Abstract

Enzymatic hydrolysis of migratory locust (Locusta migratoria L.) protein flour (MLPF) was investigated as a method to improve the techno-functional properties. Experiments were conducted under variation of the applied proteases (Alcalase, Neutrase, Flavourzyme, Papain) or combinations thereof, enzyme–substrate ratio (0.05–1.0% w/w), heat pre-treatment (60–80 °C; 15–60 min), and hydrolysis time (0–24 h). Protein degradation was monitored in terms of degree of hydrolysis (DH) and SDS-PAGE. Solubility, emulsifying, foaming and water/oil binding properties of the hydrolysates were determined. In comparison to the control (DH = 5%), hydrolysis resulted in considerably higher DH values up to 42%. SDS-PAGE profiles revealed a steady decrease of bands between 25 and 75 kDa and an increase of low molecular weight bands (10–15 kDa). However, different heat pre-treatments resulted in impaired hydrolytic cleavage as evidenced by lower DH values. Protein solubility of MLPF hydrolysates was improved over a broad pH range from initially 10–22% up to 55% at alkaline conditions. Furthermore, hydrolysis resulted in enhanced emulsifying activity (54%) at pH 7, improved foamability (326%) at pH 3 and advanced oil binding capacity. The results of this study have clearly demonstrated the potential of targeted enzymatic degradation to improve the techno-functionality of migratory locust protein in order to produce tailored insect-based ingredients for the use in food applications.

Similar content being viewed by others

Introduction

Compositional analyses of several edible insect species and their different metamorphic stages reveal promising nutritional quality in terms of protein and fat content, valuable amino acid and fatty acid profiles and noteworthy concentrations of certain micronutrients [1,2,3,4,5]. Species belonging to the order Orthoptera such as locusts, grasshoppers and crickets were reported to exhibit highest average protein concentrations up to 77% db (dry base) among all insect orders [5]. Next to mealworm species, crickets and the black soldier fly, the migratory locust (Locusta migratoria L.) is among the most promising candidates for the integration of edible insects in western food and feed industry due to auspicious crude protein content of 65% db, well-balanced amino acid profile and already existing rearing know-how on a commercial scale for pet food or even human nutrition [6,7,8,9,10].

The predicted growth of world population to more than nine billion people in 2050 coupled with the increase in the global need for protein and caloric energy in human nutrition and livestock production have driven the research for novel and sustainable raw material sources providing high nutritional quality [11]. The consumption of insects—also referred to as entomophagy—is originated in Asia, Africa, Central and South-America, where they are mainly handpicked in nature and consumed in whole or low processed form using culinary preparation techniques [12, 13]. However, this traditional praxis is not likely to be adapted by western markets due to the highly industrialised food and feed industry and consumer habits [14,15,16]. Consequently, the development of industrial-scale mass rearing systems and efficient processes for the recovery of functional insect-derived fractions such as protein, fat or chitin will be a prerequisite to promote consumer acceptance and the industrial use of edible insects in western countries and to explore a wide range of potential food and non-food applications [17].

Transforming edible insects into familiar food items can be based on conventional or emerging food processing technologies enhancing product functionality, stability, safety, appearance and acceptance [14,15,16, 18, 19]. However, there is a need to explore the techno-functional properties of insect derived protein fractions. Additionally, concepts are required for their tailored modification to further develop promising application areas and to provide superior alternatives to currently used functional proteins.

To date, only few studies are available regarding the functional performance of edible insect proteins. For mealworm (Tenebrio molitor) and black soldier fly larvae (Hermetia illucens), protein solubilities between 3 and 95% were observed and found to be significantly influenced by the solvent pH, purity of the protein fraction and previous processing [20,21,22]. However, near the isoelectric point (IP) around pH 3 to 7—which reflects the common pH range of many food products—the protein solubility was lowest, especially for non-purified insect flours [20, 22, 23]. Protein solubility of untreated, defatted and acid-hydrolysed mealworm and silkworm pupae (Bombyx mori) flour were reported to range between 12 and 13% at pH 7.6 [24]. Furthermore, several studies reported low or negligible functionality in terms of emulsifying, foaming and/or gelling properties of proteins from Mexican fruit fly larvae (Anastrepha ludens), mealworm, superworm (Zophobas morio), lesser mealworm (Alphitobius diaperinus), house cricket (Acheta domesticus), Dubia cockroach (Blaptica dubia), emperor moth (Cirina forda) and caterpillar larvae (Imbrasia oyemensis) [25,26,27,28].

Enzymatic modification is a well-established tool to attain improved techno-functional properties (e.g. protein solubility, emulsifying or foaming properties) by limited proteolysis of proteins in comparison to the native, non-hydrolysed protein as already shown for a variety of conventional proteins such as soy proteins [29], rape seed proteins [30] and milk proteins [31]. Similar studies investigating targeted enzymatic hydrolysis of insect proteins to enhance functional properties are scarce. Wang et al. [32] studied the influence of enzymatic hydrolysis on house fly larvae (Musca domestica) proteins showing high solubility of the resulting hydrolysates of > 90%. Improved solubility, emulsifying and foaming properties after enzymatic hydrolysis of tropical banded cricket (Gryllodes sigillatus) depending on enzyme–substrate ratio, hydrolysis time and applied solvent pH were reported by Hall et al. [33].

Since the knowledge about the modification of insect proteins by enzymatic hydrolysis is still limited, the present study investigates enzymatic proteolysis of migratory locust protein flour (MLPF) using different hydrolysis settings under variation of the applied enzyme or enzyme combination, enzyme–substrate ratio and hydrolysis time. The specific objectives were to determine: (1) the effect of the parameters on protein degradation in terms of degree of hydrolysis (DH) and molecular weight distribution (SDS-PAGE), (2) impact of thermal treatment on the accessibility of proteins for enzymatic cleavage by partial unfolding, and (3) the influence on the resulting techno-functional properties, including protein solubility, emulsifying activity, foaming properties as well as water and oil binding capacity.

Materials and methods

Raw material and chemicals

Migratory locust protein flour (MLPF) was commercially purchased (Crawlers, Auckland, New Zealand). According to the manufacturer, locusts were reared in Thailand on a vegetable substrate, cleaned, thermally decontaminated, dried and vacuum packed. Between the experiments, MLPF was stored vacuum sealed under refrigerated conditions.

