Abstract

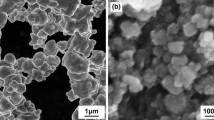

In the present study, nickel matrix composites reinforced with in situ oxides were densified by the hot pressing process (HP). Mechanical alloying was used to synthesis in situ matrix and reinforced phases. The mechanical alloying process allows the ignition of aluminothermic reaction in the NiO/Al system. The formation of Ni-Al2O3 powder composites with residual NiO, indicating an incomplete reaction. At the end of the sintering process, two composites were formed: Ni-Al2O3 and Ni-NiAl2O4. The formed phases were identified by X-ray diffraction analysis (XRD) and examined by scanning electron microscopy (SEM). The density of composites was evaluated by the Archimedes method. The results revealed that the milling time significantly affected the density obtained after sintering. The highest density (5.74 g/cm3) was recorded for 10 h of milling. Composites’ dry sliding wear behavior was tested using a ball-on-disc test under different loads. The tribological results show the impact of milling times and applied load on wear rate and the friction coefficient. The worn surfaces of the samples were examined by SEM to identify the wear behavior. Hence, abrasive wear was identified as the main mechanism.

Similar content being viewed by others

Availability of data and material

The authors confirm that the data supporting the findings of this study are available within the article. The raw data that support the findings of this study are available upon a reasonable request.

References

Ibrahim I, Mohamed F, Lavernia EJ (1991) Particulate reinforced metal matrix composites—a review. J Mater Sci 26(5):1137–1156

Saheb N, Iqbal Z, Khalil A, Hakeem AS, Al Aqeeli N, Laoui T, Al-Qutub A, Kirchner R (2012) Spark plasma sintering of metals and metal matrix nanocomposites: a review. J Nanomater 2012

Yamanoğlu R, Karakulak E, Zeren A, Zeren M (2013) Effect of heat treatment on the tribological properties of Al–Cu–Mg/nanoSiC composites. Mater Des 49:820–825

Daoud I, Miroud D, Yamanoglu R (2018) Microstructure characterization and quantitative analysis of copper alloy matrix composites reinforced with WC-xNi powders prepared by spontaneous infiltration. J Min Metall B 54 (2):169–177

Djematene F, Djerdjare B, Boukantar A-R, Rezzoug A, Abdi S, Daoud I, Ortiz AL (2020) A comparative study of the dry sliding wear of WC-10wt.%(Co+ Fe+ Ni) cemented carbides pressureless sintered with different Fe/Co ratios. J Asian Ceram Soc 8(4):1043–1050

Chatterjee S, Ghosh Sur S, Bandyopadhyay S, Basumallick A (2016) Effect of microstructure and residual stresses on nano-tribological and tensile properties of Al2O3-and SiC-reinforced 6061-Al metal matrix composites. J Compos Mater 50(19):2687–2698

Lieberthal M, Kaplan WD (2001) Processing and properties of Al2O3 nanocomposites reinforced with sub-micron Ni and NiAl2O4. Mater Sci Eng A 302(1):83–91. https://doi.org/10.1016/S0921-5093(00)01358-7

Chen Y-C, Fan F-Y, Tsai M-H, Wu C-H, Chen S-T, Ou S-F (2019) Microstructure and mechanical properties of Ti nitride/Ni metal-based composites fabricated by reactive sintering. Ceram Int 45(8):10834–10839

Iacob G, Ghica VG, Buzatu M, Buzatu T, Petrescu MI (2015) Studies on wear rate and micro-hardness of the Al/Al2O3/Gr hybrid composites produced via powder metallurgy. Compos Part B Eng 69:603–611

Bhaskar KV, Sundarrajan S, Rao BS, Ravindra K (2018) Effect of reinforcement and wear parameters on dry sliding wear of aluminum composites - a review. Mater Today: Proc 5(2, Part 1):5891–5900. https://doi.org/10.1016/j.matpr.2017.12.188

Muktinutalapati NR (2011) Materials for gas turbines–an overview. Adv Gas Turbine Technol 23

Yamanoglu R, Bradbury W, Karakulak E, Olevsky E, German R (2014) Characterisation of nickel alloy powders processed by spark plasma sintering. Powder Metall 57(5):380–386

Suárez S, Ramos-Moore E, Mücklich F (2013) A high temperature X-ray diffraction study of the influence of MWCNTs on the thermal expansion of MWCNT/Ni composites. Carbon 51:404–409

Heragh MF, Eskandarinezhad S, Dehghan A (2020) Ni-Cu matrix composite reinforced with CNTs: preparation, characterization, wear and corrosion behavior, inhibitory effects. J Compos Compd 2(4):123–128. https://doi.org/10.29252/jcc.2.3.3

Kumar BA, Ananthaprasad M, GopalaKrishna K (2016) A review on mechanical and tribological behaviors of nickel matrix composites. Ind J Sci Technol 9:2

