Abstract

The frequency domain error of the machined surface in the ultra-precision machining attracts more attention for its strong relationship with the functional requirements of the workpieces. As the key component of ultra-precision machine tool, the spindle error largely influences the machined surface errors. However, little attention has been paid to the influence of spindle error on the surface error formation mechanism in the frequency domain for ultra-precision flycutting. This paper deeply studies the influence of spindle error on the frequency domain error formation of machined surface in ultra-precision flycutting. The influence analysis of the spindle error is theoretically and experimentally carried out according to two different evaluation directions of the machined surface by flycutting, i.e., cutting direction and feed direction. The KDP crystal flycutting experiment is designed and conducted for the theoretical verification. The theoretical analysis has been found to agree well with the experimental results. This study is quite meaningful for deeply understanding the influence law of spindle error from the viewpoint of frequency domain. The research results are quite useful for the spindle error control, machined surface error prediction, machining process planning, and also show the potential use for the spindle (machine tool) design.

Similar content being viewed by others

References

Zhang SJ, To S, Zhu ZW, Zhang GQ (2016) A review of fly cutting applied to surface generation in ultra-precision machining. Int J Mach Tools Manuf 103:13–27

Liang Y, Chen W, Sun Y, Chen G, Wang T, Sun Y (2012) Dynamic design approach of an ultra-precision machine tool used for optical parts machining. Proc Inst Mech Eng B J Eng 226(11):1930–1936

Liang Y, Chen W, Bai Q, Sun Y, Chen G, Zhang Q, Sun Y (2013) Design and dynamic optimization of an ultraprecision diamond flycutting machine tool for large KDP crystal machining. Int J Adv Manuf Technol 69(1–4):237–244

Cheung CF, Lee WB (2000) A theoretical and experimental investigation of surface roughness formation in ultra-precision diamond turning. Int J Mach Tools Manuf 40(7):979–1002

Zhang SJ, To S, Zhang GQ, Zhu ZW (2015) A review of machine-tool vibration and its influence upon surface generation in ultra-precision machining. Int J Mach Tools Manuf 91:34–42

Zhou L, Cheng K (2009) Dynamic cutting process modelling and its impact on the generation of surface topography and texture in nano/micro cutting. Proc Inst Mech Eng B J Eng 223(3):247–266

Ehmann KF, Hong MS (1994) A generalized model of the surface generation process in metal cutting. CIRP Ann Manuf Technol 43(1):483–486

Luo XK, Cheng K, Luo XC, Liu XW (2005) A simulated investigation on the machining instability and dynamic surface generation. Int J Adv Manuf Technol 26(7–8):718–725

Chen G, Liang Y, Ehmann KF, Sun Y, Bai Q (2014) Fourier transform based dynamic error modeling method for ultra-precision machine tool. Proc SPIE 9281:928102

Chen G, Liang Y, Sun Y, Chen W, Wang B (2013) Volumetric error modeling and sensitivity analysis for designing a five-axis ultra-precision machine tool. Int J Adv Manuf Technol 68(9–12):2525–2534

Liang Y, Chen G, Chen W, Sun Y, Chen J (2013) Analysis of volumetric error of machine tool based on monte carlo method. J Comput Theor Nanosci 10(5):1290–1295

Liang Y, Chen W, An C, Luo X, Chen G, Zhang Q (2014) Investigation of the tool-tip vibration and its influence upon surface generation in flycutting. Proc Inst Mech Eng C J Mech 228(12):2162–2167

Chen W, Liang Y, Sun Y, An C, Chen G (2015) Investigation of the influence of constant pressure oil source fluctuations on ultra-precision machining. Proc Inst Mech Eng B J Eng 229(2):372–376

Chen W, Lu L, Yang K, Su H, Chen G (2016) An experimental and theoretical investigation into multimode machine tool vibration with surface generation in flycutting. Proc Inst Mech Eng B J Eng 230(2):381–386

Sun Y, Chen W, Liang Y, An C, Chen G, Su H (2015) An integrated method for waviness simulation on large-size surface. Proc Inst Mech Eng B J Eng 229(1):178–182

Moon KS, Sutherland JW (1994) The origin and interpretation of spatial frequencies in a turned surface profile. J Eng Ind Trans ASME 116(3):340–347

Chen G, Liang Y, Sun Y (2014) Frequency domain error analysis in turning. Int J Adv Manuf Technol 73(5–8):929–940

Hocheng H, Hsieh ML (2004) Signal analysis of surface roughness in diamond turning of lens molds. Int J Mach Tools Manuf 44(15):1607–1618

Marsh E, Arneson DA, Van Doren MJ, Blystone SA (2005) The effects of spindle dynamics on precision flycutting. The 20th annual meeting of ASPE, Norfolk, VA, USA

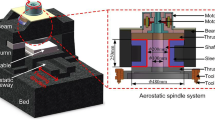

An CH, Zhang Y, Xu Q, Zhang FH, Zhang JF, Zhang LJ, Wang JH (2010) Modeling of dynamic characteristic of the aerostatic bearing spindle in an ultra-precision fly cutting machine. Int J Mach Tools Manuf 50(4):374–385

Chen D, Fan J, Zhang F (2013) Extraction the unbalance features of spindle system using wavelet transform and power spectral density. Measurement 46(3):1279–1290

Zhang SJ, To S, Cheung CF, Wang HT (2012) Dynamic characteristics of an aerostatic bearing spindle and its influence on surface topography in ultra-precision diamond turning. Int J Mach Tools Manuf 62:1–12

Zhang SJ, To S (2013) The effects of spindle vibration on surface generation in ultra-precision raster milling. Int J Mach Tools Manuf 71:52–56

Kong LB, Cheung CF, Kwok TC (2014) Theoretical and experimental analysis of the effect of error motions on surface generation in fast tool servo machining. Precis Eng 38(2):428–438

Marsh ER (2007) Precision spindle metrology. DEStech Publications, Lancaster

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, G., Sun, Y., Zhang, F. et al. Influence of ultra-precision flycutting spindle error on surface frequency domain error formation. Int J Adv Manuf Technol 88, 3233–3241 (2017). https://doi.org/10.1007/s00170-016-9024-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9024-3