Enzymes used in this study including Alcalase® 2.4 L FG (endoprotease from B. licheniformis), Flavourzyme® 1000 L (endoprotease and exopeptidase from (A) oryzae) and Neutrase® 0.8 L (endoprotease from (B) amyloliquefaciens) were kindly provided by Novozymes A/S (Bagsvaerd, Denmark). Lyophilised Papain (cysteine-protease from papaya latex; ≥ 10 units/mg protein) was purchased from Sigma-Aldrich (St. Louis, MO, USA). All chemicals used for analytical purposes were of analytical grade if not stated otherwise.

Chemical composition of migratory locust protein flour

The dry matter content was determined by oven drying method at 105 ± 3 °C based on AOAC 950.46 [34]. The crude fat content was analysed gravimetrically based on the ICC standard method No. 136 [35] after solvent extraction with petroleum ether (b.p. 40–60 °C) in a Soxhlet extractor. In addition, the ash content was determined according to the AOAC 923.03 [34] via muffle furnace method. The chitin-derived nitrogen content was assayed as described elsewhere [36] via alkaline hydrolysis and subsequent total nitrogen determination of the dried residue using the Kjeldahl method according to AOAC 928.08 [34]. Chitin content was calculated using the nitrogen conversion factor 14.5 [37]. The total nitrogen content was analysed using the Kjeldahl method according to AOAC 928.08 [34]. After subtraction of the chitin-derived nitrogen content, the crude protein content was calculated using the nitrogen conversion factor (N) of 6.25. All determinations were done in triplicate.

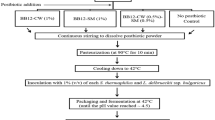

Enzymatic hydrolysis of migratory locust protein flour

For the experiments, four commercially available food-grade enzymes were used. These enzyme preparations are commonly applied in the food industry for the production of protein hydrolysates. Hydrolysis conditions were set to 50 °C and pH 8.0 according to the manufacturer’s recommendation. The enzyme–substrate ratio (E/S) of 0.05, 0.5 and 1.0% w/w for endo- and exoproteases has been chosen according to Meinlschmidt et al. [29] representing typical dosages used in industry. The different applied hydrolysis settings are illustrated in Table 1.

Single enzyme treatments

Single enzyme treatments were performed in temperature-controlled reaction vessels applying different endo- or exo-proteases (Alcalase, Flavourzyme, Neutrase and Papain). Therefore, MLPF was dispersed in deionised water at a protein concentration of 5% (w/v) using a rotor–stator disperser (X10, Ystral GmbH, Ballrechten-Dottingen, Germany) at 11,000 rpm for 60 s. After 1 h of solubilisation under constant stirring at room temperature, the dispersions were adjusted to 50 °C and pH 8.0 with 1 M NaOH prior to enzyme addition. Afterwards, the respective enzyme was added at an E/S of 0.05, 0.5 or 1.0% and MLPF was hydrolysed for 24 h, while aliquots were taken after 30, 60, 120, 240, 480, and 1440 min. During hydrolysis, the mixture was continuously shaken, but without pH adjustment. After sampling, hydrolysis was immediately stopped by heat treatment at 90 °C for 20 min. Control samples without enzyme addition were also prepared and treated analogously. Subsequently, samples were either frozen at − 30 °C and stored for the determination of protein degradation parameters or lyophilised for techno-functional analyses (FreeZone 6, Labconco, Kansas City, MO, USA). Experiments were performed in duplicate.

Combined enzyme treatments

Enzyme combinations were applied to investigate synergistic effects on protein degradation and techno-functionality. For the one-step (OS) process (see Table 1), between two and four enzymes were simultaneously added at an E/S of 0.05% (Papain), 0.5% (Alcalase, Neutrase) and 1% (Flavourzyme), and MLPF dispersions were digested for 24 h. Aliquots were taken after 30, 60, 120, 240, 480, and 1440 min. During the two-step (TS) process (Table 1), up to three endoproteases were used in the first hydrolysis stage for pre-digestion of the MLPF. After 1 h of incubation, Flavourzyme (E/S 1.0%) was added. Aliquots were taken after 60, 120, 240, 480, and 1440 min. Sample dispersion preparation, hydrolysis, enzyme inactivation and hydrolysate stabilisation prior analysis were performed in analogy to the single enzyme treatments described in “Single enzyme treatments”. Experiments were conducted in duplicate.

Thermal pre-treatments prior to enzymatic hydrolysis

The effect of thermal treatment prior to single enzyme hydrolysis on enzymatic degradation of MLPF dispersions was investigated as well. Therefore, 5% (w/v) MLPF dispersions were prepared as previously described and heat treated in a water bath under continuous shaking for 15 and 60 min at 60 or 80 °C. Afterwards, MLPF dispersions were hydrolysed at 50 °C and pH 8.0 using Alcalase, Neutrase and Flavourzyme (E/S 0.5%). Further procedure was done as described in the previous subchapters and experiments were performed in duplicate.

Determination of protein degradation

Degree of hydrolysis (DH)—o-phthaldialdehyde (OPA) method

The DH of all samples was calculated by determining the free α-amino groups with o-phthaldialdehyde (≥ 99%, Roth, Karlsruhe, Germany) using serine as calibration standard according to the method of Nielsen et al. [38]. The calculation of DH was performed as indicated in Eqs. 1 and 2:

where h is the number of hydrolysed bonds; h tot is the total number of peptide bonds per protein equivalent; α is the degree of dissociated α-amino bonds; and β is the gradient of standard hydrolysis curve. The general h tot factor of 8 (soy 7.8; fish 8.2; meat 7.6) and the α and β values of 1.0 and 0.4, respectively, reported by Adler-Nissen [39] and Nielsen et al. [38] were used. Measurements were performed in quadruplicates for each sample.

Molecular weight distribution—sodium dodecyl sulfate–polyacrylamide gel electrophoresis (SDS–PAGE)

The molecular weight distribution of control and hydrolysed samples was determined according to Laemmli [40] using SDS-PAGE under reducing conditions. The samples were diluted with Tris–HCl treatment buffer (0.125 mol L− 1 Tris–HCl, 4% SDS, 20% v/v Glycerol, 0.2 mol L− 1 DTT, 0.02% bromophenol blue, pH 6.8). Samples were boiled for 3 min to cleave noncovalent bonds and centrifuged at 14,000×g for 10 min (Mini Spin, Eppendorf AG, Hamburg, Germany). The electrophoresis was performed on 4–20% midi Criterion™ TGX Stain-Free™ precast gels (Bio-Rad, Ismaning, Germany) and the proteins were separated using the Midi Criterion™ Cell (Bio-Rad, Ismaning, Germany) and an electrophoretic power supply (E835, Consort, Turnhout, Belgium). A molecular weight marker containing recombinant protein bands in the range of 10–250 kDa (Precision Plus Protein™ Unstained Standard, Bio-Rad Laboratories Inc., Hercules, CA, USA) was additionally loaded onto the gel. Electrophoresis conditions were 200V, 60 mA, 100 W at room temperature. Protein visualisation and evaluation were performed by Criterion Stain-Free Gel Doc™ EZ Imager (Bio-Rad, Ismaning, Germany).

