Abstract

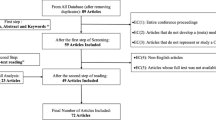

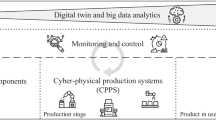

Cyber Physical Systems (CPSs) play a crucial role in the Industry 4.0 paradigm. The application of CPSs in production and manufacturing environments gave rise to the term Cyber Physical Production Systems (CPPSs). There is a growing interest in CPPSs, yet research in this area is scattered and needs to be reviewed for understanding their development status and maturity. The aim of this study is to carry out a systematic literature review (SLR) to analyze the current research activities on CPPSs according to their contributions to the engineering life cycle of such production system. Firstly, a method for SLR is presented. Then, literature analysis of CPPSs is conducted to present research activities in the light of the concept development and engineering development stages. Finally, based on the results of the literature analysis, a concept map of CPPSs research is proposed, which depicts the existing research topics in the engineering life cycle of CPPSs. And we exploit it to propose a research agenda of the CPPSs integration process required to ensure their efficient industrial use. Findings of this review can help researchers to examine the maturity of the development status of CPPSs, to discover which phases require improvement, and to know the future research directions for their industrial practices.

Similar content being viewed by others

References

Kagermann H, Wahlster W, Helbig J (2013) Recommendations for implementing the strategic initiative INDUSTRIE 4.0 -- securing the future of German manufacturing industry. acatech -- National Academy of Science and Engineering, München

Sanislav T, Miclea L (2012) Cyber-physical systems-concept, challenges and research areas. J Control Eng Appl Inform 14:28–33

Monostori L, Kádár B, Bauernhansl T, Kondoh S, Kumara S, Reinhart G, Sauer O, Schuh G, Sihn W, Ueda K (2016) Cyber-physical systems in manufacturing. CIRP Ann 65:621–641. https://doi.org/10.1016/j.cirp.2016.06.005

Lee J (2003) E-manufacturing—fundamental, tools, and transformation. Robot Comput Integr Manuf 19:501–507. https://doi.org/10.1016/S0736-5845(03)00060-7

Zhang Y, Jiang P, Huang GQ, Qu T, Hong J (2012) Task-driven e-manufacturing resource configurable model. J Intell Manuf 23:1681–1694. https://doi.org/10.1007/s10845-010-0470-8

Katchasuwanmanee K, Bateman R, Cheng K (2016) Development of the Energy-smart Production Management system (e-ProMan): a Big Data driven approach, analysis and optimisation. Proc Inst Mech Eng B J Eng Manuf 230:972–978. https://doi.org/10.1177/0954405415586711

Lee J, Bagheri B, Jin C (2016) Introduction to cyber manufacturing. Manuf Lett 8:11–15. https://doi.org/10.1016/j.mfglet.2016.05.002

Monostori L (2014) Cyber-physical production systems: roots, expectations and R&D challenges. Procedia CIRP 17:9–13. https://doi.org/10.1016/j.procir.2014.03.115

Cheng K, Bateman RJ (2008) e-Manufacturing: characteristics, applications and potentials. Prog Nat Sci 18:1323–1328. https://doi.org/10.1016/j.pnsc.2008.03.027

Cardin O (2019) Classification of cyber-physical production systems applications: proposition of an analysis framework. Comput Ind 104:11–21. https://doi.org/10.1016/j.compind.2018.10.002

Liao Y, Deschamps F, de Rocha Loures E, Ramos LFP (2017) Past, present and future of Industry 4.0 - a systematic literature review and research agenda proposal. Int J Prod Res 55:3609–3629. https://doi.org/10.1080/00207543.2017.1308576

Kusiak A (2018) Smart manufacturing. Int J Prod Res 56:508–517. https://doi.org/10.1080/00207543.2017.1351644

Alguliyev R, Imamverdiyev Y, Sukhostat L (2018) Cyber-physical systems and their security issues. Comput Ind 100:212–223. https://doi.org/10.1016/j.compind.2018.04.017

Ng CK, Wu CH, Yung KL, Ip WH, Cheung T (2018) A semantic similarity analysis of Internet of Things. Enterp Inf Syst 12:820–855. https://doi.org/10.1080/17517575.2018.1464666

Jula A, Sundararajan E, Othman Z (2014) Cloud computing service composition: a systematic literature review. Expert Syst Appl 41:3809–3824. https://doi.org/10.1016/j.eswa.2013.12.017

Schmidt N, Luder A, Rosendahl R, Ryashentseva D, Foehr M, Vollmar J (2015) Surveying integration approaches for relevance in cyber physical production systems. In: 2015 IEEE 20th Conf. Emerg. Technol. Fact. Autom. ETFA, IEEE, Luxembourg, pp 1–8. https://doi.org/10.1109/ETFA.2015.7301518

Wang L, Törngren M, Onori M (2015) Current status and advancement of cyber-physical systems in manufacturing. J Manuf Syst 37:517–527. https://doi.org/10.1016/j.jmsy.2015.04.008

