1992) Numerical prediction of checking during timber drying a new mechano-sorptive creep model. Holz Roh-Werkst 50:195–200

Shames IH, Cozzarelli FA (1992) Elastic and inelastic stress analysis. Prentice-Hall, Englewood Cliffs, New Jersey

Svensson S (1995) Strain and shrinkage force in wood under kiln drying conditions. Part 1. Measuring strain and shrinkage under controlled climate conditions. Equipment and preliminary results. Holzforschung 49(4):363–368

Svensson S (1996) Strain and shrinkage force in wood under kiln drying conditions. Part 2. Strain, shrinkage and stress measurements under controlled climate conditions. Equipment and preliminary results. Holzforschung 50(5):463–469

Wu Q, Milota MR (1995) Rheological behavior of Douglas-fir perpendicular to the grain at elevated temperatures. Wood Fiber Sci 27(3):285–295

Wu Q, Milota MR (1996) Mechano-sorptive deformation of Douglas-Fir specimens under tangential tensile stress during moisture adsorption. Wood Fiber Sci 28(1):128–132

Acknowledgments

The authors are grateful for the financial support of this research from Natural Sciences and Engineering Research Council of Canada (No. 224297) and Forintek Canada Corp.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moutee, M., Fortin, Y. & Fafard, M. A global rheological model of wood cantilever as applied to wood drying. Wood Sci Technol 41, 209–234 (2007). https://doi.org/10.1007/s00226-006-0106-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-006-0106-5