Abstract

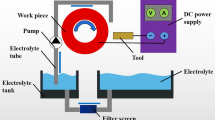

Electrochemical machining (ECM) has a strong advantage in dealing with difficult-to-machine materials and complex shaped parts. In order to improve machining accuracy, some researchers, based on the principle of interactions between the magnetic field and electric field, proposed the magnetic field-assisted ECM technology that is advantageous in improving surface roughness and facilitating material removal amount. Pitifully, little attention has been attached to effects of the coupled magnetic field, electric field, and electrolyte motion on the amount of materials removed. This paper aims to find out how arrangements of magnetic fields and coupled of the three energy (which were magnetic field, electric field, and electrolyte motion) will work on the amount of material removed in ECM. Here established a Navier-Stokes equation and a model of material removal amount in the anode under the electromagnetic field. Physical and mathematical models of the electrolyte’s flow characteristics and material removal amount were constructed through the COMSOL Multiphysics software, and simulations were carried out. An experiment was implemented to test models and the simulations. Simulation results indicated that different arrangements of the magnetic field had delivered different impacts on flow characteristics of the flow field and material removal amount. Experiment results revealed that the material removal amount had increased regardless of arrangements of magnetic fields and that the flow rate of the electrolyte had played a role in this connection. The study involved in this paper showed that the introduction of the magnetic field worked favorably to lift the material removal amount and that arrangements of magnetic fields also had the same effect in this regard. Also, it was found that a growing flow rate of the electrolyte had hindered the increases of the material removal amount.

Similar content being viewed by others

Reference

Wang D, Zhu Z, Bao J, Zhu D (2015) Reduction of stray corrosion by using iron coating in nano3 solution during electrochemical machining. Int J Adv Manuf Technol 76(5):1365–1370

Tang L, Yang F, Zhu QL, Gan WM (2016) Electrochemical machining flow field simulation and experimental verification for irregular vortex paths of a closed integer impeller. Int J Adv Manuf Technol 83(1):275–283

Pa PS (2008) Rolling-leveling assistance in ultrasonic electrochemical finishing of external cylindrical surface. Adv Mater Res 44-46:455–462

Lai LJ, Zhou H, Du YJ, Li CX, Zhang L, Jiang LM et al (2014) Electrochemical micromachining with wet stamping: instrument design and experimental investigation. Precis Eng 38(3):569–577

Qu NS, Xu ZY (2013) Improving machining accuracy of electrochemical machining blade by optimization of cathode feeding directions. Int J Adv Manuf Technol 68(5):1565–1572

Jia JL, Fan ZJ (2011) Research on higher frequency, short pulses and assisted magnetic field electrochemical machining. Adv Mater Res 189-193:3162–3165

Yong Y, Zhang WM, Zhang ZJ, Xing J (2013) Research on technology of compound ecm with high-frequency group pulse and rotating magnetic field. Transactions of Beijing Institute of Technology 33(4):353–356 (in Chinese)

Tang L, Gan WM (2014) Experiment and simulation study on concentrated magnetic field-assisted ecm s-03 special stainless steel complex cavity. Int J Adv Manuf Technol 72(5):685–692

Pa PS (2009) Super finishing with ultrasonic and magnetic assistance in electrochemical micro-machining. Electrochim Acta 54(25):6022–6027

Fan Z, Wang T, Zhong L (2004) The mechanism of improving machining accuracy of ecm by magnetic field. J Mater Process Technol 149(1–3):409–413

Enache S, Opran C (1989) The mathematical model of the e.c.m. with magnetic field. CIRP Ann Manuf Technol 38(1):207–210

Stephenson DJ (2007) Influence of magnetic field distribution on ecm process. Key Eng Mater 339:50–58

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Long, L., Baoji, M.A., Ruifeng, W. et al. The coupled effect of magnetic field, electric field, and electrolyte motion on the material removal amount in electrochemical machining. Int J Adv Manuf Technol 91, 2995–3006 (2017). https://doi.org/10.1007/s00170-017-9983-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-9983-z