Trappey AJC, Trappey CV, Govindarajan UH, Sun JJ, Chuang AC (2016) A review of technology standards and patent portfolios for enabling cyber-physical systems in advanced manufacturing. IEEE Access 4:7356–7382. https://doi.org/10.1109/ACCESS.2016.2619360

Jiang Y, Yin S, Kaynak O (2018) Data-driven monitoring and safety control of industrial cyber-physical systems: basics and beyond. IEEE Access 6:47374–47384. https://doi.org/10.1109/ACCESS.2018.2866403

Atmojo UD, Vyatkin V (2018) A review on programming approaches for dynamic industrial cyber physical systems. In: 2018 IEEE 16th Int. Conf. Ind. Inform. INDIN, pp 713–718. https://doi.org/10.1109/INDIN.2018.8471945

Rossit DA, Tohmé F, Frutos M (2019) Production planning and scheduling in cyber-physical production systems: a review. Int J Comput Integr Manuf 32:385–395. https://doi.org/10.1080/0951192X.2019.1605199

Rojas RA, Rauch E (2019) From a literature review to a conceptual framework of enablers for smart manufacturing control. Int J Adv Manuf Technol 104:517–533. https://doi.org/10.1007/s00170-019-03854-4

Cronin P, Ryan F, Coughlan M (2008) Undertaking a literature review: a step-by-step approach. Br J Nurs 17:38–43. https://doi.org/10.12968/bjon.2008.17.1.28059\

Kossiakoff A (2011) Systems engineering principles and practice, 2nd edn. Wiley, Hoboken

Lee J, Bagheri B, Kao H-A (2015) A cyber-physical systems architecture for Industry 4.0-based manufacturing systems. Manuf Lett 3:18–23. https://doi.org/10.1016/j.mfglet.2014.12.001\

Vom BJ, Alexander S, Bjoern N, Bjorn N, Kai R, Ralf P, Anne C (2009) Reconstructing the giant: on the importance of rigour in documenting the literature search process. In: ECIS 2009 Proc, vol 9, pp 2206–2217

Wittenberg C (2016) Human-CPS interaction - requirements and human-machine interaction methods for the Industry 4.0. In: 13th IFAC Symp. Anal. Des. Eval. Hum.-Mach. Syst. HMS 2016, vol 49, pp 420–425. https://doi.org/10.1016/j.ifacol.2016.10.602

Albers A, Gladysz B, Pinner T, Butenko V, Stürmlinger T (2016) Procedure for defining the system of objectives in the initial phase of an Industry 4.0 project focusing on intelligent quality control systems. In: Sixth Int. Conf. Chang. Agile Reconfigurable Virtual Prod. CARV 2016, vol 52, pp 262–267. https://doi.org/10.1016/j.procir.2016.07.067

Odważny F, Szymańska O, Cyplik P (2018) Smart factory: the requirements for implementation of the industry 4.0 solutions in FMCG environment – case study. LogForum 14:257–267

Heidel R, Hoffmeister M, Hankel M, Döbrich U (2019) The Reference Architecture Model RAMI 4.0 and the Industrie 4.0 component. VDE Verlag

S.-W. Lin, M. Bradford, D. Jacques, J. Rajive, D. Paul, C. Amine, T. Reinier, Industrial internet reference architecture, Ind. Internet Consort. IIC. Tech Rep. (2015).

Jiang J-R (2018) An improved cyber-physical systems architecture for Industry 4.0 smart factories. Adv Mech Eng 10:1687814018784192. https://doi.org/10.1177/1687814018784192

Tang D, Zheng K, Zhang H, Zhang Z, Sang Z, Zhang T, Espinosa-Oviedo J-A, Vargas-Solar G (2018) Using autonomous intelligence to build a smart shop floor. Int J Adv Manuf Technol 94:1597–1606. https://doi.org/10.1007/s00170-017-0459-y

Liu C, Jiang P (2016) A cyber-physical system architecture in shop floor for intelligent manufacturing. Procedia CIRP 56:372–377. https://doi.org/10.1016/j.procir.2016.10.059

Song Z, Moon Y (2017) Assessing sustainability benefits of cyber manufacturing systems. Int J Adv Manuf Technol 90:1365–1382. https://doi.org/10.1007/s00170-016-9428-0

Rojas RA, Rauch E, Vidoni R, Matt DT (2017) Enabling connectivity of cyber-physical production systems: a conceptual framework. Procedia Manuf 11:822–829. https://doi.org/10.1016/j.promfg.2017.07.184

Ferrer BR, Mohammed WM, Martinez Lastra JL, Villalonga A, Beruvides G, Castano F, Haber RE (2018) Towards the adoption of cyber-physical systems of systems paradigm in smart manufacturing environments. In: 2018 IEEE 16th Int. Conf. Ind. Inform. INDIN, IEEE, Porto, pp 792–799. https://doi.org/10.1109/INDIN.2018.8472061