Techno-functional properties

Protein solubility

The protein solubility was determined at different solvent pH (2–10) according to Morr et al. [41] with slight modifications. Briefly, samples were suspended (3% w/v) in deionised water containing 0, 1 or 3% NaCl. The pH was adjusted with 0.1 M HCl or 0.1 M NaOH and the samples were solubilised for 2 h at ambient temperature. Protein extracts were centrifuged 15 min at 3220×g (5810 R, Eppendorf, Hamburg, Germany) and 10 min at 14,000×g (5430, Eppendorf, Hamburg, Germany). The supernatants were filtered through 0.45 µm PES syringe filters (Chromafil®, Machery-Nagel, Düren, Germany) and subsequently subjected to Biuret assay according to Robinson, Hogden [42]. Therefore, 200 µl of the supernatant was added to 800 µl Biuret reagent [0.235% (w/v) anhydrous copper (II) sulfate, 0.806% (w/v) sodium potassium L(+)-tartrate tetrahydrate, and 30% (v/v) of 10% (w/v) NaOH] followed by an incubation period of 20 min at 37 °C. The absorption of the sample was analysed at 540 nm (U-1500, Hitachi, Tokyo, Japan) against a blank value containing water. Bovine serum albumin (> 98%, Roth, Karlsruhe, Germany) was used as calibration standard. Dissolving procedure and spectrophotometric measurements were each done in duplicate. The protein solubility index (PSI) was finally calculated according to Eq. 3 [43], where P S and P IS are the protein contents of the supernatant and the initial sample, respectively.

Emulsifying activity

The emulsifying activity (EA) was determined based on the method of Chamba et al. [44] with slight modifications. Briefly, aqueous sample solutions with different pH (3, 5, 7, 9) containing 3.35% w/v soluble protein were prepared and solubilised for 2 h at ambient temperature. After centrifugation at 3220×g for 15 min and at 14,000×g for 10 min, the supernatant was mixed with commercial sunflower oil (1:1 v/v) and emulsified using a rotor–stator disperser (X10, Ystral GmbH, Ballrechten-Dottingen, Germany) at 11,000 rpm for 30 s. Aliquots (15 mL) of the emulsion were immediately transferred into scaled tubes and centrifuged at 3220×g for 15 min at ambient temperature. The height of the resulting emulsified layer (H EL) and the total height of solution (H S) were used to calculate the EA (Eq. 4). Measurements were performed in triplicate.

Foamability and foam stability

The preparation of the protein solutions was carried out analogously to the procedure described in the previous subchapter (“Emulsifying activity”). A defined volume of the supernatant was transferred into a graduated cylinder and subsequently stirred for 120 s using a rotor–stator disperser at 11,000 rpm. The height of the foam was documented over a period of 30 min. The overrun (OR) was calculated according to Hammershøj, Larsen [45] as indicated in Eq. 5, where V t is the foam volume at the time t after foaming and V t=0 is the initial liquid volume before foaming. For the characterisation of the foamability, OR at t = 30 s (OR30s) were calculated. The ratio of OR30min to OR30s in percentage was defined as the foam stability (FS). Foaming properties were analysed in triplicate.

Water and oil binding capacity

The water binding capacity (WBC) was assayed according to Quinn, Paton [46] with small modifications. Briefly, 0.5 g sample was mixed with 2.5 mL deionised water, vortexed for 60 s (Vortex Genie 2, Scientific Industries, Bohemia, NY, USA) and centrifuged for 20 min at 3220×g and room temperature. The supernatant was removed by decantation and drainage of the residual non-bound water by placing the centrifugation tube upside-down on a filter paper for 60 min. WBC was calculated according to Eq. 6 [47]:

where m 0 is the initial weight, m 1 is the final weight and m 0,DM is the initial weight of the sample based on dry matter. The oil binding capacity (OBC) was analysed using rapeseed oil instead of deionised water. Except for the vortexing step (120 s), experimental procedure was performed in analogy to the WBC assay. OBC was similarly calculated. Analysis of WBC and OBC was done in quadruplicate.

Statistical analysis

Statistical analyses were carried out using Statgraphics Centurion XVI (Statpoint Technologies Inc., Warrenton, VA, USA). All data are expressed as mean ± standard deviation (SD) of the performed replications. Data were subjected to one-way analysis of variances (ANOVA) and means were generated and adjusted using Bonferroni post-hoc test. Unless stated otherwise, a 95% confidence level (statistical significance at p ≤ 0.05) was considered.

Results and discussion

Chemical composition of migratory locust protein flour

Chemical analysis of migratory locust protein flour (MLPF) resulted in the following composition: 96.3 ± 0.21% dry matter; 69.94 ± 0.22% db crude protein; 10.22 ± 0.06% db chitin; 8.58 ± 0.06% db crude fat; 3.53 ± 0.07% db ash. According to the data reported in the literature, the composition (dry base) of whole migratory locusts in terms of protein, fat, and ash content ranges from 55.5 to 65.9%, 17.9–29.6%, and 3.1–4.31% depending on age and diet [8, 9]. The higher amount of crude protein in MLPF can be ascribed to the partial removal of fat during flour production resulting in a considerable lower crude fat content. Data concerning the chitin or fibre content of migratory locusts are not available, but the chemical characterisation of other species from the same order (Orthoptera) revealed total dietary fiber contents between 10–16% db [5, 48, 49].

Protein degradation

Degree of hydrolysis (DH)

The DH value is an indicator for the cleavage of peptide bonds and the breakdown of the complex and structured proteins into smaller peptides. Various parameters such as type, activity, and concentration of the enzyme(s), initial degree of nativity/denaturation of the protein, milieu conditions (T, pH, ionic strength) and hydrolysis time (t H) affect the proteolysis and consequently the resulting DH value [50]. The DH of the MLPF was continuously monitored during the different enzymatic hydrolyses (Table 2). The unhydrolysed MLPF showed a DH of 5.1%, reflecting a certain degree of denaturation or hydrolysis which might be ascribed to the processing procedure of MLPF (see “Raw material and chemicals ”). This is in accordance to the findings of Hall et al. [33] who reported an initial DH of 5.2% of pasteurised tropical banded cricket slurry. However, with increasing hydrolysis time (t H), the DH continuously increased up to 11–42% after 24 h depending on the regarded hydrolytic setting used in the present study.

