Abstract

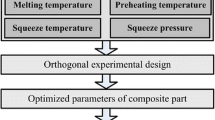

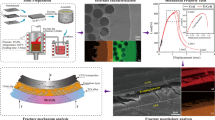

2D-Cf/Al composites were prepared by liquid extrusion infiltration under the different extrusion temperatures of 570, 585, 600, 615, and 630 °C of infiltration mold. Through the observation and analysis of the microstructure and ultimate tensile strength (UTS) of the composites, it showed that extrusion temperature had important influence on the infiltration effect and tensile property of 2D-Cf/Al composites. When the extrusion temperatures were 570 and 585 °C, very few aluminum alloy liquid was filled into the carbon fiber preform, and the UTS(s) of composites was low. When the temperature reached 600 °C, infiltration effect and UTS had been improved. With the increase of extrusion temperature at 615 °C, the infiltration of aluminum alloy liquid was sufficient, the distribution of carbon fibers was uniform, and defects of casting holes and fiber damage could not be found. UTS had been improved 115.8% more than that of the matrix. However, when extrusion temperature reached 630 °C, infiltration of the alloy was sufficient, but there was fiber damage, which would reduce the UTS of the composites. The increased proportion of UTS was only 21.7%, and this was not satisfied. Through comparison and analysis, 615 °C was a better extrusion temperature than others, and infiltration effect and UTS were more satisfied. It was adverse for preparing ideal 2D-Cf/Al composite to have too low and too high extrusion temperatures.

Similar content being viewed by others

References

Daoud A (2005) Microstructure and tensile properties of 2014 Al alloy reinforced with continuous carbon fibers manufactured by gas pressure infiltration. Mater Sci Eng A 391:114–120

Zhang Y, Wu G (2006) Microstructure and mechanical properties of 2D Gr/Al composite. Trans Nonferrous Metals Soc China 16:1509–1512

Yang QR, Liu JX, Li SK, Wang FC, Wu TT (2014) Fabrication and mechanical properties of Cu-coated woven carbon fibers reinforced aluminum alloy composite. Mater Des 57:442–448

Song M, Song J, Chen G, Wang N, Wu G (2009) Dimensional stability of 2D Cf/Mg-2.0Re-0.2Zr composites. Acta Metall Sin 45(1):119–123

Wei X, Qi L, Ju L, Tian W, Hou X, Li H (2016) Effect of holding pressure on densification and mechanical properties of Cf/Mg composites. Mater Sci Tech-lond 33(5):629–634

Qi LH, Ma YQ, Zhou JM, Hou XH, Li HJ (2015) Effect of fiber orientation on mechanical properties of 2D-Cf/Al composites by liquid–solid extrusion following vacuum infiltration technique. Mater Sci Eng A 625:343–349

Ma YQ, Qi LH, Zhang T, Zhou JM, Yao GZ (2017) Study on defects of 2D-Cf/Al composite prepared by liquid-solid extrusion following vacuum infiltration technique. Int J Adv Manuf Technol 88(1):89–96

Wang HW, Zhang GD, Wu RJ (1995) Fiber reinforced metal matrix composites liquid metal infiltration filling process. J Acta Mater Compos Sin 12:38–41

Ma YQ, Qi LH, Zheng WQ, Zhou JM, Ju LY (2013) Effect of specific pressure on fabrication of 2D-Cf/Al composite by vacuum and pressure infiltration. Trans Nonferrous Metals Soc China 23:1915–1921

Qi LH, Su LZ, Zhou JM, Guan JT, Hou XH, Li HJ (2012) Infiltration characteristics of liquid AZ91D alloy into short carbon fiber perform. J Alloy Compd 527:10–15

Hajjari E, Divandari M, Mirhabibi AR (2010) The effect of applied pressure on fracture surface and tensile properties of nickel coated continuous carbon fiber reinforced aluminum composites fabricated by squeeze casting. Mater Des 31:2381–2386

Seong HG, Lopez HF, Robertson DP, Rohatgi PK (2008) Interface structure in carbon and graphite fiber reinforced 2014 aluminum alloy processed with active fiber cooling. Mater Sci Eng A 487:201–209

Michaud VJ, Sommer JL, Mortensen A (1999) Infiltration of fibrous preforms by a pure metal: Part V. Influence of preform compressibility. Metall Mater Trans A 30(2):471–482

Ma Y, Qi L, Wei X, Zheng W (2015) Fabrication of 2D-Cf/Al composite by an extrusion directly following vacuum pressure infiltration technique and its microstructure and properties. Rare Metal Mat Eng 44(1):179–183

Ju LY, Qi LH, Wei XL, Li HJ, Zhou JM (2016) Influence of fabric architecture on compressive and failure mechanism of Cf/Mg composite fabricated by LSEVI. Mater Sci Eng A 651:127–134

Sheng LY, Yang F, Guo JT, Xi TF, Ye HQ (2013) Investigation on NiAl-TiC-Al2O3 composite prepared by self-propagation high temperature synthesis with hot extrusion. Compos Part B-Eng 45(1):785–791

Sheng LY, Yang F, Xi TF, Guo JT, Ye HQ (2012) Microstructure evolution and mechanical properties of Ni3Al/Al2O3 composite during self-propagation high-temperature synthesis and hot extrusion. Mater Sci Eng A 555:131–138

Arora HS, Singh H, Dhindaw BK (2012) Composite fabrication using friction stir processing—a review. Int J Adv Manuf Technol 61:1043–1055

Khosravi J, Givi MKB, Barmouz M, Rahi A (2014) Microstructural, mechanical, and thermophysical characterization of Cu/WC composite layers fabricated via friction stir processing. Int J Adv Manuf Technol 74:1087–1096

Xu WF, Liu JH, Chen DL, Luan GH (2014) Low-cycle fatigue of a friction stir welded 2219-T62 aluminum alloy at different welding parameters and cooling conditions. Int J Adv Manuf Technol 74(1–4):209–218

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, Y.Q., Qi, L.H. Effect of extrusion temperature on the microstructure and tensile property of 2D-Cf/Al composites by liquid extrusion infiltration. Int J Adv Manuf Technol 94, 1349–1355 (2018). https://doi.org/10.1007/s00170-017-0998-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0998-2