Sanderson D, Chaplin JC, Ratchev S (2018) Conceptual framework for ubiquitous cyber-physical assembly systems in airframe assembly. IFAC-Pap. 51:417–422. https://doi.org/10.1016/j.ifacol.2018.08.331

Wang S, Wan J, Imran M, Li D, Zhang C (2018) Cloud-based smart manufacturing for personalized candy packing application. J Supercomput 74:4339–4357. https://doi.org/10.1007/s11227-016-1879-4

Pirvu B-C, Zamfirescu C-B, Gorecky D (2016) Engineering insights from an anthropocentric cyber-physical system: a case study for an assembly station. Mechatronics. 34:147–159. https://doi.org/10.1016/j.mechatronics.2015.08.010

Francalanza E, Borg J, Constantinescu C (2017) A knowledge-based tool for designing cyber physical production systems. Comput Ind 84:39–58. https://doi.org/10.1016/j.compind.2016.08.001

Fantini P, Tavola G, Taisch M, Barbosa J, Leitao P, Liu Y, Sayed MS, Lohse N (2016) Exploring the integration of the human as a flexibility factor in CPS enabled manufacturing environments: methodology and results. In: IECON 2016 - 42nd Annu. Conf. IEEE Ind. Electron. Soc, pp 5711–5716. https://doi.org/10.1109/IECON.2016.7793579

Ansari F, Khobreh M, Seidenberg U, Sihn W (2018) A problem-solving ontology for human-centered cyber physical production systems. CIRP J Manuf Sci Technol 22:91–106. https://doi.org/10.1016/j.cirpj.2018.06.002

Wang S, Zhang C, Li D (2016) A big data centric integrated framework and typical system configurations for smart factory. In: Wan J, Humar I, Zhang D (eds) Ind. IoT Technol. Appl. Springer International Publishing, Cham, pp 12–23. https://doi.org/10.1007/978-3-319-44350-8_2

Wu D, Terpenny J, Zhang L, Gao R, Kurfess T (2016) Fog-enabled architecture for data-driven cyber-manufacturing systems. In: Mater. Biomanufacturing Prop. Appl. Syst. Sustain. Manuf, vol 2. American Society of Mechanical Engineers, Blacksburg, p V002T04A032. https://doi.org/10.1115/MSEC2016-8559

Miranda J, Pérez-Rodríguez R, Borja V, Wright PK, Molina A (2017) Integrated product, process and manufacturing system development reference model to develop cyber-physical production systems - the sensing, smart and sustainable microfactory case study. IFAC-Pap. 50:13065–13071. https://doi.org/10.1016/j.ifacol.2017.08.2006

Weyer S, Meyer T, Ohmer M, Gorecky D, Zühlke D (2016) Future modeling and simulation of CPS-based factories: an example from the automotive industry. IFAC-Pap. 49:97–102. https://doi.org/10.1016/j.ifacol.2016.12.168

Bakakeu J, Fuchs J, Javied T, Brossog M, Franke J, Klos H, Eberlein W, Tolksdorf S, Peschke J, Jahn L (2018) Multi-objective design space exploration for the integration of advanced analytics in cyber-physical production systems. In: 2018 IEEE Int. Conf. Ind. Eng. Eng. Manag. IEEM, pp 1866–1873. https://doi.org/10.1109/IEEM.2018.8607483

Ming L, Shuzi Y, Xiaohong Y, Ming L, Tseng MM (1998) A CORBA-based agent-driven design for distributed intelligent manufacturing systems. J Intell Manuf 9:457–465. https://doi.org/10.1023/A:1008800717777

Vogel-Heuser B, Lee J, Leitão P (2015) Agents enabling cyber-physical production systems. Autom 63:777–789. https://doi.org/10.1515/auto-2014-1153

Zhang Y, Qian C, Lv J, Liu Y (2017) Agent and cyber-physical system based self-organizing and self-adaptive intelligent shopfloor. IEEE Trans Ind Inf 13:737–747. https://doi.org/10.1109/TII.2016.2618892

Cruz Salazar LA, Ryashentseva D, Lüder A, Vogel-Heuser B (2019) Cyber-physical production systems architecture based on multi-agent’s design pattern—comparison of selected approaches mapping four agent patterns. Int J Adv Manuf Technol 105:4005–4034. https://doi.org/10.1007/s00170-019-03800-4

Li D, Tang H, Wang S, Liu C (2017) A big data enabled load-balancing control for smart manufacturing of Industry 4.0. Clust Comput 20:1855–1864. https://doi.org/10.1007/s10586-017-0852-1

Dias-Ferreira J, Ribeiro L, Akillioglu H, Neves P, Onori M (2018) BIOSOARM: a bio-inspired self-organising architecture for manufacturing cyber-physical shopfloors. J Intell Manuf 29:1659–1682. https://doi.org/10.1007/s10845-016-1258-2