In general, single enzyme hydrolysis of MLPF suspensions led to a higher DH as the enzyme–substrate ratio (E/S) and the hydrolysis time (t H) increased. According to the DH value, the most effective protein degradation among the single enzyme hydrolyses was achieved after treatment with Alcalase (31.1%) followed by Neutrase (26.2%), Flavourzyme (24.1%) and Papain (20.6%) at highest E/S ratio (1%) and longest tH (24 h). A similar trend was already reported by Meinlschmidt et al. [51] for the hydrolysis of soy protein isolate. Studies regarding enzymatic degradation of insect protein are rather scarce. Hall et al. [33] reported DH values of Alcalase-hydrolysed cricket protein in the range between 26.1–36.3% after hydrolysis at 50 °C and pH 8 (E/S 0.5; t H 30–60 min). These results are significantly higher than the values found in the present study (DH 9.5–12.8%; E/S 0.5; t H 30–60 min), which may be ascribed to different methods used for DH analysis. Spellman et al. [52] reported that DH values of whey protein determined by OPA method were around 15% lower than those determined via TNBS method, which was used by Hall et al. [33]. However, Nielsen et al. [38] approved the appropriateness of the OPA method as an accurate and fast method for the monitoring of enzymatic degradation without using toxic reagents.

Among the one-step (OS) hydrolyses (see Table 1), OS4 and OS5 have reached the highest DH of about 39% after 24 h, followed by OS1 and OS2 with values of 31 and 29%, respectively. These hydrolysates were produced with enzyme combinations containing Alcalase and/or Neutrase, which were already shown to be most effective when used individually. Except for OS4, samples hydrolysed using Papain showed the lowest DH of only 11% (OS7), 21% (OS6) and 24% (OS3). In comparison to the single enzyme hydrolysis, the combination of enzymes led to higher overall protein degradation due to the synergistic effect of exo- and endo-proteases, which was similarly shown by Meinlschmidt et al. [29] for soy proteins.

Analogously to the one-step procedures, the two-step (TS) hydrolyses containing Alcalase and/or Neutrase resulted in highest DH up to 41.6% (TS4), 40.9% (TS1), 40.5% (TS5) and 38.7% (TS6) after 24 h. The general extent of protein degradation after two-step treatment is higher in comparison to single enzymes and one-step procedures. The initial hydrolysation rate during pre-digestion (0–60 min) is considerably slower as evidenced by low DH values (Table 2). After the addition of the exoprotease Flavourzyme, degradation rate increased rapidly during the initial period (60–120 min) due to the higher availability of end peptide sites produced by endoprotease activity.

In addition, different thermal pre-treatments (60–80 °C, 15–60 min) prior to single enzyme hydrolysis were applied in order to initiate partial protein unfolding and enhance susceptibility of the proteins to enzymatic proteolysis. The results are illustrated in Fig. 1. For all tested enzymes—Alcalase, Neutrase and Flavourzyme (E/S 0.5%)—the protein degradation after each heat pre-treatment was lower in comparison to the non-heated control as demonstrated by lower DH. This leads to the assumption that all applied heat pre-treatments favoured thermal aggregation reactions and, hence, impeded enzymatic cleavage of the locust proteins due to masking of previously exposed cleavage sites. In contrast, thermal pre-treatment of other proteins such as egg white (50–77 °C, 20 min), pea (100 °C, 30 min) and whey protein (80 °C, 15 min) were reported to enhance subsequent enzymatic hydrolysis by protein reorientation and exposure of previously hidden sites [53,54,55]. In contrast, heat pre-treatment of lotus seed protein (> 60 °C, 75 min) led to an impaired enzymatic degradation comparable to the present findings, which was ascribed to thermal protein aggregation [56]. Those contrary observations may be explained by the different extent of thermal-induced protein denaturation or aggregation via disulphide bond formation.

Molecular weight distribution (SDS–PAGE)

The SDS-PAGE profiles of MLPC and selected hydrolysates thereof (Neu2, Fla2, OS2, and TS2) are displayed in Fig. 2. Several bands in the range of 10–75 kDa were observed for the unhydrolysed MLPC (t H = 0 min), including a sharp characteristic band around 45 kDa and various bands between 25 and 37 kDa. As already indicated by the increase of the DH value over hydrolysis time (Table 1), different hydrolysis settings led to different proteolytic pattern according to the SDS-PAGE profiles. As a general consequence of the decomposition of high molecular weight bands, the intensity of the low molecular protein fragments from 10 to 15 kDa increased over the course of the different hydrolyses.

Protein degradation of migratory locust protein (MLPF) during enzymatic hydrolysis shown by SDS-PAGE profiles. Exemplary results for the hydrolytic settings Neu 2, Fla 2, OS 2, and TS 2 (see Table 1) are shown. Molecular weight of the protein marker bands (M) are indicated in kilodalton (kDa). Electrophoresis was carried out with 4–20% polyacrylamide gradient gels

Single enzyme treatment with Neutrase (Neu2; E/S 0.5%) effectively degraded the high molecular weight bands (especially at 45 kDa) within the first 30 min and continuously lowered the intensity of the bands around 30 kDa within 24 h. The SDS-PAGE profiles of the hydrolysates obtained by proteolysis with Flavourzyme (Fla2; E/S 0.5%) showed a considerable deviating pattern. The bands at 45 kDa and 37 kDa were gradually decomposed and completely eliminated only after 24 h. The slower decomposition of the proteins by Flavourzyme was also demonstrated by the lower increase of the intensity of the predominant low molecular weight bands (10–15 kDa). Similar observations were reported by Meinlschmidt et al. [51] and attributed to the fact that Flavourzyme contains exoproteases, which cleave small peptides fragments at the end of proteins, hence leading to a slow, step-wise protein decomposition.

Hydrolytic cleavage with Papain (Pap1-3; SDS-PAGE profiles not shown) turned out to be very effective which was not expected considering the results of the DH analysis in comparison to the other enzymes used (Table 2). This divergence was similarly observed by Meinlschmidt et al. [51] and might be ascribed to the weak, unstable fluorescent product build by the reaction of o-phthaldialdehyde and cysteine residues released during enzymatic cleavage with Papain [57].

