Abstract

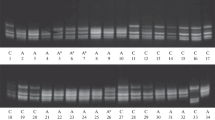

Eleven barley landraces (Hordeum vulgare L.) grown under the same climatic and soil conditions according to the same organic protocol and corresponding malt samples were considered in this study. In order to assess the modification induced by the mashing process on barley samples cultivated under the same conditions, the enzymatic activity of alpha and beta-amylase was determined in all samples. In addition, the modification induced by the germination process on the protein pattern was also investigated by SDS–PAGE. Barley samples resulted different both in protein content and in amylase quality and quantity; these differences, evidently related to genetic factors, also were found in malt samples. Although two bands at 41–42 kDa and 55–58 kDa were found in the Betamyl extracts analysed by SDS–PAGE, only the 55–58 kDa had discriminating ability, and for this reason, it could be considered in order to evaluate barley suitability for beer production.

Similar content being viewed by others

References

MacGregor AW, Dushnicky L (1989) α-Amylase in developing barley kernel: a reappraisal. J Inst Brew 95:29–33

MacGregor AW, LaBerge DE, Meredith WOS (1971) Changes in barley kernels during growth and maturation. Cereal Chem 48:255–269

Georg-Kraemer JE, Mundstock EC, Cavalli-Molina L (2001) Developmental expression of amylase during barley malting. J Cereal Sci 33:279–288

Buttimer ET, Briggs DE (2000) Characterization of solubilized forms of bound β-amylase released by various agents. J Inst Brew 106:71–82

Grime KH, Briggs DE (1995) Release and activation of barley β-amylase. J Inst Brew 101:337–343

Ma YF, Eglinton JK, Evans DE, Logue SJ, Langridge P (2000) Removal of the four C-terminal glycine-rich repeats enhances the termostability and substrate binding affinity of barley beta-amylase. Biochem 39:13350–13355

Evans DE, Wallace W, Lance RCM, MacLeod LC (1997) Measurement of Beta-amylase in malting barley (Hordeum vulgare L). II. The effect of germination and kilning. J Cereal Sci 26:241–250

UNI, Ente Nazionale Italiano di Unificazione, 1994, The Association, Milan, Italy

ICC, Standard Methods of the International Association for Cereal Science and Technology, 2005, The Association, Vienna, Austria

EBC (European Brewery Convention) (1975) Analytica EBC, 3rd edn. Numberg, Germany

McCleary BV, Sheehan H (1987) Measurement of cereal α-amylase: a new assay procedure. J Cereal Sci 6:237–251

McCleary BV, Codd R (1989) Measurement of β-amylase in cereal flours and commercial enzyme preparation. J Cereal Sci 9:17–33

Payne PI, Law CN, Mudd EE (1980) Control by homologous group 1 chromosomes of the high-molecular-weight subunits of glutenin, a major protein of wheat endosperm. Theor Appl Genet 58:113–120

Pogna NE, Mellini F, Beretta AM, Bianchi A (1988) Composizione in subunità gluteniniche ad alto peso molecolare (APM) delle varietà di grano tenero coltivate in Italia. Sementi Elette 34(4):3–12

El-Negoumy AM, Newman CW, Hockett EA (1982) Effect of level of nitrogen fertilizer on protein composition of some barley cultivars. Nutr Rep Int 25:89–96

Howard KA, Gayler KR, Eagles HA, Halloran GM (1996) The relationship between D hordein and malting quality in barley. J Cereal Sci 24:47–53

Buiatti S, Sensidoni A, Fontana M (2006) Barley and malt quality control. Tecnica Molitoria 57(7):749–764

Wolfe MS, Baresel JP, Desclaux D, Goldringer I, Hoad S, Kovacs G, Löschenberger F, Miedaner T, Østergard H, Lammerts van Bueren ET (2008) Developments in breeding cereals for organic agriculture. Euphytica 163:323–346

Arends AM, Fox DP, Henry RJ, Marschke RJ, Symons MN (1995) Genetic and environmental variation in the diastatic power of Australian barley. J Cereal Sci 20:63–70

Tronier B, Ory RL (1970) Association of bound beta-amylase with protein bodies in barley. Cereal Chem 47:464–471

Hara-Nishimura I, Nishimura M, Daussant J (1986) Conversion of free β-amylase to bound β-amylase on starch granules in the barley endosperm during desiccation phase of seed development. Protoplasma 134:149–153

Sopanen T, Laurière C (1989) Release and activity of bound β-amylase in a germinationg barley grain. Plant Physiol 89:244–249

Yin C, Zhang GP, Wang JM, Chen JX (2002) Variation of beta-amylase activity in barley as affected by cultivar and environment and its relation to protein content and grain weight. J Cereal Sci 36:307–312

Wang J, Zhang G, Chen J, Shen Q, Wu F (2003) Genotypic and environmental variation in barley beta-amylase activity and its relation to protein content. Food Chem 83:163–165

Gupta M, Abu-Ghannam N, Gallaghar E (2010) Barley for brewing: characteristic changes during malting, brewing and applications of its by-products. Compr Rev Food Sci Food Saf 9:318–328

McCafferty CA, Jenkinson HR, Brosnam JM, Bryce JH (2004) Limit dextrinase-does its malt activity relate to its activity during brewing? J Inst Brew 110:284–296

Ross HA, Sungurtas J, Ducreux L, Swanston JS, Davies HV, McDougall GJ (2003) Limit dextrinase in barley cultivars of different malting quality: activity, inhibitors and limit dextrin profiles. J Cereal Sci 38:325–334

Rhodes AP, Gill AA (1980) Fractionation and amino acid analysis of the salt-soluble protein fractions of normal and high-lysine barleys. J Sci Food Agric 31:467–473

Linko R, Lapveteläinen A, Laaskso P, Kallio H (1989) Protein composition of a high-protein barley flour and barley grain. Cereal Chem 66:478–482

Chandra GS, Proudlove MO, Baxter ED (1999) The structure of barley endosperm—An important determinant of malt modification. J Sci Food Agric 79:37–46

Acquistucci R, Turfani V, Bonafaccia G, Aureli G (2006) In: Proceeding of the 6th national congress of food chemistry, Taro ed, pp 7–11

Acknowledgments

This work was supported by the Italian Ministry for Agricultural, Food and Forestry Policies (MiPAAF) in the frame of the project BIOAGRIBIO.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Acquistucci, R., Turfani, V. & Aureli, G. Amylase modification induced by the germination process in organic barley. Eur Food Res Technol 232, 583–590 (2011). https://doi.org/10.1007/s00217-011-1423-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-011-1423-y