Siafara LC, Kholerdi HA, Bratukhin A, TaheriNejad N, Wendt A, Jantsch A, Treytl A, Sauter T (2017) SAMBA: a self-aware health monitoring architecture for distributed industrial systems. In: IECON 2017 - 43rd Annu. Conf. IEEE Ind. Electron. Soc. IEEE, Beijing, pp 3512–3517. https://doi.org/10.1109/IECON.2017.8216594

Vrabič R, Kozjek D, Malus A, Zaletelj V, Butala P (2018) Distributed control with rationally bounded agents in cyber-physical production systems. CIRP Ann 67:507–510. https://doi.org/10.1016/j.cirp.2018.04.037

Jiang Z, Jin Y, Mingcheng E, Li Q (2018) Distributed dynamic scheduling for cyber-physical production systems based on a multi-agent system. IEEE Access 6:1855–1869. https://doi.org/10.1109/ACCESS.2017.2780321

Foit K, Banaś W, Gwiazda A, Hryniewicz P (2017) The comparison of the use of holonic and agent-based methods in modelling of manufacturing systems. IOP Conf Ser Mater Sci Eng 227:012046. https://doi.org/10.1088/1757-899X/227/1/012046

Woo J, Shin S-J, Seo W, Meilanitasari P (2018) Developing a big data analytics platform for manufacturing systems: architecture, method, and implementation. Int J Adv Manuf Technol 99:2193–2217. https://doi.org/10.1007/s00170-018-2416-9

Niknejad N, Ismail W, Ghani I, Nazari B, Bahari M, Hussin ARBC (2020) Understanding Service-Oriented Architecture (SOA): A systematic literature review and directions for further investigation. Inf Syst 101491:101491. https://doi.org/10.1016/j.is.2020.101491

Dai W, Wanqi H, Vyatkin V (2016) Knowledge-driven service orchestration engine for flexible information acquisition in industrial cyber-physical systems. In: 2016 IEEE 25th Int. Symp. Ind. Electron. ISIE, IEEE, Santa Clara, pp 1055–1060. https://doi.org/10.1109/ISIE.2016.7745038

Lu Y, Riddick F, Ivezic N (2016) The paradigm shift in smart manufacturing system architecture. In: Nääs I, Vendrametto O, Mendes Reis J, Gonçalves RF, Silva MT, von Cieminski G, Kiritsis D (eds) Adv. Prod. Manag. Syst. Initiat. Sustain. World. Springer International Publishing, Cham, pp 767–776. https://doi.org/10.1007/978-3-319-51133-7_90

Lu Y, Ju F (2017) Smart manufacturing systems based on Cyber-Physical Manufacturing Services (CPMS). IFAC-Pap. 50:15883–15889. https://doi.org/10.1016/j.ifacol.2017.08.2349

Tao F, Qi Q (2019) New IT Driven Service-Oriented Smart Manufacturing: Framework and Characteristics. IEEE Trans Syst Man Cybern Syst Hum 49:81–91. https://doi.org/10.1109/TSMC.2017.2723764

Quintanilla FG, Cardin O, L’Anton A, Castagna P (2016) Implementation framework for cloud-based holonic control of cyber-physical production systems. In: 2016 IEEE 14th Int. Conf. Ind. Inform. INDIN, IEEE, Poitiers, pp 316–321. https://doi.org/10.1109/INDIN.2016.7819179

Zhang L (2018) Modeling smart cyber physical systems based on Modelicaml. In: 2018 IEEE SmartWorld Ubiquitous Intell. Comput. Adv. Trust. Comput. Scalable Comput. Commun. Cloud Big Data Comput. Internet People Smart City Innov. SmartWorldSCALCOMUICATCCBDComIOPSCI, IEEE, Guangzhou, pp 1–8. https://doi.org/10.1109/SmartWorld.2018.00037

Kannengiesser U, Muller H (2018) Multi-level, viewpoint-oriented engineering of cyber-physical production systems: an approach based on Industry 4.0, system architecture and semantic web standards. In: 2018 44th Euromicro Conf. Softw. Eng. Adv. Appl. SEAA, IEEE, Prague, pp 331–334. https://doi.org/10.1109/SEAA.2018.00061

Choi S, Kang G (2018) Towards development of cyber-physical systems based on integration of heterogeneous technologies. Int J Comput Appl Technol 58:129–136

Contreras JD, Garcia JI, Diaz JD (2017) Developing of Industry 4.0 applications. Int J Online Eng: IJOE 13:30–47. https://doi.org/10.3991/ijoe.v13i10.7331

Pisching MA, Pessoa MAO, Junqueira F, Miyagi PE (2018) PFS/PN technique to model Industry 4.0 systems based on RAMI 4.0. In: 2018 IEEE 23rd Int. Conf. Emerg. Technol. Fact. Autom. ETFA, IEEE, Turin, pp 1153–1156. https://doi.org/10.1109/ETFA.2018.8502573

