Abstract

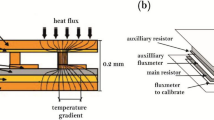

Preform design plays a significant role in forging design especially for parts with complex shapes. Conventional preform design approaches include trial-and-error approach, electric field method, and shape optimization-based approaches. In this paper, by introducing the structural design optimization concept, a 3D topological preform design optimization method has been developed. In this method, a new criterion for element elimination and addition is proposed and employed for plastic deformation problems in blade forging. Based on the finite element (FE) simulation combined with optimization, the optimized preforms with and without equal cross-section constraint can be obtained. Using the optimized preform, physical experiment on forging of a blade has been implemented to validate the optimization result. Other preform-related issues, such as the feasible approaches for preparation of optimized preforms, are also discussed in detail. The result suggested that the optimized preforms could improve the deformation uniformity during forging processes with better die-filling rate and reduced waste of raw materials.

Similar content being viewed by others

References

Ou H, Balendra R (1998) Die-elasticity for precision forging of aerofoil sections using finite element simulation. J Mater Process Technol 76(1–3):56–61

Ou H, Armstrong CG (2006) Evaluating the effect of press and die elasticity in forging of aerofoil sections using finite element simulation. Finite Elem Anal Des 42(10):856–867

Lu X, Balendra R (2001) Temperature-related errors on aerofoil section of turbine blade. J Mater Process Technol 115(2):240–244

Bruschi S, Ghiotti A (2008) Distortions induced in turbine blades by hot forging and cooling. Int J Mach Tools Manuf 48(7–8):761–767

Ou H, Armstrong CG, Price MA (2003) Die shape optimisation in forging of aerofoil sections. J Mater Process Technol 132(1–3):21–27

Rosochowski A (2001) Die compensation procedure to negate die deflection and component springback. J Mater Process Technol 115(2):187–191

Lu B, Ou H, Armstrong CG, Rennie A (2009) 3D die shape optimisation for net-shape forging of aerofoil blades. Mater Des 30(7):2490–2500

Ou H, Wang P, Lu B, Long H (2012) Finite element modelling and optimisation of net-shape metal forming processes with uncertainties. Comput Struct 90–91:13–27

Ou H, Balendra R. (1998) Preform design for forging of aerofoil sections using FE simulation. Journal of Materials Processing Technology 80-81(144–148

Lapovok R (1998) Improvement of die life by minimisation of damage accumulation and optimisation of preform design. J Mater Process Technol 80–81:608–612

Zhan M, Liu Y, Yang H (2002) Influence of the shape and position of the preform in the precision forging of a compressor blade. J Mater Process Technol 120(1–3):80–83

Lv C, Zhang L, Mu Z, Tai Q, Zheng Q (2008) 3D FEM simulation of the multi-stage forging process of a gas turbine compressor blade. J Mater Process Technol 198(1–3):463–470

Alimirzaloo V, Biglari FR, Sadeghi MH. (2011) Numerical and experimental investigation of preform design for hot forging of an aerofoil blade. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture

Park JJ, Rebelo N, Kobayashi S (1983) A new approach to preform design in metal forming with the finite element method. Int J Mach Tool Des Res 23(1):71–79

Wang Z, Xue K, Liu Y (1997) Backward UBET simulation of the forging of a blade. J Mater Process Technol 65(1–3):18–21

Gao T, Yang H, Y-l L (2006) Backward tracing simulation of precision forging process for blade based on 3D FEM. Trans Nonferrous Metals Soc China 16(2):639–644

Alimirzaloo V, Sadeghi MH, Biglari FR (2012) Optimization of the forging of aerofoil blade using the finite element method and fuzzy-Pareto based genetic algorithm. J Mech Sci Technol 26(6):1801–1810

Xie YM, Steven GP (1993) A simple evolutionary procedure for structural optimization. Comput Struct 49(5):885–896

Querin O, Steven G, Xie Y (1998) Evolutionary structural optimization (ESO) using a bidirectional algorithm. Eng Comput 15(8):1031–1048

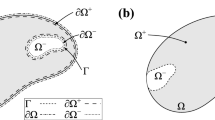

Lu B, Ou H, Cui ZS (2011) Shape optimisation of preform design for precision close-die forging. Struct Multidiscip Optim 44(6):785–796

Shao Y, Lu B, Ou H, Ren F, Chen J (2014) Evolutionary forging preform design optimization using strain-based criterion. Int J Adv Manuf Technol 71(1–4):69–80

Shao Y, Lu B, Ou H, Chen J (2015) A new approach of preform design for forging of 3D blade based on evolutionary structural optimization. Struct Multidiscip Optim 51(1):199–211

Rezaei Ashtiani HR, Parsa MH, Bisadi H (2012) Constitutive equations for elevated temperature flow behavior of commercial purity aluminum. Mater Sci Eng A 545:61–67

Lu B, Ou H, Long H (2011) Die shape optimisation for net-shape accuracy in metal forming using direct search and localised response surface methods. Struct Multidiscip Optim 44(4):529–545

Wu CY, Hsu YC (2002) Optimal shape design of an extrusion–forging die using a polynomial network and a genetic algorithm. Int J Adv Manuf Technol 20(2):128–137

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shao, Y., Lu, B., Xu, D. et al. Topology-based preform design optimization for blade forging. Int J Adv Manuf Technol 86, 1593–1605 (2016). https://doi.org/10.1007/s00170-015-8263-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-8263-z