Pollock TM, Tin S (2006) Nickel-based superalloys for advanced turbine engines: chemistry, microstructure and properties. J Propuls Power 22(2):361–374

Bakshi SR, Lahiri D, Agarwal A (2010) Carbon nanotube reinforced metal matrix composites-a review. Int Mater Rev 55(1):41–64

Karmakar R, Maji P, Ghosh SK (2021) A review on the nickel based metal matrix composite coating. Metal Mater Int 27(7):2134–2145

Yazdani A, Isfahani T (2018) A facile method for fabrication of nano-structured Ni-Al2O3 graded coatings: Structural characterization. Trans Nonferrous Mat Soc China 28(1):77–87

Yazdani A, Isfahani T (2018) Hardness, wear resistance and bonding strength of nano structured functionally graded Ni-Al2O3 composite coatings fabricated by ball milling method. Adv Powder Technol 29(5):1306–1316

Dehgahi S, Amini R, Alizadeh M (2017) Microstructure and corrosion resistance of Ni-Al2O3-SiC nanocomposite coatings produced by electrodeposition technique. J Alloys Compd 692:622–628

Shaaban A (2019) Influence of NiAl2O4 spinel formation on the oxidation behavior of the Ni50Al alloy at 1273 K in air. Surf Coat Technol 379:125023

Yancheshmeh MS, Sahraei OA, Aissaoui M, Iliuta MC (2020) A novel synthesis of NiAl2O4 spinel from a Ni-Al mixed-metal alkoxide as a highly efficient catalyst for hydrogen production by glycerol steam reforming. Appl Catal B 265:118535. https://doi.org/10.1016/j.apcatb.2019.118535

Zurita-MÈndez N, Espinosa-Medina M, Carbajal-De la Torre G (2021) Vacuum sol-gel synthesis and characterization of NiAl2O4 nanoparticles. Acta Microscopica 30(2):71–79

Awotunde MA, Ayodele OO, Adegbenjo AO, Okoro AM, Shongwe MB, Olubambi PA (2019) NiAl intermetallic composites—a review of processing methods, reinforcements and mechanical properties. Int J Adv Manuf Technol 104(5):1733–1747. https://doi.org/10.1007/s00170-019-03984-9

Zhang Z, Wu X, Jiang C, Ma N (2014) Electrodeposition of Ni matrix composite coatings containing ZrC particles. Surf Eng 30(1):21–25

Singh S, Gupta D, Kaushal S (2020) Dry sliding wear performance of Ni–SiC composites developed through an in situ microwave casting process. J Tribol 142(10):101704

Pingale AD, Owhal A, Katarkar AS, Belgamwar SU, Rathore JS (2021) Recent researches on Cu-Ni alloy matrix composites through electrodeposition and powder metallurgy methods: a review. Mater Today: Proc 47:3301–3308. https://doi.org/10.1016/j.matpr.2021.07.145

Zhao Z, Yu X, Wang L, Yao S, Song X, Qi Q (2021) Effect of Ni on the formation mechanism of TiC/Ni composites fabricated by reactive sintering. Int J Refract Met Hard Mater 100:105611

Mamnooni S, Borhani E, Bovand D (2019) In-situ synthesis of aluminum matrix composite from Al–NiO system by mechanical alloying. Met Mater Int 1–8

Yamanoglu R (2014) Production and characterization of Al-xNi in situ composites using hot pressing. J Min Metall B 50(1):45–52

Mameri A, Azem S, Bilek A (2018) Synthesis of metallic and intermetallic matrix composites reinforced by alumina by reaction in NiO/Al mixtures. Trans Ind Inst Met 71(3):727–736

Yamanoglu R, Daoud I, Olevsky EA (2018) Spark plasma sintering versus hot pressing–densification, bending strength, microstructure, and tribological properties of Ti5Al2. 5Fe alloys. Powder Metall 61(2):178–186

Cavaliere P (2019) Spark plasma sintering of materials: Advances in processing and applications. Springer

Rahaei MB, Jia D (2014) Processing behavior of nanocrystalline NiAl during milling, sintering and mechanical loading and interpretation of its intergranular fracture. End Fract Mech 132:136–146

Rodeghiero ED, Chisaki J, Giannelis EP (1997) In situ microstructural control of Ni/Al2O3 and Ni/NiAl2O4 composites from layered double hydroxides. Chem Mater 9(2):478–484

Jones SA, Burlitch JM (1994) In situ formation of composites of alumina with nickel and with nickel aluminide. Mater Lett 19(5–6):233–235

Henriques B, Ferreira P, Buciumeanu M, Fredel M, Cabral A, Silva FS, Miranda G (2017) Copper–nickel-based diamond cutting tools: Stone cutting evaluation. Int J Adv Manuf Technol 92(1):1339–1348. https://doi.org/10.1007/s00170-017-0220-6