Yli-Ojanperä M, Sierla S, Papakonstantinou N, Vyatkin V (2019) Adapting an agile manufacturing concept to the reference architecture model industry 4.0: A survey and case study. J Ind Inf Integr 15:147–160. https://doi.org/10.1016/j.jii.2018.12.002

Suri K, Cadavid J, Alferez M, Dhouib S, Tucci-Piergiovanni S (2017) Modeling business motivation and underlying processes for RAMI 4.0-aligned cyber-physical production systems. In: 2017 22nd IEEE Int. Conf. Emerg. Technol. Fact. Autom. ETFA, IEEE, Limassol, pp 1–6. https://doi.org/10.1109/ETFA.2017.8247702

Neubauer M, Krenn F, Majoe D, Stary C (2017) Subject-orientation as design language for integration across organisational control layers. Int J Prod Res 55:3644–3656. https://doi.org/10.1080/00207543.2016.1198058

Rudtsch V, Gausemeier J, Gesing J, Mittag T, Peter S (2014) Pattern-based business model development for cyber-physical production systems. Procedia CIRP 25:313–319. https://doi.org/10.1016/j.procir.2014.10.044

Neghina M, Zamfirescu C-B, Larsen PG, Lausdahl K, Pierce K (2018) Multi-paradigm discrete-event modelling and co-simulation of cyber-physical systems. Stud Inform Control 27. https://doi.org/10.24846/v27i1y201804

Havard V, Jeanne B, Lacomblez M, Baudry D (2019) Digital twin and virtual reality: a co-simulation environment for design and assessment of industrial workstations. Prod Manuf Res 7:472–489. https://doi.org/10.1080/21693277.2019.1660283

Novák P, Kadera P, Wimmer M (2017) Agent-based modeling and simulation of hybrid cyber-physical systems. In: IEEE, pp 1–8. https://doi.org/10.1109/CYBConf.2017.7985755

Liu Q, Chen J, Liao Y, Mueller E, Jentsch D, Boerner F, She M (2015) An application of horizontal and vertical integration in cyber-physical production systems. In: IEEE. IEEE, pp 110–113. https://doi.org/10.1109/CyberC.2015.22

Ding K, Jiang P-Y (2017) Social sensors (s2ensors): a kind of hardware-software-integrated mediators for social manufacturing systems under mass individualization. Chin J Mech Eng 30:1150–1161. https://doi.org/10.1007/s10033-017-0167-4

Suri K, Cuccuru A, Cadavid J, Gerard S, Gaaloul W, Tata S (2017) Model-based development of modular complex systems for accomplishing system integration for industry 4.0. In: Proc. 5th Int. Conf. Model-Driven Eng. Softw. Dev. SCITEPRESS - Science and Technology Publications, Porto, pp 487–495. https://doi.org/10.5220/0006210504870495

Vargas Martínez C, Vogel-Heuser B (2018) Towards industrial intrusion prevention systems: a concept and implementation for reactive protection. Appl Sci 8:2460. https://doi.org/10.3390/app8122460

Etz D, Fruhwirth T, Ismail A, Kastner W (2018) Simplifying functional safety communication in modular, heterogeneous production lines. In: 2018 14th IEEE Int. Workshop Fact. Commun. Syst. WFCS. IEEE, Imperia, pp 1–4. https://doi.org/10.1109/WFCS.2018.8402371

Yin S, Bao J, Zhang Y, Huang X (2017) M2M security technology of CPS based on blockchains. Symmetry. 9:193. https://doi.org/10.3390/sym9090193

Toublanc T, Guillet S, de Lamotte F, Berruet P, Lapotre V (2017) Using a virtual plant to support the development of intelligent gateway for sensors/actuators security. IFAC-Pap. 50:5837–5842. https://doi.org/10.1016/j.ifacol.2017.08.541

Hoffmann M, Meisen T, Jeschke S (2017) OPC UA based ERP agents: enabling scalable communication solutions in heterogeneous automation environments. In: Demazeau Y, Davidsson P, Bajo J, Vale Z (eds) Adv. Pract. Appl. Cyber-Phys. Multi-Agent Syst. PAAMS Collect. Springer International Publishing, Cham, pp 120–131. https://doi.org/10.1007/978-3-319-59930-4_10

Nguyen N-T, Leu MC, Liu XF (2017) Real-time communication for manufacturing cyber-physical systems. In: 2017 IEEE 16th Int. Symp. Netw. Comput. Appl. NCA. IEEE, Cambridge, pp 1–4. https://doi.org/10.1109/NCA.2017.8171361

Sonawala NM, Tank B, Patel H (2017) IoT protocol based environmental data monitoring. In: 2017 Int. Conf. Comput. Methodol. Commun. ICCMC. IEEE, Erode, pp 1041–1045. https://doi.org/10.1109/ICCMC.2017.8282629

Heynicke R, Krush D, Cammin C, Scholl G, Kaercher B, Ritter J, Gaggero P, Rentschler M (2018) IO-Link wireless enhanced factory automation communication for Industry 4.0 applications. J Sens Sens Syst 7:131–142. https://doi.org/10.5194/jsss-7-131-2018

