Abstract

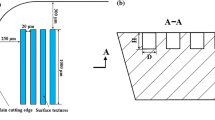

Increasing the cutting speed to an ultra-high level usually gives rise to a chip flow transition from continuously serrated to discontinuously segmented, which is one of the most fundamental and challenging problems in metal cutting. In this work, we experimentally performed the ultra-high-speed cutting on Ti-6Al-4V with a maximum cutting speed of 210 m/s, focusing on the physical phenomena accompanying the discontinuously segmented chip flow. It reveals that the discontinuously segmented chip flow can be attributed to the shear fracture induced by the fully matured shear banding, and there exists a ductile-brittle transition of the shear fracture as the cutting speed increases to an ultra-high level. In addition, the critical condition for the onset of segmented chip flow is presented using the momentum diffusion-based shear band evolution model, which gives good prediction for the chip segmentation.

Similar content being viewed by others

References

Salomon CJ (1931) Process for the machining of metals or similarly acting materials when being worked by cutting tools. German Patent, Number 523594, 1931–04

Xu D, Feng P, Li W, Ma Y, Liu B (2014) Research on chip formation parameters of aluminum alloy 6061-T6 based on high-speed orthogonal cutting model. Int J Adv Manuf Technol 72:955–962

Ma J, Wang F, Jia Z, Xu Q, Yang Y (2014) Study of machining parameter optimization in high speed milling of Inconel 718 curved surface based on cutting force. Int J Adv Manuf Technol 75:269–277

Barry J, Byrne G (2002) The mechanisms of chip formation in machining hardened steels. J Manuf Sci Eng 124:528–535

Jiang MQ, Dai LH (2009) Formation mechanism of lamellar chips during machining of bulk metallic glass. Acta Mater 57:2730–2738

Shaw MC, Vyas A (1993) Chip formation in the machining of hardened steel. CIRP Ann Manuf Technol 42:29–33

Pu CL, Zhu G, Yang S, Yue EB, Subramanian SV (2015) Effect of microstructure softening events on the chip morphology of AISI 1045 steel during high speed machining. Int J Adv Manuf Tech

Kountanya R, Al-Zkeri I, Altan T (2009) Effect of tool edge geometry and cutting conditions on experimental and simulated chip morphology in orthogonal hard turning of 100Cr6 steel. J Mater Process Technol 209:5068–5076

Wang H, To S, Chan CY, Cheung CF, Lee WB (2010) A study of regularly spaced shear bands and morphology of serrated chip formation in microcutting process. Scr Mater 63:227–230

Wang H, To S, Chan CY, Cheung CF, Lee WB (2010) Elastic strain induced shear bands in the microcutting process. Int J Mach Tool Manuf 50:9–18

Wang H, To S, Chan CY, Cheung CF, Lee WB (2011) Dynamic modelling of shear band formation and tool-tip vibration in ultra-precision diamond turning. Int J Mach Tool Manuf 51:512–519

Molinari A, Musqua C, Sutter G (2002) Adiabatic shear banding in high speed machining of Ti-6Al-4V: experiments and modeling. Int J Plast 18:443–459

Duan CZ, Zhang LC (2012) Adiabatic shear banding in AISI 1045 steel during high speed machining: mechanisms of microstructural evolution. Mater Sci Eng A 532:111–119

Cai SL, Dai LH (2014) Suppression of repeated adiabatic shear banding by dynamic large strain extrusion machining. J Mech Phys Solids 73:84–102

Wan L, Wang D, Gao Y (2015) The investigation of mechanism of serrated chip formation under different cutting speeds. Int J Adv Manuf Tech

Recht RF (1964) Catastrophic thermoplastic shear. J Appl Mech 189–193

Hou ZB, Komanduri R (1997) Modeling of thermomechanical shear instability in machining. Int J Mech Sci 39:1279–1314

Molinari A, Dudzinski D (1992) Stationary shear band in high-speed machining. CR Acad Sci Paris 315:399–405

Huang J, Aifantis EC (1997) A note on the problem of shear localization during chip formation in orthogonal machining. J Mater Eng Perform 6:25–26

Huang J, Kalaitzidou K, Sutherland JW, Aifantis EC (2007) Validation of a predictive model for adiabatic shear band formation in chips produced via orthogonal machining. J Mech Behav Mater 18:243–263

Ye GG, Chen Y, Xue SF, Dai LH (2014) Critical cutting speed for onset of serrated chip flow in high speed machining. Int J Mach Tool Manuf 86:18–33

Duan C, Zhang L (2012) A reliable method for predicting serrated chip formation in high-speed cutting: analysis and experimental verification. Int J Adv Manuf Technol 64:1587–1597

Gao C, Zhang L (2013) Effect of cutting conditions on the serrated chip formation in high-speed cutting. Mach Sci Technol 17:26–40

