Abstract

In order to achieve accurate pipe hole cutting applied to joint preparations for joining pipe with set-in branch, this paper presents a novel method of torch path planning which integrates the plasma beam radius compensation. The geometrical models of intersecting pipes and sing-V welding groove cover the most complex intersecting mode and provide adjustable groove angle configuration. They construct the foundation of the path planning method and generate the theoretical cutting line. Based on the principle of three-dimensional tool radius compensation, a plasma beam radius compensation interface is designed for dynamic compensation value, which can cope with variable plasma kerf width caused by large fluctuant bevel angle. The correlative algorithm modules are connected by homogeneous matrices, with which the torch’s position and orientation are described as well. The experiment validates the feasibility of the torch path planning method and demonstrates the corresponding accuracy improvement.

Similar content being viewed by others

References

Yin YH, Xie JY (2011) Reconfigurable manufacturing execution system for pipe cutting. Enterp Inf Syst 5(3):287–299. doi:10.1080/17517575.2011.579177

Qin YF, Xiao JL, Wang G (2011) The open architecture CNC system based on 6-axis flame pipe cutting machine. Proc 3rd Int Conf Measur Technol Mechatron Autom, ICMTMA 3:878–881. doi:10.1109/ICMTMA.2011.792

Borboni A, Bussola R, Faglia R, Magnani PL, Menegolo A (2008) Movement optimization of a redundant serial robot for high-quality pipe cutting. J Mech Des 130(8):0823011–0823016. doi:10.1115/1.2918907

BS 2971:1991 Specification for Class II arc welding of carbon steel pipework for carrying fluids

Nemchinsky VA, Severance WS (2006) What we know and what we do not know about plasma arc cutting. J Phys D Appl Phys 39(22):423–438. doi:10.1088/0022-3727/39/22/R01

Liu X, Huang S, Chen FZ, Yang XL, Wu LB, Xu WJ (2015) Research on the cold plasma jet assisted cutting of Ti6Al4V. Int J Adv Manuf Technol 77(9-12):2125–2133. doi:10.1007/s00170-014-6607-8

Maity KP, Bagal DK (2015) Effect of process parameters on cut quality of stainless steel of plasma arc cutting using hybrid approach. Int J Adv Manuf Technol 78(1-4):161–175. doi:10.1007/s00170-014-6552-6

Oysu C (2007) Automation of welding face shaping process for tubular structures. Ind Robot Int J 34(1):32–38. doi:10.1108/01439910710718423

Chen YQ, Bai X (2010) Mathematical model for NC cutting saddle type of welding groove with edge. Trans China Weld Instit 31(7):91–94

Cai J, Ding ZX, Zhang Y, Liu M (2015) Trajectory planning and simulation for intersecting line cutting of theindustry robot. Proc 11th World Congr Intell Control Autom, WCICA 2014 (3):63–68. doi:10.1109/WCICA.2014.7052688

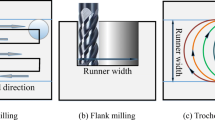

Chen YD, Wang TM (2013) Three-dimensional tool radius compensation for multi-axis peripheral milling. Chin J Mech Eng 26(3):547–554. doi:10.3901/CJME.2013.03.547

Lin PD, Liao TT (2009) An effective-wire-radius compensation scheme for enhancing the precision of wire-cut electrical discharge machines. Int J Adv Manuf Technol 40(3-4):324–331. doi:10.1007/s00170-007-1333-0

Craig JJ (2003) Introduction to Robotics: mechanics and control, 3rd edn. Prentice Hall, London

Yu JP, Shi P (2015) Observer and command-filter-based adaptive fuzzy output feedback control of uncertain nonlinear systems. IEEE Trans Ind Electron 62(9):5962–5970. doi:10.1109/TIE.2015.2418317

ISO 9692-1:2013 (2013) Welding and allied processes—types of joint preparation—part 1: manual metal arc welding, gas-shielded metal arc welding, gas welding, TIG welding and beam welding of steels

Shi L, Tian XC (2014) Automation of main pipe-rotating welding scheme for intersecting pipes. Int J Adv Manuf Technol 77(5-8):955–964. doi:10.1007/s00170-014-6526-8

Ramakrishnan S, Shrinet V, Polivka FB, Kearney TN, Koltun P (2000) Influence of gas composition on plasma arc cutting of mild steel. J Phys D Appl Phys 33 (18):2288–2299. doi:10.1088/0022-3727/33/18/313

Gonzalez-Aguilar J, Sanjurjo CP, Rodriguez-Yunta A, Calderon MAG (1999) A theoretical study of a cutting air plasma torch. IEEE Trans Plasma Sci 27(1):264–271. doi:10.1109/27.763132

ISO 9013:2002 (2002) Thermal cutting—Classification of thermal cuts—Geometrical product specification and quality tolerances

Salonitis K, Vatousianos S (2012) Experimental investigation of the plasma arc cutting process. 45th CIRP Conf Manuf Syst, CMS 3(1):287–292. doi:10.1016/j.procir.2012.07.050

Messay T, Ordonez R, Marcil E (2016) Computationally efficient and robust kinematic calibration methodologies and their application to industrial robots. Robot Comput Integr Manuf 37:33–48. 10.1016/j.rcim.2015.06.003

Hypertherm Inc (2015) Powermax65 & Powermax85 Service Manual. http://www.hypertherm.com/en/Service/Manuals/

GB/T 4380-2004 (2004) Assessment of departure from roundness—two-and three-point methods

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shi, L., Song, R. & Tian, X. Plasma beam radius compensation-integrated torch path planning for CNC pipe hole cutting with welding groove. Int J Adv Manuf Technol 88, 1971–1981 (2017). https://doi.org/10.1007/s00170-016-8915-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8915-7