Berardinelli L, Maetzler E, Mayerhofen T, Wimmer M (2016) Integrating performance modeling in industrial automation through automationML and PMIF. In: 2016 IEEE 14th Int. Conf. Ind. Inform. INDIN, IEEE, Poitiers, pp 383–388. https://doi.org/10.1109/INDIN.2016.7819190

Willner A, Diedrich C, Ben Younes R, Hohmann S, Kraft A (2017) Semantic communication between components for smart factories based on oneM2M. In: 2017 22nd IEEE Int. Conf. Emerg. Technol. Fact. Autom. ETFA. IEEE, Limassol, pp 1–8. https://doi.org/10.1109/ETFA.2017.8247690

Kim D-Y, Kim S, Hassan H, Park JH (2017) Radio resource management for data transmission in low power wide area networks integrated with large scale cyber physical systems. Clust Comput 20:1831–1842. https://doi.org/10.1007/s10586-017-0841-4

Zarte M, Pechmann A, Wermann J, Gosewehr F, Colombo AW (2016) Building an Industry 4.0-compliant lab environment to demonstrate connectivity between shop floor and IT levels of an enterprise. In: IECON 2016 - 42nd Annu. Conf. IEEE Ind. Electron. Soc. IEEE, Florence, pp 6590–6595. https://doi.org/10.1109/IECON.2016.7792956

Urbina M, Astarloa A, Lazaro J, Bidarte U, Villalta I, Rodriguez M (2017) Cyber-physical production system gateway based on a programmable SoC platform. IEEE Access 5:20408–20417. https://doi.org/10.1109/ACCESS.2017.2757048

Marini A, Bianchini D (2016) Big data as a service for monitoring cyber-physical production systems. In: Claus T, Herrmann F, Manitz M, Rose O (eds) ECMS 2016 Proc. ECMS, pp 579–586. https://doi.org/10.7148/2016-0579

Silva R, Reis J, Neto L, Goncalves G (2017) Universal parser for wireless sensor networks in industrial cyber physical production systems. In: 2017 IEEE 15th Int. Conf. Ind. Inform. INDIN, IEEE, Emden, pp 633–638. https://doi.org/10.1109/INDIN.2017.8104845

Dai W, Zhang Z, Wang P, Vyatkin V, Christensen JH (2017) Service-oriented data acquisition and management for industrial cyber-physical systems. In: 2017 IEEE 15th Int. Conf. Ind. Inform. INDIN, pp 759–764. https://doi.org/10.1109/INDIN.2017.8104867

Ding K, Jiang P, Su S (2018) RFID-enabled social manufacturing system for inter-enterprise monitoring and dispatching of integrated production and transportation tasks. Robot Comput Integr Manuf 49:120–133. https://doi.org/10.1016/j.rcim.2017.06.009

Deng C, Guo R, Liu C, Zhong RY, Xu X (2018) Data cleansing for energy-saving: a case of cyber-physical machine tools health monitoring system. Int J Prod Res 56:1000–1015. https://doi.org/10.1080/00207543.2017.1394596

Xu X, Hua Q (2017) Industrial big data analysis in smart factory: current status and research strategies. IEEE Access 5:17543–17551. https://doi.org/10.1109/ACCESS.2017.2741105

Wiemer H, Drowatzky L, Ihlenfeldt S (2019) Data mining methodology for engineering applications (DMME)—a holistic extension to the CRISP-DM model. Appl Sci 9. https://doi.org/10.3390/app9122407

Xu LD, Duan L (2019) Big data for cyber physical systems in industry 4.0: a survey. Enterp Inf Syst 13:148–169. https://doi.org/10.1080/17517575.2018.1442934

Tao F, Qi Q, Liu A, Kusiak A (2018) Data-driven smart manufacturing. Spec Issue Smart Manuf 48:157–169. https://doi.org/10.1016/j.jmsy.2018.01.006

Wan J, Tang S, Li D, Wang S, Liu C, Abbas H, Vasilakos AV (2017) A manufacturing big data solution for active preventive maintenance. IEEE Trans Ind Inf 13:2039–2047. https://doi.org/10.1109/TII.2017.2670505

Niggemann O, Frey C (2015) Data-driven anomaly detection in cyber-physical production systems. Autom 63:821–832. https://doi.org/10.1515/auto-2015-0060

Kißkalt D, Fleischmann H, Kreitlein S, Knott M, Franke J (2018) A novel approach for data-driven process and condition monitoring systems on the example of mill-turn centers. Prod Eng 12:525–533. https://doi.org/10.1007/s11740-018-0797-0

Lee J, Noh S, Kim H-J, Kang Y-S (2018) Implementation of cyber-physical production systems for quality prediction and operation control in metal casting. Sensors. 18:1428. https://doi.org/10.3390/s18051428