The combination of enzymes was shown to be very effective in hydrolysing MLPF. One-step (OS2) as well as two-step treatment (TS2) effectively degraded the bands in the range of 45–75 kDa within the first 30 and 60 min, respectively. Over the course of hydrolysis, also the bands around 30 kDa were eliminated entirely resulting in hydrolysates with mainly low molecular protein fragments.

Techno-functional properties

Protein solubility

The solubility of proteins is considered the most critical techno-functional characteristic since it decisively affects other functional properties such as emulsifying, foaming and gelation. The changes in protein solubility of selected hydrolysates (Neu2, Fla2, OS2, and TS2) depending on the pH (3–9) and hydrolysis time (t H = 30–120 min) in comparison to the unhydrolysed MLPF (control) are illustrated in Fig. 3. The particular hydrolytic setting and hydrolysis time was chosen for the techno-functional analyses in order to cover the range from low (DH = 7.9) to medium intensive hydrolysis (DH = 15.1) as similarly done by Chabanon et al. [30]. Protein solubility of the control ranged from 10 to 22% with its minimum and maximum at pH 5 and pH 9, respectively. The isoelectric point (IP) was found to be located at pH 4 (data not shown). These results are in accordance with studies reporting considerable low solubility of insect protein flours derived from mealworm larvae (3–45%; pH 2–9), black soldier fly larvae (10–35%; pH 2–9), house cricket (12–23%, pH 3–9) and tropical banded cricket (5–25%; pH 3–10), especially at weak acidic conditions [20, 23, 33]. In contrast, Azagoh et al. [22] observed higher protein solubility of flour from mealworm larvae between 40–76% from pH 2–10.

Protein solubility index (PSI) of migratory locust protein flour (MLPF; control) and different hydrolysates depending on applied enzyme / enzyme combination, hydrolysis time (t H) and solvent pH. All values are means ± SD (n = 4). Different superscripts within one diagram indicate significant differences (p ≤ 0.05; one-way ANOVA, Bonferroni)

Except for the hydrolysis with Flavourzyme (Fla2), the protein solubility of hydrolysates was significantly increased with increasing t H at each applied pH level. Among the four tested hydrolytic settings, highest solubility of up to 22% (Fla2), 33% (Neu2), 54% (OS2), and 55% (TS2) was achieved—consistently at pH 9 and t H = 120 min. The increase in solubility is generally attributed to the release of smaller peptide fragments associated with an increase in ionisable groups (amino/carboxyl), which interact with water molecules and enhance protein hydration [39]. Consequently, the increase in protein solubility was lowest after hydrolysis with Flavourzyme but most pronounced for hydrolyses using enzyme combinations (OS2, TS2) due to the more efficient degradation of MLPF proteins and the generation of better soluble low molecular weight peptides (see Table 2; Fig. 2).

Only a few studies have investigated the influence of enzymatic hydrolysis on solubility of insect protein. Hall et al. [33] reported an improved solubility of tropical banded cricket protein after hydrolysis with Alcalase (E/S = 0.5–3.0%; t H = 30–90 min; DH = 26–52%) to about 30% at pH 3 and 92% at pH 10. Protein solubilities between 93–98% in the pH range from 3 to 7 were shown for housefly larvae protein after two-step hydrolysis with Alcalase and Flavourzyme (E/S = 2%; t H = 13 h; DH = 60%) by Wang et al. [32]. Differences in the extent of solubility increase can be ascribed to the different insect species, pre-treatment, used enzyme(s), E/S ratio, t H, and DH [50].

Emulsifying and foaming properties

Changes in protein properties such as molecular weight, surface activity, and hydrophobicity as a result of hydrolysis would modify specific surface characteristics of the proteins, and hence their techno-functional performance [58]. Table 3 summarizes the results for the emulsifying activity (EA), foamability (OR30s) and foam stability (FS) of hydrolysed and non-hydrolysed MLPF.

The untreated MLPF (control) revealed highest EA at pH 9 (45%) but deteriorated emulsion properties under acidic and neutral conditions which might be attributed to the lower electrostatic repulsion of the protein-stabilised lipid droplets near the IP [59]. Enzymatic hydrolysis with Neutrase (Neu2) could not achieve any improvement of the EA in the tested pH range, while treatments including exoproteases (Fla2, OS2, TS2) significantly enhanced the EA at pH 5 and/or pH 7 to a maximum of 40% (pH 5) and 54% (pH 7). The increased emulsifying activity may be due to the decomposition of large protein molecules and the increased surface hydrophobicity by the exposure of previously buried hydrophobic groups [60]. An increase in emulsifying capacity was similarly found after comparable hydrolysis treatments of tropical banded crickets [33]. However, some hydrolytic settings were also shown to reduce emulsifying properties due to excessive protein degradation which negatively affects interfacial adsorptivity and molecular rearrangement at the surface [29, 33, 51].

The unhydrolysed control showed no ability to form foam at pH 3 but best initial foamability (OR30s) of around 200% at pH 5. Single enzyme treatments have led to a significant improvement (p ≤ 0.05) of foamability at pH 3 up to 210% (Neu2; t H = 120 min) while OR30s was considerably lowered at all other pH levels tested. Both combined enzymatic hydrolyses (OS2, TS2) similarly affected the foamability of the hydrolysates resulting in high overruns up to 326% under weak acidic conditions (pH 3–5) independent of the t H. Hall et al. [33] have also found improved foamability of banded cricket hydrolysates up to 155% (Alcalase; ES 0.5%, t H = 30 min) in comparison to the control (90%). Similar to phenomena influencing emulsifying properties of MLPF hydrolysates, conformational changes induced by enzymatic cleavage led to the generation of small peptides and exposure of surface-stabilising residues resulting in improved foamability due to rapid diffusion and stabilisation of the interfacial layer [50]. In analogy to the results of the single enzyme hydrolyses, the combination of enzymes resulted in deteriorated foamability of MLPF hydrolysates at neutral and alkaline pH, which might be ascribed to the higher repulsive forces and lower elasticity of the interfacial layer at pH 7–9 in comparison to the isoelectric point around pH 4 [61].