Stanciu C, da Cunha JM, Chicinaş I, Isnard O (2019) Structural, magnetic and Mössbauer spectroscopy characterisation of the Fe-15 wt% Si nanocrystalline powder obtained by mechanical alloying and annealing. J Alloys Compd 797:865–873

Han YS, Li JB, Ning XS, Yang XZ, Chi B (2004) Study on NiO excess in preparing NiAl2O4. Mater Sci Eng A 369(1–2):241–244

Trumble KP, Rühle M (1991) The thermodynamics of spinel interphase formation at diffusion-bonded Ni/Al2O3 interfaces. Acta Metall Mater 39(8):1915–1924. https://doi.org/10.1016/0956-7151(91)90160-3

Zhou S, Liu X, Xu Y (2018) Microstructure, mechanical properties and tribological properties of NiAlComposites reinforced by CrMnFeCoNiHigh-entropy alloy. Materials 11(10):1850

Fellah M, Samad MA, Labaiz M, Assala O, Iost A (2015) Sliding friction and wear performance of the nano-bioceramic α-Al2O3 prepared by high energy milling. Tribol Int 91:151–159

Geuzens E, Mullens S, Cooymans J, Luyten J, Lemoisson F, Sastry K, Froyen L, D’Haen J, Van Bael M, Van den Rul H (2008) Synthesis and mechanical and tribological characterization of alumina–yttria stabilized zirconia (YSZ) nanocomposites with YSZ synthesized by means of an aqueous solution–gel method or a hydrothermal route. Ceram Int 34 (5):1315–1325

Sierra C, Vazquez AJ (2006) Dry sliding wear behaviour of nickel aluminides coatings produced by self-propagating high-temperature synthesis. Intermetallics 14(7):848–852

Góral A, Lityńska-Dobrzyńska L, Kot M (2017) Effect of Surface Roughness and Structure Features on Tribological Properties of Electrodeposited Nanocrystalline Ni and Ni/Al2O3 Coatings. J Mater Eng Perform 26 : 2118–2128.

Nemati N, Khosroshahi R, Emamy M, Zolriasatein A (2011) Investigation of microstructure, hardness and wear properties of Al–4.5 wt.% Cu–TiC nanocomposites produced by mechanical milling. Mater Des 32(7):3718–3729

Chowdhury M, Khalil M, Nuruzzaman D, Rahaman ML (2011) The effect of sliding speed and normal load on friction and wear property of aluminum. Int J Mech Mechatron Eng 11(1):45–49

Al-Qutub AM, Allam IM, Samad A (2008) Wear and friction of Al–Al 2 O 3 composites at various sliding speeds. J Mater Sci 43(17):5797–5803

Ozdemir O, Zeytin S, Bindal C (2008) Tribological properties of NiAl produced by pressure-assisted combustion synthesis. Wear 265(7–8):979–985

Akbarpour M, Alipour S (2018) Microstructure and tribological properties of nanostructured aluminum reinforced with SiC nanoparticles fabricated by powder metallurgy route. Trans Ind Ins Met 71(3):745–752

Kumar S, Chakraborty M, Sarma VS, Murty BS (2008) Tensile and wear behaviour of in situ Al–7Si/TiB2 particulate composites. Wear 265(1–2):134–142

Hosseini N, Karimzadeh F, Abbasi M, Enayati MH (2010) Tribological properties of Al6061–Al2O3 nanocomposite prepared by milling and hot pressing. Mater Des 31(10):4777–4785

Acknowledgements

The Research Center in Industrial Technologies (CRTI) team (Fabrication and Characterization Workshop) and Laboratory of Science and Materials Engineering (LSGM), University of Science and Technology Houari Boumediene Algeria (USTHB), are greatly acknowledged.

Funding

This study was financially supported by the Scientific Research Unit at Kocaeli University (Proje No:2021/2473) in collaboration with Semiconductors Technology for Energetic Research Center, ALGIERS, Algeria.

Author information

Authors and Affiliations

Contributions

Ali MAMERI: conceptualization, experimental work, data curation, and writing (original draft preparation). Ismail DAOUD: investigation, experimental work, reviewing, and editing. Amine REZZOUG: methodology, reviewing and editing (final draft), review, and editing. Said AZEM: supervision, project administration. Ridvan YAMANOGLU: supervision, methodology, reviewing, and editing.

Corresponding author

Ethics declarations

Ethics approval

This study complies with the ethical standards set out by Springer. All the authors read and approved the final manuscript.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mameri, A., Daoud, I., Rezzoug, A. et al. Tribological properties of in situ oxide reinforced nickel matrix composites produced by pressure-assisted sintering. Int J Adv Manuf Technol 120, 3731–3740 (2022). https://doi.org/10.1007/s00170-022-08998-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-08998-4