Freitag M, Becker T, Duffie NA (2015) Dynamics of resource sharing in production networks. CIRP Ann 64:435–438. https://doi.org/10.1016/j.cirp.2015.04.124

Jiang Z, Jin Y, Mingcheng E, Li Q (2018) Method of tasks and resources matching and analysis for cyber-physical production system. Adv Mech Eng 10:168781401877782. https://doi.org/10.1177/1687814018777828

Wan J, Chen B, Imran M, Tao F, Li D, Liu C, Ahmad S (2018) Toward dynamic resources management for IoT-based manufacturing. IEEE Commun Mag 56:52–59. https://doi.org/10.1109/MCOM.2018.1700629

Mladineo M, Celar S, Celent L, Crnjac M (2018) Selecting manufacturing partners in push and pull-type smart collaborative networks. Adv Eng Inform 38:291–305. https://doi.org/10.1016/j.aei.2018.08.001

Haubeck C, Pokahr A, Lamersdorf W, Chakraborty A, Ladiges J, Fay A (2017) Evolution of cyber-physical production systems supported by community-enabled experiences. In: 2017 IEEE 15th Int. Conf. Ind. Inform. INDIN, IEEE, Emden, pp 867–874. https://doi.org/10.1109/INDIN.2017.8104886

Sandor H, Genge B, Haller P, Duka A-V, Crainicu B (2017) Cross-layer anomaly detection in industrial cyber-physical systems. In: 2017 25th Int. Conf. Softw. Telecommun. Comput. Netw. SoftCOM. IEEE, Split, pp 1–5. https://doi.org/10.23919/SOFTCOM.2017.8115523

Khalid A, Kirisci P, Khan ZH, Ghrairi Z, Thoben K-D, Pannek J (2018) Security framework for industrial collaborative robotic cyber-physical systems. Comput Ind 97:132–145. https://doi.org/10.1016/j.compind.2018.02.009

Qi Q, Zhao D, Liao TW, Tao F (2018) Modeling of cyber-physical systems and digital twin based on edge computing, fog computing and cloud computing towards smart manufacturing. In: MSEC2018, vol 1. Additive Manufacturing; Bio and Sustainable Manufacturing. https://doi.org/10.1115/MSEC2018-6435

Konstantinov S, Ahmad M, Ananthanarayan K, Harrison R (2017) The cyber-physical e-machine manufacturing system: virtual engineering for complete lifecycle support. In: Manuf. Syst. 40 – Proc. 50th CIRP Conf. Manuf. Syst, vol 63, pp 119–124. https://doi.org/10.1016/j.procir.2017.02.035

Uhlemann TH-J, Lehmann C, Steinhilper R (2017) The digital twin: realizing the cyber-physical production system for industry 4.0. Procedia CIRP 61:335–340. https://doi.org/10.1016/j.procir.2016.11.152

Lu Y, Xu X (2018) Resource virtualization: a core technology for developing cyber-physical production systems. J Manuf Syst 47:128–140. https://doi.org/10.1016/j.jmsy.2018.05.003

Damjanovic-Behrendt V, Behrendt W (2019) An open source approach to the design and implementation of Digital Twins for Smart Manufacturing. Int J Comput Integr Manuf 32:366–384. https://doi.org/10.1080/0951192X.2019.1599436

Ding K, Chan FTS, Zhang X, Zhou G, Zhang F (2019) Defining a digital twin-based cyber-physical production system for autonomous manufacturing in smart shop floors. Int J Prod Res 57:6315–6334. https://doi.org/10.1080/00207543.2019.1566661

Uhlemann TH-J, Schock C, Lehmann C, Freiberger S, Steinhilper R (2017) The digital twin: demonstrating the potential of real time data acquisition in production systems. Procedia Manuf 9:113–120. https://doi.org/10.1016/j.promfg.2017.04.043

Tao F, Cheng J, Qi Q, Zhang M, Zhang H, Sui F (2018) Digital twin-driven product design, manufacturing and service with big data. Int J Adv Manuf Technol 94:3563–3576. https://doi.org/10.1007/s00170-017-0233-1

Liu Q, Zhang H, Leng J, Chen X (2019) Digital twin-driven rapid individualised designing of automated flow-shop manufacturing system. Int J Prod Res 57:3903–3919. https://doi.org/10.1080/00207543.2018.1471243

Kück M, Ehm J, Hildebrandt T, Freitag M, Frazzon EM (2016) Potential of data-driven simulation-based optimization for adaptive scheduling and control of dynamic manufacturing systems. In: 2016 Winter Simul. Conf. WSC, pp 2820–2831. https://doi.org/10.1109/WSC.2016.7822318

Graessler I, Poehler A (2017) Integration of a digital twin as human representation in a scheduling procedure of a cyber-physical production system. In: IEEE, pp 289–293. https://doi.org/10.1109/IEEM.2017.8289898

Wang J, Ye L, Gao RX, Li C, Zhang L (2019) Digital Twin for rotating machinery fault diagnosis in smart manufacturing. Int J Prod Res 57:3920–3934. https://doi.org/10.1080/00207543.2018.1552032

