Abstract

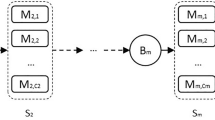

For maintenance of gas turbines (GTs) in oil and gas applications, capital parts are removed and replaced by parts of the same type taken from the warehouse. When the removed parts are found not broken, they are repaired at the workshop and returned to the warehouse, ready to be used in future maintenance. The management of this flow is of great importance for the profitability of a GT plant. In this paper, we adopt a previously developed formalized framework of the part flow and reinforcement learning (RL) to optimize part flow management. The formal framework and RL algorithm are extended to account for the stochastic failure process of the involved parts. An application to a scaled-down case study derived from an industrial application is illustrated.

Similar content being viewed by others

References

Yang K, He C, Huang Q, Huang ZY, Wang C, Wang Q, Liu YJ, Zhong B (2016) Very high cycle fatigue behaviors of a turbine engine blade alloy at various stress ratios. International Journal of Fatigue

Morini M, Pinelli M, Spina PR, Venturini M (2010) Influence of blade deterioration on compressor and turbine performance. J Eng Gas Turb Power 132:3

Boyce BL, Ritchie RO (2001) Effect of load ratio and maximum stress intensity on the fatigue threshold in Ti–6Al–4V. Eng Fract Mech 68(2):129–147

Bodrov AI, Stalder JP (1998) An analysis of axial compressor fouling and a blade cleaning method. J Turbomach 120:256–61

Kurz R, Brun K (2012) Fouling mechanisms in axial compressors. J Eng Gas Turb Power 134:3

Peters JO, Ritchie RO (2000) Influence of foreign-object damage on crack initiation and early crack growth during high-cycle fatigue of Ti–6Al–4V. Eng Fract Mech 67(3):193–207

Eliaz N, Shemesh G, Latanision RM (2002) Hot corrosion in gas turbine components. J Eng Gas Turb Power 9(1):31–43

Goward GW (1998) Progress in coatings for gas turbine airfoils. Surf Coat Technol 108:73–79

Compare M, Martini F, Mattafirri S, Carlevaro F, Zio E (2016) Semi-Markov model for the oxidation degradation mechanism in gas turbine nozzles. IEEE Trans Reliab 65(2):574–581

Ng I, Parry G, Wild P, McFarlane D, Tasker P (2011) Complex engineering service systems: concepts and research. Springer, London

Wang W (2010) A model for maintenance service contract design, negotiation and optimization. Eur J Oper Res 201:239–246

Murthy DNP, Asgharizadeh E (1999) Optimal decision making in a maintenance service operation. Eur J Oper Res 116:259–273

Godoy DR, Pascual R, Knights P (2014) A decision-making framework to integrate maintenance contract conditions with critical spares management. Reliab Eng Syst Safety 131:102–108

Jin T, Tian Z, Xie M (2015) A game-theoretical approach for optimizing maintenance, spares and service capacity in performance contracting. Int J Prod Econ 161:31–43

Jackson C, Pascual R, Knights P (2008) Optimal maintenance service contract negotiation with ageing equipment. Eur J Oper Res 189(2):387–398

Bollapragada S, Gupta A, Lawsirirat C (2007) Managing a portfolio of long term service agreements. Eur J Oper Res 182:1399–1411

Hu Q, Boylan JE, Chen H, Labib A (2018) in spare parts management: a review. Eur J Oper Res 266:395–414

Sutton R, Barto A (1998) Introduction to reinforcement learning, vol 135. MIT Press, Cambridge

Lieckens KT, Colen PJ, Lambrecht MR (2015) Network and contract optimization for maintenance services with remanufacturing. Comput Oper Res 54:232–244

Kurz J (2016) Capacity planning for a maintenance service provider with advanced information. Eur J Oper Res 251:466–477

Olde Keizer MCA, Teunter RH, Veldman J (2017) Joint condition-based maintenance and inventory optimization for systems with multiple components. Eur J Oper Res 257:209–222

Van Horenbeek A, Buré J, Cattrysse D, Pintelon L, Vansteenwegen P (2013) Joint maintenance and inventory optimization systems: a review. Int J Prod Econ 143:499–508

Jaturonnatee J, Murthy DNP, Boondiskulchok R (2006) Optimal preventive maintenance of leased equipment with corrective minimal repairs. Eur J Oper Res 174:201–215

Zanjani MK, Nourelfath M (2014) Integrated spare parts logistics and operations planning for maintenance service providers. Int J Prod Econ 158:44–53

Compare M, Bellani L, Cobelli E, Zio E, Annunziata F, Sepe M, Carlevaro F A Reinforcement Learning approach to optimal part flow management for gas turbine maintenance, submitted for publication to European Journal of Operational Research

Kaelbling LP, Littman ML, Moore AW (1996) Reinforcement learning: a survey. J Artif Intell Res 4:237–285

Szepesvári Cs (2010) Algorithms for reinforcement learning. Morgan and Claypool

Kuznetsova E, Li YF, Ruiz C, Zio E, Ault G, Bell K (2013) Reinforcement learning for microgrid energy management. Energy Elsevier 59:133–146

Rahimiyan M, Mashhadi HR (2010) An adaptive Q-learning algorithm developed for agent-based computational modeling of electricity market. IEEE Trans Syst Man Cybrn Part C, Appl Rev 40(5):547

Barde S, Yacout S, Shin H (2016) Optimal preventive maintenance policy based on reinforcement learning of a fleet of military trucks. J Intell Manuf, 1–15

Aissani N, Beldjilali B, Trentesaux D (2009) Dynamic scheduling of maintenance tasks in the petroleum industry: a reinforcement approach. Eng Appl Artif Intell 22(7):1089–1103

Pontrandolfo P, Gosavi A, Okogbaa OG, Das T (2002) Global supply chain management: a reinforcement learning approach. Int J Prod Res 40(6):1299–1317

Giannoccaro I, Pontrandolfo P (2002) Inventory management in supply chains: a reinforcement learning approach. Int J Prod Econ 78(2):153–161

Kim CO, Jun J, Baek JK, Smith RL, Kim YD (2005) Adaptive inventory control models for supply chain management. Int J Adv Manuf Technol 26(9–10):1184–1192

Ehleiter A, Jaehn F (2016) Housekeeping: foresightful container repositioning. Int J Prod Econ 179:203–211

Kim KH, Lee KM, Hwang H (2003) Receiving operations for yard cranes in port container terminals sequencing delivery. Int J Prod Econ 84:283–292

Zio E (2007) An introduction to the basics of reliability and risk analysis, vol 13. World Scientific

Wang YH, Li TH, Lin CJ (2013) Backward Q-learning: the combination of Sarsa algorithm and Q-learning. Eng Appl Artif Intel 26:2184–2193

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Compare, M., Bellani, L., Cobelli, E. et al. Reinforcement learning-based flow management of gas turbine parts under stochastic failures. Int J Adv Manuf Technol 99, 2981–2992 (2018). https://doi.org/10.1007/s00170-018-2690-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2690-6