The results for the foam stability (FS) of MLPF and hydrolysates thereof are given in Table 3. Foam stability between 30–40% at pH 5 and pH 9 was observed for the untreated control while FS was not assignable (na) at pH 3 and pH 7. Initial foam stability of untreated MLPF is considerably low in comparison to conventional food proteins such as soy protein isolate (5% w/v) or rapeseed albumin solution (1.5% w/v) exhibiting an FS of 90% and 76% after 60 and 30 min, respectively [30, 51]. Enzymatic hydrolysis resulted in a sharp increase of the foam stability at pH 7 (72%) and a limited improvement at pH 9 (82%). Deteriorated foam stability < 10% was observed at pH 3 throughout all enzymatic settings and at pH 5 after combined enzyme hydrolyses. The increase in foam stability of certain MLPF hydrolysates contrasts with findings of previous studies which reported diminished foam stability of soy protein, rapeseed protein, and cricket protein after enzymatic hydrolysis due to the decomposition of large protein molecules which are needed to enhance viscoelasticity of the air–water interface and stabilize the foam [29, 30, 33, 51].

Water and oil binding capacity

The results for the water binding (WBC) and oil binding capacity (OBC) are summarised in Fig. 4 as a function of the hydrolytic setting and t H. The WBC of the different MLPF hydrolysates remained unchanged in comparison to the control at around 1.50 gH2O/gDM. This leads to the assumption that the protein network was still able to retain the bound water even after 120 min of proteolysis with different enzymes or enzyme combinations. In contrast, Meinlschmidt et al. [51] observed a decrease in WBC of soy protein isolate after hydrolysis with different enzymes (e.g. Flavourzyme and Alcalase) but an increase after proteolysis with Papain. The general extent of water binding was significantly higher in comparison to several flours and protein fractions of mealworm (0.8 gH2O/gDM) and black soldier fly larvae (0.7 gH2O/gDM) as reported by Bußler et al. [20].

Water binding capacity (WBC) and oil binding capacity (OBC) of migratory locust protein flour (MLPF; control) and different hydrolysates depending on applied enzyme/enzyme combination and hydrolysis time (t H). All values are means ± SD (n = 4). Different superscripts within one diagram indicate significant differences (p ≤ 0.05; one-way ANOVA, Bonferroni)

The OBC was significantly enhanced by the applied enzymatic treatments independent of the hydrolysis time (t H) ranging from 30 to 120 min. The initial OBC of the non-hydrolysed MLPF (1.10 gOil/gDM) was increased to a maximum of 1.54, 1.78, 1.83, and 2.33 gOil/gDM for Fla2, Neu2, OS2, and TS2, respectively, and can be ascribed to the exposure of hydrophobic residues initially buried in the core of the protein. Thereby, the individual increase in OBC reflects well the extent of protein degradation as shown by DH and SDS-PAGE pattern (see “Protein degradation ”). Similar observations of enhanced oil binding properties were reported for globulin-based rapeseed isolate and soy protein isolate after enzymatic hydrolysis [30, 51]. The general degree of oil binding found for the hydrolysed and non-hydrolysed MLPF significantly surpasses the OBC of different flours and protein fractions of mealworm and black soldier fly larvae ranging between 0.4 and 0.9 gOil/gDM [20].

Conclusion

The aim of the present study was the investigation of different enzymatic hydrolysis settings on the protein degradation kinetics and techno-functional properties of migratory locust proteins. The extent of enzymatic protein cleavage of MLPF was shown to be highly influenced by the hydrolysis parameters (enzyme(s) used, pre-treatment, E/S ratio, hydrolysis time) as evidenced by the course of the degree of hydrolysis (DH) and the SDS-PAGE profiles. In particular, combined enzyme treatments turned out to be very effective in MLPF hydrolysis while thermal pre-treatment prior to hydrolysis caused impaired proteolysis. Further, the results clearly demonstrate that controlled enzymatic cleavage of migratory locust proteins in terms of selected enzyme(s), enzyme–substrate ratio and hydrolysis time leads to hydrolysates with improved techno-functional properties and, hence, better industrial applicability as functional ingredients for complex food systems. The solubility was successfully enhanced over a broad pH range (pH 3–9) covering the pH spectrum of common food items. Depending on the applied hydrolytic setting, significant improvement of emulsifying activity at pH 5–7, foamability at pH 3–5 and oil binding capacity in comparison to the non-hydrolysed MLPF was achieved.

However, further research is needed to evaluate (1) the influence of enzymatic hydrolysis on sensory properties of the migratory locust hydrolysates, (2) the techno-functional properties depending on the ionic strength, and (3) the functional performance in more complex food formulations. Furthermore, alternative pre-treatments (e.g.: high hydrostatic pressure, high pressure homogenisation) should be investigated in order to facilitate subsequent enzymatic decomposition by targeted unfolding of insect proteins. Besides the utilisation to improve techno-functionality, enzymatic degradation might be also a promising approach to reduce the allergenic potential of insect proteins and to generate hypoallergenic products by cleavage of specific epitopes which cause allergic reactions or cross-reactions.

References

Rumpold BA, Schlüter OK (2013) Nutritional composition and safety aspects of edible insects. Mol Nutr Food Res 57:802–823. https://doi.org/10.1002/mnfr.201200735

Nowak V, Persijn D, Rittenschober D, Charrondiere UR (2016) Review of food composition data for edible insects. Food Chem 193:39–46. https://doi.org/10.1016/j.foodchem.2014.10.114

Finke MD (2002) Complete nutrient composition of commercially raised invertebrates used as food for insectivores. Zoo Biol 21:269–285. https://doi.org/10.1002/zoo.10031

Payne CL, Scarborough P, Rayner M, Nonaka K (2016) A systematic review of nutrient composition data available for twelve commercially available edible insects, and comparison with reference values. Trends Food Sci Technol 47:69–77

Ramos-Elorduy J, Moreno JMP, Prado EE, Perez MA, Otero JL, de Guevara OL (1997) Nutritional value of edible insects from the State of Oaxaca, Mexico. J Food Compos Anal 10(2):142–157. https://doi.org/10.1006/jfca.1997.0530

van Huis A (2015) Edible insects contributing to food security? Agric Food Secur 4(1):1–9. https://doi.org/10.1186/s40066-015-0041-5

EFSA (2015) Risk profile related to production and consumption of insects as food and feed. EFSA J 13:(10)

Oonincx DGBA., van der Poel AFB (2011) Effects of diet on the chemical composition of migratory locusts (Locusta migratoria). Zoo Biol 30(1):9–16. https://doi.org/10.1002/zoo.20308

Barroso FG, de Haro C, Sánchez-Muros M-J, Venegas E, Martínez-Sánchez A, Pérez-Bañón C (2014) The potential of various insect species for use as food for fish. Aquaculture 422:193–201