Zhuang C, Liu J, Xiong H (2018) Digital twin-based smart production management and control framework for the complex product assembly shop-floor. Int J Adv Manuf Technol 96:1149–1163. https://doi.org/10.1007/s00170-018-1617-6

Zinnikus I, Antakli A, Kapahnke P, Klusch M, Krauss C, Nonnengart A, Slusallek P (2017) Integrated semantic fault analysis and worker support for cyber-physical production systems. In: IEEE, pp 207–216. https://doi.org/10.1109/CBI.2017.54

Fischer J, Pantforder D, Vogel-Heuser B (2017) Improvement of maintenance through speech interaction in cyber-physical production systems. In: 2017 IEEE 15th Int. Conf. Ind. Inform. INDIN, IEEE, Emden, pp 290–295. https://doi.org/10.1109/INDIN.2017.8104787

Constantinescu CL, Francalanza E, Matarazzo D (2015) Towards knowledge capturing and innovative human-system interface in an open-source factory modelling and simulation environment, 9th CIRP Conf. Intell Comput Manuf Eng - CIRP ICME 14(33):23–28. https://doi.org/10.1016/j.procir.2015.06.006

Hoos E, Hirmer P, Mitschang B (2017) Context-aware decision information packages: an approach to human-centric smart factories. In: Kirikova M, Nørvåg K, Papadopoulos GA (eds) Adv. Databases Inf. Syst. Springer International Publishing, Cham, pp 42–56. https://doi.org/10.1007/978-3-319-66917-5_4

Rahm J, Graube M, Muller R, Klaeger T, Schegner L, Schult A, Bonse R, Carsch S, Oehm L, Urbas L (2018) Kommdia: dialogue-driven assistance system for fault diagnosis and correction in cyber-physical production systems. In: 2018 IEEE 23rd Int. Conf. Emerg. Technol. Fact. Autom. ETFA. IEEE, Turin, pp 999–1006. https://doi.org/10.1109/ETFA.2018.8502615

Galaske N, Anderl R (2016) Disruption management for resilient processes in cyber-physical production systems. Procedia CIRP 50:442–447. https://doi.org/10.1016/j.procir.2016.04.144

Grundstein S, Freitag M, Scholz-Reiter B (2017) A new method for autonomous control of complex job shops – Integrating order release, sequencing and capacity control to meet due dates. J Manuf Syst 42:11–28. https://doi.org/10.1016/j.jmsy.2016.10.006

Scholze S, Barata J (2016) Context awareness for flexible manufacturing systems using cyber physical approaches. In: Camarinha-Matos LM, Falcão AJ, Vafaei N, Najdi S (eds) Technol. Innov. Cyber-Phys. Syst. Springer International Publishing, Cham, pp 107–115. https://doi.org/10.1007/978-3-319-31165-4_11

Weidmann D, Kattner N, Hollauer C, Becerril L, Chucholowski N, Lindemann U (2016) Methods collection to support requirements engineering with focus on structuring and consolidation of requirements. In: 2016 IEEE Int. Conf. Ind. Eng. Eng. Manag. IEEM, IEEE, Bali, pp 1215–1219. https://doi.org/10.1109/IEEM.2016.7798071

Fritz S, Weber F, Ovtcharova J (2019) A guideline for the requirements engineering process of SMEs regarding to the development of CPS. In: 2019 8th Int. Conf. Ind. Technol. Manag. ICITM. IEEE, Cambridge, pp 85–94. https://doi.org/10.1109/ICITM.2019.8710732

Wiesner S, Gorldt C, Soeken M, Thoben K-D, Drechsler R (2014) Requirements engineering for cyber-physical systems: challenges in the context of “Industrie 4.0,”. In: Bayro-Corrochano E, Hancock E (eds) Prog. Pattern Recognit. Image Anal. Comput. Vis. Appl. Springer International Publishing, Cham, pp 281–288. https://doi.org/10.1007/978-3-662-44739-0_35

Borgne AL, Belloir N, Bruel J-M, Nguyen T (2016) Formal requirements engineering for smart industries: toward a model-based graphical language. In: 2016 Intl IEEE Conf. Ubiquitous Intell. Comput. Adv. Trust. Comput. Scalable Comput. Commun. Cloud Big Data Comput. Internet People Smart World Congr. UICATCScalComCBDComIoPSmartWorld, IEEE, Toulouse, pp 1028–1032. https://doi.org/10.1109/UIC-ATC-ScalCom-CBDCom-IoP-SmartWorld.2016.0160

Funding

The paper of the first author is financially supported by China Scholarship Council under Grant 201706020154.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, X., Goepp, V. & Siadat, A. Concept and engineering development of cyber physical production systems: a systematic literature review. Int J Adv Manuf Technol 111, 243–261 (2020). https://doi.org/10.1007/s00170-020-06110-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06110-2