Sowerby R, Chandrasekaran N (1989) A proposal for the onset of chip segmentation in machining. Mater Sci Eng A 119:219–229

Marusich T, Ortiz M (1995) Modelling and simulation of high-speed machining. Int J Numer Methods Eng 38:3678–3694

Lin ZC, Lo SP (2001) 2-D discontinuous chip cutting model by using strain energy density theory and elastic-plastic finite element method. Int J Mech Sci 43:381–398

Lin ZC, Lin YY (2001) Three-dimensional elastic-plastic finite analysis for orthogonal cutting with discontinuous chip of 6-4 brass. Theor Appl Fract Mech 35:137–153

Guo YB, Yen DW (2004) A FEM study on mechanisms of discontinuous chip formation in hard machining. J Mater Process Technol 155–156:1350–1356

Liu Z, Su G (2012) Characteristics of chip evolution with elevating cutting speed from low to very high. Int J Mach Tool Manuf 54–55:82–85

Sutter G, List G (2013) Very high speed cutting of Ti–6Al–4V titanium alloy—change in morphology and mechanism of chip formation. Int J Mach Tool Manuf 66:37–43

Gu L, Wang M, Duan C (2013) On adiabatic shear localized fracture during serrated chip evolution in high speed machining of hardened AISI 1045 steel. Int J Mech Sci 75:288–298

Cui X, Zhao B, Jiao F, Zheng J (2015) Chip formation and its effects on cutting force, tool temperature, tool stress, and cutting edge wear in high- and ultra-high-speed milling. Int J Adv Manuf Tech

Ye GG, Xue SF, Ma W, Jiang MQ, Ling Z, Tong XH, Dai LH (2012) Cutting AISI 1045 steel at very high speeds. Int J Mach Tool Manuf 56:1–9

Li A, Zhao J, Zhou Y, Chen X, Wang D (2011) Experimental investigation on chip morphologies in high-speed dry milling of titanium alloy Ti-6Al-4V. Int J Adv Manuf Technol 62:933–942

Zhu Z, Sun J, Li J, Huang P (2015) Investigation on the influence of tool wear upon chip morphology in end milling titanium alloy Ti6Al4V. Int J Adv Manuf Tech

Wang B, Liu Z (2014) Investigations on the chip formation mechanism and shear localization sensitivity of high-speed machining Ti6Al4V. Int J Adv Manuf Technol 75:1065–1076

Cho KM, Chi YC, Duffy J (1990) Microscopic observations of adiabatic shear bands in three different steels. Metall Trans A 21:1161–1175

Barry J, Byrne G, Lennon G (2001) Observations on chip formation and acoustic emission in machining Ti-6Al-4V alloy. Int J Mach Tool Manuf 41:1055–1070

Grady DE (1994) Dissipation in adiabatic shear bands. Mech Mater 17:289–293

Fukumasu H, Kobayashi T, Toda H, Shibue K (2000) Dynamic fracture toughness of a Ti-45Al-1.6Mn alloy at high temperature. Metall Mater Trans A 31A:2000–3053

Ozel T, Altan T (2000) Determination of workpiece flow stress and friction at the chip–tool contact for high-speed cutting. Int J Mach Tool Manuf 40:133–152

Sartkulvanich P, Altan T, Göcmen A (2005) Effects of flow stress and friction models in finite element simulation of orthogonal cutting—a sensitivity analysis. Mach Sci Technol 9:1–26

Ye GG, Xue SF, Jiang MQ, Tong XH, Dai LH (2013) Modeling periodic adiabatic shear band evolution during high speed machining Ti-6Al-4V alloy. Int J Plast 40:39–55

Oxley PLB (1989) Mechanics of machining. Wiley, New York

Grady DE, Kipp ME (1987) The growth of unstable thermoplastic shear with application to steady-wave shock compression in solids. J Mech Phys Solids 35:95–118

Grady DE (1992) Properties of an adiabatic shear-band process zone. J Mech Phys Solids 40:1197–1215

Aifantis EC (1987) The physics of plastic deformation. Int J Plast 3:211–247

Tsagrakis I, Aifantis EC (2015) On the effect of strain gradient on adiabatic shear banding. Metall Mater Trans A 46:4459–4467

Lee WS, Lin CF (1998) High-temperature deformation behaviour of Ti6Al4V alloy evaluated by high strain-rate compression tests. J Mater Process Technol 75:127–136

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ye, G.G., Xue, S.F., Ma, W. et al. Onset and evolution of discontinuously segmented chip flow in ultra-high-speed cutting Ti-6Al-4V. Int J Adv Manuf Technol 88, 1161–1174 (2017). https://doi.org/10.1007/s00170-016-8847-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8847-2