Osimani A, Garofalo C, Milanović V, Taccari M, Cardinali F, Aquilanti L, Pasquini M, Mozzon M, Raffaelli N, Ruschioni S, Riolo P, Isidoro N, Clementi F (2016) Insight into the proximate composition and microbial diversity of edible insects marketed in the European Union. Eur Food Res Technol 243:1157–1171. https://doi.org/10.1007/s00217-016-2828-4

Aiking H (2011) Future protein supply. Trends Food Sci Technol 22(2–3):112–120http://doi.org/10.1016/j.tifs.2010.04.005

van Huis A (2013) Potential of insects as food and feed in assuring food security. Annu Rev Entomol 58:563–583

DeFoliart GR (1992) Insects as human food. Crop Prot 11(5):395–399

Hartmann C, Shi J, Giusto A, Siegrist M (2015) The psychology of eating insects: a cross-cultural comparison between Germany and China. Food Qual Prefer 44:148–156. https://doi.org/10.1016/j.foodqual.2015.04.013

Gere A, Székely G, Kovács S, Kókai Z, Sipos L (2017) Readiness to adopt insects in Hungary: a case study. Food Qual Prefer 59:81–86. https://doi.org/10.1016/j.foodqual2017.02.005

Balzan S, Fasolato L, Maniero S, Novelli E (2016) Edible insects and young adults in a north-east Italian city an exploratory study. Br Food J 118:318–326. https://doi.org/10.1108/BFJ-04-2015-0156

Schlüter O, Rumpold B, Holzhauser T, Roth A, Vogel RF, Quasigroch W, Vogel S, Heinz V, Jäger H, Bandick N, Kulling S, Knorr D, Steinberg P, Engel K-H (2017) Safety aspects of the production of foods and food ingredients from insects. Mol Nutr Food Res 61(6):1600520. https://doi.org/10.1002/mnfr.201600520

Schösler H, Boer JD, Boersema JJ (2012) Can we cut out the meat of the dish? Constructing consumer-oriented pathways towards meat substitution. Appetite 58(1):39–47. https://doi.org/10.1016/j.appet.2011.09.009

Tan HSG, Fischer ARH, Tinchan P, Stieger M, Steenbekkers LPA, van Trijp HCM (2015) Insects as food: Exploring cultural exposure and individual experience as determinants of acceptance. Food Qual Prefer 42(0):78–89. https://doi.org/10.1016/j.foodqual.2015.01.013

Bußler S, Rumpold BA, Jander E, Rawel HM, Schlüter OK (2016) Recovery and techno-functionality of flours and proteins from two edible insect species: meal worm (Tenebrio molitor) and black soldier fly (Hermetia illucens) larvae. Heliyon 2:e00218. https://doi.org/10.1016/j.heliyon.2016.e00218

Bußler S, Rumpold BA, Fröhling A, Jander E, Rawel HM, Schlüter OK (2016) Cold atmospheric pressure plasma processing of insect flour from Tenebrio molitor: impact on microbial load and quality attributes in comparison to dry heat treatment. Innov Food Sci Emerg Technol 36:277–286. https://doi.org/10.1016/j.ifset.2016.07.002

Azagoh C, Ducept F, Garcia R, Rakotozafy L, Cuvelier ME, Keller S, Lewandowski R, Mezdour S (2016) Extraction and physicochemical characterization of Tenebrio molitor proteins. Food Res Int 88:24–31. https://doi.org/10.1016/j.foodres.2016.06.010

Sipponen MH, Mäkinen OE, Rommi K, Heiniö R-L, Holopainen-Mantila U, Hokkanen S, Hakala TK, Nordlund E (2017) Biochemical and sensory characteristics of the cricket and mealworm fractions from supercritical carbon dioxide extraction and air classification. Eur Food Res Technol. https://doi.org/10.1007/s00217-017-2931-1

Kim H-W, Setyabrata D, Lee YJ, Jones OG, Kim YHB (2016) Pre-treated mealworm larvae and silkworm pupae as a novel protein ingredient in emulsion sausages. Innov Food Sci Emerg Technol 38:(Part A):116–123. https://doi.org/10.1016/j.ifset.2016.09.023

Del Valle FR, Mena MH, Bourges H (1982) An investigation into insect protein. J Food Process Preserv 6(2):99–110. https://doi.org/10.1111/j.1745-4549.1982.tb00645.x

Yi L, Lakemond CMM, Sagis LMC, Eisner-Schadler V, van Huis A, van Boekel MAJS. (2013) Extraction and characterisation of protein fractions from five insect species. Food Chem 141:3341–3348. https://doi.org/10.1016/j.foodchem.2013.05.115

Akpossan RA, Digbeu YD, Koffi MD, Kouadio JPE, Dué EA, Kouamé PL (2015) Protein fractions and functional properties of dried Imbrasia oyemensis larvae full-fat and defatted flours. Int J Biochem Res Rev 5(2):116–126

Omotoso O (2006) Nutritional quality, functional properties and anti-nutrient compositions of the larva of Cirina forda (Westwood)(Lepidoptera: Saturniidae). J Zhejiang Univ Sci B 7(1):51–55

Meinlschmidt P, Schweiggert-Weisz U, Brode V, Eisner P (2016) Enzyme assisted degradation of potential soy protein allergens with special emphasis on the technofunctionality and the avoidance of a bitter taste formation. LWT Food Sci Technol 68:707–716. https://doi.org/10.1016/j.lwt.2016.01.023

Chabanon G, Chevalot I, Framboisier X, Chenu S, Marc I (2007) Hydrolysis of rapeseed protein isolates: kinetics, characterization and functional properties of hydrolysates. Process Biochem 42(10):1419–1428. https://doi.org/10.1016/j.procbio.2007.07.009

Chobert JM, Bertrand-Harb C, Nicolas MG (1988) Solubility and emulsifying properties of caseins and whey proteins modified enzymically by trypsin. J Agric Food Chem 36(5):883–892

Wang J, Wang Y, Dang X, Zheng X, Zhang W (2013) Housefly larvae hydrolysate: orthogonal optimization of hydrolysis, antioxidant activity, amino acid composition and functional properties. BMC Res Notes 6:197–197. https://doi.org/10.1186/1756-0500-6-197

Hall FG, Jones OG, O’Haire ME, Liceaga AM (2017) Functional properties of tropical banded cricket (Gryllodes sigillatus) protein hydrolysates. Food Chem 224:414–422. doi:https://doi.org/10.1016/j.foodchem.2016.11.138

AOAC (2002) Official methods of analysis, vol 2. Association of Official Analytical 623 Chemists, Gaithersburg, p 17

ICC (1984) Cereals and cereal products—Determination of total fat content, ICC Recomendation No. 136. ICC Standard methods

Daum G (2005) Aerobe Deproteinierung von Crustaceaen-Abfällen zur Gewinnung von Chitin mittels proteolytischer Mikroorganismen. Universität Hamburg, Hamburg

No HK, Meyers SP (1997) Preparation of chitin and chitosan. In: Muzzarelli RAA, Peter MG (eds.) Chitin Handbook. Atec, Grottamare, Italien, pp 475–489

Nielsen P, Petersen D, Dambmann C (2001) Improved method for determining food protein degree of hydrolysis. J Food Sci 66(5):642–646

Adler-Nissen J (1986) Enzymic hydrolysis of food proteins. Elsevier Applied Science Publishers, Amsterdam

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227:680–685

Morr CV, German B, Kinsella JE, Regenstein JM, Buren JPV, Kilara A, Lewis BA, Mangino ME (1985) A Collaborative Study to develop a standardized food protein solubility procedure. J Food Sci 50(6):1715–1718. https://doi.org/10.1111/j.1365-2621.1985.tb10572.x

Robinson HW, Hogden CG (1940) The biuret reaction in the determination of serum proteins. 1. A study of the conditions necessary for the production of a stable color which bears a quantitative relationship to the protein concentration. J Biol Chem 135:707–725

Vojdani F (1996) Solubility. In: Hall GM (ed.) Methods of testing protein functionality, Blackie Academic & Professional, London, pp 11–60

Chamba MVM, Hua Y, Dawa Q, Jakpo O, Zhang C (2013) Effects of synthetic and natural extraction chemicals on functional properties, polyphenol content and antioxidant activity of soy protein isolates extracted from full-fat and defatted flours. J Food Technol 11(3):52–59

Hammershøj M, Larsen LB (1999) Foaming of ovalbumin and egg albumen fractions and the role of disulfide bonds at various pH levels. In: Proceedings of VIII European Symposium on the Quality of Eggs and Egg Products, pp 351–357

Quinn J, Paton D (1979) A practical measurement of water hydration capacity of protein materials [Cereal food products]. Cereal Chemistry

Bußler S, Steins V, Ehlbeck J, Schlüter O (2015) Impact of thermal treatment versus cold atmospheric plasma processing on the techno-functional protein properties from Pisum sativum ‘Salamanca’. J Food Eng 167(Part B):166–174. https://doi.org/10.1016/j.jfoodeng.2015.05.036

Finke MD (2007) Estimate of chitin in raw whole insects. Zoo Biol 26(2):105–115. https://doi.org/10.1002/zoo.20123

Chakravorty J, Ghosh S, Jung C, Meyer-Rochow VB (2014) Nutritional composition of Chondacris rosea and Brachytrupes orientalis: two common insects used as food by tribes of Arunachal Pradesh, India. J Asia Pacific Entomol 17(3):407–415. https://doi.org/10.1016/j.aspen.2014.03.007

Panyam D, Kilara A (1996) Enhancing the functionality of food proteins by enzymatic modification. Trends Food Sci Technol 7(4):120–125. https://doi.org/10.1016/0924-2244(96)10012-1

Meinlschmidt P, Sussmann D, Schweiggert-Weisz U, Eisner P (2016) Enzymatic treatment of soy protein isolates: effects on the potential allergenicity, technofunctionality, and sensory properties. Food Sci Nutr 4(1):11–23. https://doi.org/10.1002/fsn3.253

Spellman D, McEvoy E, O’Cuinn G, Fitzgerald RJ (2003) Proteinase and exopeptidase hydrolysis of whey protein: comparison of the TNBS, OPA and pH stat methods for quantification of degree of hydrolysis. Int Dairy J 13(6):447–453. https://doi.org/10.1016/S0958-6946(03)00053-0

Chao D, He R, Jung S, Aluko RE (2013) Effect of pressure or temperature pretreatment of isolated pea protein on properties of the enzymatic hydrolysates. Food Res Int 54(2):1528–1534. https://doi.org/10.1016/j.foodres.2013.09.020

Adjonu R, Doran G, Torley P, Agboola S (2013) Screening of whey protein isolate hydrolysates for their dual functionality: influence of heat pre-treatment and enzyme specificity. Food Chem 136(3):1435–1443. https://doi.org/10.1016/j.foodchem.2012.09.053

Van der Plancken I, Delattre M, Indrawati, Van Loey A, Hendrickx MEG (2004) Kinetic Study on the changes in the susceptibility of egg white proteins to enzymatic hydrolysis induced by heat and high hydrostatic pressure pretreatment. J Agric Food Chem 52(18):5621–5626. https://doi.org/10.1021/jf049716u

Pan AD, Zeng H-Y, Alain GBFC., Feng B (2016) Heat-pretreatment and enzymolysis behavior of the lotus seed protein. Food Chem 201:230–236. https://doi.org/10.1016/j.foodchem.2016.01.069

Chen RF, Scott C, Trepman E (1979) Fluorescence properties of o-phthaldialdehyde derivatives of amino acids. Biochim Biophys Acta (BBA) Protein Struct 576(2):440–455

Molina Ortiz SE, Wagner JR (2002) Hydrolysates of native and modified soy protein isolates: structural characteristics, solubility and foaming properties. Food Res Int 35(6):511–518. https://doi.org/10.1016/S0963-9969(01)00149-1

Franzen KL, Kinsella JE (1976) Functional properties of succinylated and acetylated soy protein. J Agric Food Chem 24(4):788–795

Wu W, Hettiarachchy N, Qi M (1998) Hydrophobicity, solubility, and emulsifying properties of soy protein peptides prepared by papain modification and ultrafiltration. J Am Oil Chem Soc 75(7):845–850

Foegeding EA, Luck PJ, Davis JP (2006) Factors determining the physical properties of protein foams. Food Hydrocoll 20(2–3):284–292. https://doi.org/10.1016/j.foodhyd.2005.03.014

Acknowledgements

Open access funding provided by University of Natural Resources and Life Sciences Vienna (BOKU). The authors would like to thank Prof. Dr. Cornelia Rauh, head of the Department of Food Biotechnology and Food Process Engineering of the TU Berlin, and her team for providing the equipment and support for electrophoretic analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have declared no conflicts of interest.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Purschke, B., Meinlschmidt, P., Horn, C. et al. Improvement of techno-functional properties of edible insect protein from migratory locust by enzymatic hydrolysis. Eur Food Res Technol 244, 999–1013 (2018). https://doi.org/10.1007/s00217-017-3017-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-017-3017-9